Method for qualitatively evaluating crack arrest toughness of steel plate by utilizing impact fracture microhardness distribution

A technology of microhardness and impact fracture, which is applied in the direction of testing material strength, strength characteristics, and testing material hardness by using one-time impact force, which can solve the problems of different microstructure deformations, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited in any way.

[0021] A method for qualitatively evaluating the crack arrest toughness of a steel plate by utilizing the microhardness distribution of impact fracture, the evaluation method comprising the following steps:

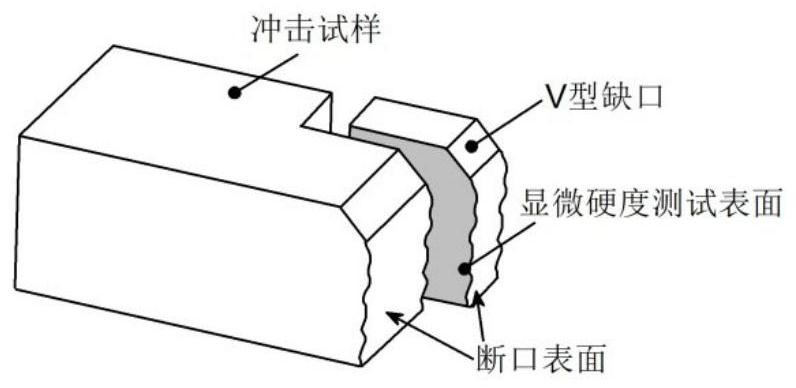

[0022] 1) The 1 / 2 position of the Kca steel plate with known and unknown crack arrest toughness is processed into a standard longitudinal impact specimen and subjected to a -60°C Charpy impact test. The impact fracture specimen is cut by wire cutting, and the cutting position is perpendicular to V At the 1 / 3 width of the mouth direction, the cutting depth is 10mm. The cutting surface is ground with different types of sandpaper and mechanically polished, and it is corroded with 4% nitric acid alcohol solution for 8 seconds before use.

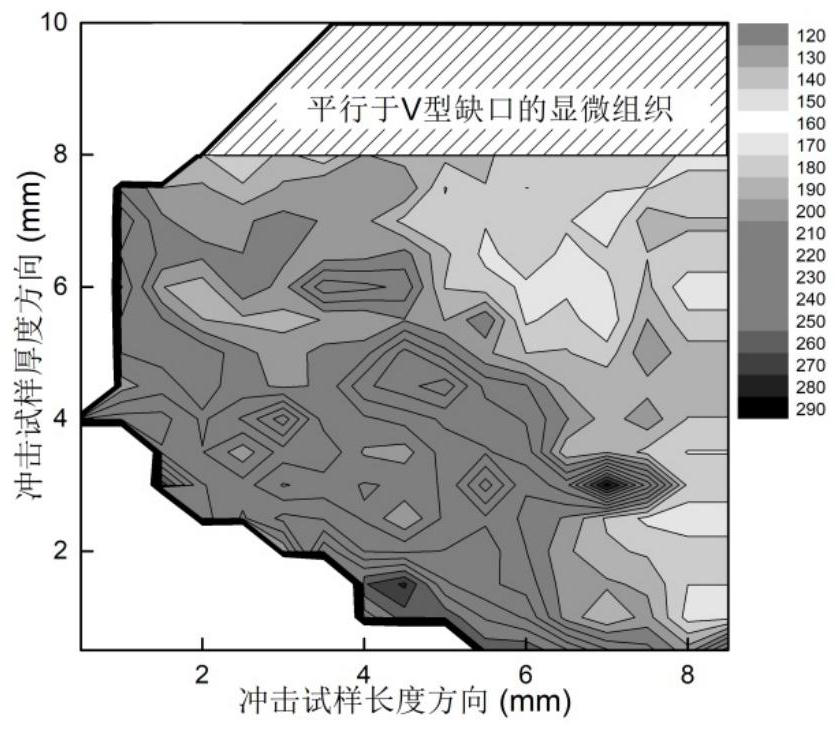

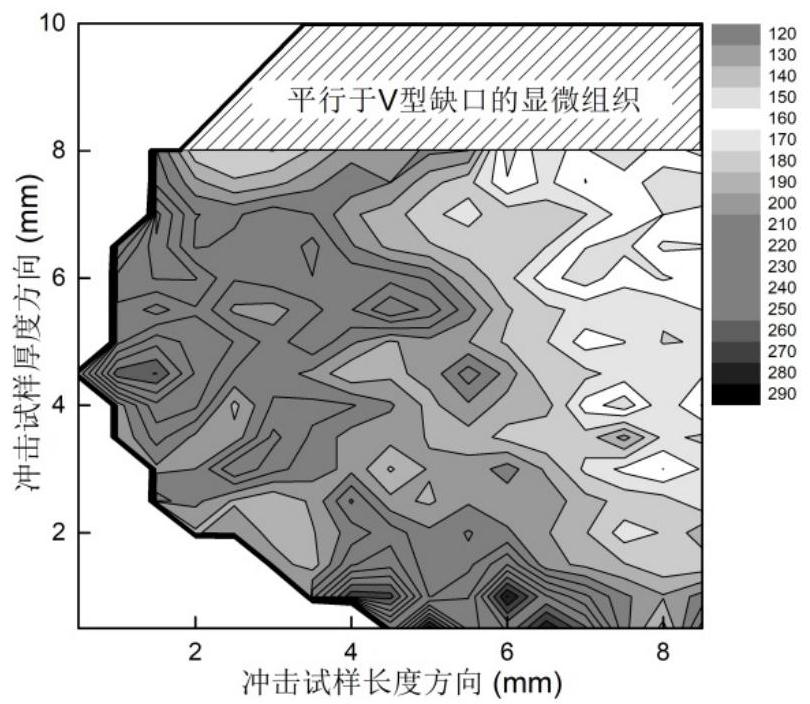

[0023] 2) Measure the microhardness at different positions on the corrosion surface w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com