Method for safety assessment of high density polyethylene material after fire

A high-density polyethylene and safety evaluation technology, applied in the field of performance evaluation of polymer materials, can solve the problems of reduced structural safety, deterioration of high-density polyethylene structural performance, no high-density polyethylene pipeline evaluation method, etc. The effect of time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

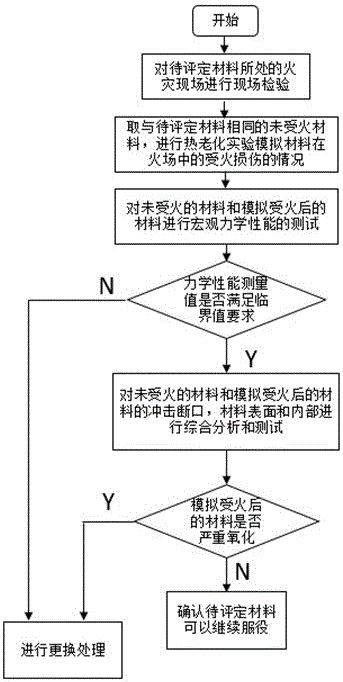

[0028] Example 1: If figure 1 As shown, the present invention provides a reasonable and practical method for evaluating the performance of high-density polyethylene materials after being exposed to fire. Below by embodiment the inventive method is further described:

[0029] After a high-density polyethylene pipeline is damaged by fire, it is necessary to evaluate its performance after fire to assess whether it can continue to serve. Follow these steps:

[0030] (1) First, conduct on-site inspection of the environment where the pipeline is located, and obtain the heat exposure temperature, heat exposure time and cooling method of the material during the fire. The heat exposure temperature and heat exposure time were 100°C and 8h, respectively, and the cooling method was air cooling.

[0031] (2) Take the same unfired pipe material as the fire-fired pipe to conduct thermal aging experiments to simulate the performance change of the pipe after fire. The experimental paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com