Gas shielded welding wire with 900MPa tensile strength

A technology of gas shielded welding wire and tensile strength, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of unstable metallographic structure of welding wire, large difference in strength of welding wire and increasing welding wire drawing process Fluctuation and other problems, to achieve the effect of good effect, stable process and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A detailed description is given below:

[0023] During the experiment, a 50kg vacuum furnace was used for smelting. In order to improve the uniformity and purity of the steel ingot, electromagnetic stirring was used, and low S and P scrap steel was used for smelting. Ni, Cu and Mo were added during charging, and Cr was added during refining. The active trace elements are added at a later stage or in a steel drum. The smelting uses Si iron and Mn iron for deoxidation and vacuum deoxidation, and strictly controls the content of trace elements and gases, and casts them into ingots. Pay attention to slowly heating the billet before the wire rod is rolled. The wire rod is made into finished welding wire by pickling, cleaning, drying, wire drawing, recrystallization annealing, water tank wire drawing, surface pickling treatment before copper plating, cleaning, copper plating, etc.

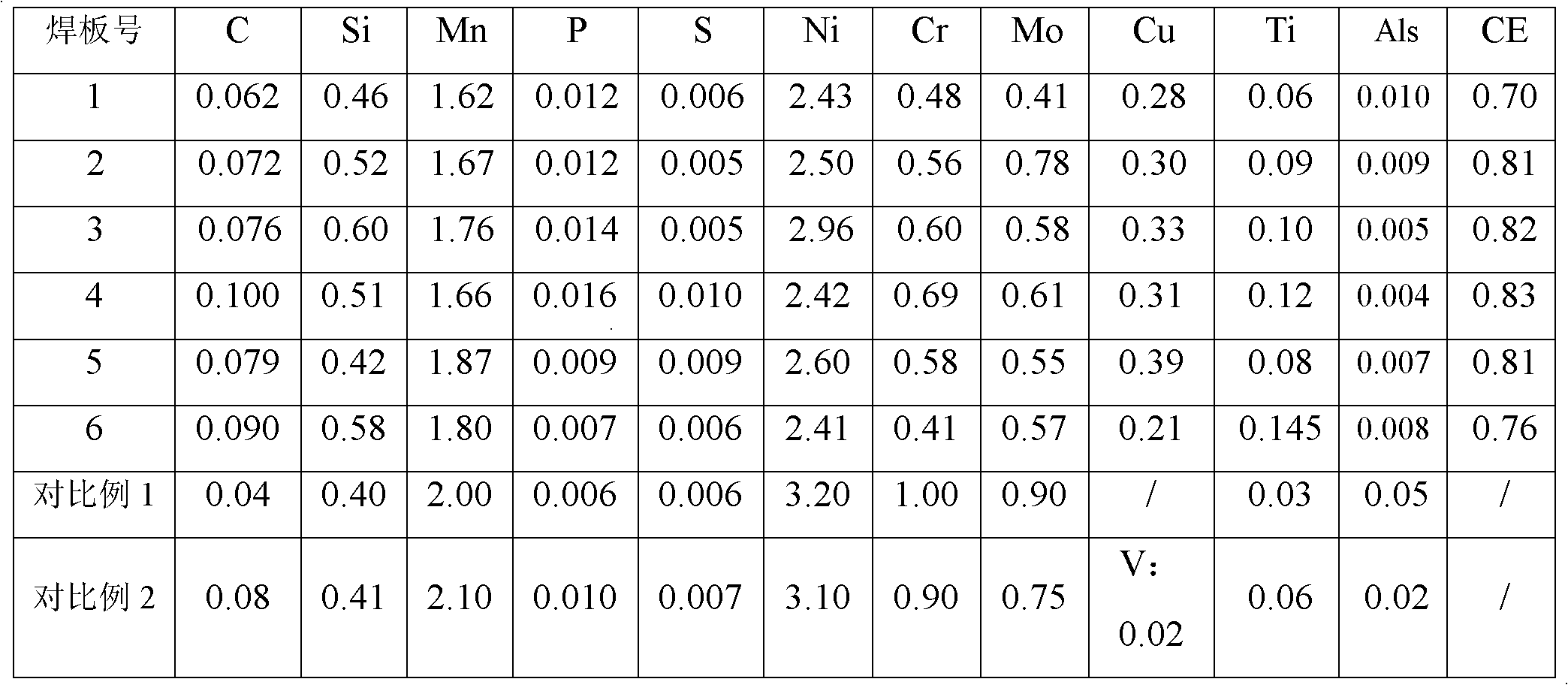

[0024] The composition, percentage by weight of the six furnaces of smelting and the composi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com