Patents

Literature

109 results about "Impacted fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Impacted fracture fracture in which one fragment is firmly driven into the other. incomplete fracture one that does not involve the complete cross section of the bone. indirect fracture one distant from the site of injury.

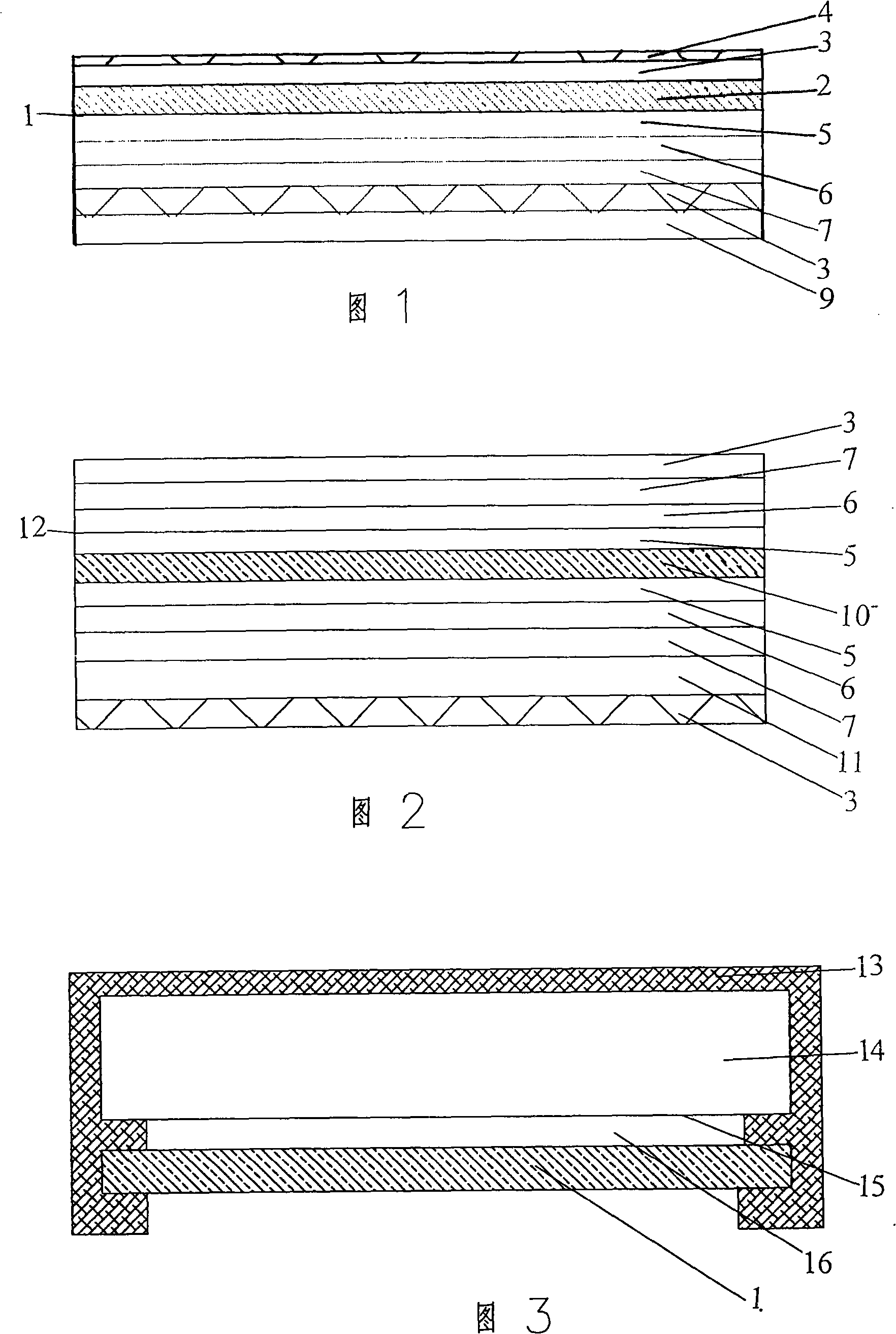

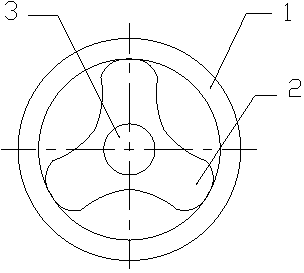

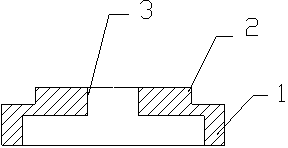

Safety glass protection screen for LCD, LCD using the same

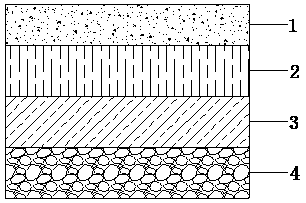

InactiveCN101295030AHigh light transmittanceIncrease productivityLayered productsNon-linear opticsLiquid-crystal displayTransmittance

The invention provides a safety glass protective screen with high light transmittance used for a liquid crystal display device, comprising a glass substrate, wherein, at least one surface of the glass substrate is compounded with a layer of plastic film by using a resin binder, the glass substrate and / or the plastic film surface are / is plated with a transmission-increasing and reflection-deducting film syngenic membrane which is composed of an Nb2O5 / SiO2 film or a TiO2 / SiO2 film. The protective screen of the invention can reduce the reflectivity and improve the light transmittance and the effect of an optical image, fully improve the impact fracture resistant capacity of a display screen and become the safe protective screen. The invention also provides the liquid crystal display device using the glass protective screen.

Owner:甘国工

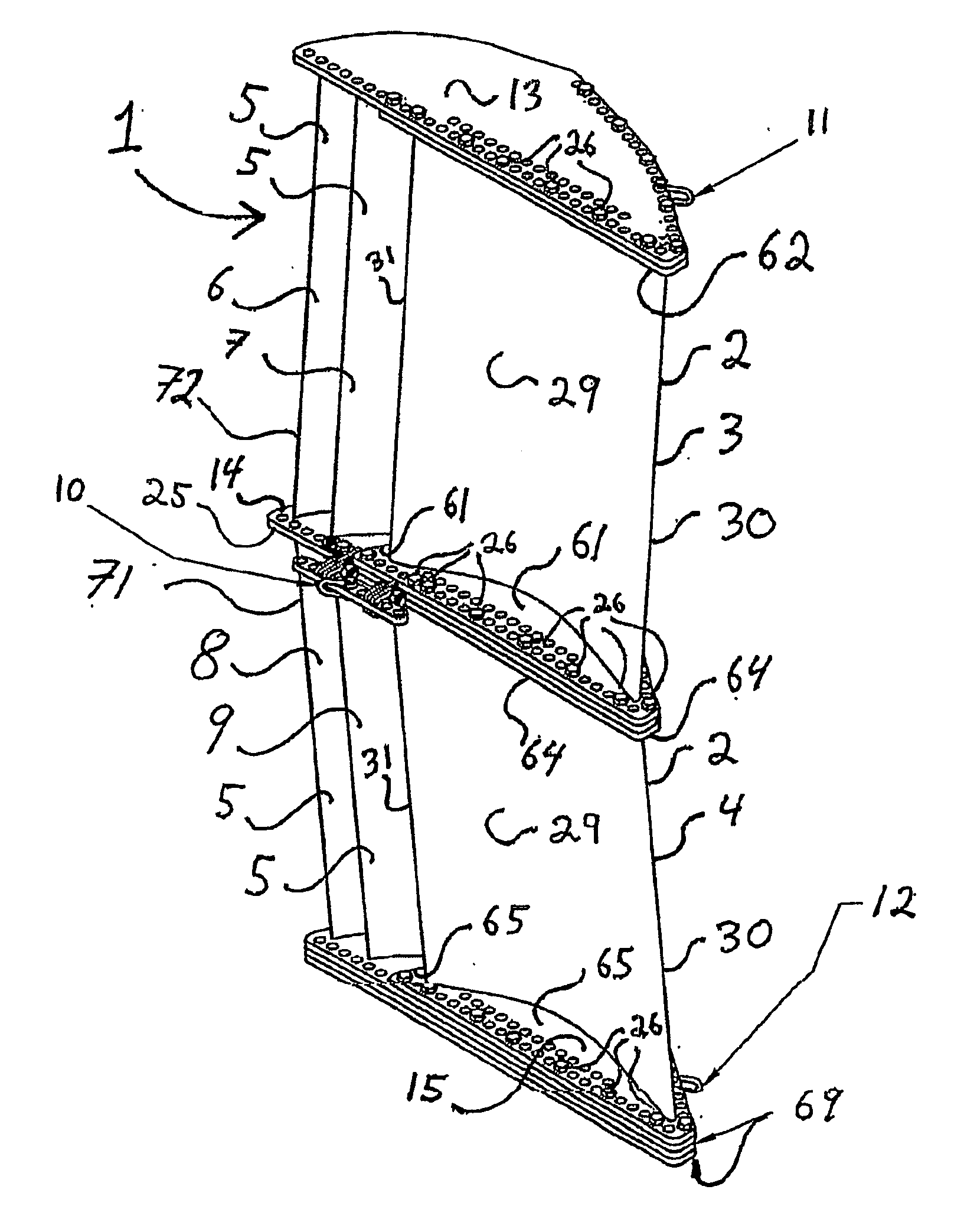

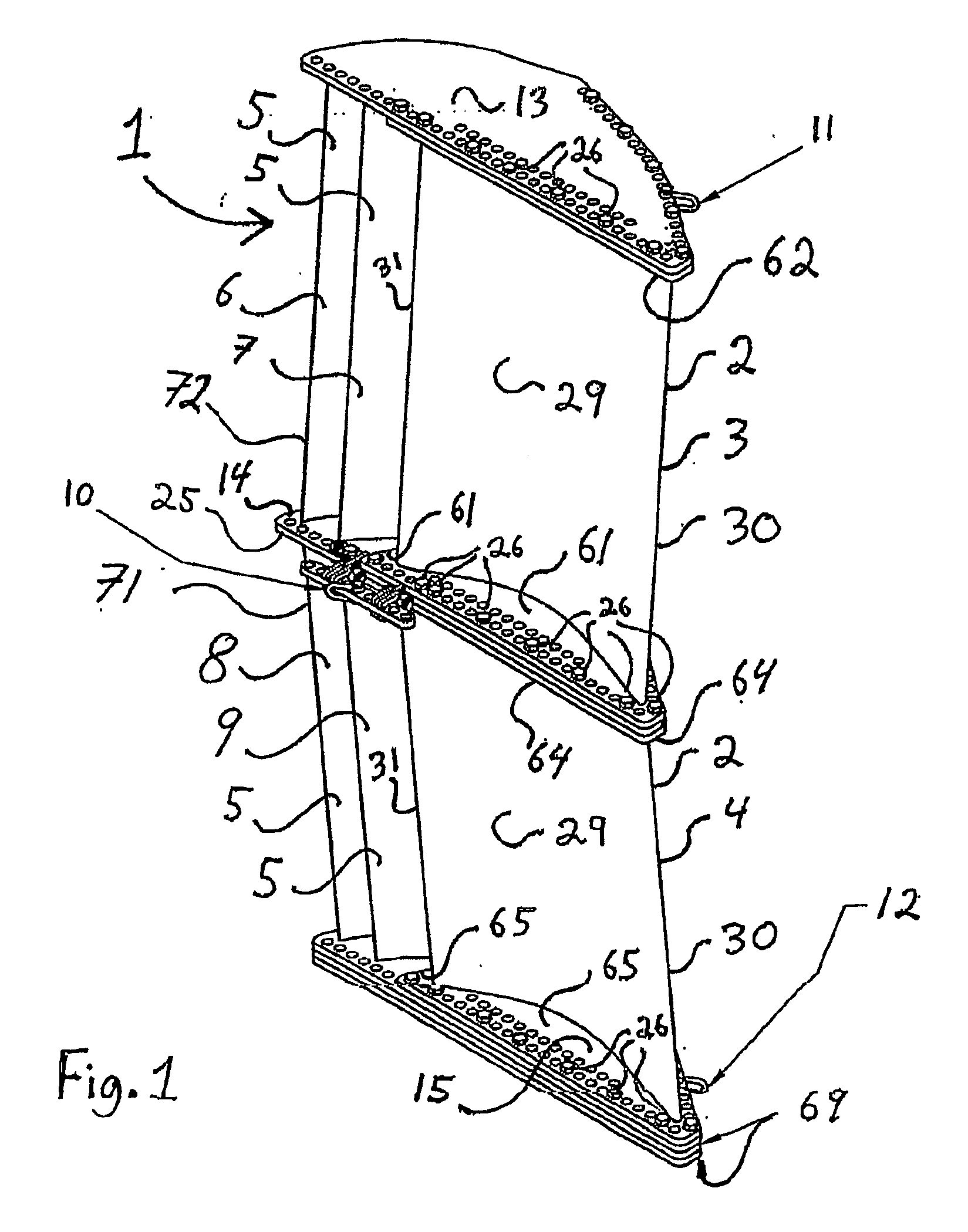

High Speed, Increased Hydrodynamic Efficiency, Light-Weight Molded Trawl Door and Methods for Use and Manufacture

A trawl door having enhanced and rather high efficiency, lightness of weight in water and ease of manufacture. The trawl door preferably includes at least one slat and preferably two slats (6, 7) disposed forward of the leading edge (31) of a single main deflector body (2), and the main deflector has a profile wherein: (I) the outer side surface (28) of said main deflector body exhibits greater camber than does the inner side surface (29) of said main deflector body; (II) the thickest part of the profile of said main deflector body is located front of center; and (III) the outer side surface (28) is convex and the inner side surface (29) is concave. In one aspect the trawl door of the invention including at least a synthetic portion, preferably a mixture of a polyamide and an elastomer, whereby the synthetic material forming the at least a synthetic portion of the trawl door receives impacts fracture free.

Owner:CANDIS EHF

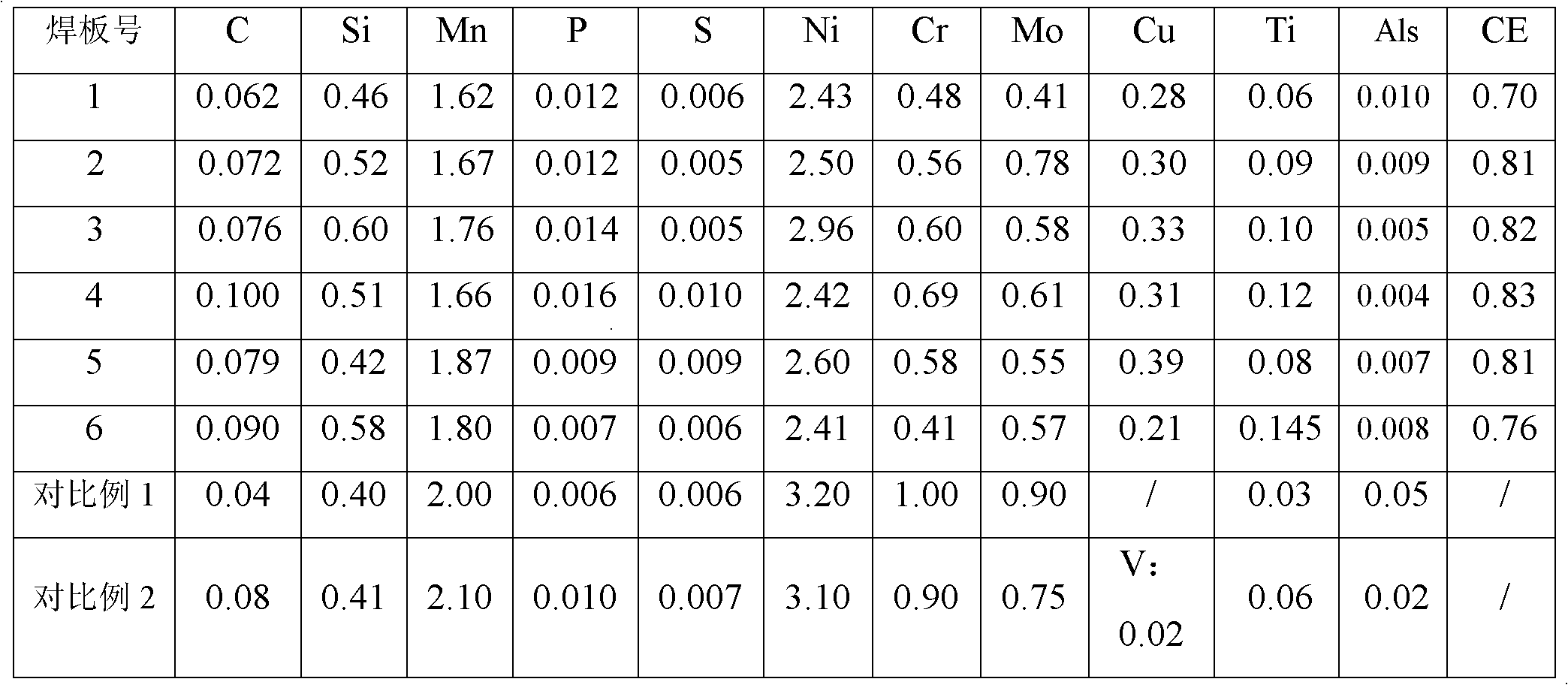

Gas shielded welding wire with 900MPa tensile strength

InactiveCN102152025AReduce contentImprove welding strengthWelding/cutting media/materialsSoldering mediaUltimate tensile strengthToughness

The invention relates to a gas shielded welding wire with 900MPa tensile strength, which comprises the following components in percents by weight: 0.06-0.10% of C, 0.40-0.60% of Si, 1.60-1.90% of Mn, not more than 0.020% of P, not more than 0.020% of S, 2.40-3.00% of Ni, 0.40-0.69% of Cr, 0.40-0.80% of Mo, 0.20-0.40% of Cu, 0.05-0.15% of Ti, not more than 0.005% of N, not more than 0.015% of Al and the balance of Fe and unavoidable impurities. The carbon equivalent CE of the welding wire is 0.70-0.85, and CE = C + Mn / 6 + (Ni+Cu) / 15 + (Cr+Mo+V) / 5. The invention provides a super-high strength gas shielded welding wire. The strength of welding joints is higher than 900MPa, and the toughness of the welding joints is higher than 227J at -20 DEG C KV. The textures of all parts of multiple layers of welding joints are uniform. The impact fractures are mainly dimple fractures. In the invention, the matched welding material for the application of super-high strength steel in China is provided.

