Bottom plate fixing piece of die spotting machine and thermal treatment technology of bottom plate fixing piece

A technology of fixing parts and mold opening machines, applied in heat treatment furnaces, heat treatment equipment, fixing devices, etc., can solve the problems of insufficient fatigue resistance and impact toughness, insufficient tensile strength, and inability to resist fatigue and impact fracture. , to achieve high fatigue resistance and impact toughness, resistance to fatigue and impact fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

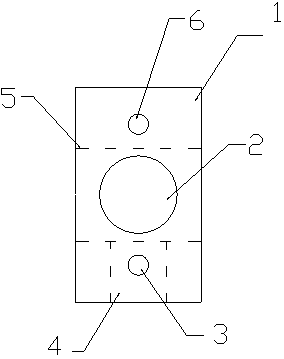

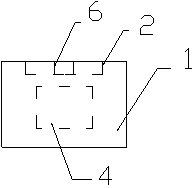

[0011] As shown in the figure, the present invention includes a body 1 and a heat treatment process. The body 1 is set as a cuboid structure, and a circular through hole is arranged in the middle, which is set as the first through hole 2. The first through hole 2 The upper and lower sides of the through hole 2 are respectively provided with a circular through hole, which are respectively the second through hole 6 and the third through hole 3, and a square groove is arranged in the middle of the body 1, which is set as the first concave Groove 5 has a square groove on its lower side, which is set as the second groove 4. The heat treatment process is characterized by immersing in a suitable quenching medium after heating to austenitization and cooling at a faster rate.

[0012] When selecting the quenching medium for the heat treatment process, sufficient cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com