Automobile frame and protection device thereof

A technology of protective device and automobile frame, applied in the direction of vehicle parts, transportation and packaging, substructure, etc., can solve the problems of lower bearing capacity, no buffer structure, inability to meet, etc., to avoid direct impact and breakage, increase connection The effect of fixing the surface and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

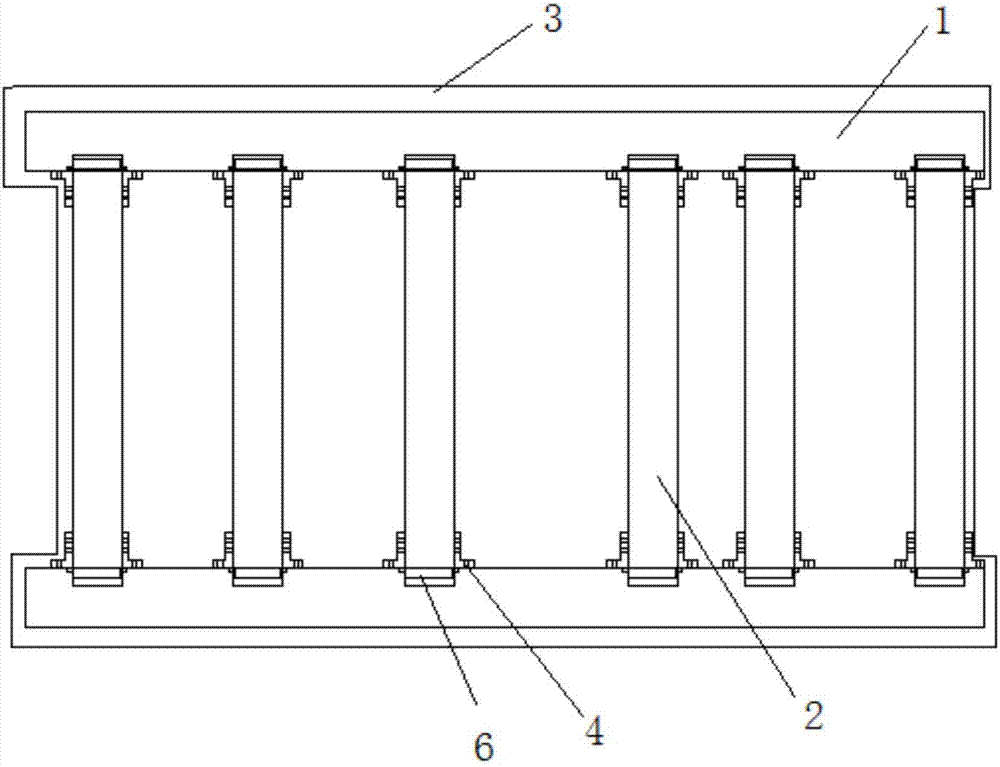

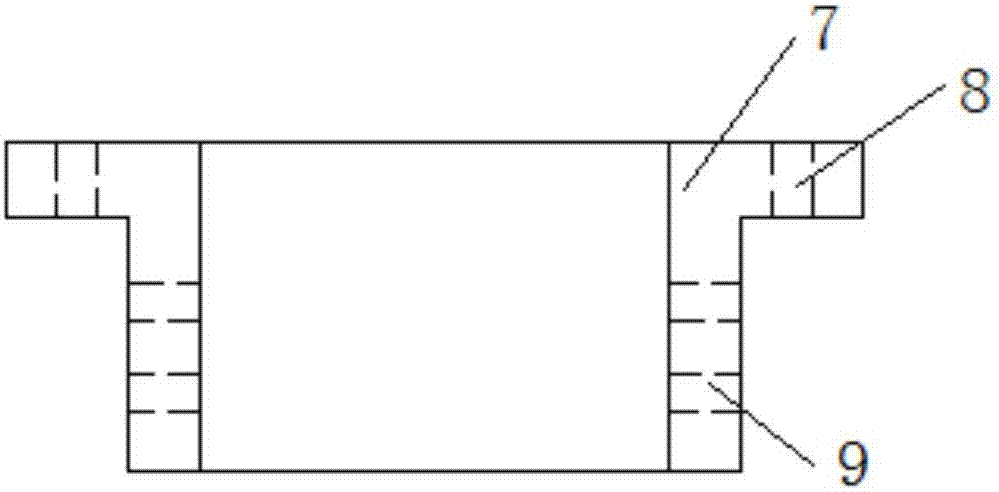

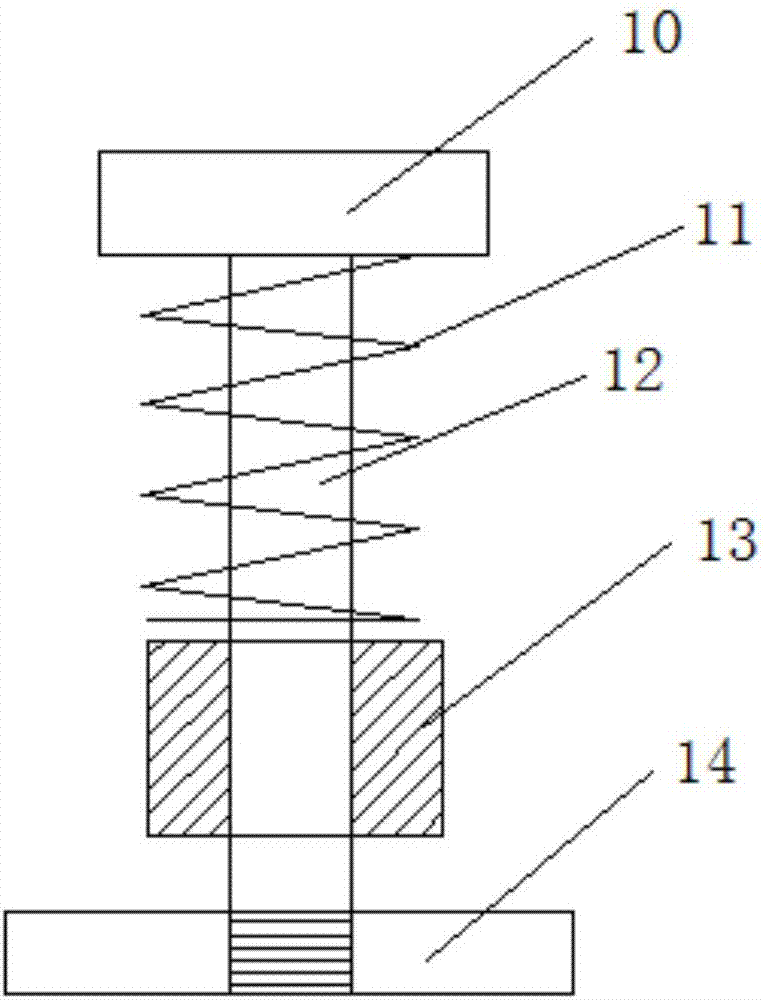

[0022] See attached picture.

[0023] An automobile frame and its protective device, comprising a frame body composed of a longitudinal beam assembly 1 and a cross beam assembly 2, a protective plate assembly 3 is arranged below the frame body; the longitudinal beam assembly includes a longitudinal beam body And the connecting assembly 4 for connecting and fixing the crossbeam and the suspension mechanism 5 for installing the protective plate, the crossbeam assembly 2 includes the main crossbeam at both ends, the transmission crossbeam, the drive shaft crossbeam, the front side fuel tank crossbeam, and the rear side fuel tank crossbeam As well as the elastic limiter 6 arranged in the inner holes at both ends of each crossbeam, the protective plate assembly 3 includes a grooved protective plate matched with the vehicle frame itself, the two sides of the grooved protective plate are inclined outwards, and the protective plate The two ends and the middle part of the plate are equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com