Method for preventing corrosion of low-temperature fracture

A low-temperature, fracture technology, applied in the direction of using a single impact force to test the strength of materials, measuring devices, instruments, etc., can solve the problems of misjudgment and difficult fracture analysis of SEM, and achieve the effect of simple method and convenient acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

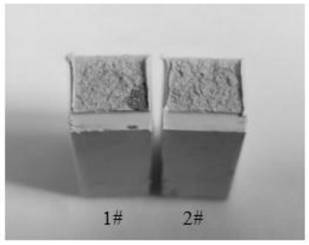

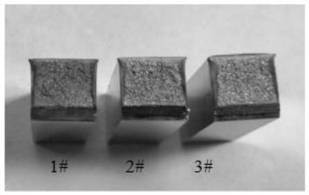

[0020] Select a group of three low-temperature impact samples, numbered 1#, 2#, and 3#, prepare a 500ml clean plastic beaker, and pour 100ml of absolute ethanol into the beaker. The -40°C low temperature impact test was carried out on 1#, 2#, and 3# samples in turn. 1# sample impact test is interrupted without any treatment, 2# sample impact test is interrupted for 1 minute and then put into the beaker, 3# sample impact test is interrupted and immediately put into the beaker; 1# and 2# Due to the low temperature on the surface of the sample, frost formed rapidly on the surface of the sample, see figure 1 ; Put the 2# sample after frosting into the beaker; after a few minutes, observe the 1# sample, there are water droplets on the outer surface of the sample, and a layer of water film can be seen on the fracture surface, see image 3 ; Place the 2# and 3# samples in the beaker for 3-5 minutes and then take them out. Due to the strong volatilization of absolute ethanol, the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com