Gamma''strengthened high performance casting nickel-based high-temperature alloy

A high-performance nickel-based superalloy technology, applied in the field of industrial technology-metal material science, can solve the problems of rapid decline in alloy strength and durable life, and achieve good structural stability and excellent tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The alloy of the present invention (No.1 alloy), the alloy composition is shown in Table 1.

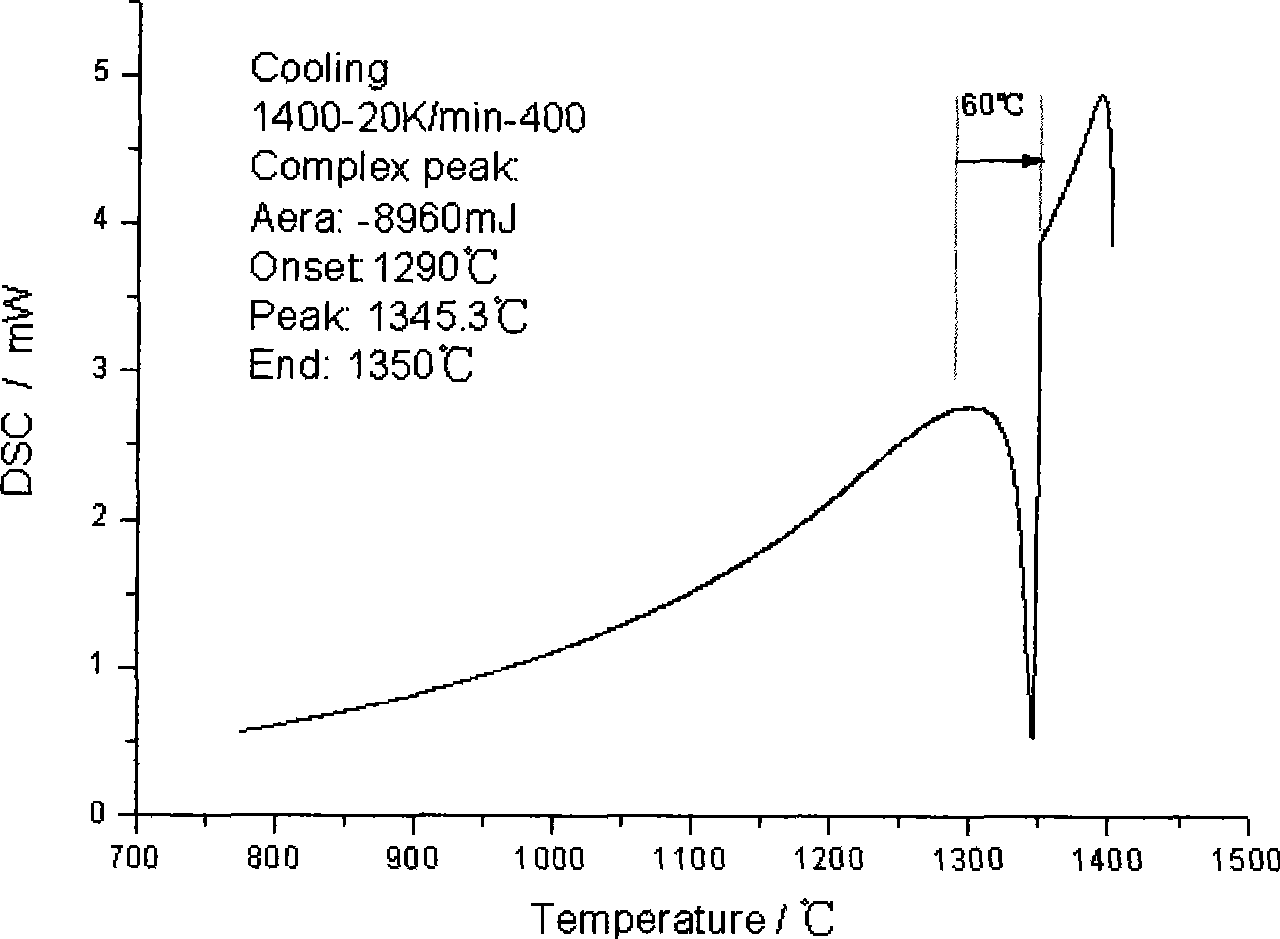

[0016] The smelting process adopted is: after the master alloy is melted and cleaned, it is refined at 1500°C for 10 minutes, cooled to 1400°C for pouring, and the shell temperature is 800°C. The heat treatment system adopted is: 1180°C, 4 hours, air cooling→775°C, 4 hours, furnace cooling to 700°C→700°C, 10 hours, air cooling.

[0017] Table 1 No.1 alloy composition, wt%

[0018] Cr co A1 Ti Nb Ta Mo C B Y Ni 18.0 12.0 0.5 1.0 4.0 3.0 3.0 0.015 0.020 0.05 Bal

