Feed grain crop breaking and refining device for livestock breeding

A feed and grain technology, which is applied to the field of grain feed crushing and refining devices for animal husbandry, can solve the problems of decreased operation crushing efficiency, inability to separate grains and insufficiently crushed grains in time, and insufficient and thorough crushing effects, and achieves grinding. Efficient and efficient, promote refinement, and improve the effect of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

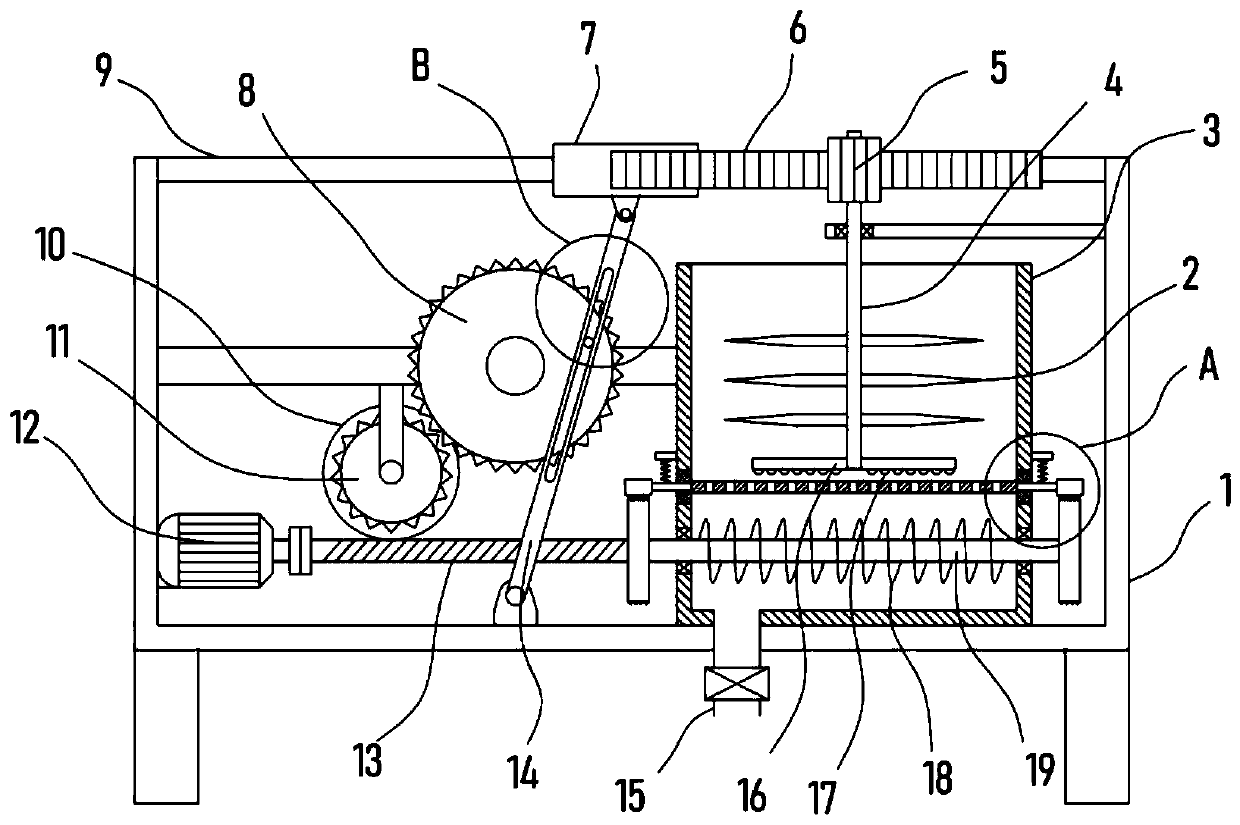

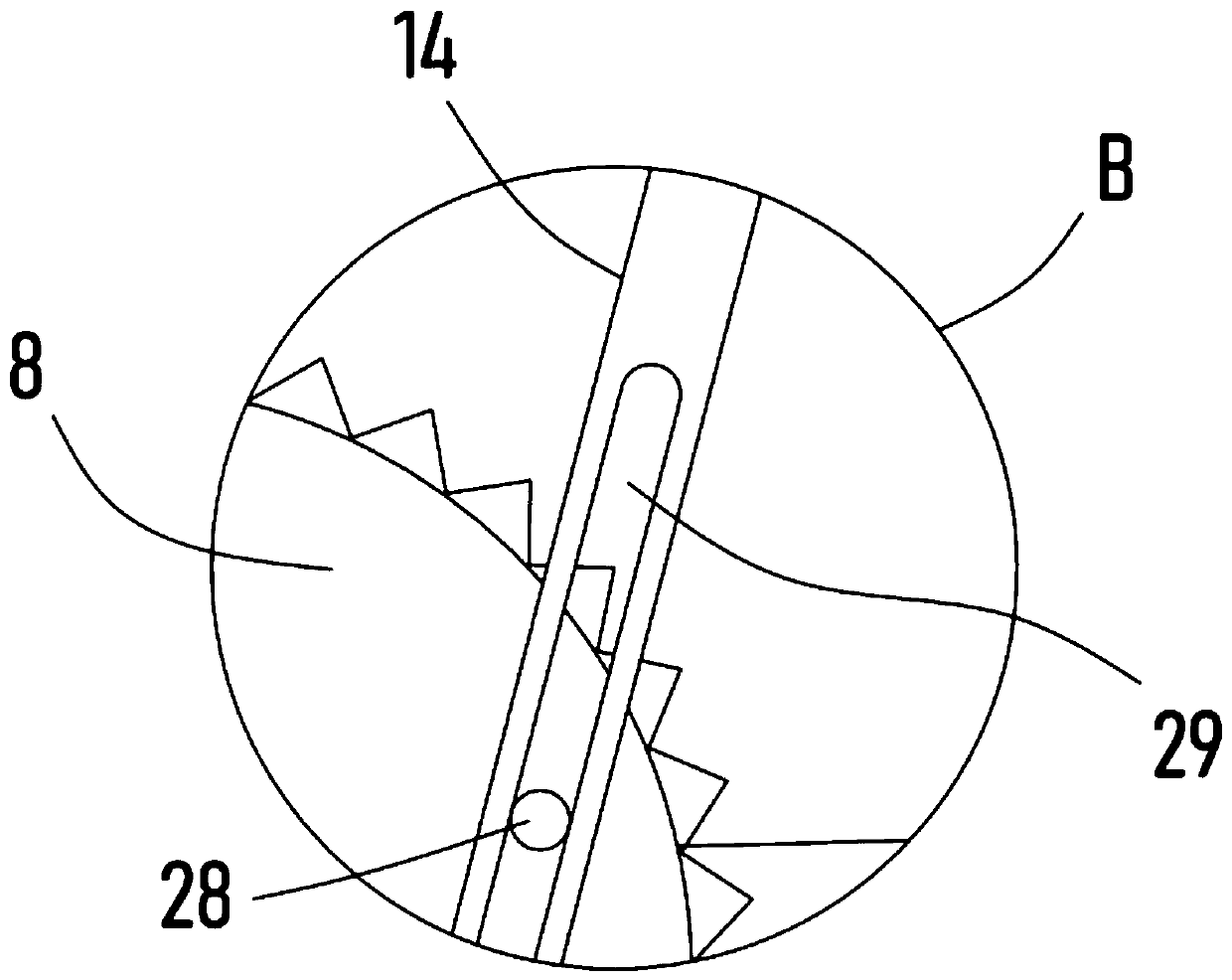

[0022] see Figure 1-4 , a grain feed crushing and refining device for animal husbandry, comprising a support frame 1, a crushing tank 3 is fixedly installed in the support frame 1, and the crushing tank 3 is an open structure for loading grain feed to be crushed. A guide rod 9 is installed horizontally on the top of the support frame 1, and a sleeve 7 is installed slidingly on the guide rod 9. A spur rack 6 is fixedly installed horizontally on the sleeve 7, and a cylindrical spur gear 5 is meshed and connected to the spur rack 6. The bushing 7 can slide laterally along the guide rod 9 , so that the bushing 7 drives the spur rack 6 to move laterally, thereby realizing the rotation of the cylindrical spur gear 5 .

[0023] The cylindrical spur gear 5 is coaxially fixed with a crushing shaft 4 extending into the crushing tank 3, and several cutting blades 2 are fixedly installed on the surface of the crushing shaft 4 at equal intervals. The bottom of the shaft 4 is horizontally...