Owner:武汉钢铁有限公司

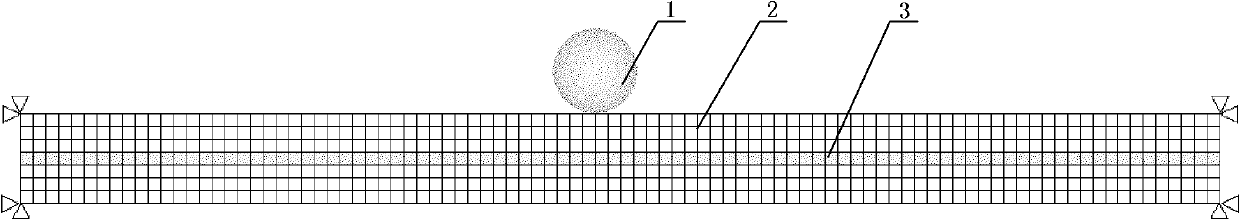

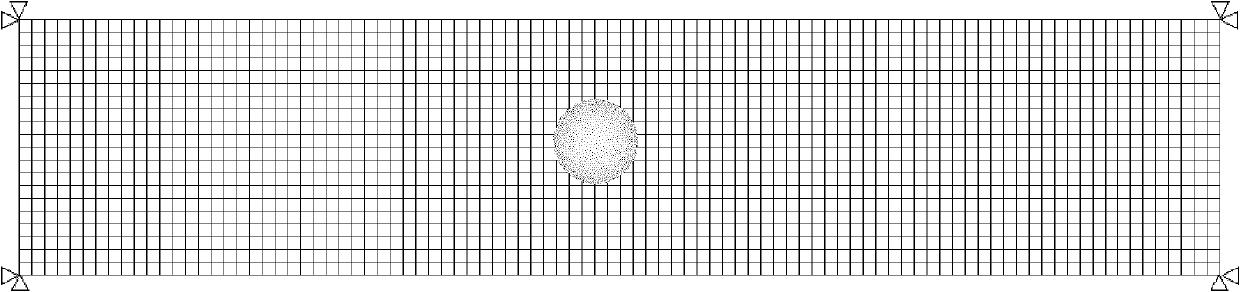

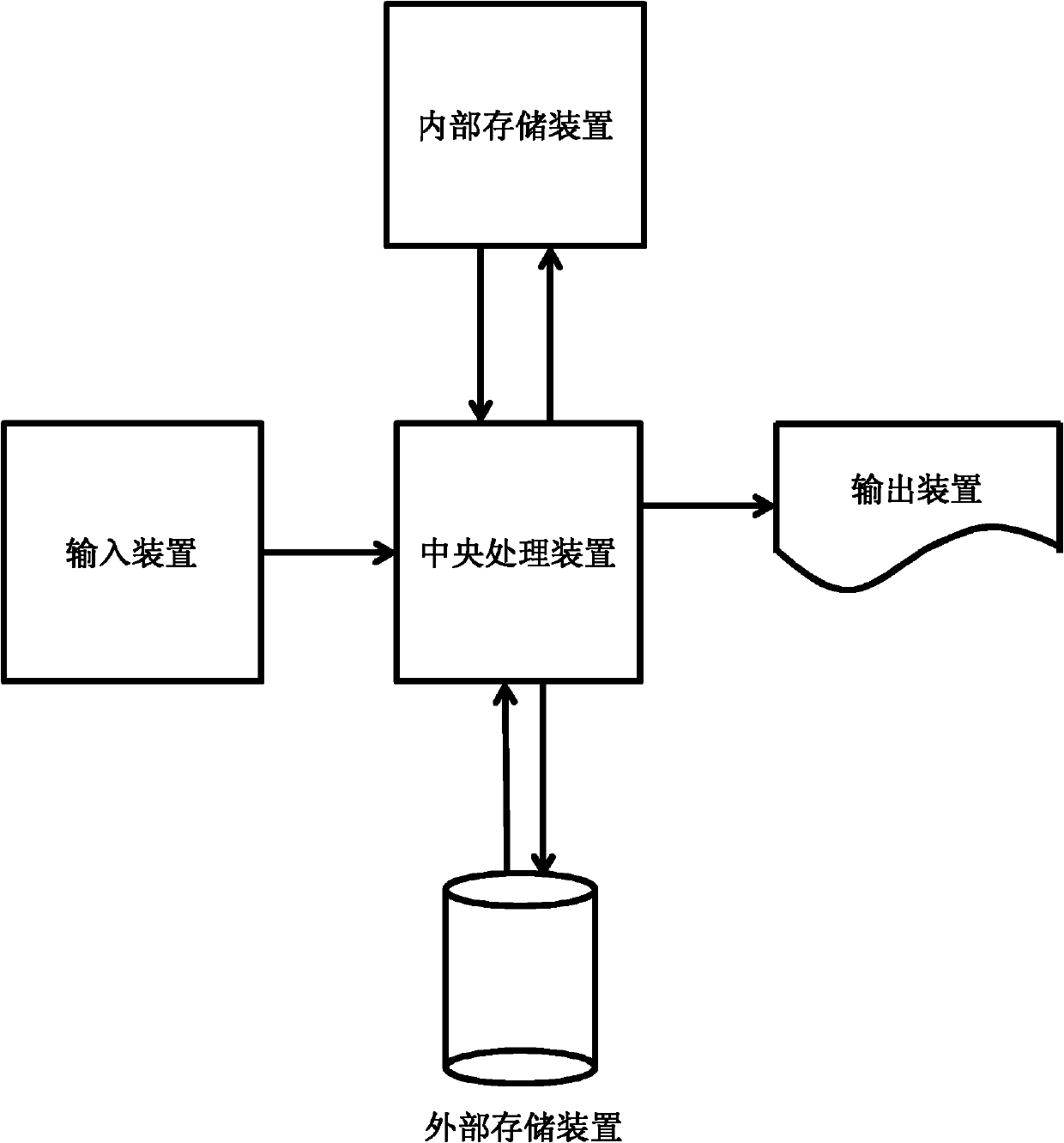

Method for rapidly acquiring impact fracture characteristics of brittle material

InactiveCN102129508AFast access to crack growthGet crack extensionMaterial strength using single impulsive forceSpecial data processing applicationsInternal memoryComputer science

The invention discloses a method for rapidly acquiring the impact fracture characteristics of a brittle material, which comprises the steps that: the serial numbers of fracture-pending finite elements are obtained through finite element positioning components; according to the serial numbers of the finite elements, discrete element generating components are used for generating 8 discrete elementsinside each finite element by means of an isoparametric inverse transformation method, and according to the scale of the discrete elements, memory spaces are allocated in an internal memory of a computer adopting the method; and kinematic and mechanic information of each finite element is transferred to the 8 discrete elements generated therein through element information transferring components so that the kinematic and mechanic information of the finite elements and the discrete elements before and after replacement are approximately equivalent; yjr information of the finite elements and the discrete elements in the internal memory are updated through element information updating components; and finally, fracture characteristics, such as crack extension, splashing of fragments and the like, of the brittle material under the action of impact load are rapidly acquired through fracture characteristic acquiring components.

Owner:SOUTH CHINA UNIV OF TECH

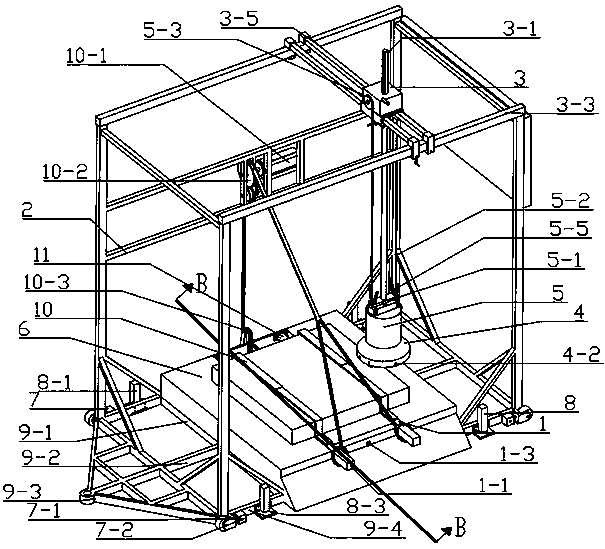

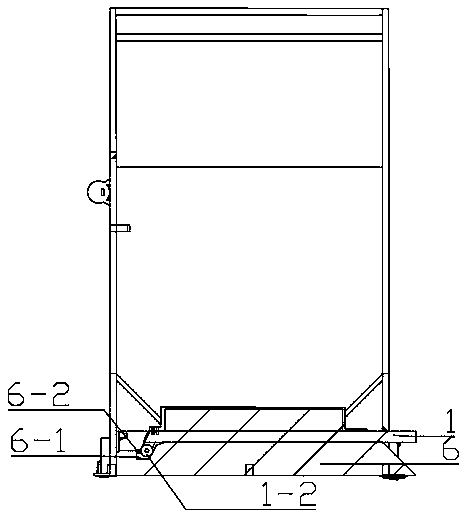

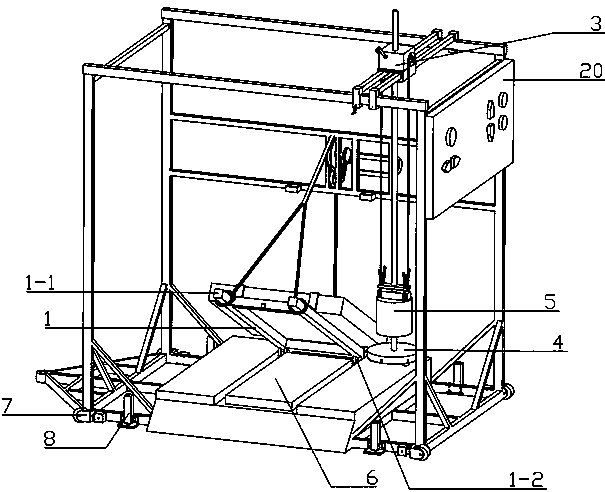

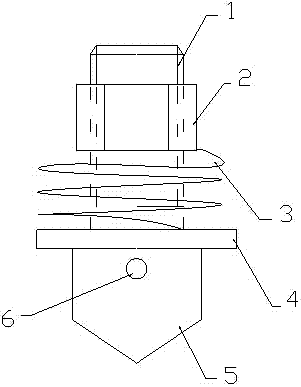

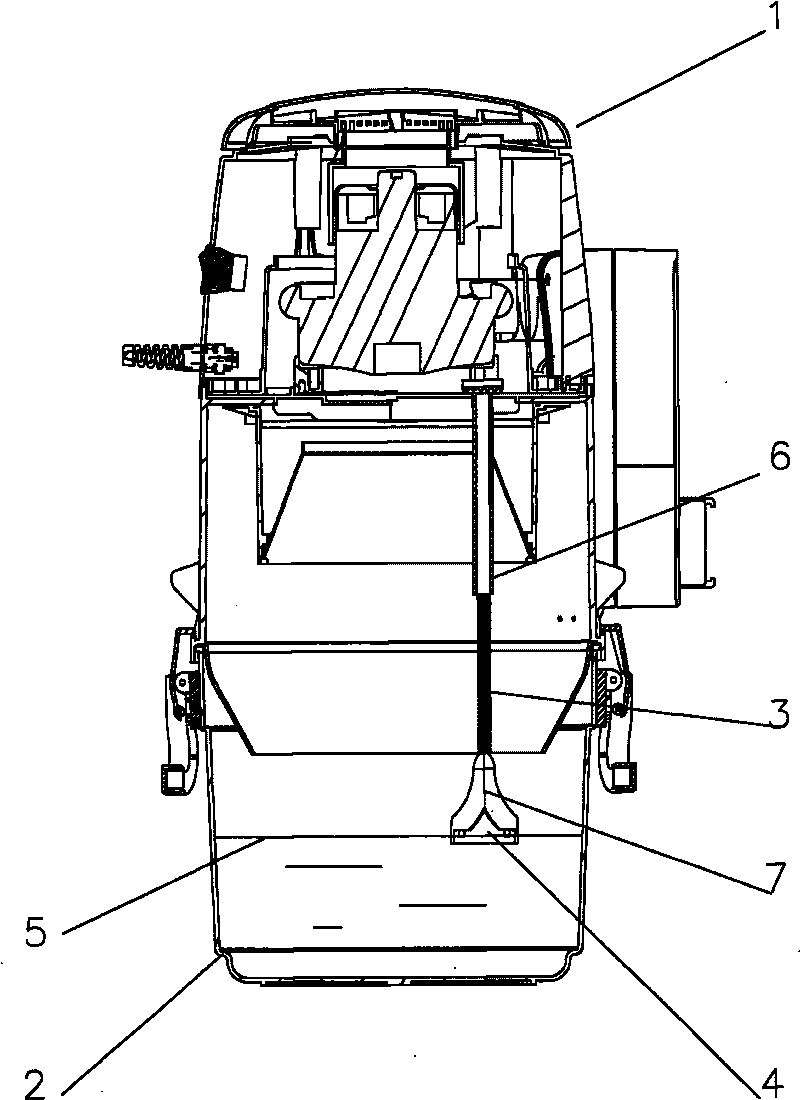

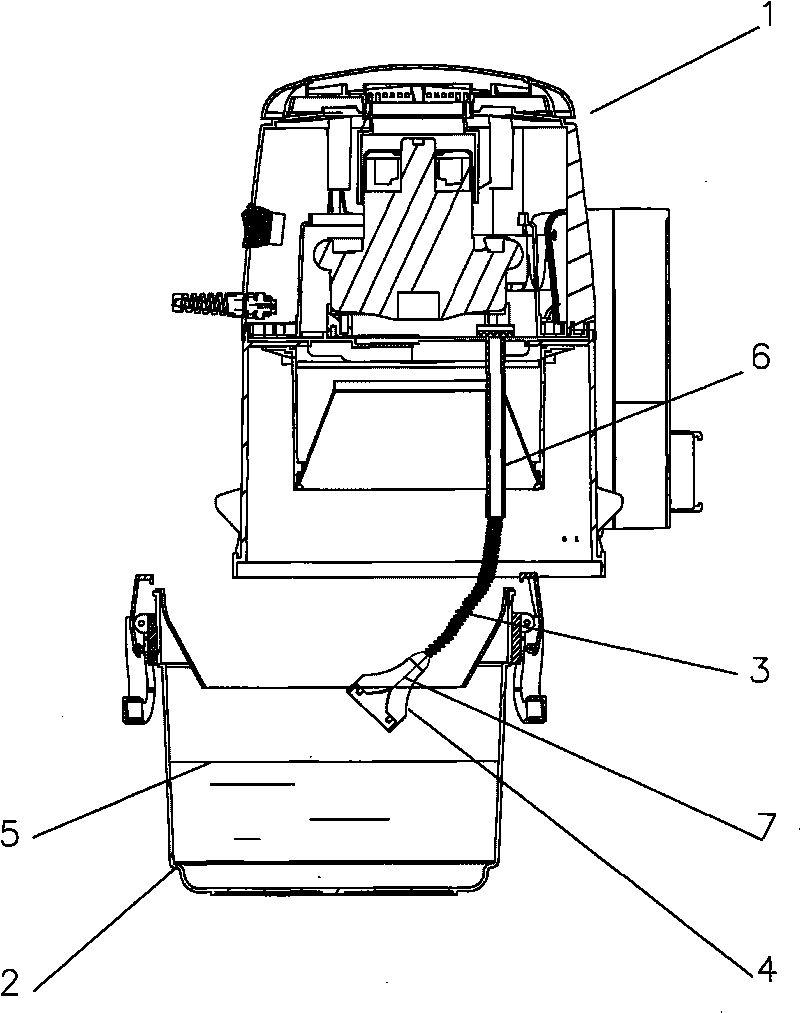

Novel multifunctional impact fracture test device and use method thereof

The invention discloses a novel multifunctional impact fracture test device and a use method thereof. The device comprises a movable test frame capable of ascending and descending, a combined supporting plate, a multi-form hammer, a multi-azimuth hammer movable assembly and an impact drop hammer, wherein the combined supporting plate is arranged at the bottom of the movable test frame capable of ascending and descending; a trolley is arranged on the combined supporting plate, the front part of the trolley is rotationally connected with the combined supporting plate, the rear part of the trolley is detachably connected with the front side of the movable testing frame capable of ascending and descending, and the lower part of the trolley is matched with the combined supporting plate; the multi-form hammer is movably connected with the movable test frame capable of ascending and descending through the multi-azimuth hammer movable assembly; the upper part of the multi-form hammer is matched with the lower part of the impact drop hammer, the impact drop hammer is arranged between the multi-form hammer and the multi-azimuth hammer movable assembly, the upper part of the impact drop hammer is movably connected with the multi-azimuth hammer movable assembly, and the multi-azimuth hammer movable assembly is movably connected with the upper part of the movable test frame capable of ascending and descending. The device has the advantages of being flexible, convenient to use and suitable for various working conditions.

