Austenite heat-resistance stainless steel resisting high temperature oxidation

A technology of heat-resistant stainless steel and high-temperature oxidation resistance, which is applied in the field of austenitic stainless steel, can solve the problems of unsatisfactory results, high price of 310S, weak high-temperature oxidation resistance, etc., and achieve high-temperature oxidation resistance and good tissue quality. Stable, cost-effective effect

Active Publication Date: 2014-04-23

BAOSTEEL DESHENG STAINLESS STEEL

View PDF12 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

1. 4828 and 309S are relatively weak in high temperature oxidation resistance, and have not achieved satisfactory results when used. 310S is expensive, which greatly increases production costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

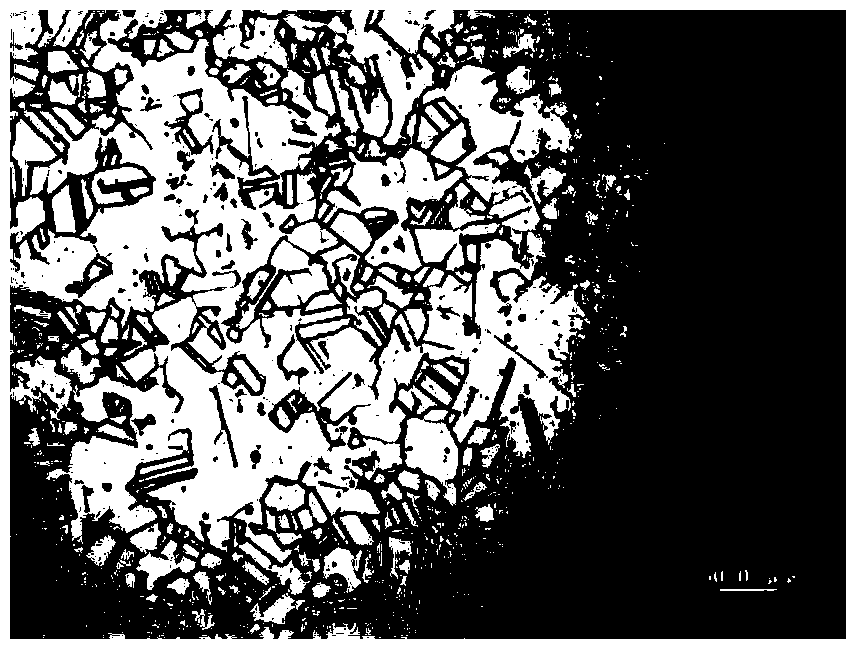

[0039] The final metallographic structure of embodiment 1 is as figure 1 As shown, the structure is mainly austenite and a small amount of metal oxides.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

