Free-cutting aluminum alloy extrudate with excellent brittle resistance at high temperature

A free-cutting, high-temperature-resistant technology, applied in the field of lead-free free-cutting aluminum alloys, which can solve problems such as fracture, brittle failure, and decreased productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] As for the preparation conditions and heat treatment of the alloy of the present invention, under conventional preparation conditions, the heat treatment can be selected according to the application. For example, you can choose T1 for hot working, T6 for solutionization and artificial aging, or T8 and T9 for solutionization, cold working and artificial aging. High-strength alloys have excellent chip cutting properties, so heat treatment such as T3, T8, and T9, which are cold-worked and artificially aged after solid solution, are particularly preferred.

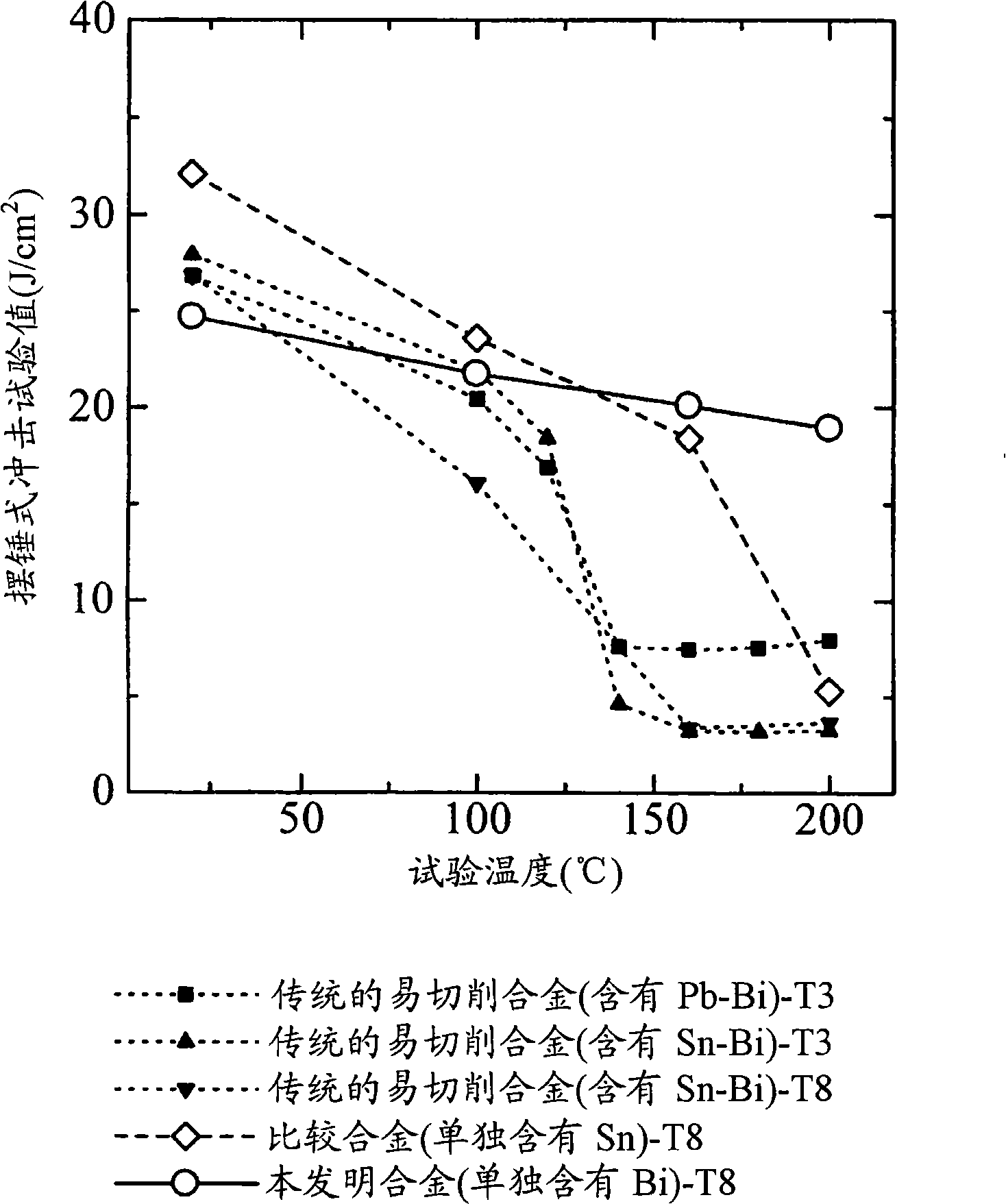

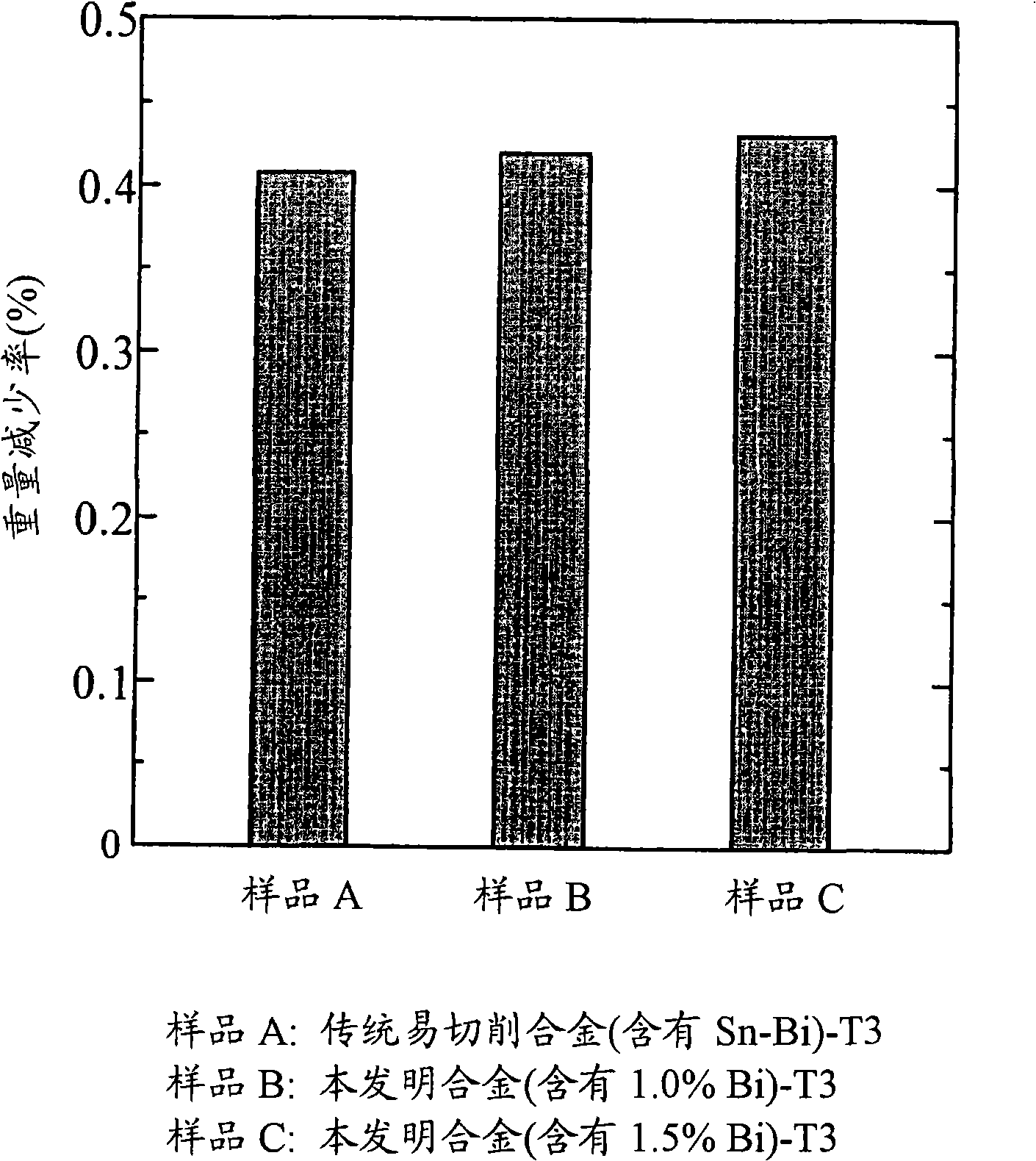

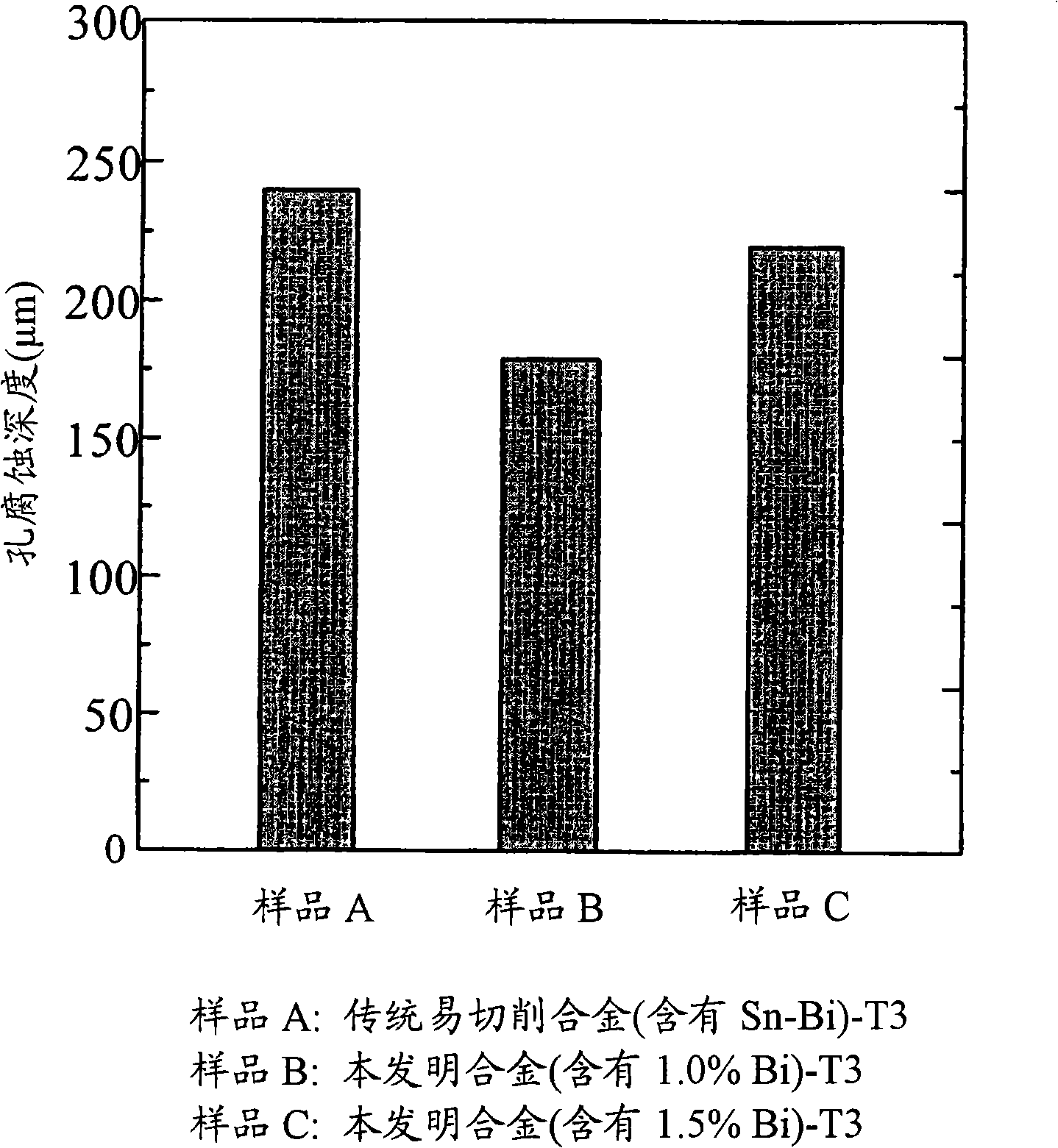

[0031] The machinability of the free-cutting aluminum alloy extruded material of the present invention, the Al-Cu lead-free alloy is equivalent to that of traditional free-cutting alloys such as JIS2011 alloy, and has excellent high-temperature resistance to brittleness and corrosion resistance.

Embodiment

[0033] Next, the present invention will be described in detail based on examples.

[0034] An alloy having a composition shown in Table 1 was melted to obtain an ingot having a diameter of 220 mm. The ingot was homogenized at 480° C. for 6 hours. The ingot was then formed into extruded rods with a diameter of 35 mm by extrusion at 400°C. The rods were quenched with water immediately after solutionization at 500° C. for 2 hours. Further, it was drawn into a 30 mm bar, and then subjected to a prescribed aging treatment to produce a heat-treated material as shown in Table 1. The aging condition of T8 treatment is 160°C, 14 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com