Owner:ZHENGZHOU UNIV

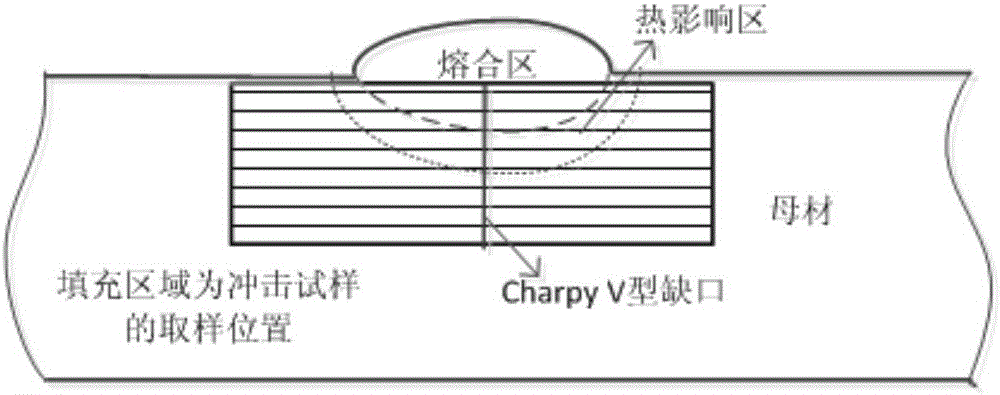

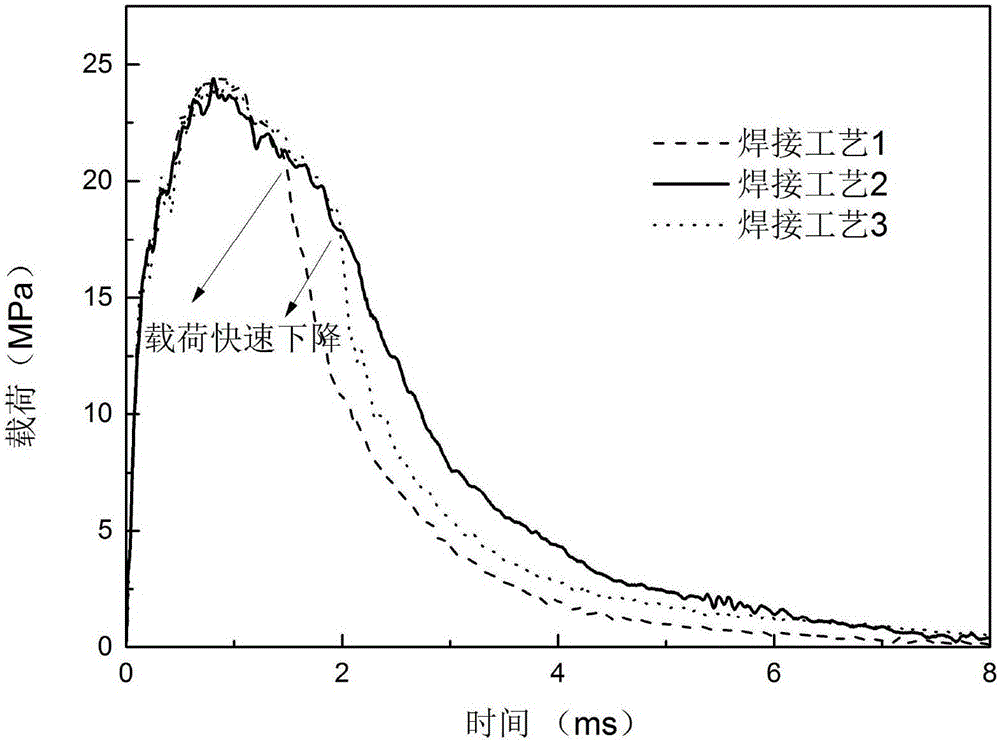

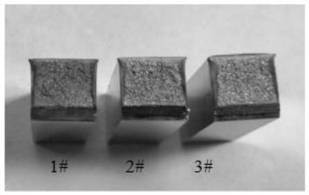

Method for screening reasonable welding process parameters based on impact toughness

ActiveCN106513925AEase of detection of deteriorationAdjust welding process parametersWelding accessoriesHeat-affected zoneAbsorbed energy

The invention discloses a method for screening reasonable welding process parameters based on impact toughness and belongs to the fields of evaluation and representation of mechanical properties of materials. The method comprises the steps: 1) pretreating a steel plate; 2) carrying out single-path welding on the steel plate to obtain a welding plate comprising a complete welding heat affected zone; 3) intercepting an impact specimen on the welding plate, and forming a V / U-shaped gap; 4) detecting the impact toughness of the impact specimen to obtain the impact absorbing energy of the impact specimen, and determining the impact fracture behavior of the heat-affected zone; and 5) judging that the welding process parameters are reasonable when the impact absorbing energy of the welding plate is larger than or equal to that of 1 / 2 of the original steel plate and the impact fracture behavior of the heat-affected zone is ductile fracture, or else, judging that the welding process parameters are unreasonable. According to the method disclosed by the invention, the welding heat-affected zone is prepared by carrying out single-pass welding on a flat plate, so that the welding process parameters can be regulated within a wide range, the deterioration degree of the impact toughness of the heat-affected zone is evaluated for different welding processes, and reasonable process parameters are screened; and the method is few in welding process, convenient and rapid in operation, capable of reducing cost and high in efficiency.

Owner:NORTHEASTERN UNIV

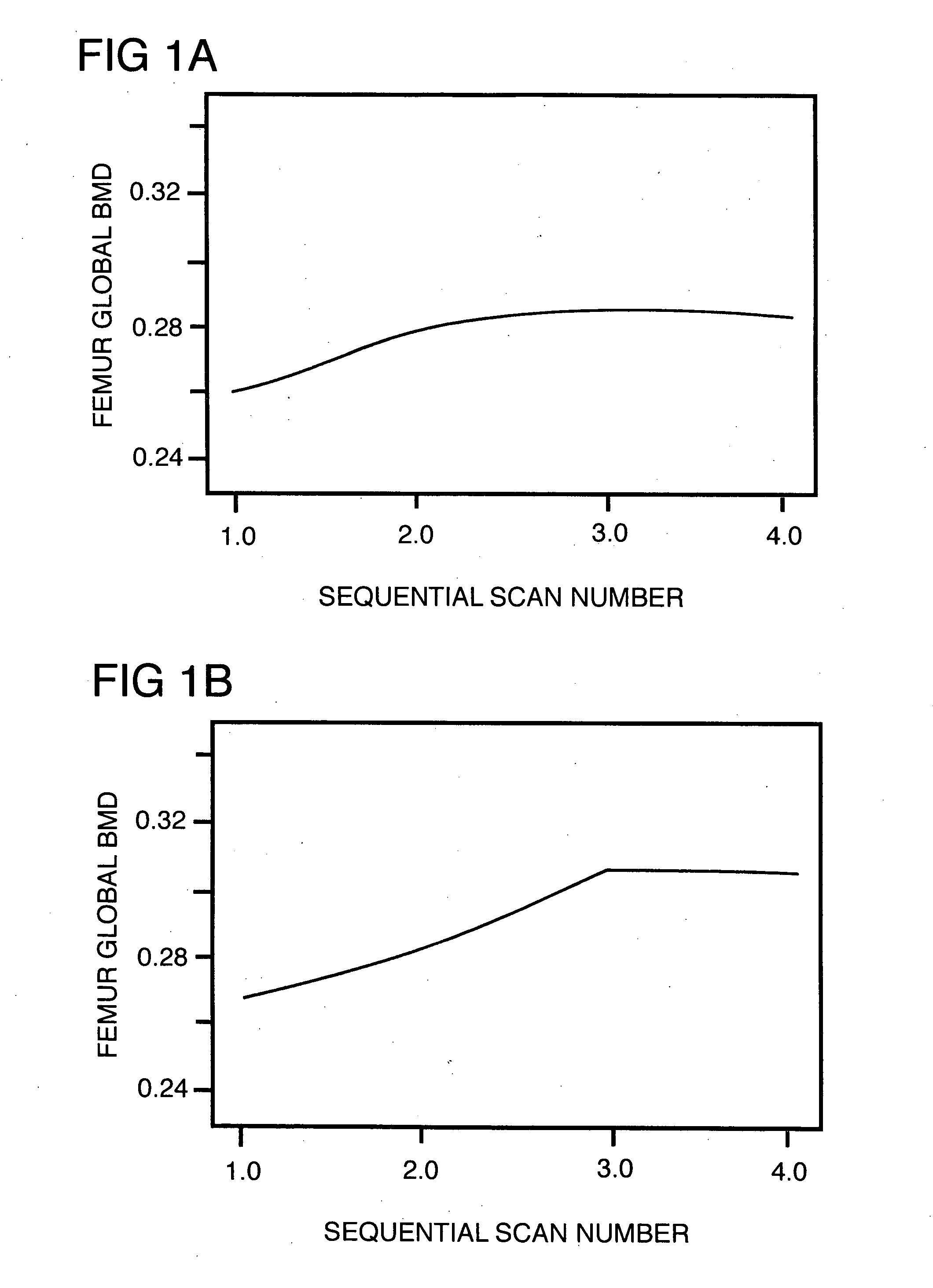

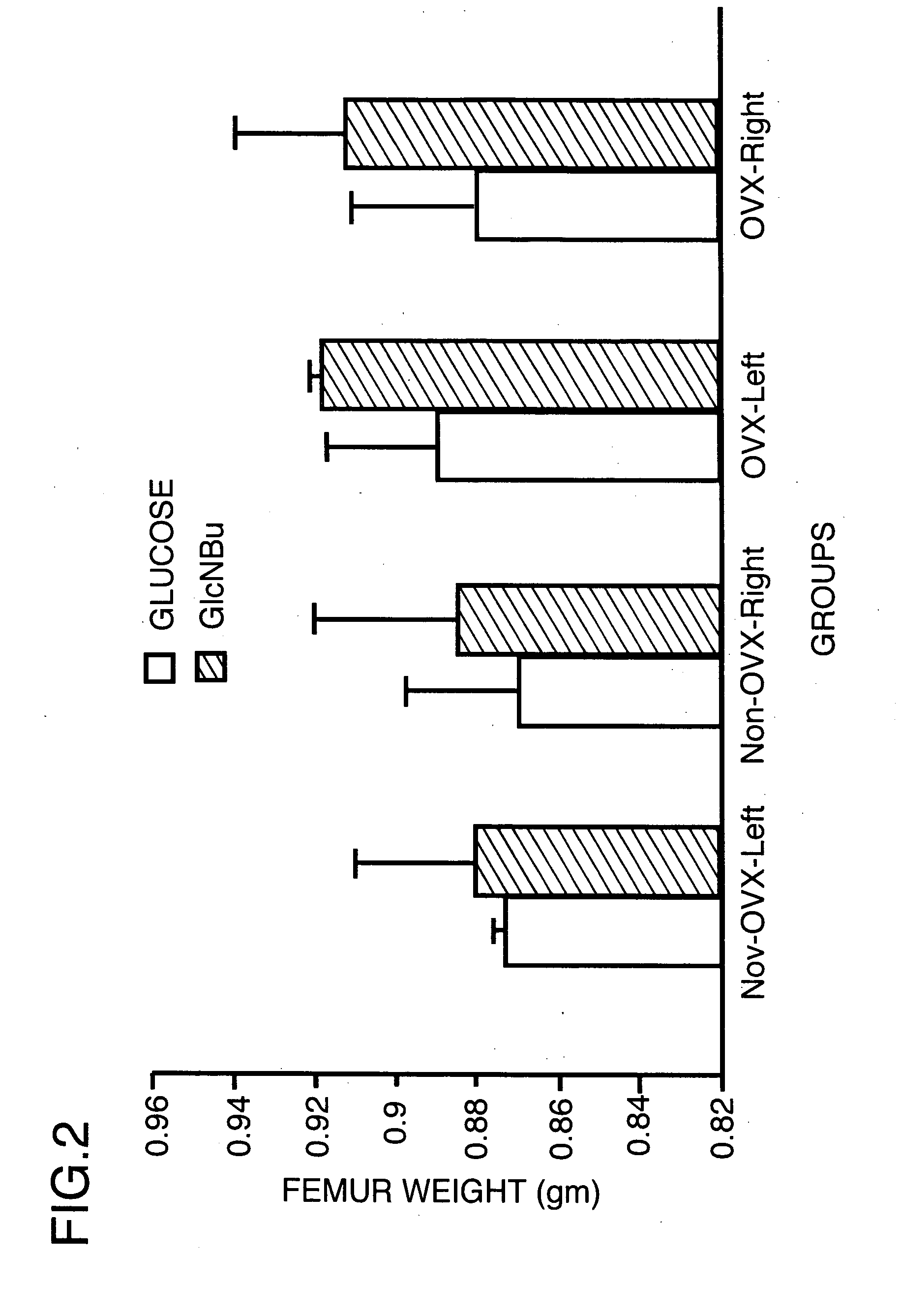

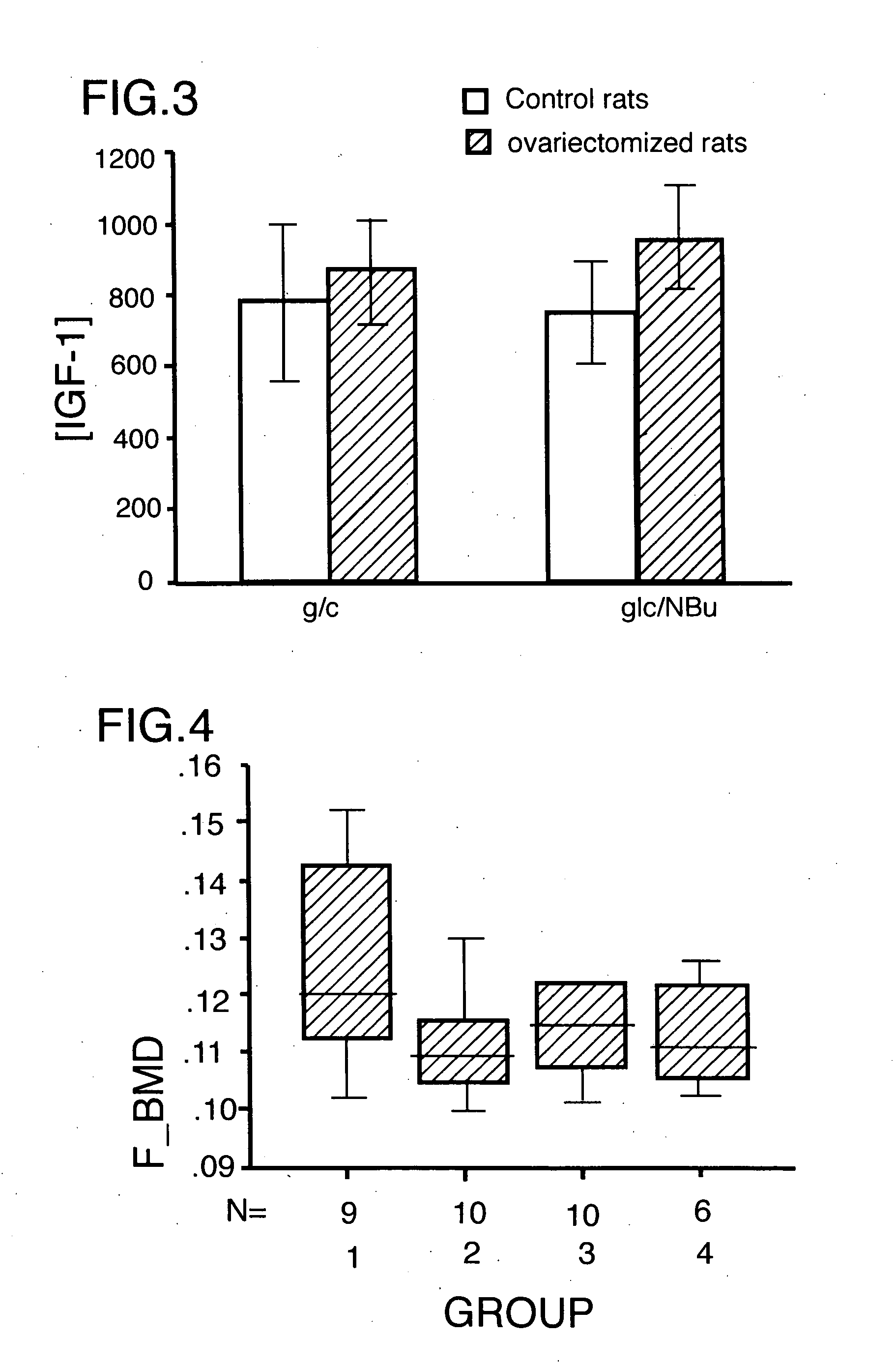

Method for increasing the bone mineral density and bone micro-architecture or connectivity of a mammal using N-acylated glucosamines

ActiveUS20060046976A1Prevent and diminish risk of fracturePromote healingBiocideSugar derivativesMammalVolumetric Mass Density

A method of treating a mammal for a purpose selected from the group consisting of (a) increasing bone mineral density (BMD), (b) treating low BMD, (c) preventing and treatment of low impact fractures, (d)treatment of high impact fractures; (e) treating osteoporosis; (f) modulating a growth factor that influences bone metabolism; and (g) improving bone micro-architecture or connectivity of bone; the method comprising administering to the mammal an effective amount of a N-acylated-2-glucosamine derivative of the general formula (I):- wherein R is an alkyl radical of the general formula CnH2n+1 and n is selected from 2-12; or pharmaceutically-acceptable salts, esters and glucosides thereof; or pharmaceutically-acceptable compositions thereof.

Owner:ANACOTI

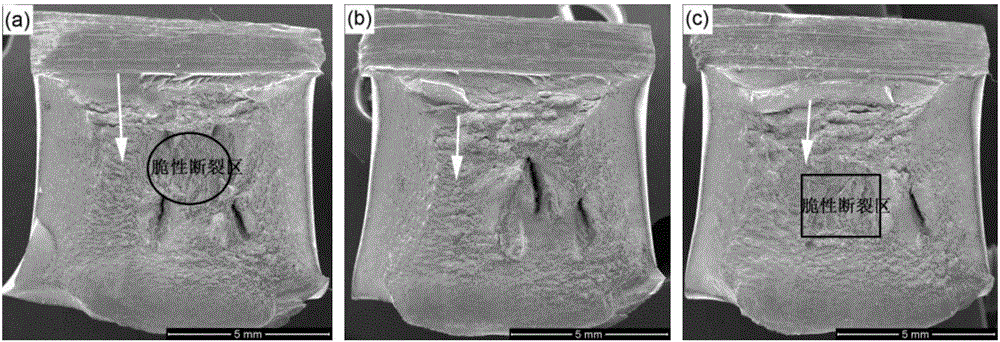

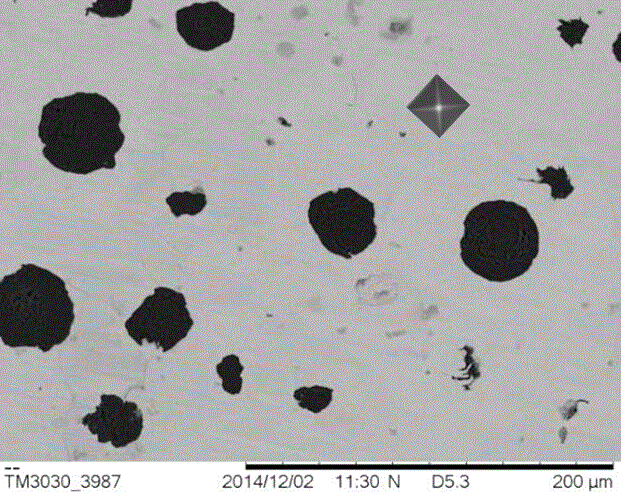

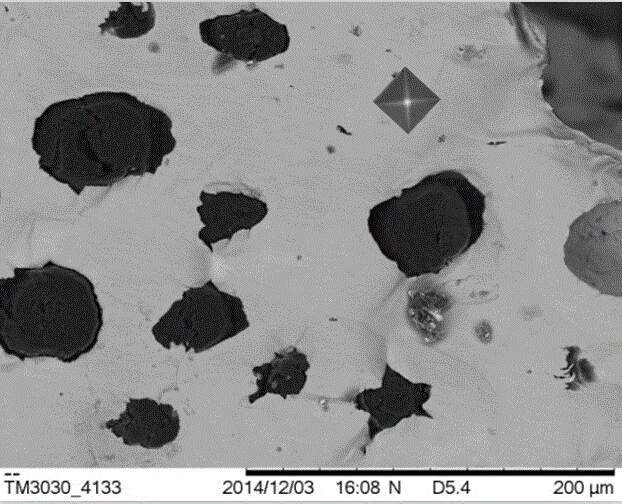

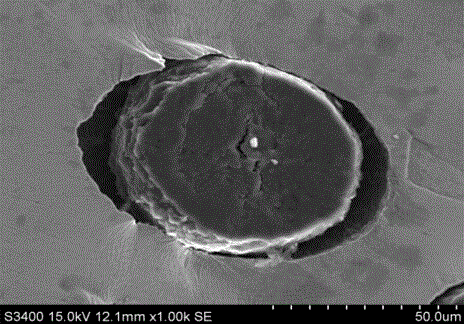

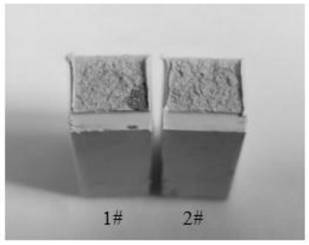

In-situ structure analytical method for nodular cast iron metal material before and after impact fracture

InactiveCN104406847AStrength propertiesMaterial analysis by measuring secondary emissionMicro structureMetallography

The invention belongs to the metallographic field and particularly relates to an observing and analyzing method of researching a micro structure metallograph of nodular cast iron before and after impact fracture at different temperatures. The method comprises the following steps: coarsely grinding, finely grinding, polishing and corroding two side faces of a V-shaped notch of a nodular cast iron impact test sample; observing under a microscope; selecting a classical region near the V-shaped notch; pressing a microhardness indentation at the center of the region as a mark, and photographing and storing; then, carrying out a Charpy notch impact test at different temperatures ranging from 20 DEG C to minus 80 DEG C; finally, combining the microhardness indentation and surrounding graphite nodule morphology features to obtain micro structure photos of a same region before and after impact so as to achieve comparative analysis of detail change of the nodular cast iron structure behind and after impact. The method is an in-situ structure analytical method which is wide in application range, simple to operate and high in reliability.