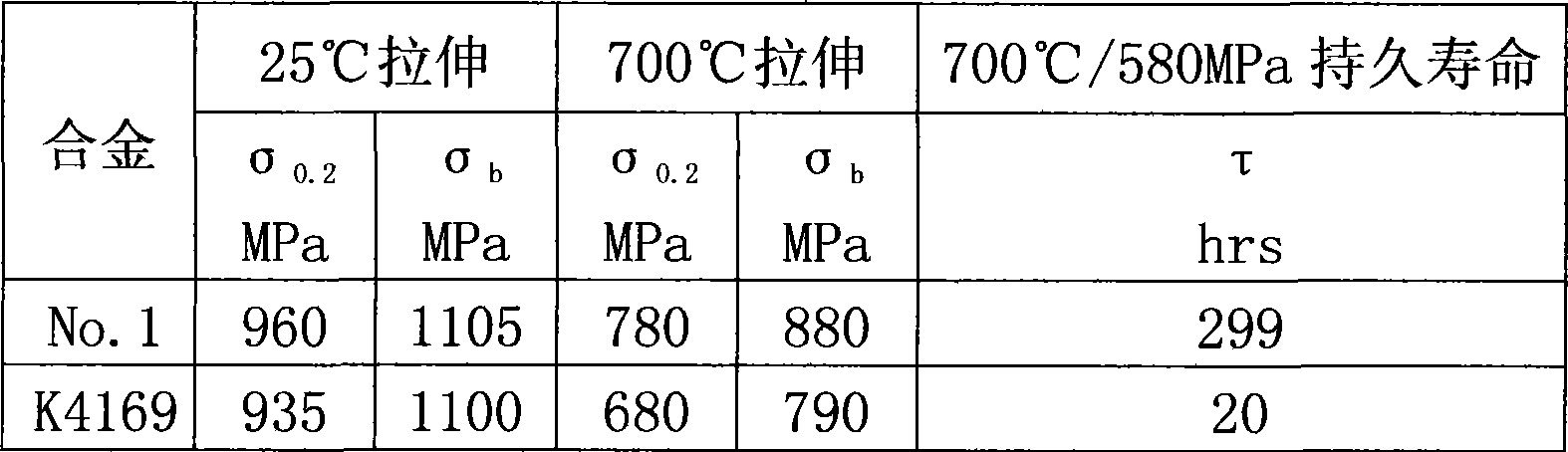

[0019] Table 2 Mechanical properties of No.1 alloy and its comparison with that of K4169

[0020]

[0021] The mechanical properties of No.1 alloy and its comparison with that of K4169 are shown in Table 2. It can be seen that the room temperature tensile yield strength and fracture strength of the invented No.1 alloy are not much improved compared with the K4169 alloy, ...

Embodiment 2

[0023] The No.2 alloy composition of the present invention is shown in Table 3, and the smelting and heat treatment process is the same as that of Example 1.

[0024] Table 3 No.2 alloy composition, wt%

[0025] Cr co A1 Ti Nb Ta Mo C B Y Ni 18.0 12.0 0.5 1.0 3.0 5.0 3.0 0.015 0.020 0.05 Bal

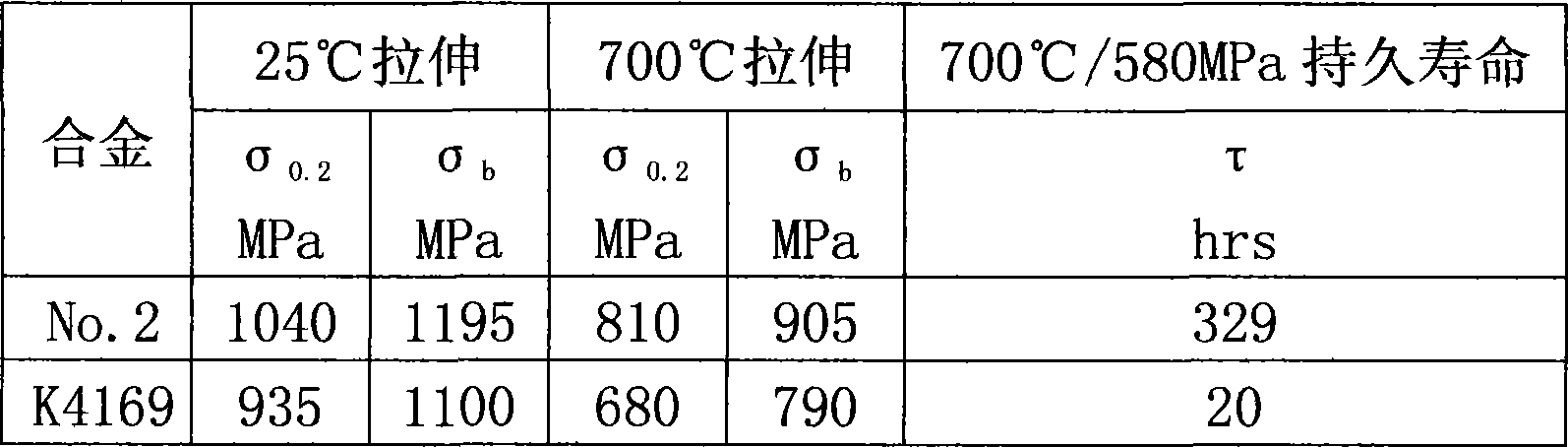

[0026] Table 4 shows the mechanical properties of No.2 alloy of the present invention and its comparison with that of K4169. It can be seen that the room temperature, 700°C tensile yield strength, fracture strength and 700°C / 580MPa durability life of No.2 alloy are significantly improved compared with K4169 alloy.

[0027] Table 4 Mechanical properties of No.2 alloy and its comparison with that of K4169

[0028]

Embodiment 3

[0030] The composition of No.3 alloy of the present invention is shown in Table 5, and the smelting and heat treatment process is the same as that of Example 1.

[0031] Table 5 No.3 alloy composition, wt%

[0032] Cr co Al Ti Nb Ta Mo W C B Y Ni

18.0

12.0

0.5

1.0

3.0

5.0

3.0 2.0 0.01

5 0.02

0 0.05 Bal

[0033] Table 6 shows the mechanical properties of No.3 alloy of the present invention and its comparison with that of K4169. It can be seen that the room temperature, 700°C tensile yield strength, fracture strength and 700°C / 580MPa durability life of No.3 alloy are significantly improved compared with K4169 alloy.

[0034] Table 6 Mechanical properties of No.3 alloy and its comparison with that of K4169

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com