Heat-resistant austenitic alloy, heat-resistant pressure-resistant member comprising the alloy, and process for producing the same

A heat-resistant alloy and austenitic technology, applied in the field of austenitic heat-resistant alloys, can solve the problems of higher material temperature than heating temperature, insufficient hot workability, broken defects, etc., and achieve good toughness and microstructure stability. Excellent, high temperature ductility excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

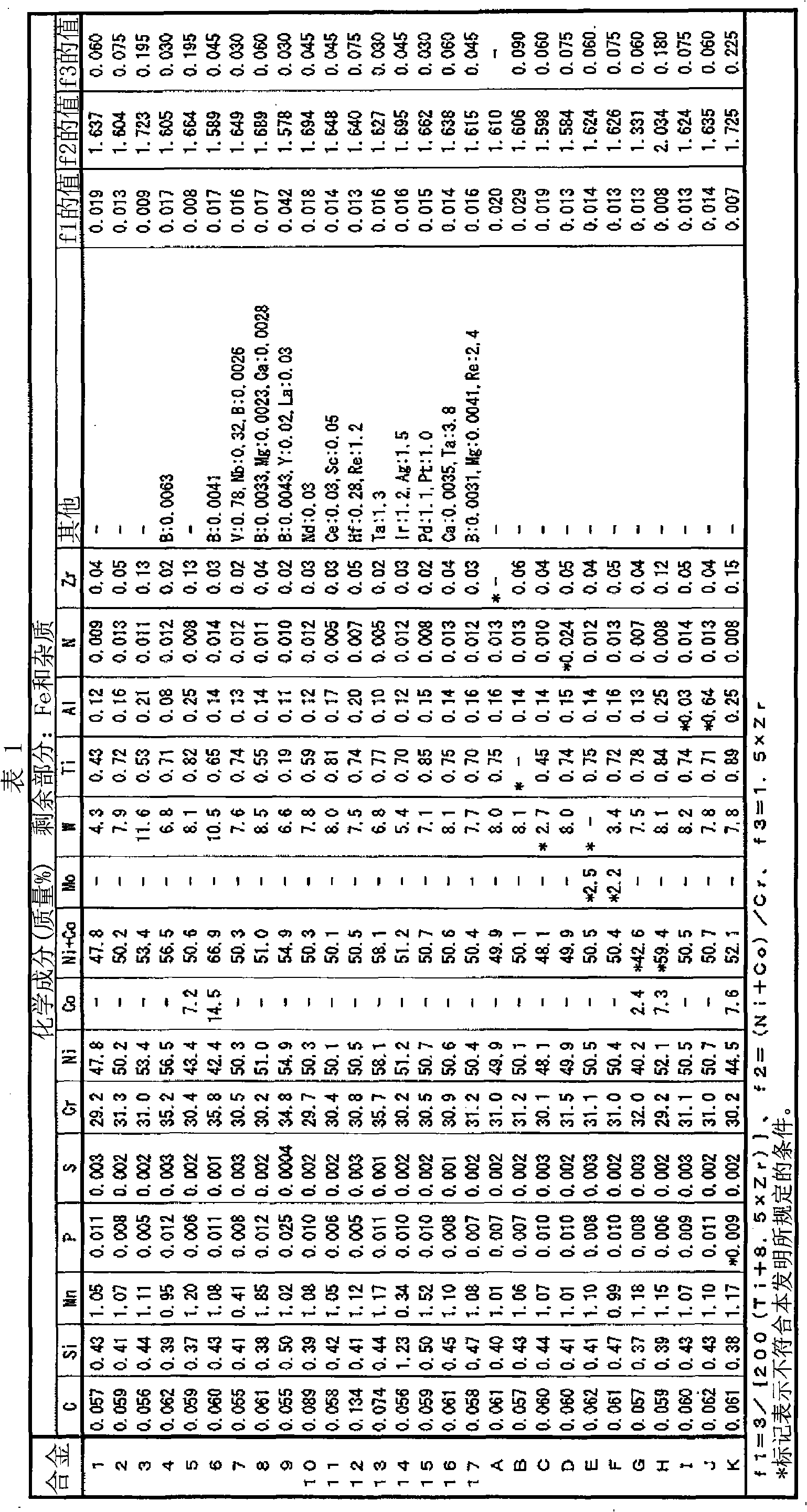

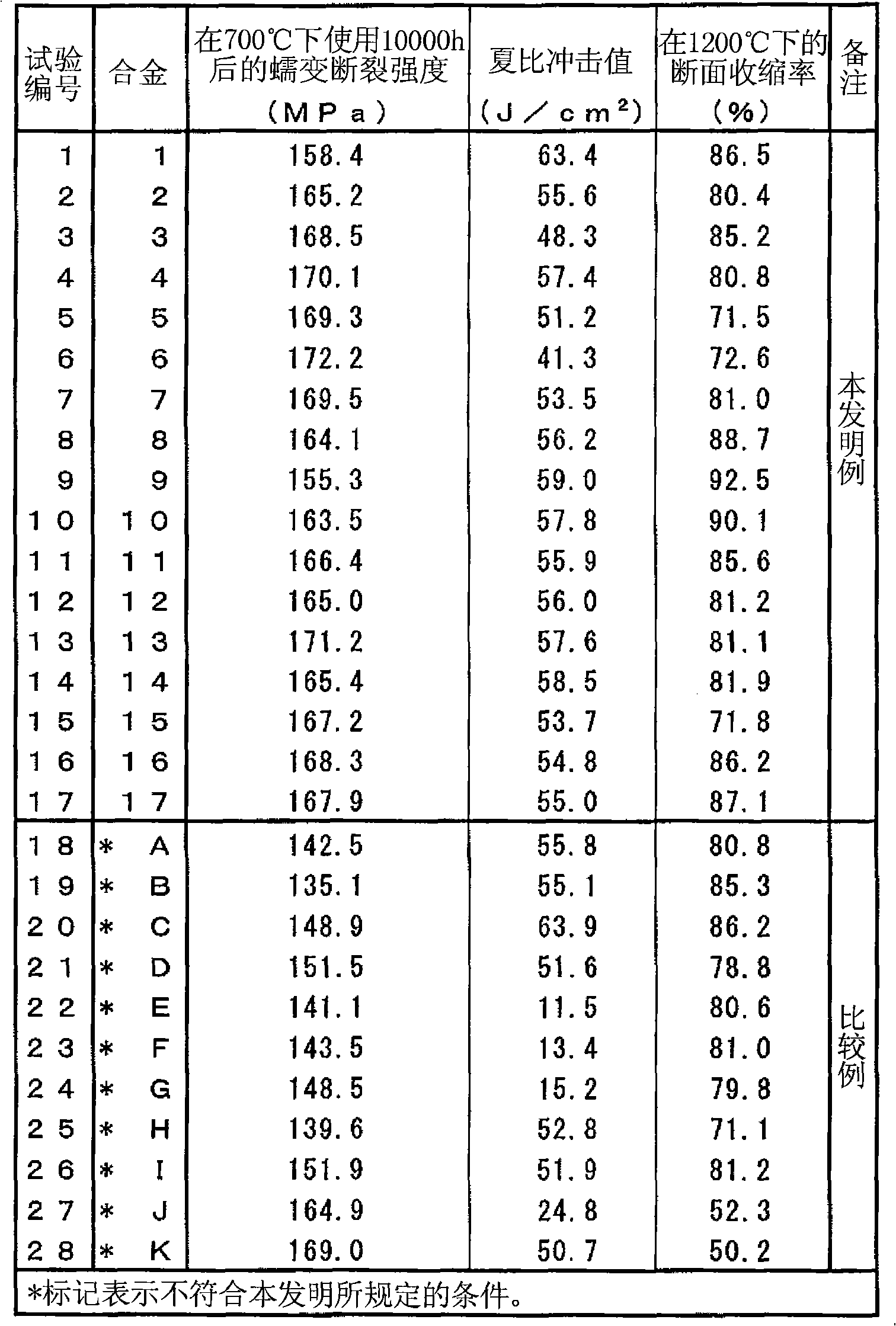

[0178] Austenitic alloys 1 to 17 and A to K having the chemical compositions shown in Table 1 were melted in a high-frequency vacuum furnace to produce a 17 kg steel ingot with an outer diameter of 100 mm.

[0179] Alloys 1 to 17 in Table 1 are alloys whose chemical components are within the range specified by the present invention. On the other hand, alloys A to K are alloys of comparative examples whose chemical components do not satisfy the conditions specified in the present invention. Among them, alloy G and alloy H are alloys in which the contents of Ni and Co are within the ranges specified in the present invention, but the value of "Ni+Co" does not satisfy the above formula (4). In addition, alloy I is an alloy whose Al content of 0.03% is within the range of "0.01% to 0.3%" stipulated in the present invention, but does not satisfy the above formula (3). In addition, alloy K is an alloy in which the P content of 0.009% is within the range of "0.03% or less" stipulated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com