Owner:SHENYANG POLYTECHNIC UNIV

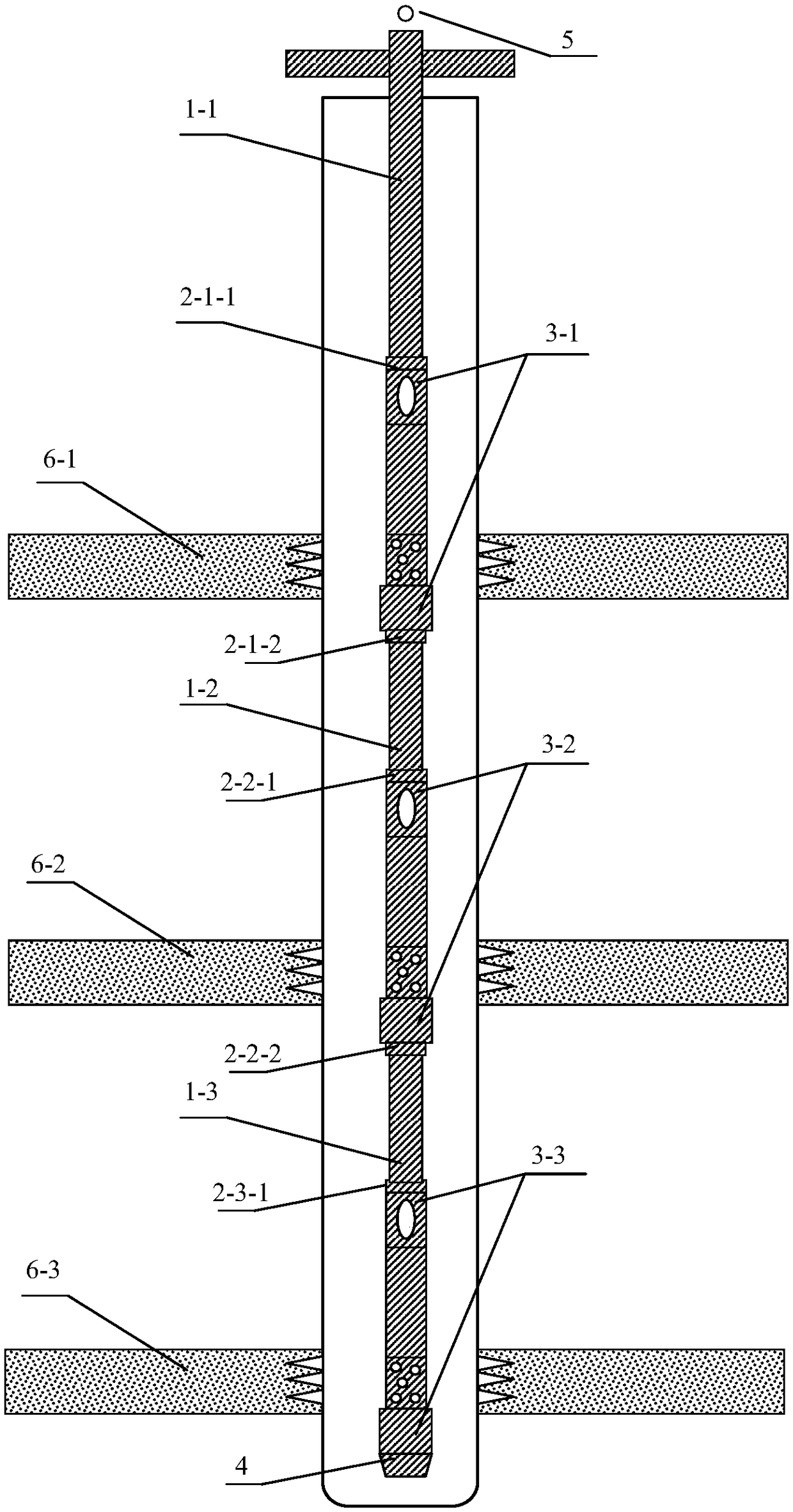

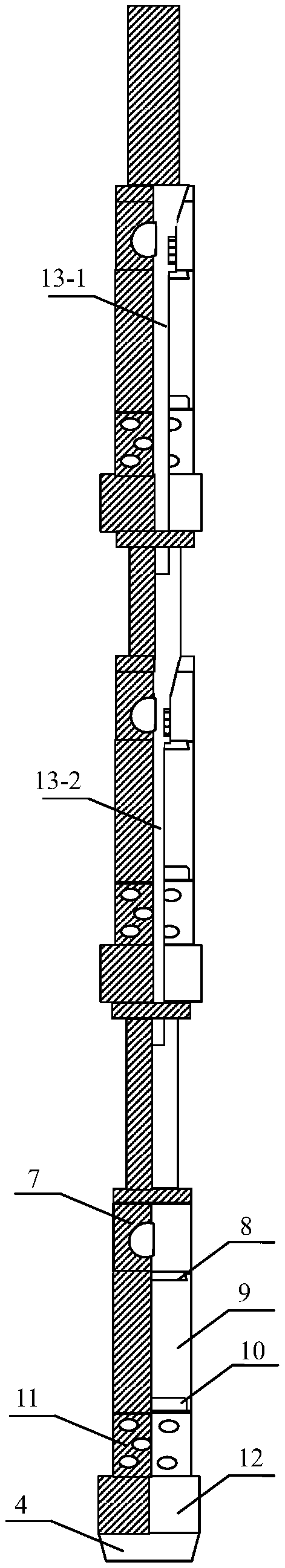

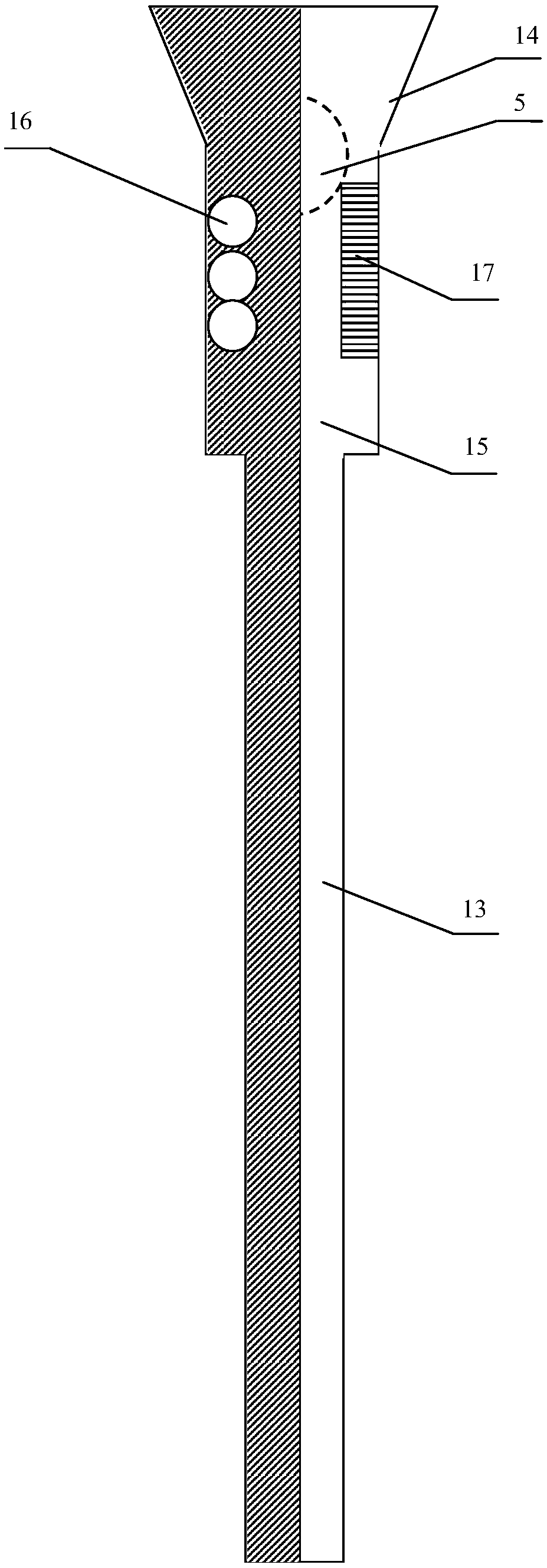

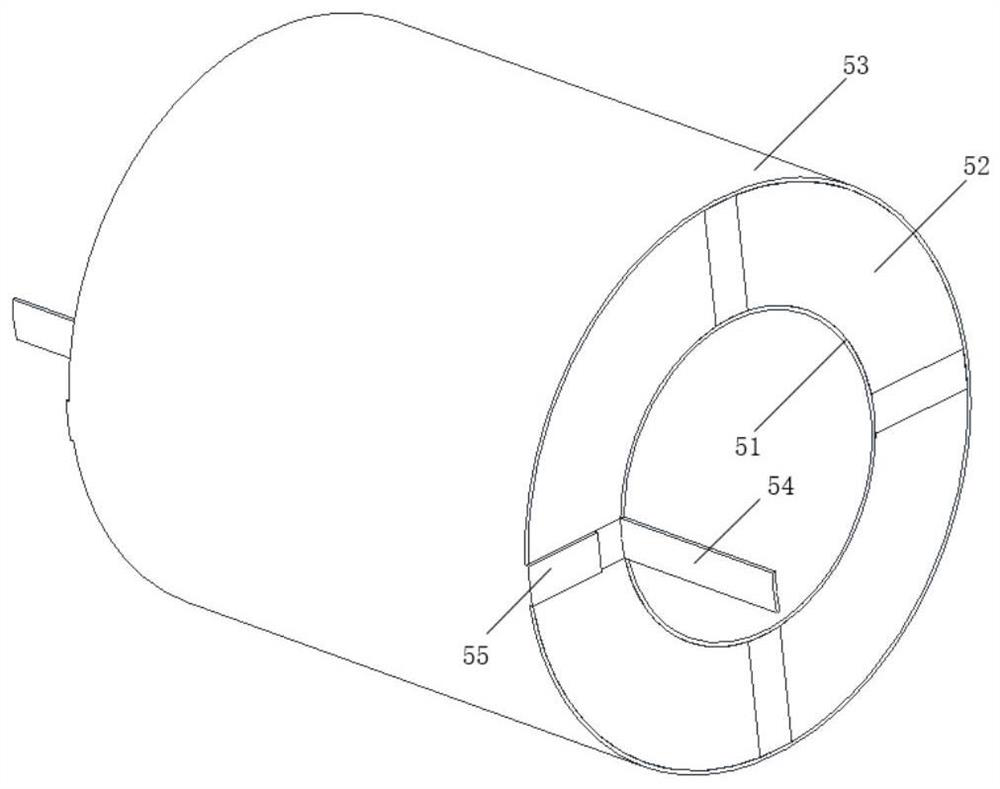

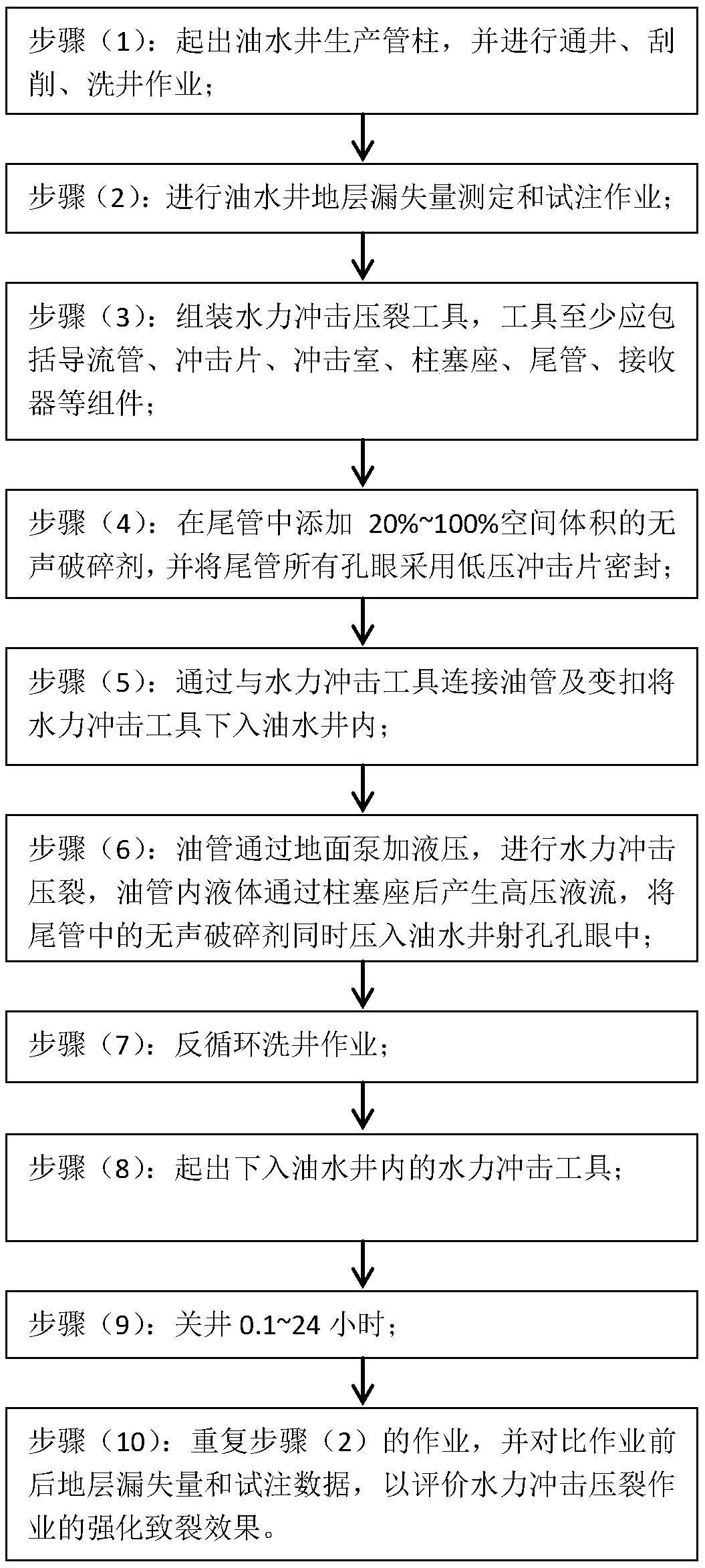

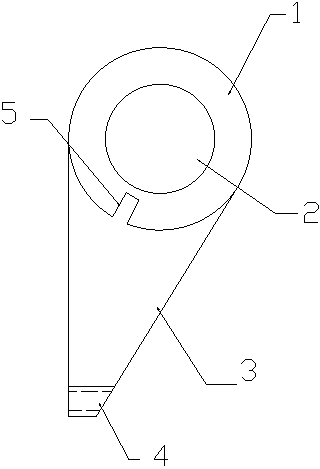

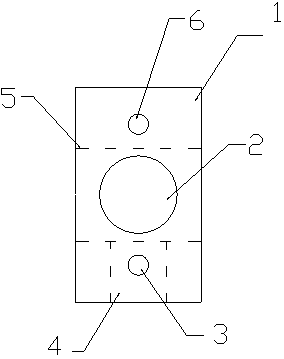

Large-span well segmented hydraulic impact fracturing pipe column and implementing method thereof

ActiveCN108952662AImprove work efficiencyReduce operating costsFluid removalHydraulic pumpSteel ball

The invention belongs to the technical field of oil-gas field reservoir transformation and discloses a large-span well segmented hydraulic impact fracturing pipe column and an implementing method thereof. The pipe column comprises two or more hydraulic impact fracturing devices connected in series. Except for the hydraulic impact fracturing device on the lowermost portion, the remaining hydraulicimpact fracturing devices are internally provided with guiding pipes, ball seats and central pipes and used for transmitting the liquid pressure and conducting hydraulic impact fracturing on the nextoperation section. During implementing, firstly, the pressure is increased to the pressure resistance value of an impact piece in the hydraulic impact fracturing device on the lowermost portion through a ground pump, and hydraulic impact of an operation section on the lowermost portion is completed; then, steel balls suitable for the ball seats in the hydraulic impact fracturing devices at the sections are sequentially released segment by segment from bottom to top, and pressurizing is conducted again through the ground pump, so that the central pipes are sealed by the steel balls falling intothe ball seats, pressure relief holes are opened through a pressurizing hole-opening valve, then continuous pressurizing is conducted, and when the pressurizing value reaches the pressure resistancevalue of an impact piece in the hydraulic impact fracturing device at the corresponding section, hydraulic impact of the operation section is completed; and the steps are repeated till hydraulic impact of all the operation sections is completed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

