Ni seamless steel pipe and manufacturing method thereof

A technology of seamless steel pipe and manufacturing method, applied in the direction of temperature control, metal rolling, etc., can solve the problems of small deformation, lack of rolling conditions, inability to control rolling and cooling of rolled plates, etc., and achieve high microstructure stability. sexual effect

Active Publication Date: 2008-12-24

BAOSHAN IRON & STEEL CO LTD

View PDF2 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It completely relies on the performance of the process equipment to ensure the low-temperature toughness of the central part of the steel plate. Baosteel’s existing steelmaking equipment does not have the production conditions for smelting low-P steel, and because there are not many trace elements in the steel, it is not suitable for the existing steel rolling equipment. It is difficult to control the fine grain and banded structure

Moreover, the method of controlled rolling and controlled cooling can be used to produce steel plates to ensure performance, while the last process of pipe making is stretching and reduction, and the deformation is smaller than that of rolled plates, which cannot reach the level of controlled rolling and controlled cooling of rolled plates

In other words, under Baosteel's existing equipment conditions, this component does not meet the conditions for rolling pipes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

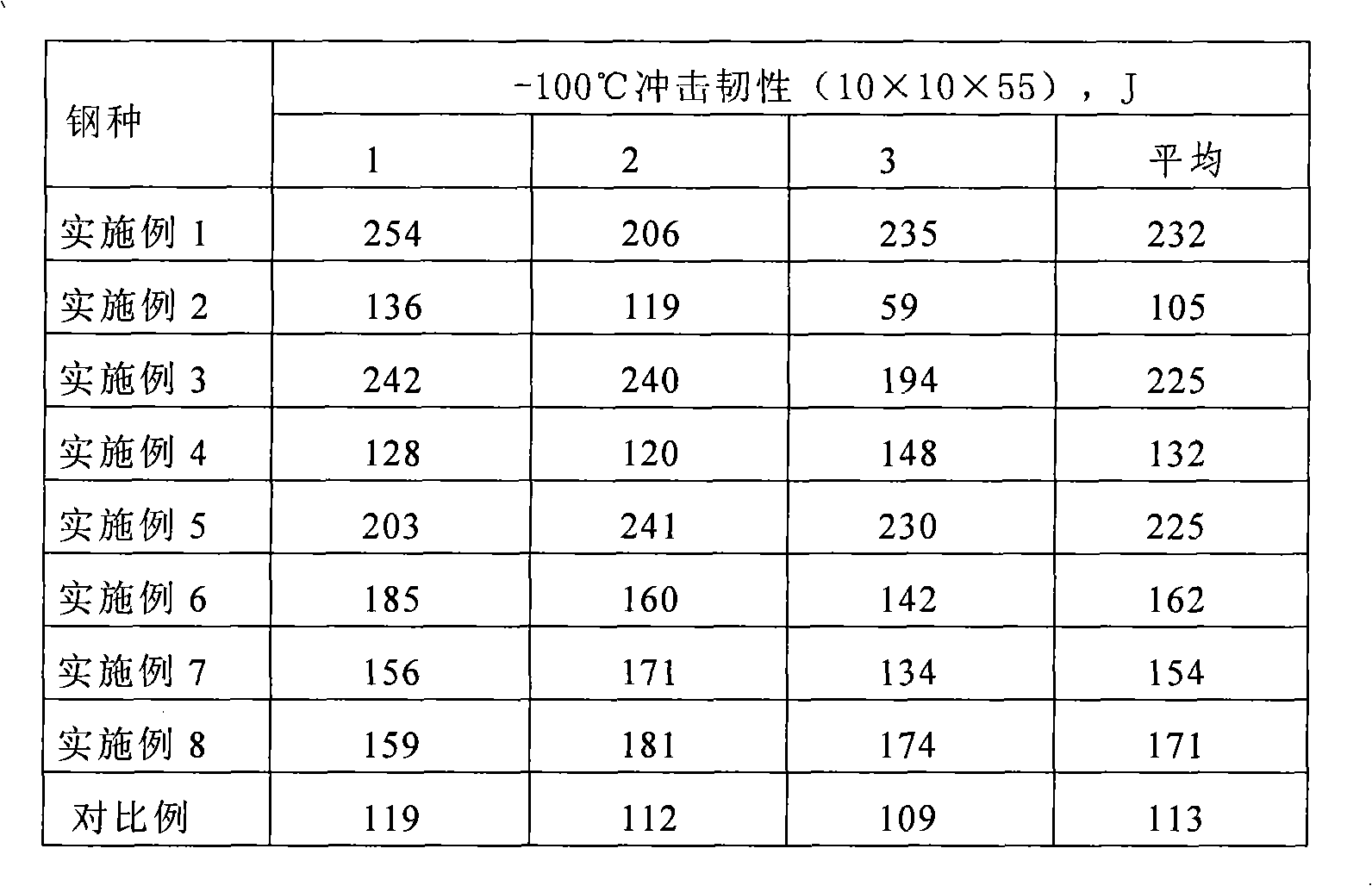

[0052] The characteristics and advantages of the steel grade of the present invention will be further described in detail below through examples and comparative examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a nickel-based seamless steel pipe which comprises the following compositions in percentage by weight: 0.05 to 0.15 percent of C, 0.20 to 0.35 percent of Si, 0.35 to 0.60 percent of Mn, 3.20 to 3.80 percent of Ni, 0.01 to 0.3 percent of Cu, 0.01 to 0.4 percent of Mo, 0.001 to 0.05 percent of Ti, 0.01 to 0.1 percent of V, 0.005 to 0.039 percent of Al, less than or equal to 0.015 percent of P, less than or equal to 0.008 percent of S, less than or equal to 0.01 percent of O, less than or equal to 0.004 percent of N, the balance being Fe and inevitable impurities; and the ratio of Ca to S is more than or less than 1. The method for manufacturing the nickel-based seamless steel pipe comprises the following steps that: a pipe blank produced by continuous casting or continuous rolling is heated at a temperature of between 1180 and 1280 DEG C, rolled and separated from a bar mold at a temperature of between 950 and 1050 DEG C, is sent to a reheating furnace, is kept at a temperature of between 850 and 1000 DEG C, is subjected to rolling, air cooling at a cooling speed of between 10 and 30 DED C / min, kept at a temperature of between 800 and 900 DEG C, tempered, kept at a temperature of between 600 and 700 DEG C and tempered, thereby manufacturing a finished pipe. The nickel-based seamless steel pipe can be used for impacting a pressure container with a toughness of more than or equal to 18 J under the conditions of having a low temperature of between 80 and 101 DEG below zero and containing methanol and other corrosion mediums.

Description

technical field [0001] The invention relates to the field of metal materials, in particular to a Ni-based seamless steel pipe and its manufacturing method, especially for pressure vessels with impact toughness ≥ 18J at a low temperature of -80°C to -101°C and containing corrosive media such as methanol. Ni-based seamless steel pipe and its manufacturing method. Background technique [0002] At present, the Ni-based seamless steel pipes required by domestic ethylene crackers under the operating conditions of -80~-101°C are difficult to purchase even if they are imported because they are used in a small amount in a cracker and have many specifications. However, domestic similar products have unstable low-temperature toughness, so stainless steel pipes such as TP304 are generally used instead. [0003] With the development of petrochemical ethylene cracking equipment in the direction of large-scale and high load, due to the low yield strength of TP304, it is necessary to incre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/16C22C38/50B21B1/46B21B37/74C21D8/10

Inventor 李敏姚雷武冬兴

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com