Fuel oil, gas energy-saving fine purification method and device

A technology for purifying treatment and gas, applied in combustion air/combustion-air treatment, charging system, combustion engine, etc., can solve the problem that the electromagnetic field frequency and output power of the treatment device are not determined, the molecular shape change cannot achieve the desired effect, and the electromagnetic Problems such as the limitation of the effect of the fuel-saving exhaust gas purification device to achieve the effect of improving the degree of refinement, improving the combustion value and saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

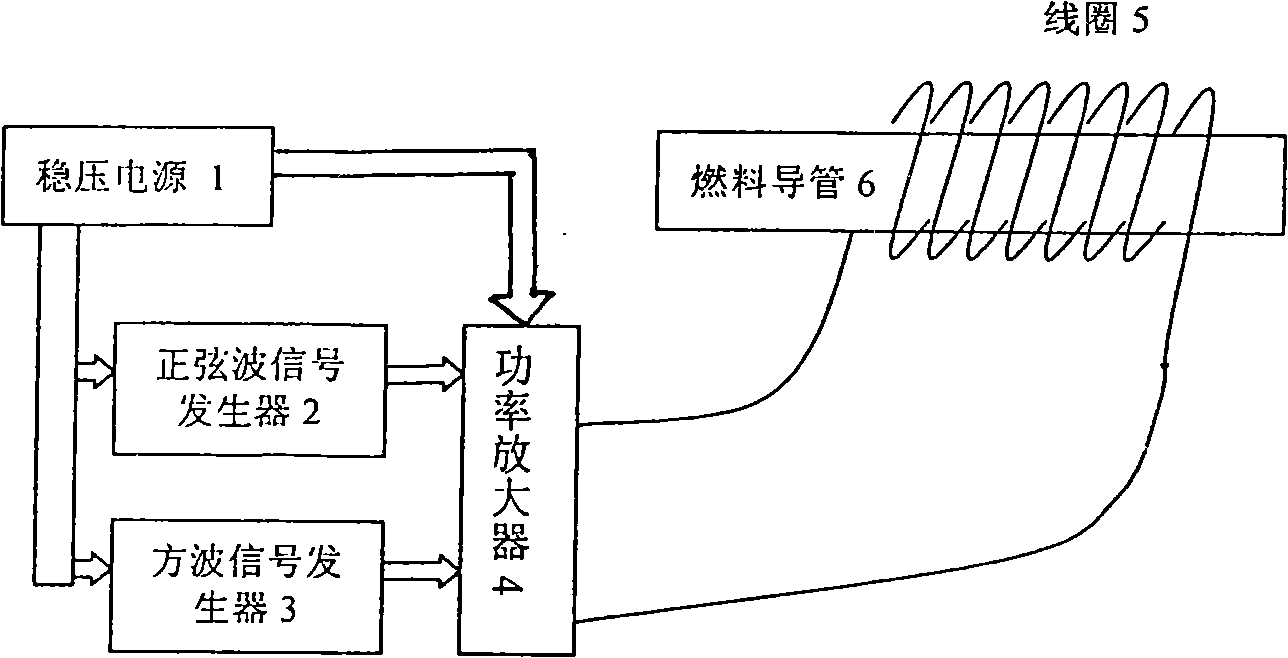

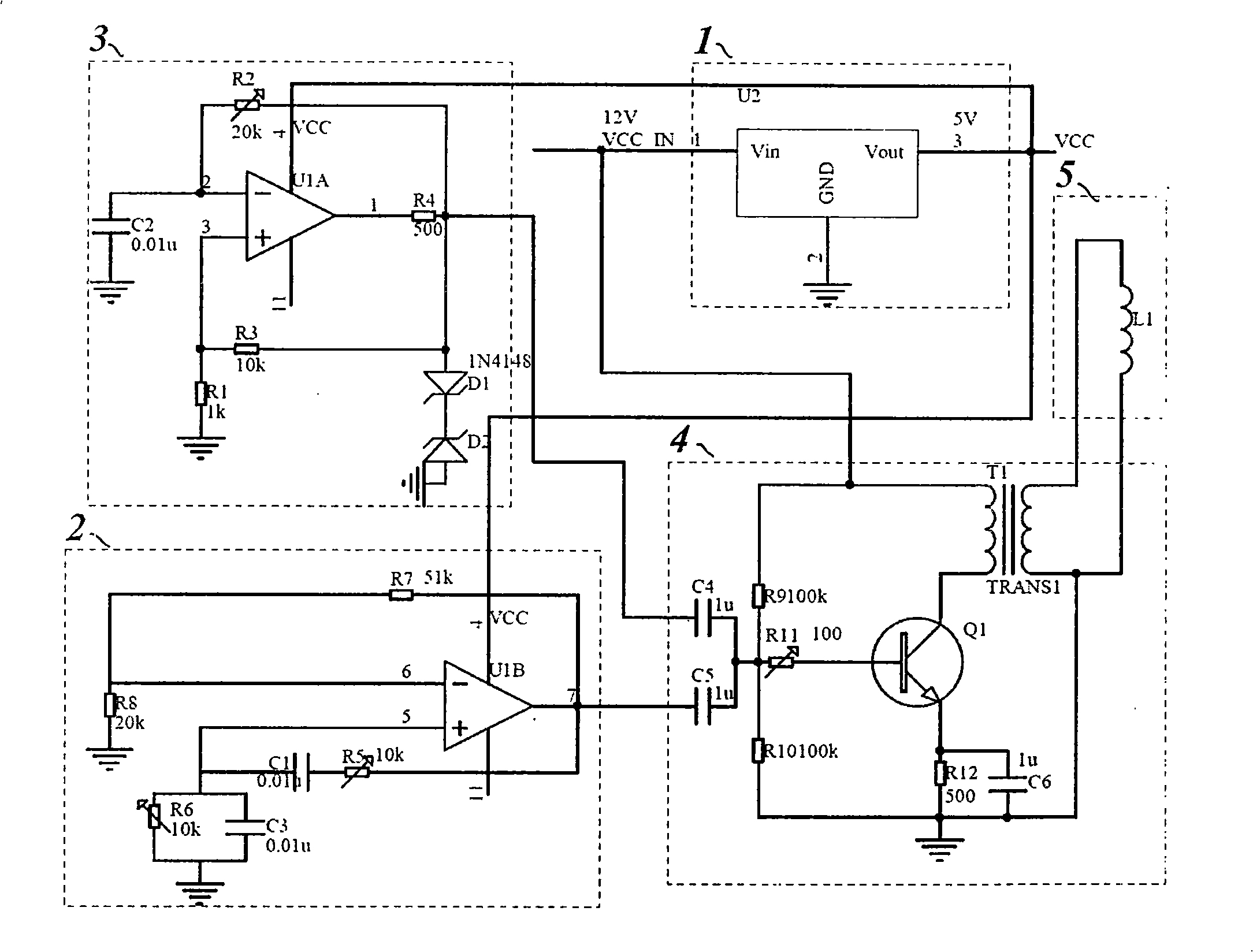

[0027] The voltage stabilizing circuit 1 is composed of a three-terminal voltage stabilizing chip U2, which converts the 12V DC power supply of the vehicle battery into a stable 5V DC power supply for the sine wave signal generator 2 and the square wave signal generator 3, and its input terminal is connected to the 12V vehicle battery DC power supply, the output terminals of which are connected to the power supply pins of operational amplifiers U1A and U1B.