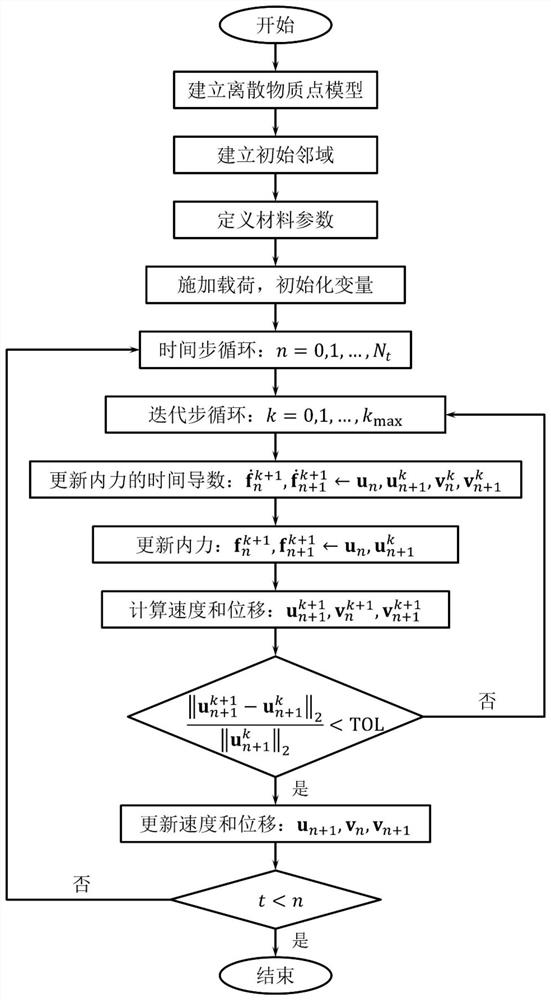

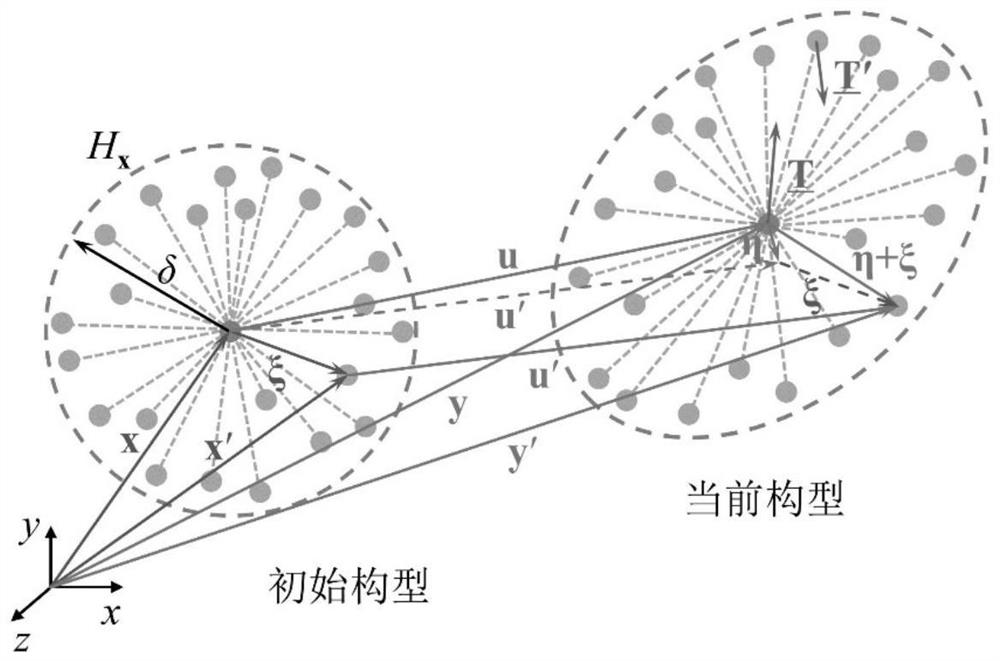

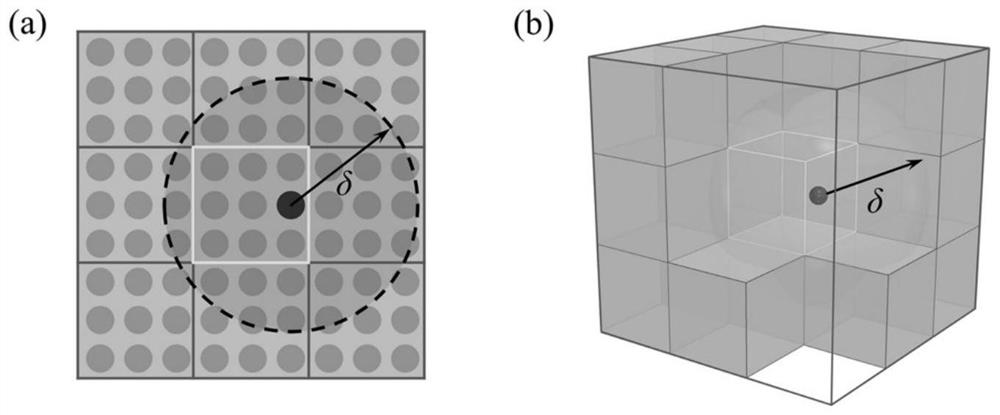

Time discontinuous state-based near-field dynamics method for structure impact elastic-plastic fracture analysis

ActiveCN114186456AEasy to handleOvercome the difficulty of accurately capturing the crack growth pathDesign optimisation/simulationComplex mathematical operationsNeighborhood searchDynamic models

The invention belongs to the field of computational mechanics, and provides a time-discontinuous state-based near-field dynamics method for structural impact elastic-plastic fracture analysis, which introduces a time-discontinuous idea into a state-based near-field dynamics theory, and effectively improves the precision of near-field dynamics explicit dynamic analysis and the capability of accurately predicting structural fracture damage. According to the method, false numerical oscillation caused by a traditional time-history integral method can be effectively controlled by adopting a time-discontinuous explicit time-history integral format, and complex mechanical behaviors of the material under the impact load are simply, conveniently and comprehensively described by adopting an unconventional state-based near-field dynamic model; and the impact fracture failure mode of the structure is effectively represented through a plurality of damage fracture criteria. In addition, a material point neighborhood is constructed and a contact neighborhood is updated by adopting a fast neighborhood search algorithm, so that the calculation efficiency is improved. As a new numerical solution format, the method provided by the invention can be realized by simply modifying an original calculation program, and the numerical implementation complexity is reduced.

Owner:DALIAN UNIV OF TECH

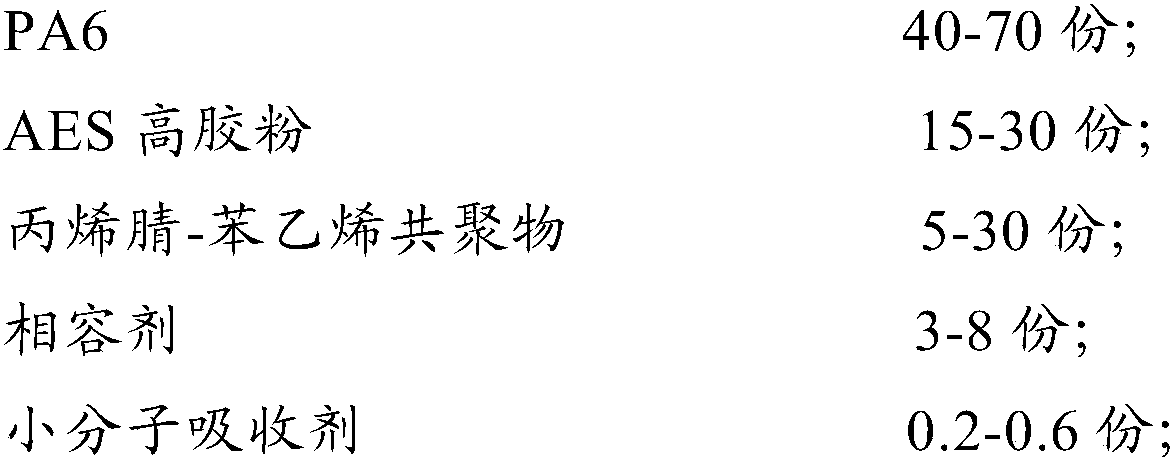

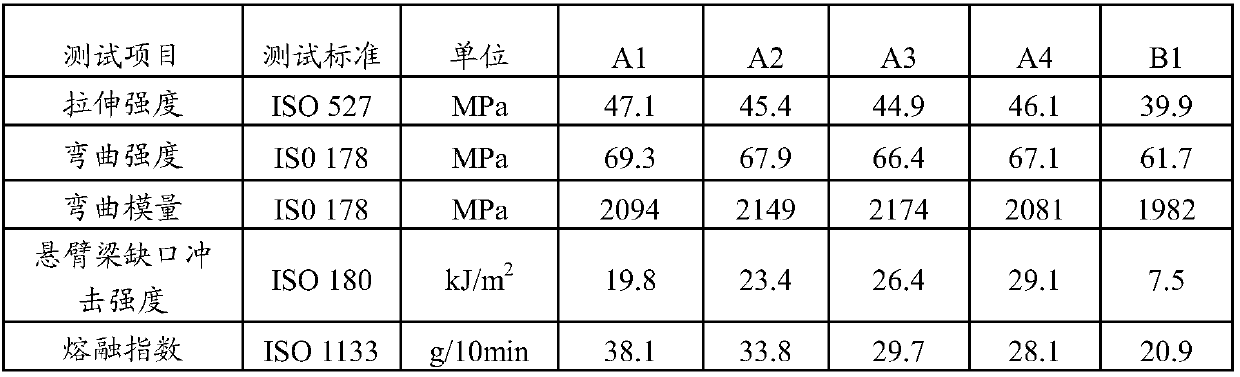

PA6/AES composite material and preparation method thereof

The invention discloses a PA6 / AES composite material and a preparation method thereof. The composite material contains the following components in parts by weight: 40-70 parts of PA6, 15-30 parts of AES high rubber powder, 5-30 parts of an acrylonitrile-styrene copolymer, 3-8 parts of a compatilizer, 0.2-0.6 part of a small molecule absorbent, 0.1-0.5 part of an antioxidant and 0.2-0.5 part of a lubricant. By adding a proper amount of the compatilizer, the wear resistance of the PA6 / AES composite material is improved; the particle size of rubber in the AES high rubber powder is relatively large, and the brakeage energy can be effectively absorbed during impact fracture, so that the impact property of the composite material is improved; and by adding a proper amount of the small molecule absorbent, small molecule substances produced in the processing material can be absorbed, so that the thermal stability of the composite material is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

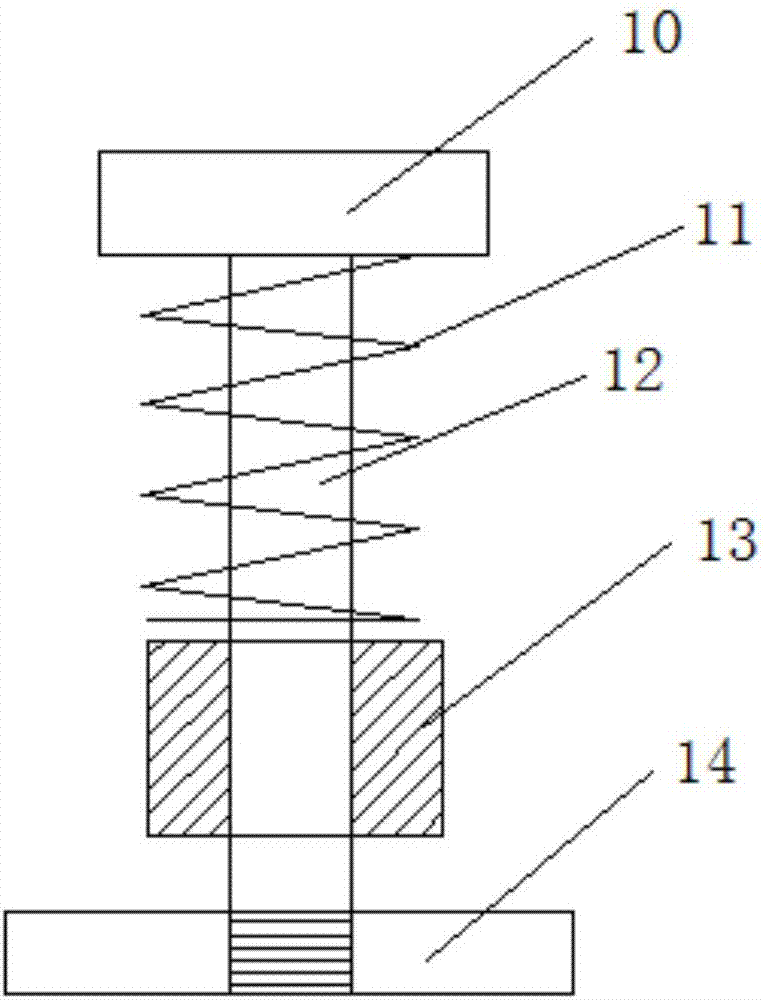

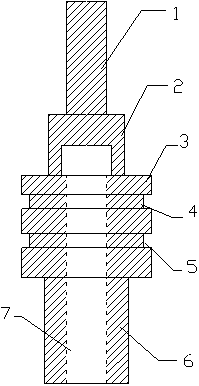

Specially-made bolt of gland of injection molding machine and heat treatment process of specially-made bolt

InactiveCN104295582AHigh tensile strengthImprove fatigue resistanceWashersNutsEngineeringInjection molding machine

The invention discloses a specially-made bolt of a gland of an injection molding machine and a heat treatment process of the specially-made bolt. The heat treatment process comprises a body treatment procedure and a heat treatment procedure. The body comprises a bolt body and a nut, the upper end of the bolt body is of an external thread-shaped structure, a spring is arranged in the middle of the bolt body, the nut is screwed into the external thread-shaped structure and presses the spring, a cylindrical baffle is arranged below the spring, the bottom of the baffle is arranged to be of a conical structure, and a circular through hole is formed in the middle of the baffle. The heat treatment process is characterized in that after the bolt is heated to be austenitized, the bolt is immersed in appropriate quenching media to be cooled at a high speed. The tensile strength of the bolt is high enough, so the bolt is resistant to lengthening, breaking, thread slipping and abrasion; the bolt also has high fatigue resistance and impact toughness, so the bolt can resist fatigue and impact fracture and be well applied to the injection molding machine.

Owner:金方明

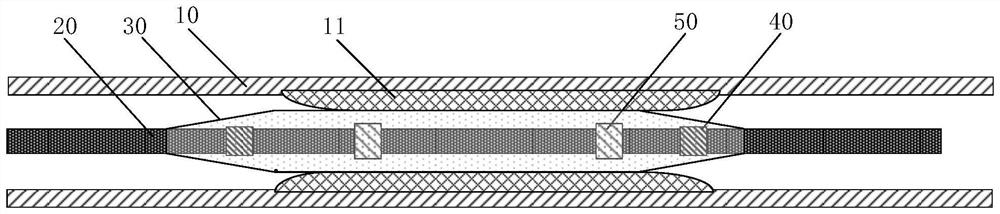

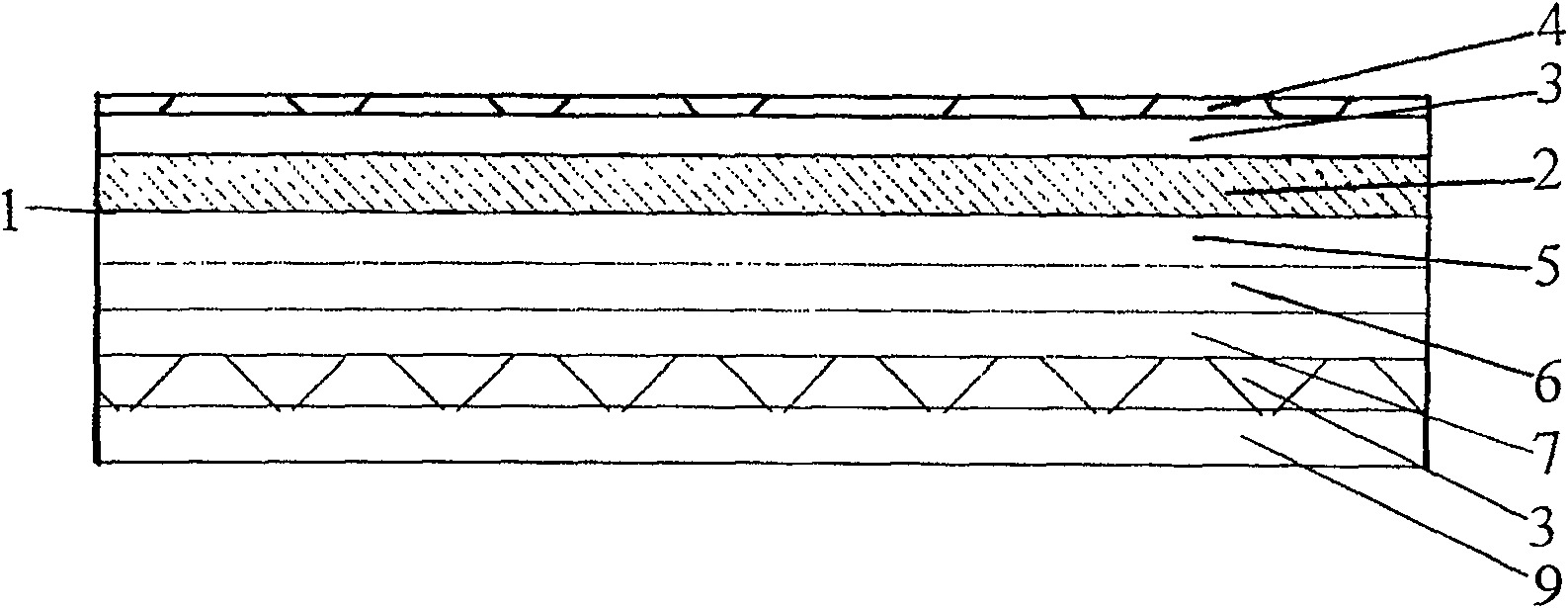

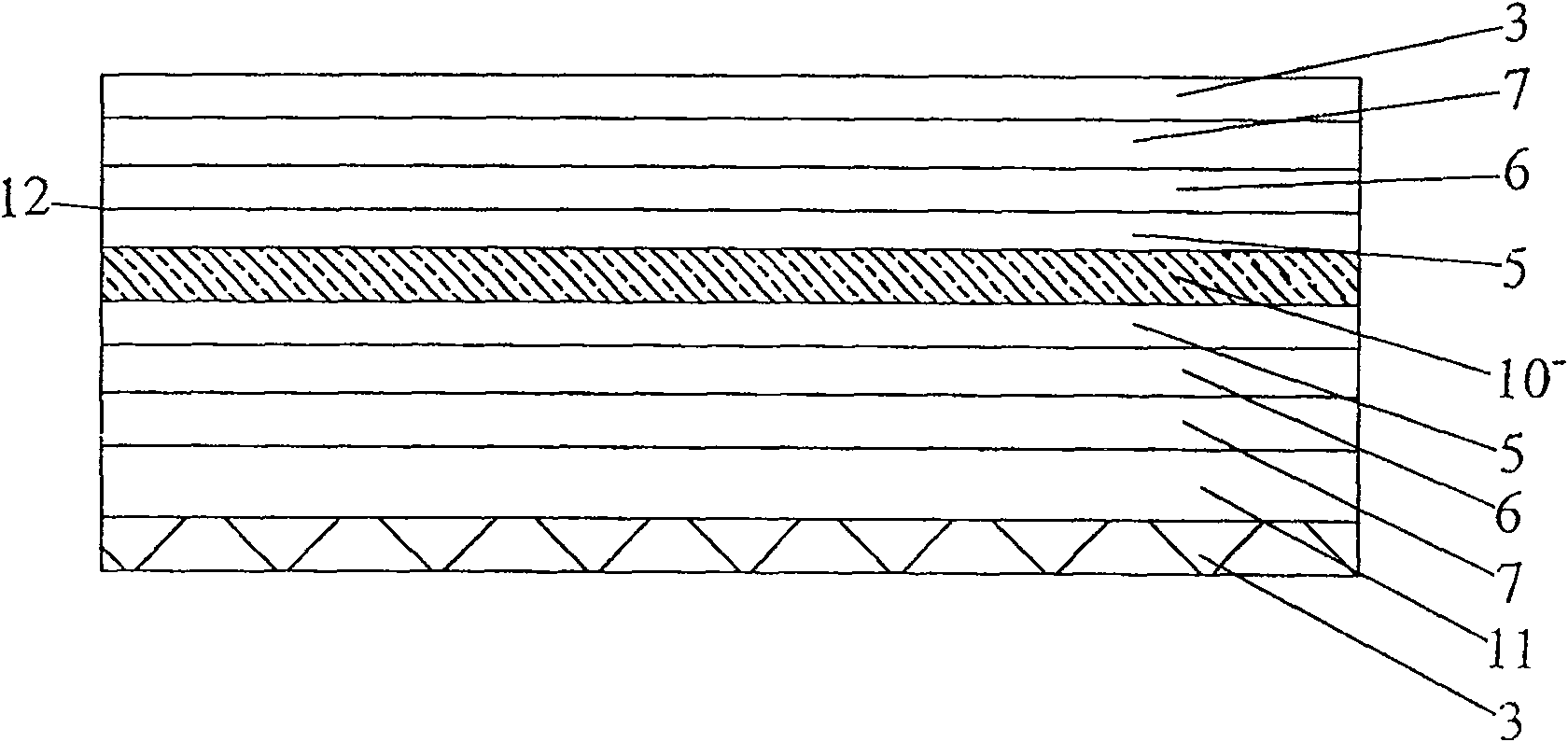

Intravascular calcified plaque impact fracture device

PendingCN114027926AImprove electromechanical conversion efficiencyReduce lossBalloon catheterSurgeryStent implantationBalloon catheter

The invention provides an intravascular calcified plaque impact fracture device, which comprises a balloon catheter, an ultrasonic transducer and a balloon arranged on the balloon catheter, wherein the ultrasonic transducer comprises a first conductive lead, a second conductive lead and an annular body arranged in the balloon and arranged on the balloon catheter in a sleeving mode, the annular body comprises a first annular electrode layer, a piezoelectric effect layer and a second annular electrode layer, the first annular electrode layer is located on the inner side in the radial direction, the second annular electrode layer is located on the outer side in the radial direction, the piezoelectric effect layer is located between the first annular electrode layer and the second annular electrode layer, and comprises a plurality of piezoelectric ceramic parts and a plurality of polymer parts without piezoelectricity, and the polymer parts and the piezoelectric ceramic parts are distributed in the circumferential direction of the annular body at intervals. According to the intravascular calcified plaque impact fracture device, the intravascular calcified plaque impact fracture effect can be well achieved, a stress ring on the calcified plaque is broken, and balloon plasty and stent implantation can be conveniently carried out.

