Dry and wet dual-purpose suction machine for garage

A wet and dry dual-purpose, vacuum cleaner technology, applied in vacuum cleaners, applications, household appliances, etc., can solve the problems of broken connecting rods, falling off of the water level detection head, etc., to prolong the service life, facilitate cleaning, and avoid the detection signal head falling off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The concrete structure of the present invention will be described in detail below with reference to accompanying drawing:

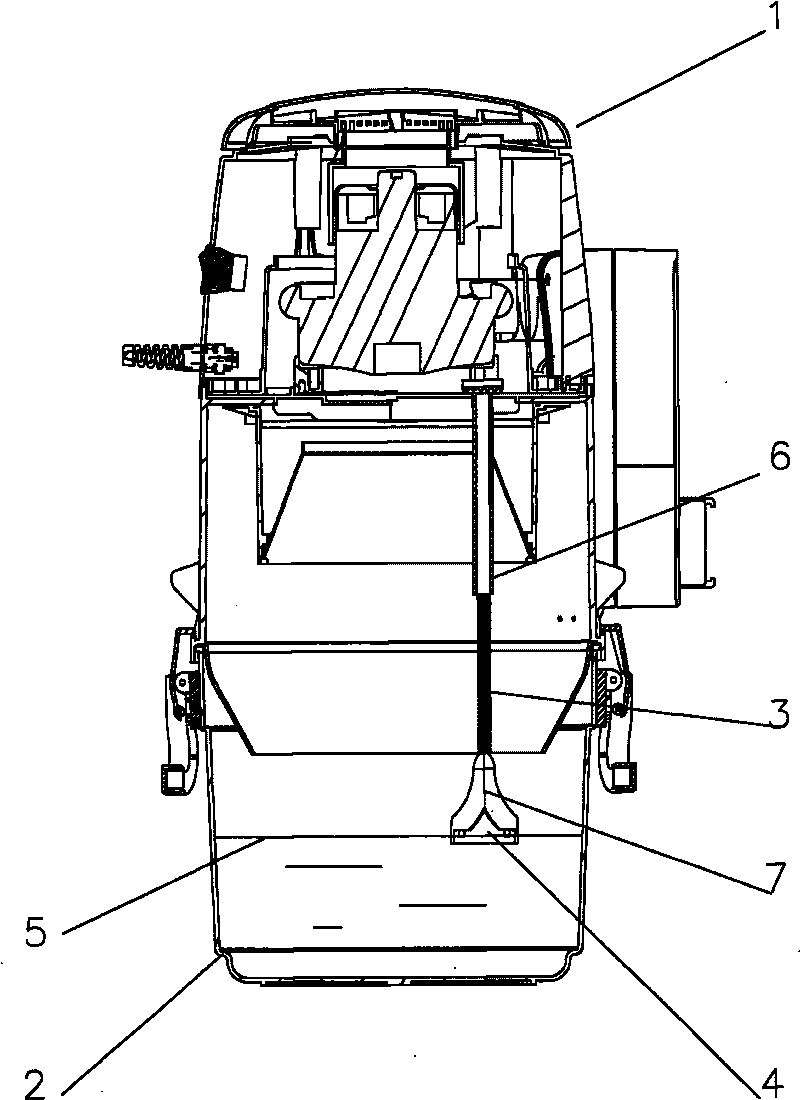

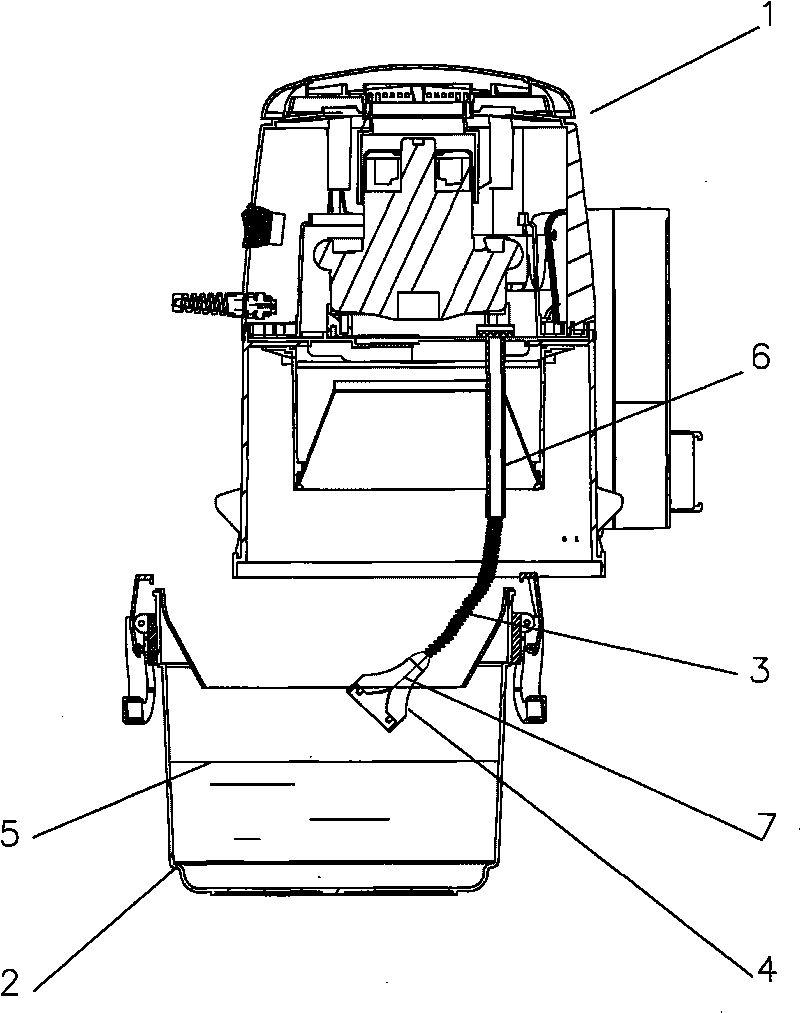

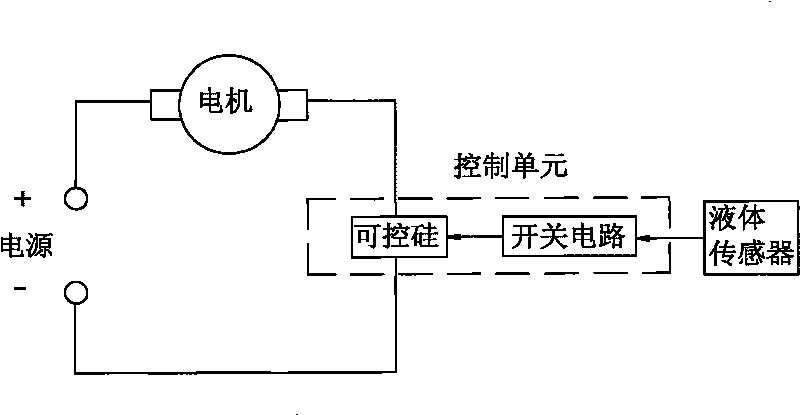

[0019] Refer to attached figure 1 Shown: a dry and wet dual-purpose garage vacuum cleaner, including a body 1, the lower end of the vacuum cleaner body 1 is detachably provided with a dust tank 2 for containing dirty liquid, and a dust tank 2 for containing dirty liquid is arranged inside the dust tank 2. The police boundary water level line 5 of liquid, this police boundary water level line 5 places are equipped with water level detection head 4, and water level detection head 4 can select liquid sensor for use. A control unit is arranged inside the body 1, and the control unit directly controls the motor to drive the vacuum cleaner to work. The water level detection head 4 is electrically connected to the control unit through a wire 7 . When the dirty liquid in the dust tube 1 reaches the police boundary water level 6, the water level detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com