[0028]The sine wave signal generator 2 is composed of resistors R5 R6 R7 R8, capacitors C1 and C3, and an operational amplifier U1B. C1 and R5 are connected in series and C3 and R6 are connected in parallel to form a positive feedback loop. R7 and R8 form a negative feedback loop. The non-phase of the operational amplifier U1B The input terminal is connected to capacitor C1 C3 and resistor R6, the other terminal of resistor R5 R7 is connected to the output terminal of operational amplifier U1B, the inverting input terminal...

Embodiment 2

[0046] Embodiment 2 of the present invention is a gas-saving device for household natural gas stoves, and the gas oil flow rate V is 1 (g / s). Natural gas is methane (C 1 h 4 ) as the main mixture.

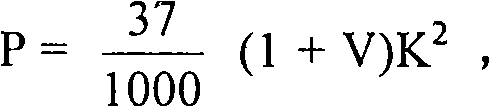

[0047] Methane (C 1 h 4 ) The relative atomic weight M of the molecule takes an integer approximation: 1×12+4×1=16

[0048] Methane (C 1 h 4 ) The bonding bond between the molecules is "C-C". Check Appendix 1 (Van der Waals force constant value table of the bonding bond between commonly used molecules) to know that the "C-C" bond van der Waals force constant is 4.5-5.6. Generally speaking, as the number of C atoms increases and the molecular weight increases, the greater the van der Waals force, the tighter the molecule; conversely, as the number of C atoms decreases and the molecular weight decreases, the van der Waals force becomes smaller. Methane (C 1 h 4 ) molecule contains only one C atom, so the smaller value K=4.7 of van der Waals force constant can be selected.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com