Owner:JIAXING JIACHUANGZHI MEDICAL EQUIP CO LTD

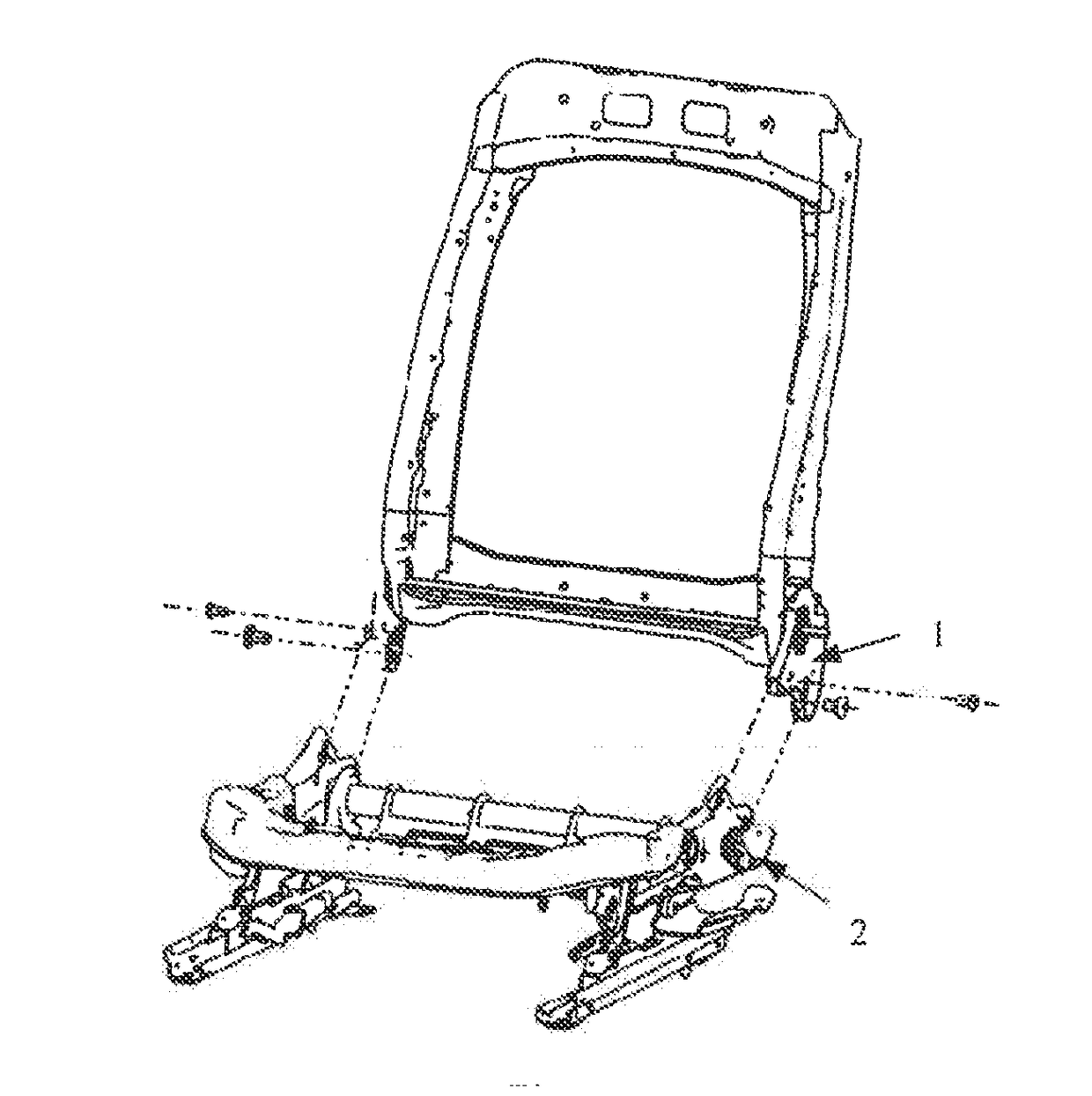

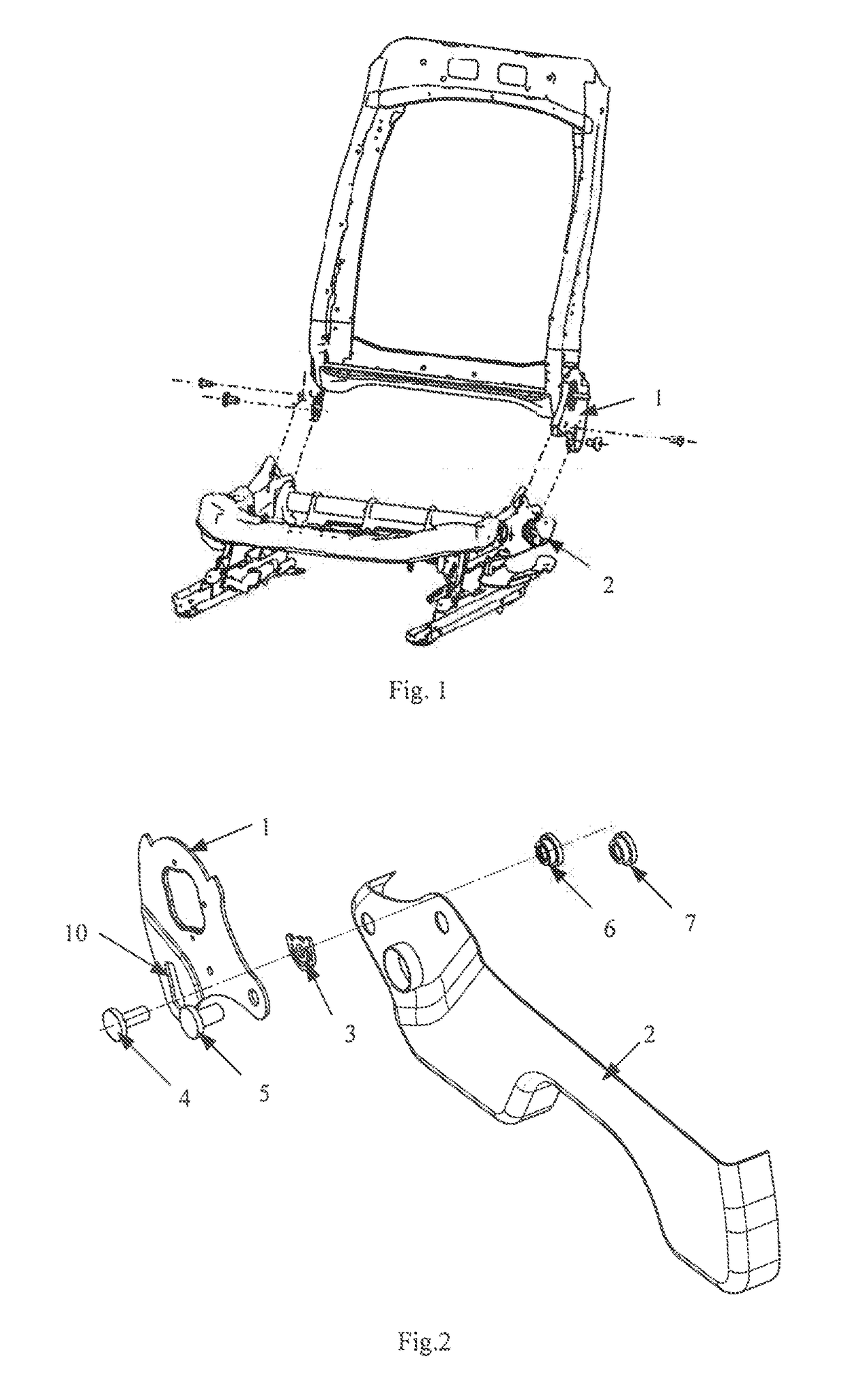

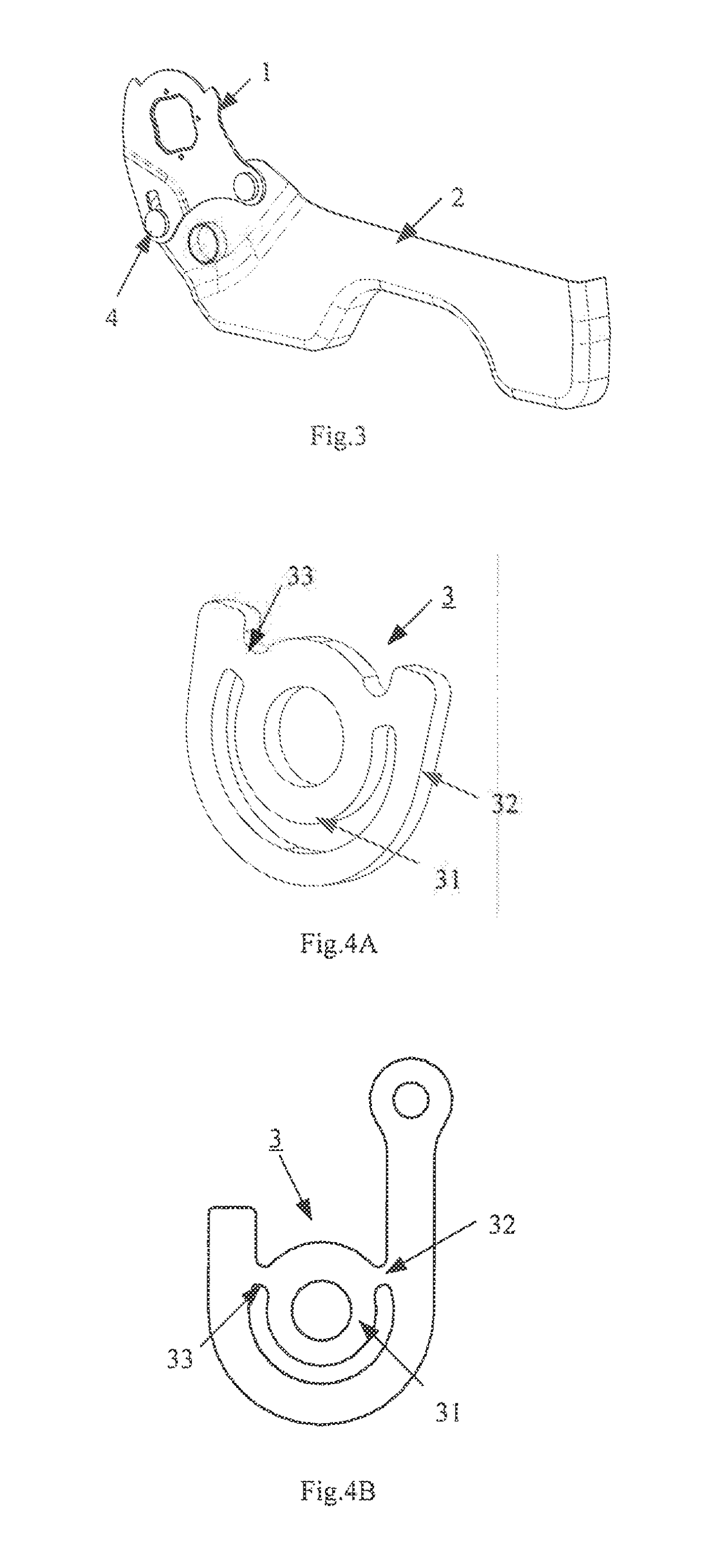

Vehicle seat with energy absorption structure

ActiveUS20180009342A1Simple structureConveniently installedSeat framesMovable seatsEnergy absorptionAbsorbed energy

A vehicle seat with an energy absorption structure, includes a cushion side plate and an angle adjuster lower connection plate, wherein an impact groove is provided on the angle adjuster lower connection plate, and the impact groove includes a straight groove part and a circular groove part communicating each other from top to bottom. The vehicle seat further includes an energy absorption disc including an annular part, a position part and impact fracture parts connected between the annular part and the position part. A first nut is securely coupled to the cushion side plate. A step bolt is provided including a head part, a step part and a stud which are coaxially connected in sequence. The stud bolt passes through the circular groove part, the annular part and threads to the first nut to make the step part passing through the circular groove part and press-fitting with the energy absorption disc. The vehicle seat has a simple structure, convenient installation, and can absorb energy during collision so as to reduce the head rebound speed during the vehicle collision and protect passengers, thereby improving vehicle safety level.

Owner:YANFENG ADIENT SEATING CO LTD

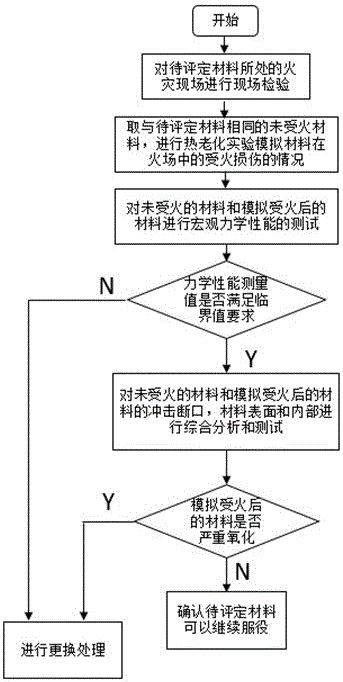

Method for safety assessment of high density polyethylene material after fire

InactiveCN106093363AAccurately judge serviceShorten the timeMaterial testing goodsStrength of materialsMicroscopic exam

The invention belongs to the field of assessment of the performances of polymer materials, and concretely relates to a method for detecting and evaluating the performances of a high density polyethylene material after a fire. The method comprises the following steps: simulating the fire damage condition of the material to obtain the mechanical performance indexes of the material at a certain temperature at a certain time; and carrying out impact fracture analysis and microscopic examination (comprising infrared analysis and thermal analysis) on the fire damaged material, and judging that whether the mechanical performances of the material are obviously decreased or not, whether the material obviously oxidized or not and whether the material can be continuously used or not according to the examination result. The method comprehensively evaluates the performance change condition of the material after fire by combining the macroscopic mechanical performance change of the material with the microstructure change of the material and utilizing various modern analyzers. The method can accurately judges that whether the material is continuously used or not, can effectively reduce the replacement time and the replacement cost of high density polyethylene pipelines after fire hazard, and has practical reference values in the evaluation of the performances of other polymer materials after fire damages.

Owner:FUDAN UNIV

Method for repairing concrete pavement by using virgin fiber cement-based repairing material

PendingCN110240454AChange brittlenessOvercome the broken plateIn situ pavingsSurface layerRepair material

The invention relates to a method for repairing a concrete pavement by using a virgin fiber cement-based repairing material. The method comprises: before construction, carrying out a mixing ratio experiment on a cement-based composite material, and carrying out experimental verification to obtain the optimal mixing ratio of the cement-based composite material; carrying out rubblization on an old cement concrete pavement, wherein the whole cement concrete pavement plate is broken into broken blocks at one time by impact equipment, such that the pavement plate is converted from the whole working state to the granule-based combination body working state; after breaking the pavement, compacting to ensure the stability and the flatness of the breaking layer, such that the conversion of the old concrete plate from the old surface layer plate to the new pavement base layer is achieved; preparing a virgin fiber cement-based composite material according to the optimal mixing ratio of the cement-based composite material, pouring, and carrying out vibrating flattening; and after 1 h, covering with a geotextile, and carrying out watering curing. According to the present invention, with the method, the damaged pavement is repaired by using the material, such that the plate breaking and impact fracture phenomenon of the concrete pavement due to the brittleness can be improved so as to avoid the occurrence of wide cracks and improve the durability of the road surface.

