Method for treating wastewater from dairy processing

A technology for processing wastewater and treatment methods, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. To biomass requirements and other issues, to achieve the effect of solving insufficient hydrolysis and acidification, solving subsequent treatment problems, and low effluent COD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

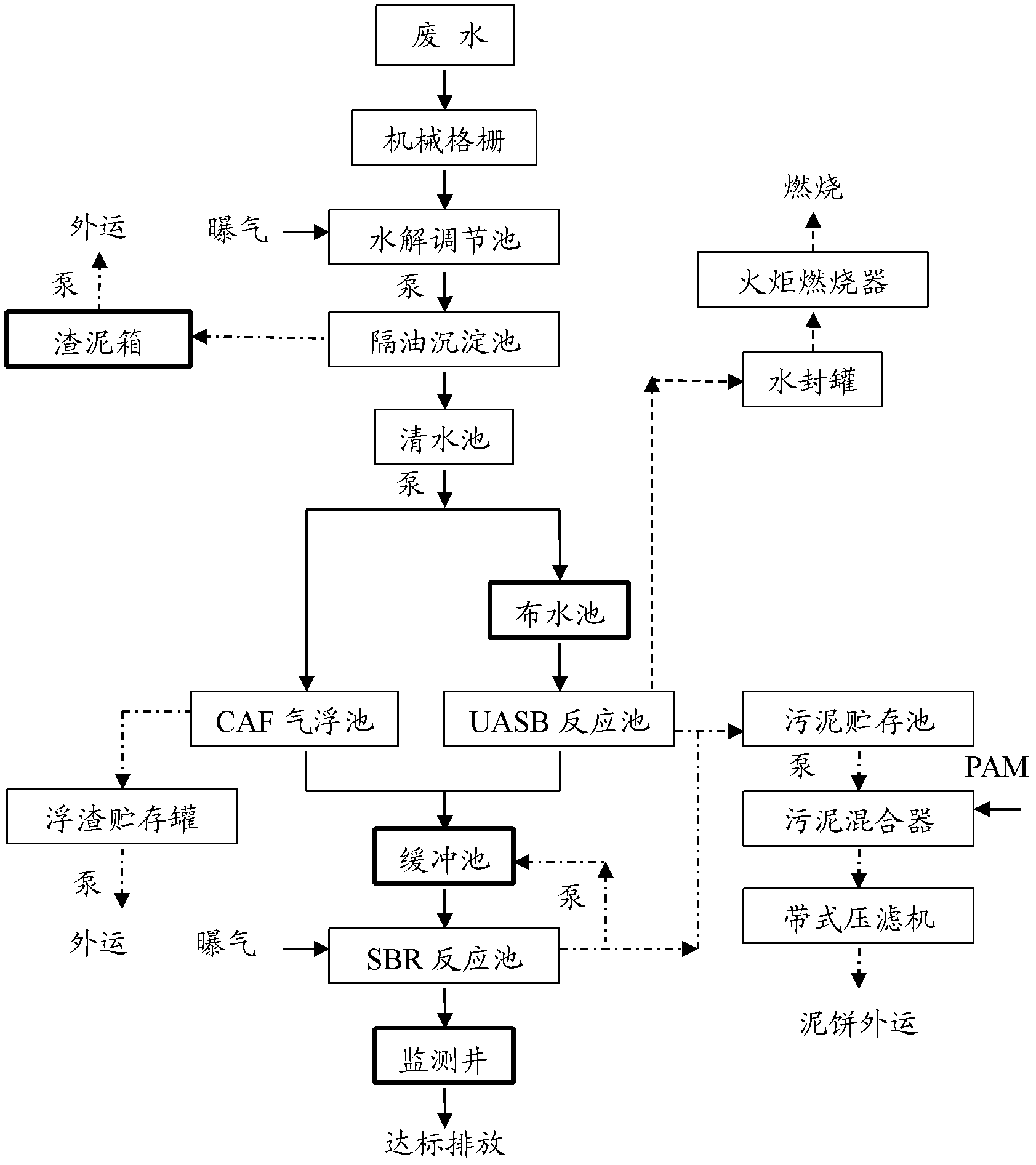

[0034] Example 1 Treatment of dairy processing wastewater

[0035] Treat 4,500 tons of dairy processing wastewater, of which the dairy processing wastewater mainly comes from high-concentration production wastewater produced by the processing and cleaning of containers, pipes, and equipment in production units such as liquid milk, cold drinks, milk powder, and raw milk, as well as production workshops Compared with the lower concentration of production wastewater and some domestic wastewater produced by site cleaning.

[0036] Use the treatment method of dairy processing waste water of the present invention, comprise the following steps:

[0037] 1) Discharge the waste water into the hydrolysis regulating tank through the mechanical grid for hydrolysis and acidification, and at the same time, reflow the aerobic activated sludge with 0.27%-0.8% of the pool capacity at the water inlet and stir it, and stir it twice a day for 10 minutes each time;

[0038] The hydrolysis regulat...

Embodiment 2

[0051] Taking the treatment of dairy processing wastewater in Jinchuan Wastewater Treatment Plant of Yili Group as an example, the implementation and effects of the present invention are introduced.

[0052] (1) Introduction of Jinchuan Wastewater Treatment Plant

[0053] Yili Group's Jinchuan Wastewater Treatment Plant is currently a relatively large-scale wastewater treatment plant in the domestic food industry. It adopts the more advanced "UASB+SBR" process and is designed to treat 10,000 tons of wastewater per day. The treated wastewater has reached the national wastewater comprehensive discharge level 1 standard. In recent years, the daily wastewater treatment volume of the wastewater treatment plant has reached an average of 5,500 tons, and the peak time is more than 10,000 tons. The average influent COD is 3,500 mg / L, and the peak time is 5,000 mg / L.

[0054] (2) The use of the improved UASB+SBR method to treat wastewater and existing problems

[0055] 1. In terms of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com