A kind of anti-crack steel plate for BCA2 container ship and its manufacturing method

A container ship and manufacturing method technology, applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve the problems of not having common production conditions, low rolling efficiency, and rising comprehensive costs, so as to increase crack initiation energy and improve quenching Permeability, the effect of less restrictions on production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

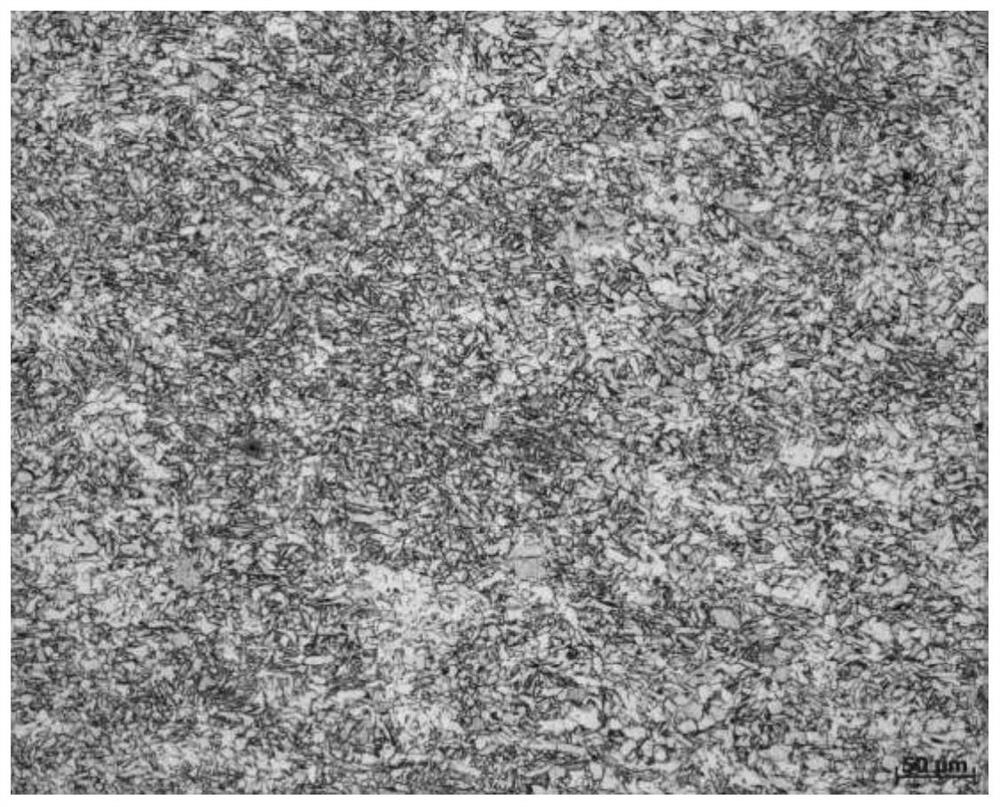

Image

Examples

Embodiment Construction

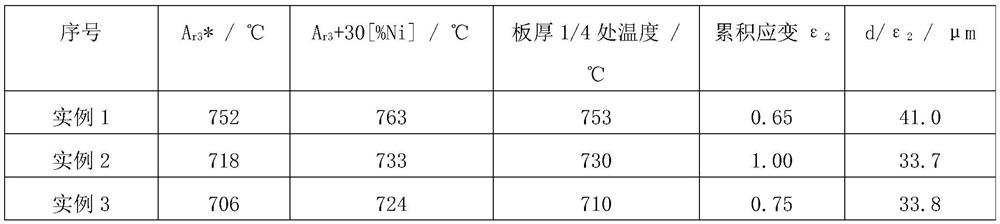

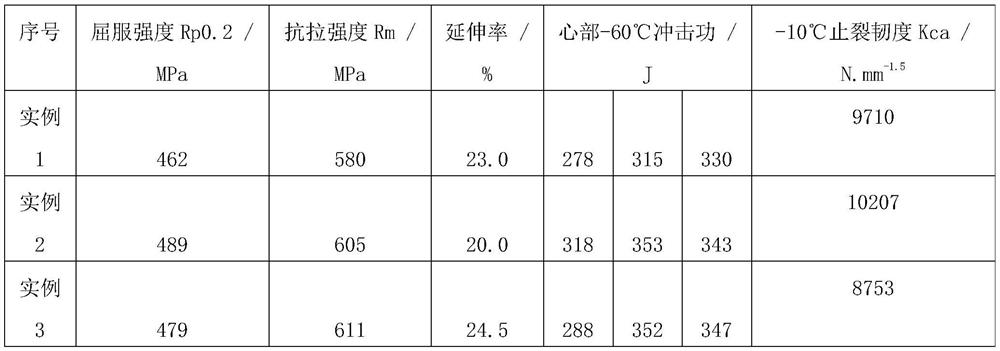

[0032] The embodiment provides a BCA2 grade crack arresting steel plate for container ships, its composition is shown in Table 1, Table 2 to Table 4 are the manufacturing process of the steel plate in the example, and Table 5 is the performance parameters of the steel plate in the example.

[0033] Table 1 Chemical composition unit: w.t.%

[0034] serial number Plate thickness / mm C Si mn P S Cr Ni Cu Nb Ti Alt Example 1 80 0.04 0.40 1.70 0.009 0.003 0.01 0.35 0.30 0.012 0.012 0.020 Example 2 90 0.09 0.10 1.85 0.004 0.002 0.10 0.50 0.20 0.030 0.005 0.030 Example 3 100 0.07 0.25 2.00 0.006 0.001 0.22 0.58 0.10 0.045 0.020 0.050

[0035] Table 2

[0036] serial number Plate thickness / mm Heating temperature / ℃ Cumulative strain ε 1

Grain size d / μm Example 1 80 1180 0.74 26.52 Example 2 90 1100 0.27 33.67 Example 3 100 1080 0.41 25.45

[0037] ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com