Owner:FUZHOU UNIV

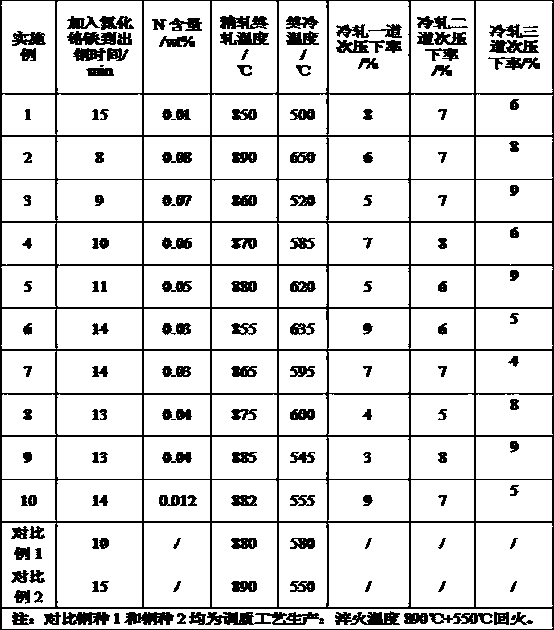

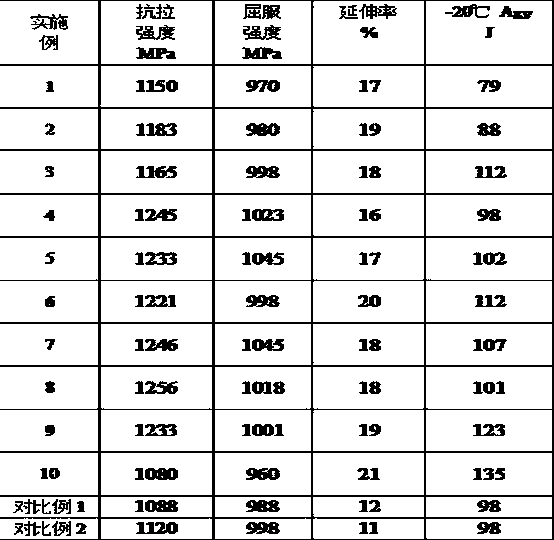

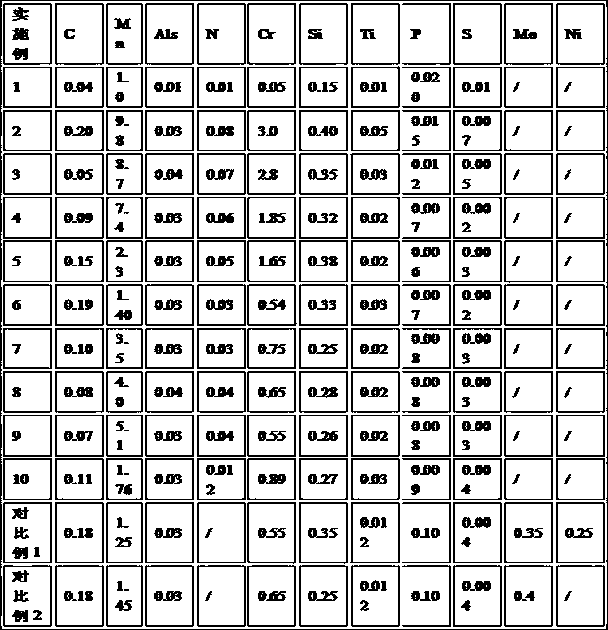

A kind of steel for construction machinery with yield strength ≥ 960mpa and its production method

Provided is engineering machinery steel with the yield strength being larger than or equal to the 960 MPa grade. The engineering machinery steel comprises the components of, by weight, 0.04%-0.20% of C, 0.15%-0.40% of Si, 1.0%-10% of Mn, 0.01%-0.08% of N, 0.010%-0.050% of Ti, 0.01%-0.06% of Als, 0-0.020% of P, 0-0.010% of S and 0.05%-3% of Cr. Production steps comprise smelting and vacuum treatment, steel tapping, casting for blank forming, heating, a hot rolling process, and cold rolling. The engineering machinery steel provided by the invention is larger than or equal to 960 MPa in yield strength, larger than or equal to 15.0% in elongation, not lower than 60 J in -20 DEG C AKV and very excellent in matching of strength and toughness, and has an impact fracture with a dimple characteristic. Adaptive N is added to the chemical components so as to ensure the strength of the steel, and adding of Mo, V, Nb and other expensive microalloy elements is cancelled. Rolling technology of the engineering machinery steel is simple and easy to operate, cold control is not needed in the rolling process, and heat treatment is not needed as well.

Owner:武汉钢铁有限公司

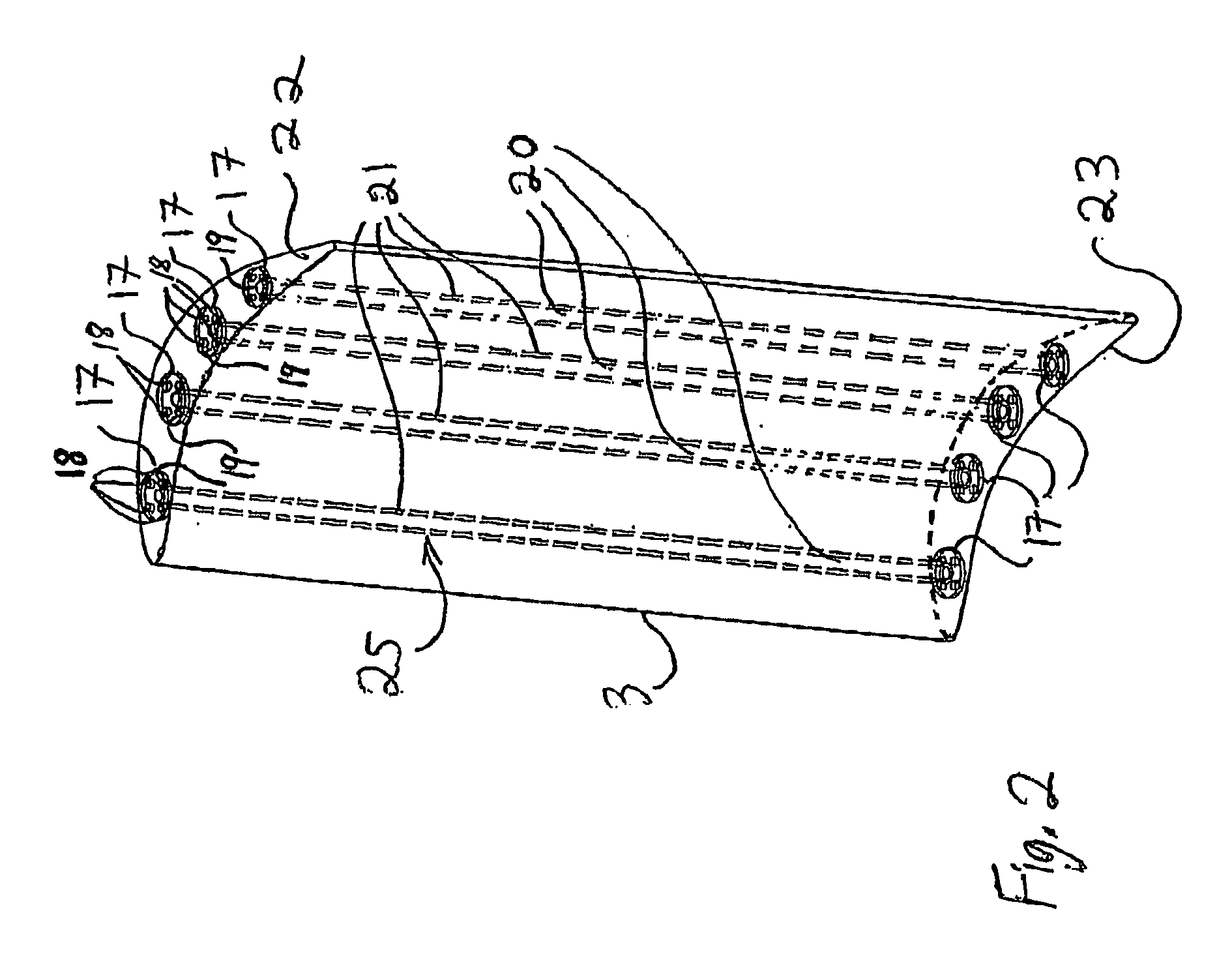

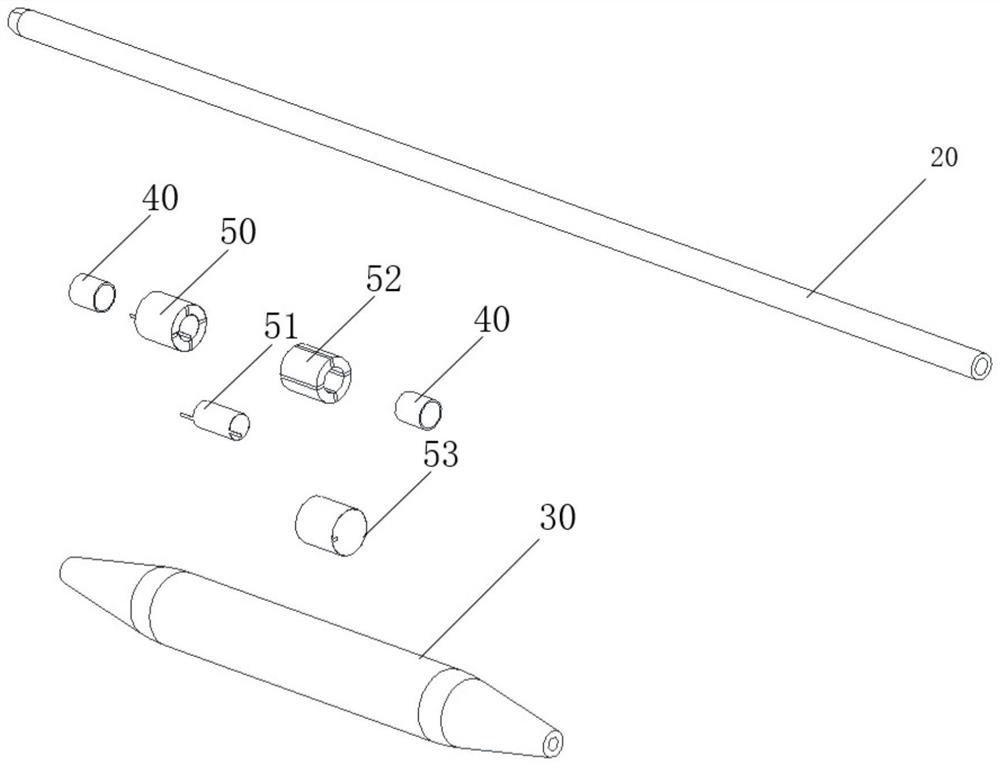

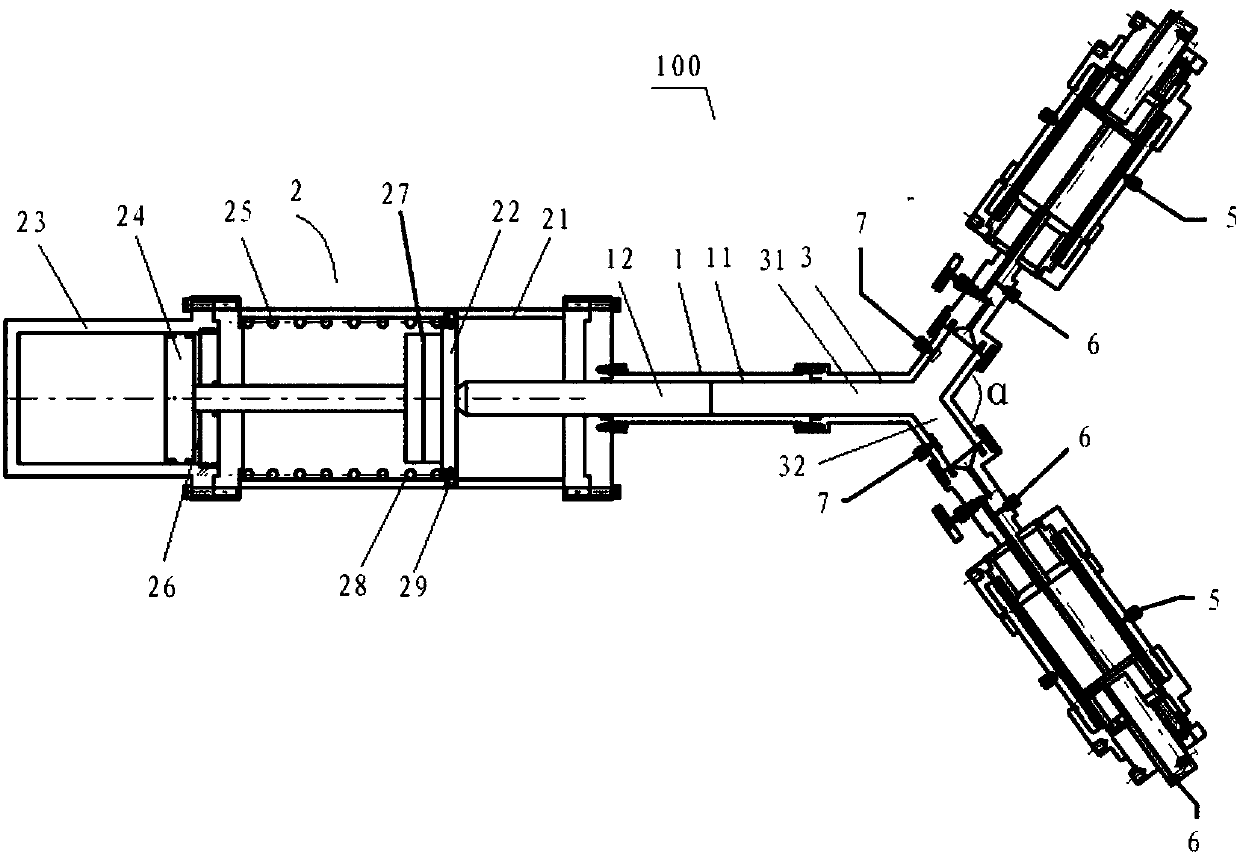

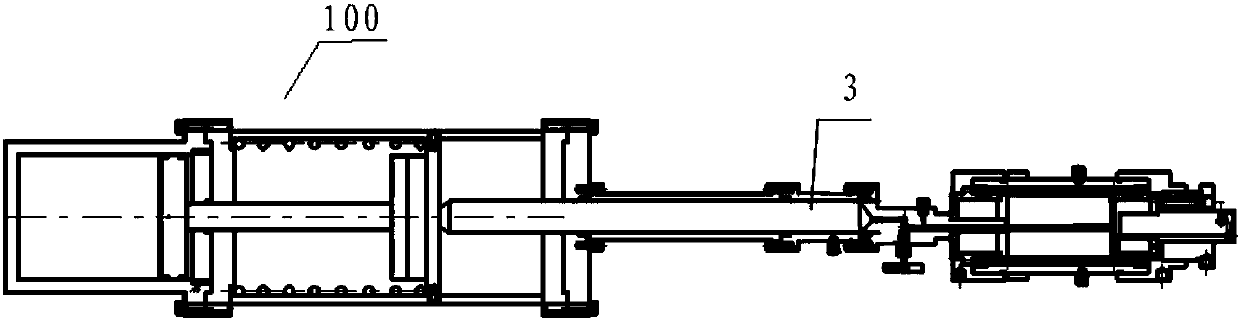

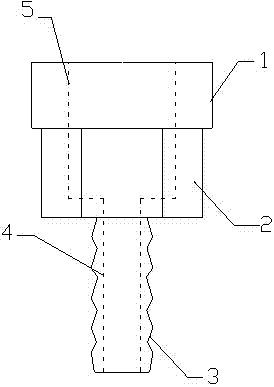

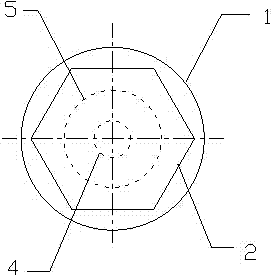

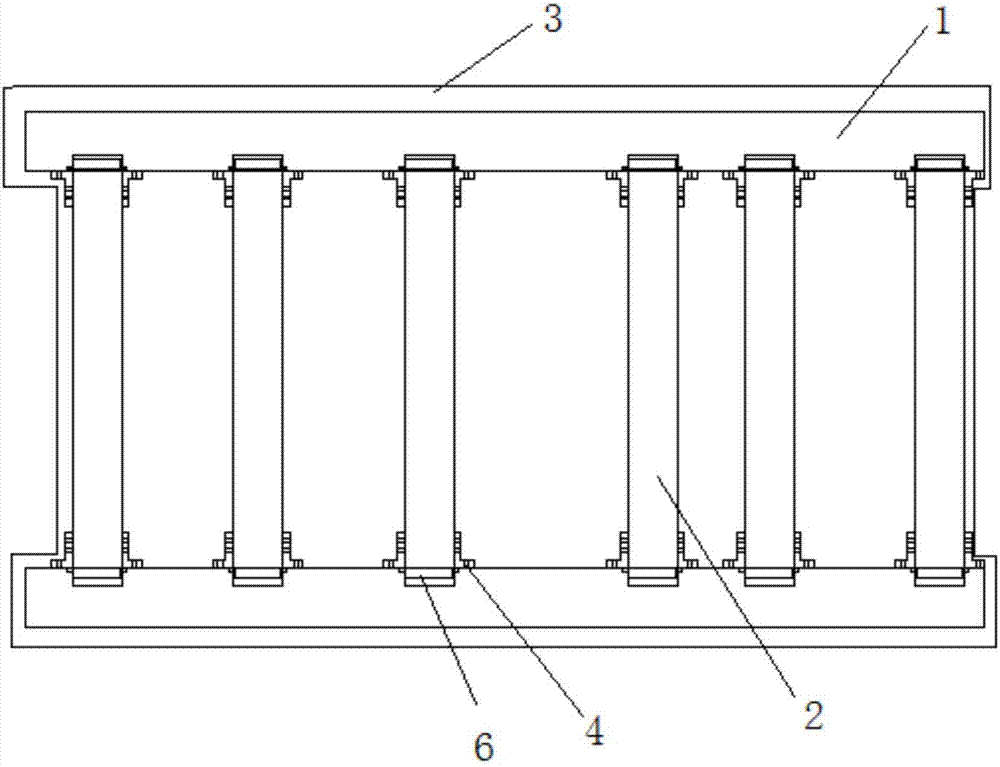

Simulating device for dynamic impact fracture of horizontal well

The invention provides a simulating device for dynamic impact fracture of a horizontal well. The simulating device comprises a force transmitter, a driver, a connector and a core clamping device. Theforce transmitter comprises a cylindrical shell and a force transmitting column arranged in the shell; a driver is arranged at the first end of the force transmitter and used for pushing the force transmitting column to move relative to the shell; the connector is arranged at the second end of the force transmitter, and an inner cavity of the connector communicates with an inner cavity of the shell; and the core clamping device is arranged at the second end of the connector. According to the simulating device, pulse pressure can be formed so as to simulate the real state in a shaft, and accordingly the crack forms of rock fracturing at the long well section and the multilayer section of the horizontal well are simulated.