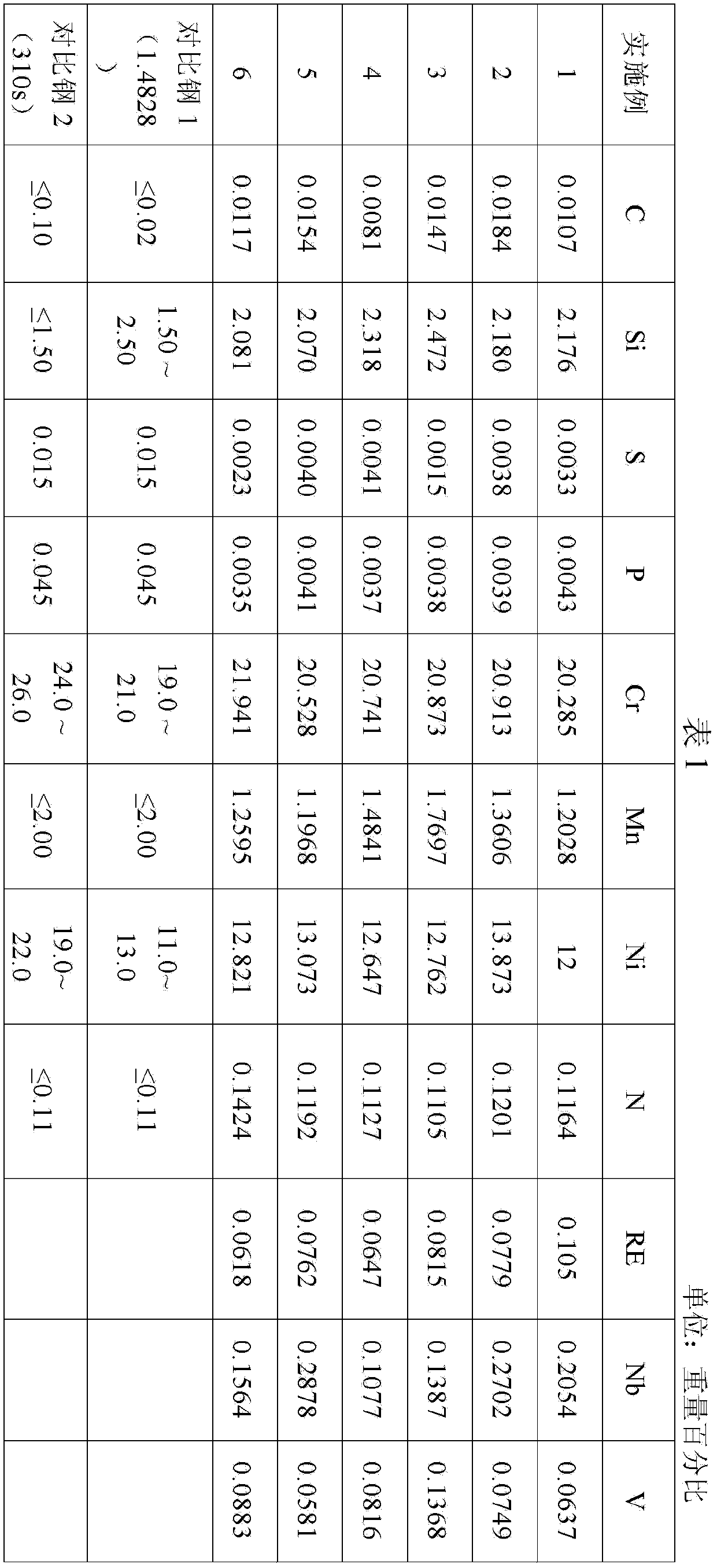

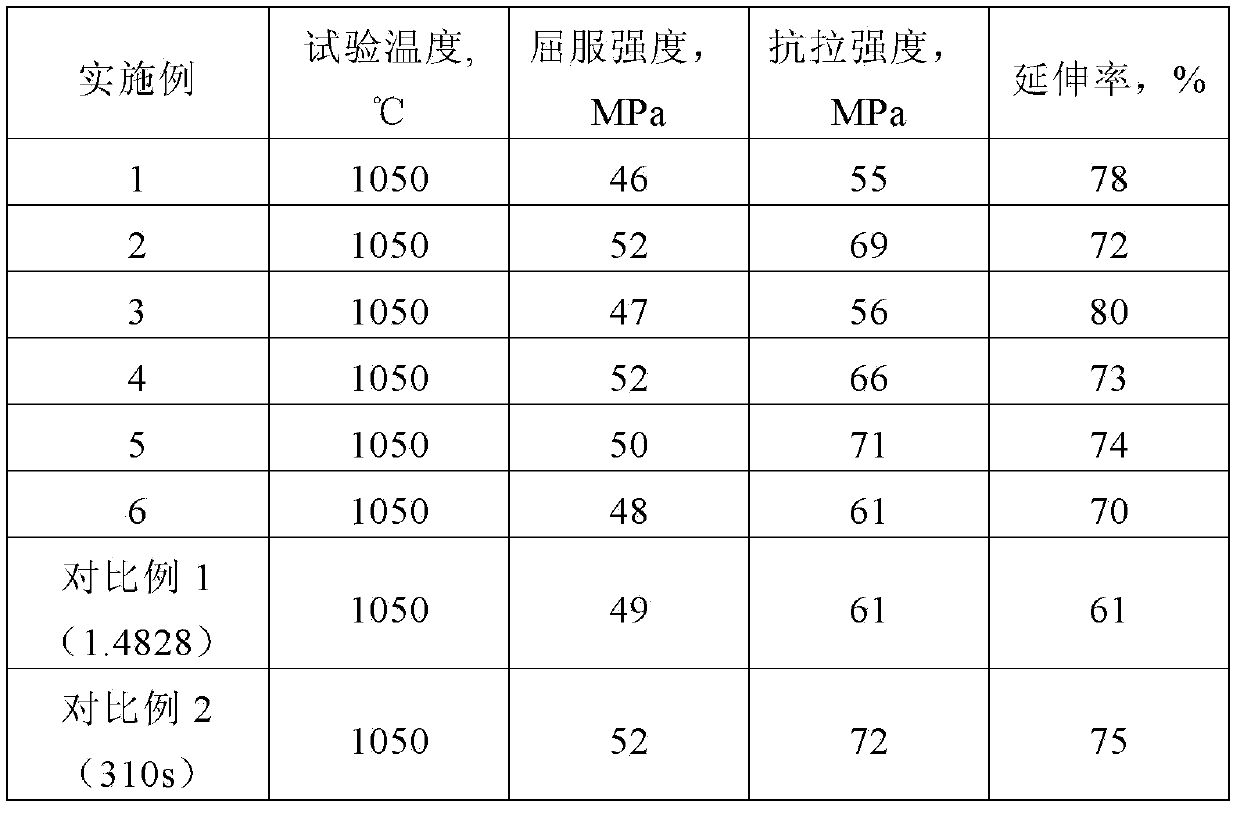

The invention discloses an austenite heat-resistance stainless steel resisting high temperature oxidation. The austenite heat-resistance stainless steel comprises the chemical components in percentage by weight: below 0.02 percent of C, 2.0-2.5 percent of Si, 1-2 percent of Mn, 20-22 percent of Cr, 12-14 percent of Ni, 0.11-0.15 percent of N, less than 0.035 percent of P, less than 0.005 percent of S, 0.06-0.11 percent of Ce+La+Y, 0.05-0.15 percent of V, 0.1-0.3 percent of Nb and the balance of Fe and inevitable impurities, wherein (Cr+1.5Si+0.5Nb) / (Ni+0.5Mn+20N) is not less than 1.4 and not more than 1.6, and (Nb+V) is not less than 1.5(C+N) and is not more than 0.35 percent. The austenite heat-resistance stainless steel disclosed by the invention has good high temperature strength, oxidation resistance and formation property, and meets the requirements of continuous rise of use temperature of an automobile exhaust system and environment protection; the use temperature of the austenite heat-resistance stainless steel can reach 1050 DEG C; the requirements on the continuously raised use temperature of an automobile exhaust air system is continuously raised and environment protection are met.

Description

technical field [0001] The invention relates to an austenitic stainless steel, in particular to an austenitic heat-resistant stainless steel resistant to high-temperature oxidation, which is suitable for making high-temperature end parts of an automobile exhaust system. Background technique [0002] Heat-resistant stainless steel is closely related to the progress of energy and power machinery, and can be used in thermal power generation, atomic energy, aerospace, aviation, petroleum and chemical industries and other fields. Recently, heat-resistant stainless steel has been gradually applied to automobile emission system engineering. Reducing automobile exhaust emissions is a huge challenge faced by all mankind. With the adjustment of automobile exhaust emission regulations, the performance of automobile engines has improved, and the exhaust gas temperature has become higher and higher. The exhaust temperature has increased from the current 900-950°C to 1000 ~ 1050 ℃, which...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/58C22C38/48

Inventor 张志霞毕洪运李鑫翟瑞银刘春粟常锷

Owner BAOSTEEL DESHENG STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com