Large-span well segmented hydraulic impact fracturing pipe column and implementing method thereof

A technology for hydraulic shock and fracturing pipe strings, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve problems such as the inability of superchargers to work, avoid repeated trips of pipe strings, and ensure overall , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

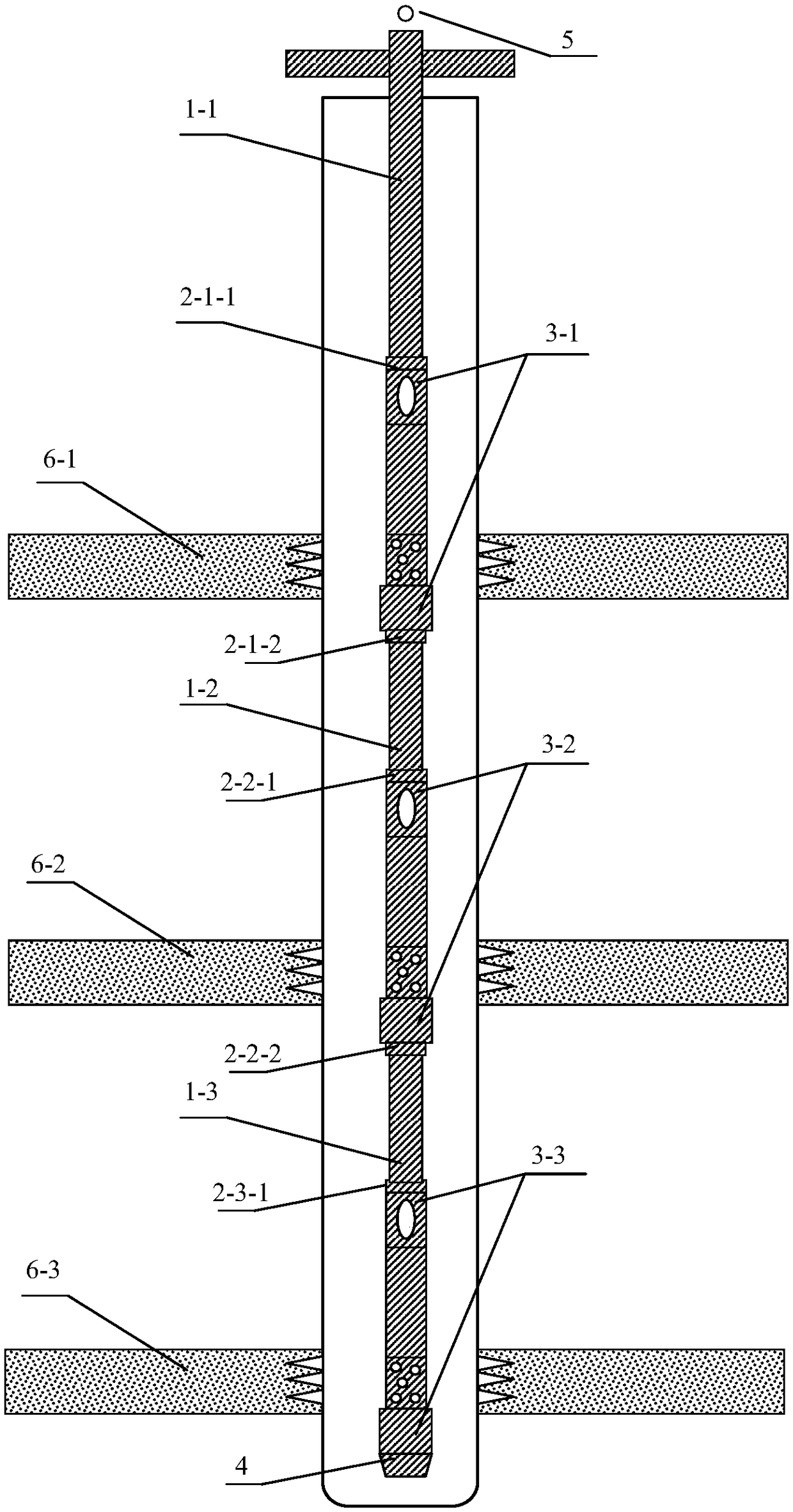

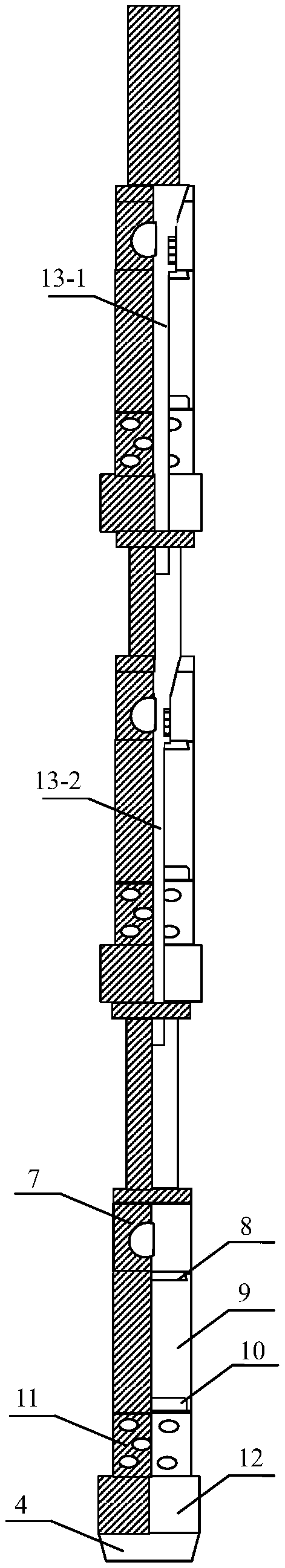

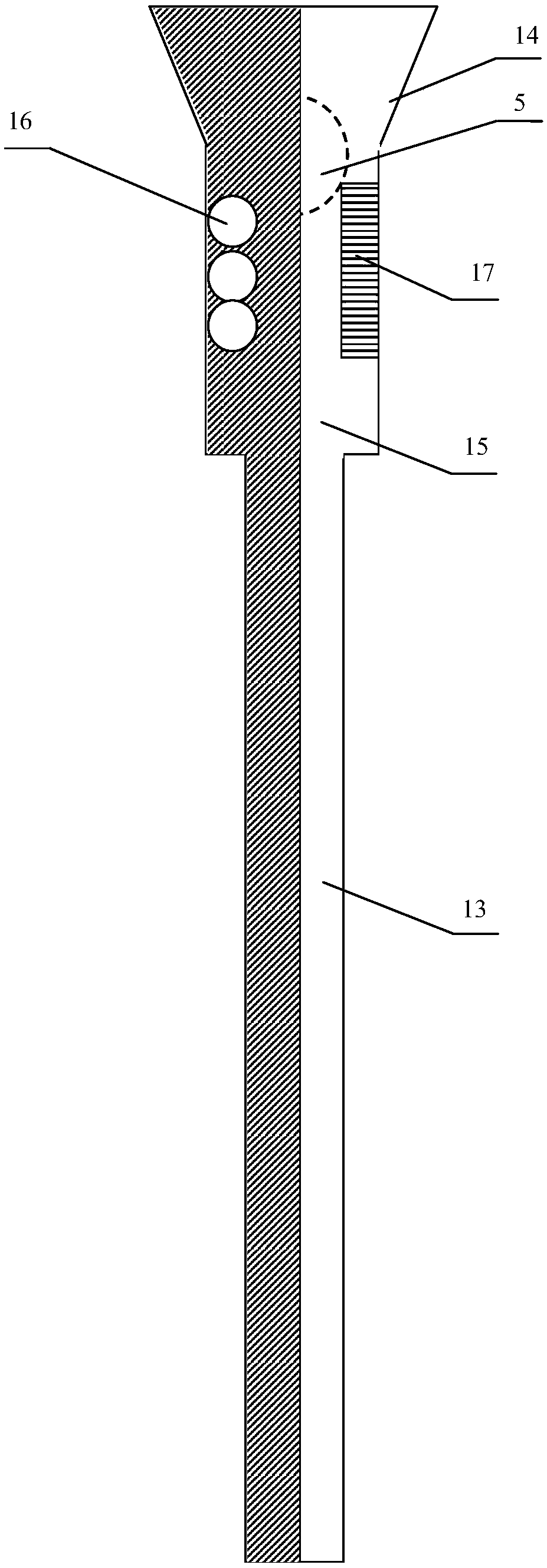

[0027] Such as Figure 1 to Figure 3 As shown, this embodiment discloses a segmented hydraulic shock fracturing string for large-span wells, including oil pipes and variable buttons for connecting the main body, and two or more oil pipes and variable buttons are connected in series from top to bottom. The number of hydraulic shock fracturing devices 3 is determined according to the number of operating sections, and each hydraulic shock fracturing device 3 corresponds to an operating section of a long-span well. Each hydraulic shock fracturing device includes components such as a draft tube 7 , a shock plate 8 , a shock chamber 9 , a plunger seat 10 , a tail pipe 11 , and a receiver 12 . The bottom of the lowermost hydraulic shock fracturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com