Owner:CHINA PETROLEUM & CHEM CORP +1

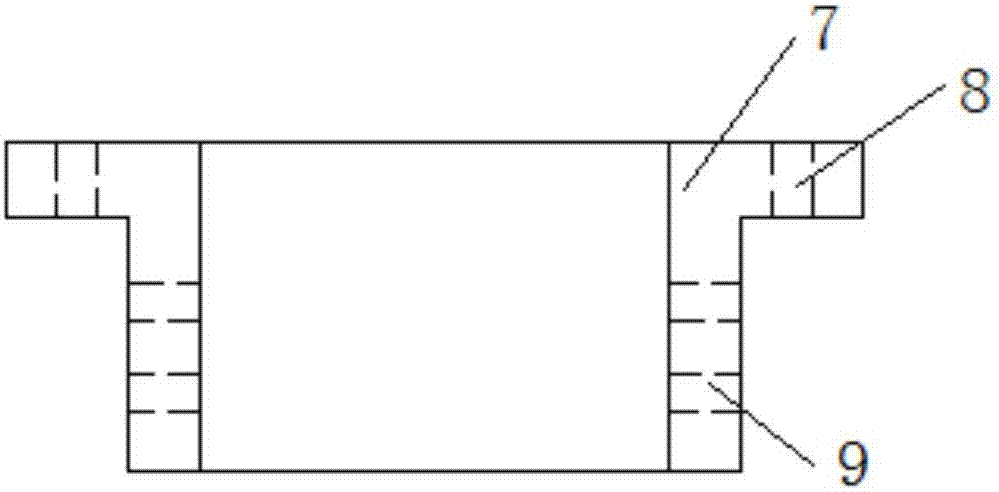

Oil pipe joint of numerical control lathe and thermal treatment process thereof

InactiveCN104266016AHigh tensile strengthImprove fatigue resistanceSleeve/socket jointsFurnace typesNumerical controlThermal treatment

The invention discloses an oil pipe joint of a numerical control lathe and a thermal treatment process thereof. The oil pipe joint of the numerical control lathe and the thermal treatment process thereof comprise a body and a thermal treatment process, wherein the upper end of the body is provided with a cylindrical structure, the middle part of the body is provided with an outside hexagonal structure, and the lower part of the body is provided with a toothed cylinder structure; the upper part in the body is provided with a cylindrical through hole structure which is arranged to be a first through hole structure, and the lower part of the body is similarly provided with a cylindrical through hole structure which is arranged to be a second through hole structure; the external diameter of the first through hole structure is greater than that of the second through hole structure; the thermal treatment process of the oil pipe joint is characterized in that the oil pipe joint is immersed into a proper quenching medium to cool at a higher speed after being heated to be austenitized. The oil pipe joint has high enough tensile strength to resist stretch, snap, slipping and wear, has higher fatigue resistance and impact toughness, can resist fatigue and impact fracture and can be excellently applied to the numerical control lathe.

Owner:PINGHU CITY DANGHU STREET FEITIANREN MACHINERY GRAPHIC DESIGN SERVICE DEPT

Method for preventing corrosion of low-temperature fracture

PendingCN113670963ASimple methodEasy accessMaterial analysis using wave/particle radiationMaterial strength using single impulsive forceAlcoholTest sample

The invention discloses a method for preventing corrosion of a low-temperature fracture, which adopts common reagents absolute ethyl alcohol and a plastic beaker in a laboratory, is simple, convenient to obtain raw materials and reusable, does not need a laboratory power supply, an electric hair dryer and the like, does not need additional investment, and can be applied to protection of low-temperature impact fractures of various metal materials. The method is suitable for fracture protection of various low-temperature test samples, and a novel fracture protection method is provided for personnel engaged in experiments and research and development in the aspects of low-temperature experiments and tests.

Owner:BAOTOU IRON & STEEL GRP

A Vacuum Cladding Surface Strengthening Method for Fracturing Pump Valve Body and Valve Seat

A vacuum cladding surface strengthening method for a fracturing pump valve body and a valve seat. Using the method of vacuum cladding, using nickel-based self-fluxing alloy powder as raw material, adding WC hard strengthening phase powder, a coating with high wear resistance, corrosion resistance and impact resistance is prepared on the surface of the valve body and valve seat of the fracturing pump. The process steps are: workpiece surface pretreatment—ball milling and mixing—making slurry—coating on workpiece surface—drying—vacuum sintering. The ingredients are composed of 5-30% of WC powder and 70-95% of Ni-Cr-Mo-Fe-B-Si-C alloy powder by weight percentage. The cladding coating prepared by the present invention has high density and small internal stress; a good metallurgical bond is formed between the coating and the substrate, which greatly improves the wear resistance, corrosion resistance and corrosion resistance of the cladding coating surface of the valve body and valve seat. Impact resistance, etc., thereby effectively improving the service life of the valve body and the valve seat; and the process of the invention is simple in operation, high in raw material utilization, low in cost, stable in process performance, and suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

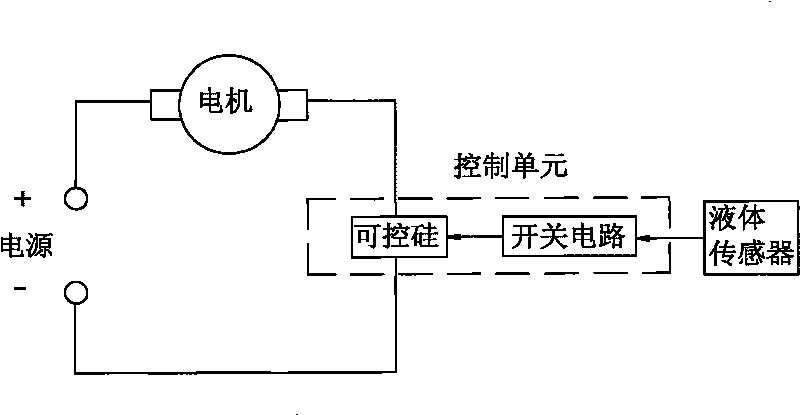

Dry and wet dual-purpose suction machine for garage

ActiveCN101697864AInhibit sheddingExtended service lifeElectric equipment installationDual purposeWater level

The invention relates to a dry and wet dual-purpose suction machine for a garage, which comprises a machine body, wherein the lower end part of the machine body is detachably provided with a dust tube containing dirt liquid; the inside of the dust tube is provided with a warning water mark; a water-level probe is arranged at a position of the warning water mark; a control unit is arranged in the machine body; the water-level probe is electrically connected with the control unit through a conductive wire; the machine body is provided with a flexible connecting piece; the lower end of the connecting piece extends into the warning water mark in the dust tube; the water-level probe is arranged at the lower end part of the connecting part; and the conductive wire for connecting the control unit and the water-level probe is arranged along the connecting piece. When the machine body and the dust tube are disassembled and separated, the dust tube impacts the water-level probe or the connecting piece in the process of moving leftwards and rightwards to cause the distortion of the connecting piece, and thus the adoption of the flexible connecting piece can prevent a detection signal head from shedding due to the impact fracture of the connecting piece during the disassembly and assembly of the dust tube, and prolong the service life of the suction machine.

Owner:SUZHOU EUP ELECTRIC CO LTD

Automobile frame and protection device thereof

InactiveCN107031720AEnsure stabilityGuaranteed service lifeUnderstructuresCross connectionVehicle frame

The invention discloses an automobile frame and a protection device thereof. The automobile frame comprises a frame body composed of a longitudinal beam assembly and a cross beam assembly, wherein a protection plate assembly is arranged below the frame body; the longitudinal beam assembly comprises longitudinal beam bodies, connection assemblies connected and fixed with cross beams, and a suspension mechanism for mounting protection plates; the cross beam assembly comprises main cross beams at two ends, a speed changer cross beam, a transmission shaft cross beam, a front fuel tank cross beam, a rear fuel tank cross beam as well as elastic limiting devices arranged in inner holes in two ends of each cross beam; and the protection plate assembly comprises a groove-shaped protection plate matched with the frame body, the two sides of the groove-shaped protection plate are obliquely arranged outwards, and connection rib plates connected with the suspension mechanism are mounted at the two ends and middle part of the protection plate. The automobile frame disclosed by the invention is simple in structure, convenient to weld and light in weight, and the stability of the frame is ensured; and the protection plate assembly has a buffer effect, thereby avoiding the breakage condition caused by direct impact and ensuring the service life of the frame and the protection plate.

Owner:安徽宏祥工业循环经济开发有限公司

Method for enhancing fracturing effect of hydraulic impact fracturing

ActiveCN109441421ARealize cross-industry applicationSolve the difficult problem of difficult construction in oil and water wellsFluid removalOil waterEngineering

The invention discloses a method for enhancing the fracturing effect of hydraulic impact fracturing. According to the method for enhancing the fracturing effect of hydraulic impact fracturing, a soundless crushing agent in the current building industry is applied to the field of petroleum exploitation, the crushing agent is rapidly pressed into perforated holes through instantaneous high pressuregenerated by hydraulic impact fracturing, the difficult problem that the crushing agent is not easily constructed in an oil-water well is solved, a crack net combination is composed of transverse cracks formed by hydraulic impact fracturing and longitudinal cracks formed by the soundless crushing agent, thus the fracturing effect of hydraulic impact fracturing can be further enhanced, and the method is simple, feasible, safe and environmentally friendly.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Swing arm fixing piece of mould opening machine and heat treatment technology thereof

InactiveCN104196875AHigh tensile strengthImprove fatigue resistanceFurnace typesPivotal connectionsEngineeringCooling down

The invention discloses a swing arm fixing piece of a mould opening machine and a heat treatment technology thereof. The swing arm fixing piece comprises a main body and a heat treatment process, wherein the upper part of the body adopts a cylindrical structure, and a square notch is formed in the lower side of the main body; a circular through hole is formed in the middle of the main body, the lower part of the body adopts a triangular structure, and an inner threaded hole is formed in the bottom of the main body. The heat treatment technology is characterized in that after being heated for austenitizing, the swing arm fixing piece is immersed into a suitable quenching medium to cool down at a quick speed. The swing arm fixing piece has high enough tensile strength to resist lengthening, snapping, slipping off and wearing, and has higher fatigue resistance and impact toughness to resist the fatigue and impact fracture, so that the heat treatment technology disclosed by the invention can be applied to the mould opening machine well.

Owner:金方明

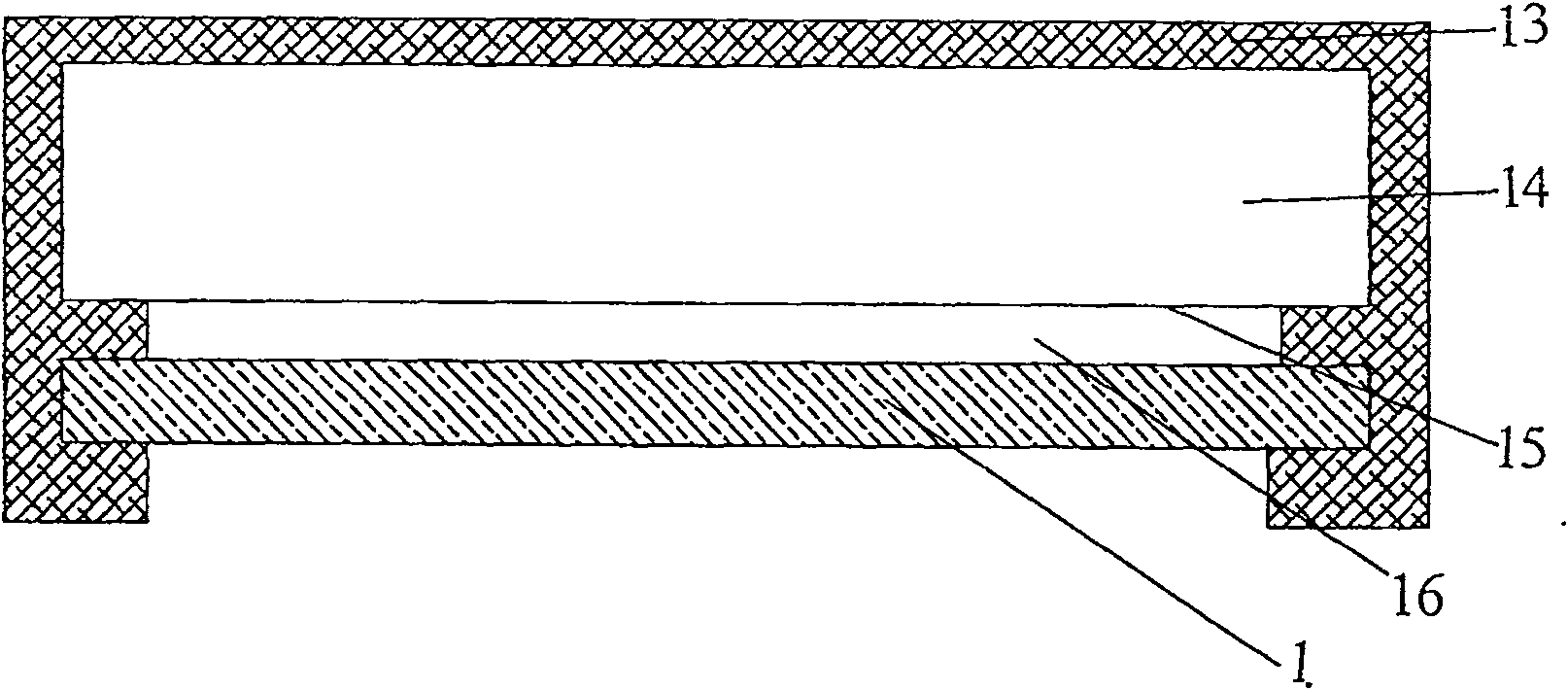

Bottom plate fixing piece of die spotting machine and thermal treatment technology of bottom plate fixing piece

InactiveCN104235124AHigh tensile strengthImprove fatigue resistanceSecuring devicesFurnace typesBiochemical engineeringThermal treatment

The invention discloses a bottom plate fixing piece of a die spotting machine and a thermal treatment technology of the bottom plate fixing piece. The bottom plate fixing piece comprises a body; the thermal treatment technology comprises a thermal treatment process; the body is of a rectangular structure, a round through hole which is set to be a first through hole is formed in the middle part of the body, two round through holes which are respectively set to be a second through hole and a third through hole are respectively formed in the upper side and the lower side of the first through hole, a square groove which is set to be a first groove is formed in the middle part of the body, and a square groove which is set to be a second groove is formed in the lower side of the first groove; the thermal treatment technology is characterized in that the bottom plate fixing piece can be cooled at a quicker speed by being immersed in an appropriate quenching medium after being heated to be austenized. According to the bottom plate fixing piece and the thermal treatment technology, disclosed by the invention, the tensile strength is high enough, and thus lengthening, snapping, slipping and wearing can be resisted; the fatigue resistance and the impact toughness are higher, thus fatigue and impact fracture can be resisted, and the bottom plate fixing piece can be well applied to the die spotting machine.

Owner:金方明

Foamed wood plastic composite material and its preparation method

The invention relates to a foamed wood plastic composite material and its preparation method, the foamed wood plastic composite material comprises the following raw materials by weight proportion: 50-60 parts of wood powder, 20-30 parts of polypropylene, 20-25 parts of polyethylene, 5-8 parts of ethane-acrylate, 2-6 parts of sodium bicarbonate and 3-5 parts of petroleum resin. The foamed wood plastic composite material has the advantages that wood powder enables good combination with a polymer, no bubbles and no pitting are generated after heating, the shock resistance is good and the number of the low temperature drop hammer impact fracture is zero.

Owner:孙天凯

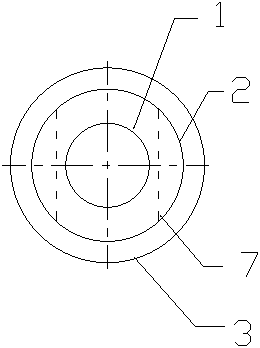

CNC lathe hoisting system connecting element and heat treatment technology of CNC lathe hoisting system connecting element

InactiveCN104212962AHigh tensile strengthImprove fatigue resistanceFurnace typesQuenching agentsNumerical controlEngineering

The invention discloses a CNC (Computerized Numerical Control) lathe hoisting system connecting element and a heat treatment technology of the CNC lathe hoisting system connecting element. The CNC lathe hoisting system connecting element comprises a body; the heat treatment technology comprises a heat treatment process; the body is made into a cylindrical structure; an arc-shaped triangular structure is arranged above the body; and the middle of the body is made into a hollow structure. The heat treatment technology is characterized in that the CNC lathe hoisting system connecting element is soaked into proper quenching media to be cooled at a higher speed after being heated to an austenization state. The CNC lathe hoisting system connecting element and the heat treatment technology have the advantages that sufficient high tensile strength is realized for resisting stretching, tension fracture, thread slipping and abrasion; higher fatigue resistance and impact toughness are realized, so that the fatigue and impact fracture can be resisted; and the CNC lathe hoisting system connecting element and the heat treatment technology can be well applied to a CNC lathe.

Owner:PINGHU CITY DANGHU STREET FEITIANREN MACHINERY GRAPHIC DESIGN SERVICE DEPT

Safety glass protection screen for LCD, LCD using the same

InactiveCN100570406CHigh light transmittanceIncrease productivityLayered productsNon-linear opticsLiquid-crystal displayTransmittance

The invention provides a safety glass protective screen with high light transmittance used for a liquid crystal display device, comprising a glass substrate, wherein, at least one surface of the glass substrate is compounded with a layer of plastic film by using a resin binder, the glass substrate and / or the plastic film surface are / is plated with a transmission-increasing and reflection-deducting film syngenic membrane which is composed of an Nb2O5 / SiO2 film or a TiO2 / SiO2 film. The protective screen of the invention can reduce the reflectivity and improve the light transmittance and the effect of an optical image, fully improve the impact fracture resistant capacity of a display screen and become the safe protective screen. The invention also provides the liquid crystal display device using the glass protective screen.

Owner:甘国工

Connecting piece for numerically controlled lathe and heat treatment technology thereof

InactiveCN104195314AHigh tensile strengthImprove fatigue resistanceBoltsFurnace typesEngineeringThermal treatment

The invention discloses a connecting piece for a numerically controlled lathe and heat treatment technology thereof. The connecting piece comprises a body and a heat treatment process, wherein the upper end of the body is designed into a cylindrical structure, namely a first cylindrical structure; the lower end of the body is also designed into the cylindrical structure, namely a second cylindrical structure; the middle of the body is designed into the cylindrical structure, namely a third cylindrical structure; two annular snap spring grooves, namely an upper snap spring groove and a lower snap spring groove, are formed in the middle of the third cylindrical structure; the bottom of the body is also designed into the cylindrical structure, namely a fourth cylindrical structure; a cylindrical groove is formed between the second cylindrical structure and the fourth cylindrical structure. The heat treatment technology of the connecting piece is characterized in that the connecting piece is heated to be austenitized and then is immersed into a proper quenching medium for cooling at a higher speed. The connecting piece disclosed by the invention has the advantages that the tensile strength is high enough, so that the elongation, pull cut, thread slipping and wearing are resisted; the fatigue resistance and impact toughness are higher, so that the fatigue and impact fracture can be resisted; the connecting piece can be better applied to the numerically controlled lathe.

Owner:PINGHU CITY DANGHU STREET FEITIANREN MACHINERY GRAPHIC DESIGN SERVICE DEPT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com