Connecting piece for numerically controlled lathe and heat treatment technology thereof

A technology of CNC lathes and connectors, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as insufficient fatigue resistance and impact toughness, insufficient high tensile strength, and inability to resist fatigue and impact fractures. Achieve high fatigue resistance and impact toughness, anti-fatigue and impact fracture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

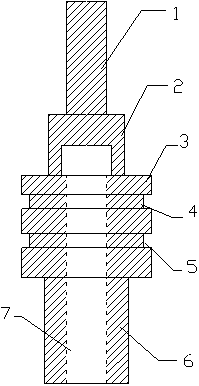

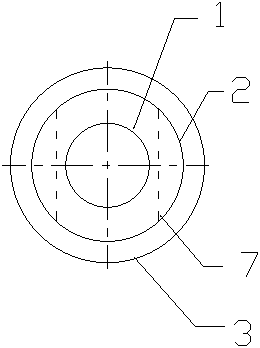

[0011] As shown in the figure, the present invention includes a body and a heat treatment process. The upper end of the body is set as a cylindrical structure, which is set as the first cylindrical structure 1, and its lower end is also set as a cylindrical structure, which is set as the second cylindrical structure. Structure 2, the middle of the body is set as a cylindrical structure, and it is set as a third cylindrical structure 3, in which two annular ring grooves are arranged in the middle, which are respectively the upper ring groove 4 and the lower ring groove 5, so that Described bottom is also set as cylindrical structure, is set as the 4th cylindrical structure 6, is provided with a cylindrical groove 7 between described second cylindrical structure 2 and the 4th cylindrical structure 6, and its heat treatment process The characteristic is that aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com