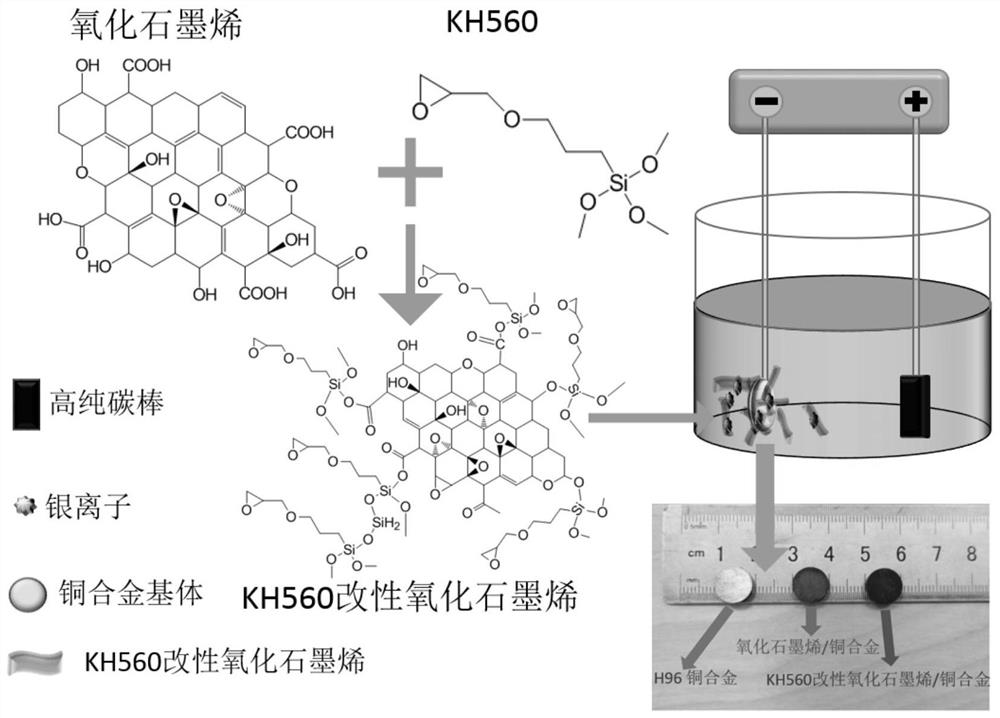

Copper-based modified graphene oxide composite material with high thermal conductivity and preparation method thereof

A composite material and high thermal conductivity technology, applied in the direction of electrolytic coating, electrophoretic plating, coating, etc., can solve the problems of weakened metal machining performance, different material properties, and environmental pollution, so as to reduce thermal contact resistance and heat dissipation. Effects of boundary resistance, improved thermal conductivity, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Using H96 brass as the substrate, using the silane coupling agent KH560 modified graphene oxide as the thermal conductivity enhancing phase, the copper-based modified graphene oxide composite material of the present invention is prepared by pulse electrophoretic deposition, specifically comprising the following steps:

[0035](1) Pretreatment of copper alloy: the quality index of Cu alloy raw material is, in terms of mass percentage: copper 95%, impurity≤0.2%, and the balance is zinc; first, H96 copper alloy is ultrasonically cleaned in clear water, and then Ultrasonic cleaning was carried out in anhydrous ethanol solution to remove impurities attached to the surface; then the copper alloy substrate was degreased in a sodium carbonate solution with a mass fraction of 15% at 55°C for 3 minutes, and then rinsed with clean water; then the copper alloy substrate was placed in The mass fraction is 30% in dilute nitric acid solution for 3 minutes, and then rinsed with water; t...

Embodiment 2

[0040] Using H96 brass as the substrate, using the silane coupling agent KH560 modified graphene oxide as the thermal conductivity enhancing phase, the copper-based modified graphene oxide composite material of the present invention is prepared by pulse electrophoretic deposition, specifically comprising the following steps:

[0041] (1) Pretreatment of copper alloy: the quality index of Cu alloy raw material is, in terms of mass percentage: copper 96%, impurity≤0.2%, and the balance is zinc; first, H96 copper alloy is ultrasonically cleaned in clear water, and then Ultrasonic cleaning was carried out in absolute ethanol solution to remove impurities attached to the surface; then the copper alloy substrate was degreased in a sodium carbonate solution with a mass fraction of 18% at 60°C for 2.5 minutes, and then rinsed with clean water; then the copper alloy substrate Remove impurities in 35% dilute nitric acid solution for 2.5 minutes, then rinse with clean water; then polish t...

Embodiment 3

[0046] Using H96 brass as the substrate, using the silane coupling agent KH560 modified graphene oxide as the thermal conductivity enhancing phase, the copper-based modified graphene oxide composite material of the present invention is prepared by pulse electrophoretic deposition, specifically comprising the following steps:

[0047] (1) Pretreatment of copper alloy: the quality index of Cu alloy raw material is, in terms of mass percentage: copper 97%, impurity≤0.2%, and the balance is zinc; first, H96 copper alloy is ultrasonically cleaned in clear water, and then Ultrasonic cleaning was carried out in absolute ethanol solution to remove impurities attached to the surface; then the copper alloy substrate was degreased in a 65°C sodium carbonate solution with a mass fraction of 20% for 2 minutes, and then rinsed with clean water; then the copper alloy substrate was placed in The mass fraction is 40% dilute nitric acid solution for 2 minutes, and then rinsed with clean water; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com