Method for preparing high-purity calcium nitrate by desulfurization and denitrification byproducts

A technology for desulfurization, denitrification, and by-products, applied in the direction of calcium/strontium/barium nitrate, etc., can solve the problem of low utilization rate of desulfurization and denitrification by-products, and achieve the effect of solving subsequent processing problems and safe and reliable process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

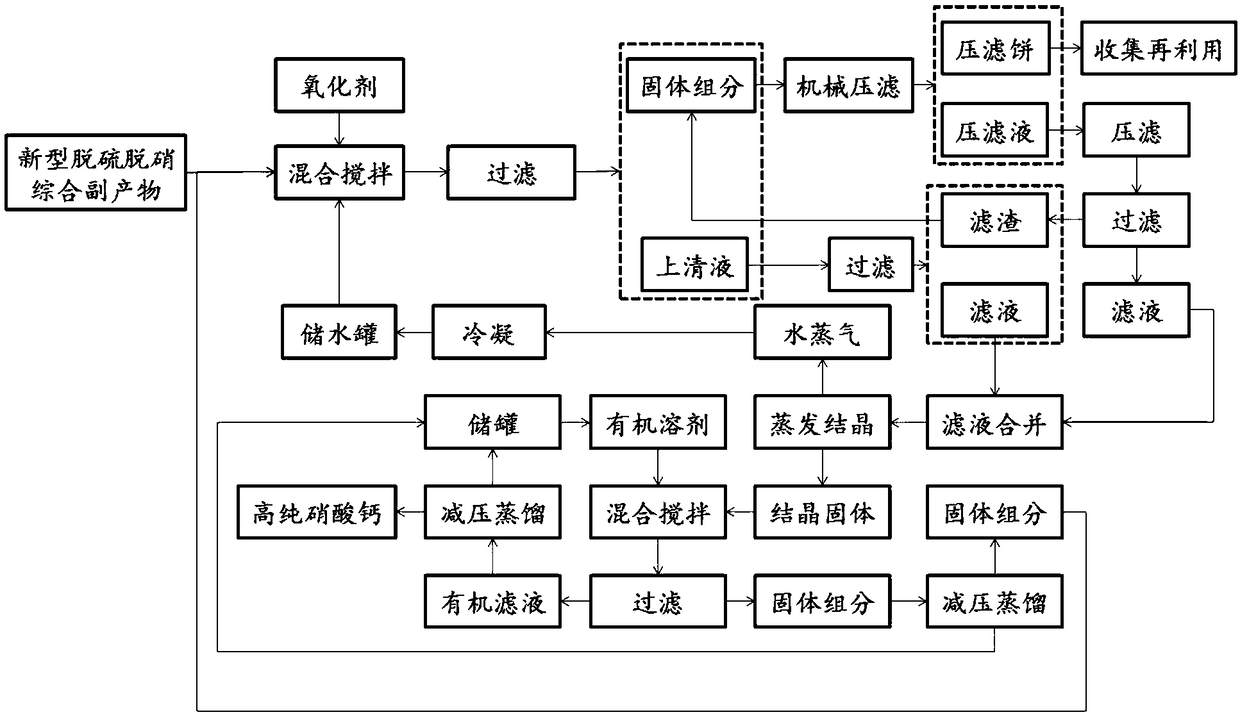

Image

Examples

Embodiment 1

[0028] The present embodiment provides a kind of method that prepares high-purity calcium nitrate with desulfurization and denitrification by-product, and it comprises the following steps:

[0029] Step S1, premixing the desulfurization and denitrification by-products and water according to a certain ratio to obtain a premixed solution; stirring the premixed solution, adding a certain amount of oxidant during the stirring process; after stirring, standing still for a certain period of time to obtain a mixed solution; Filtrating the mixed solution for solid-liquid separation to produce a first filtrate and a first solid component; filtering the first filtrate to produce a first residue and a second filtrate; combining the first residue with the first solid component, and the second Filtrate enters step S2;

[0030] Perform mechanical pressure filtration on the first solid component, collect and reuse the pressure filter cake, and then filter the press filtrate obtained after pr...

Embodiment 2

[0057] This embodiment provides a method for preparing high-purity calcium nitrate with desulfurization and denitrification by-products, which includes:

[0058] Water and desulfurization and denitrification by-products are premixed at a mass ratio of 1:1, the temperature of the premixed solution is 40°C, and the pH value of the premixed solution is not adjusted. The oxidant used is ozone gas, the ozone concentration is 10%, and the mass ratio of desulfurization and denitrification by-products to pure ozone is 100, and the ozone concentration is converted to ozone volume. Stir for 45 minutes at a stirring speed of 200 r / min. During the stirring process, ozone is continuously injected in proportion by air blast.

[0059] After the mixing and stirring, solid-liquid separation is performed; a first filtrate and a first solid component are produced; the first filtrate is filtered to produce a first residue and a second filtrate; the first residue is combined with the first solid c...

Embodiment 3

[0064] This embodiment provides a method for preparing high-purity calcium nitrate with desulfurization and denitrification by-products, which includes:

[0065] Water and desulfurization and denitrification by-products are premixed at a mass ratio of 2:1, the temperature of the premixed solution is 60°C, and the pH of the mixed solution is adjusted to 3 with nitric acid solution. The oxidizing agent used is hydrogen peroxide, the concentration of hydrogen peroxide is 25%, and the mass ratio of desulfurization and denitrification by-products to hydrogen peroxide is 150 for mixing. Stir for 40 minutes at a stirring speed of 250 r / min, and add hydrogen peroxide to the premixed solution at one time.

[0066] After the mixing and stirring, solid-liquid separation is performed; a first filtrate and a first solid component are produced; the first filtrate is filtered to produce a first residue and a second filtrate; the first residue is combined with the first solid component.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com