Embodiment 2

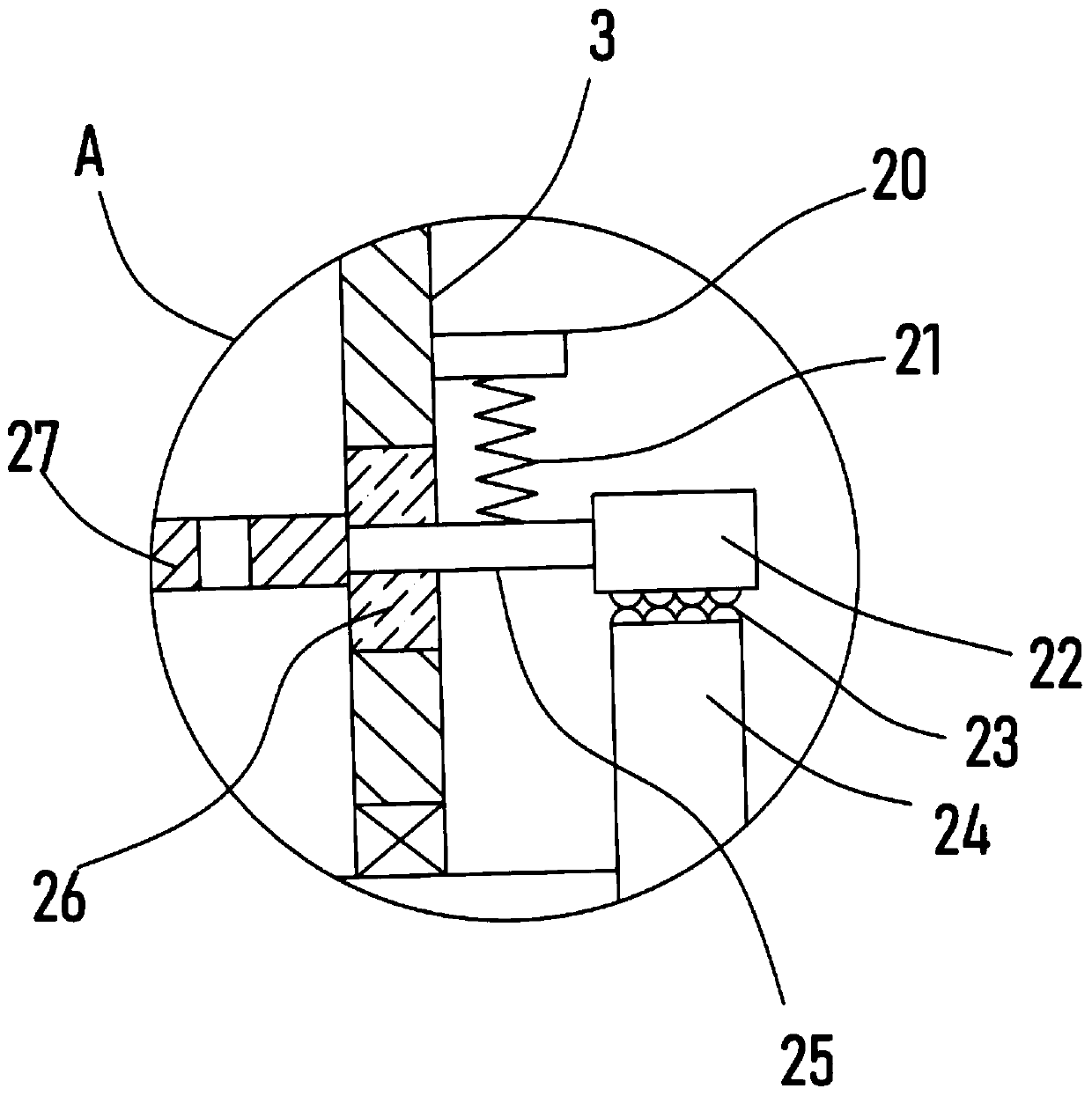

[0029] On the basis of Embodiment 1, in addition, the connection between the extension rod 25 and the crushing tank 3 is sleeved with an elastic cotton pad 26 that is sealed. The set elastic cotton pad 26 realizes deformation during the up-and-down vibration of the extension rod 25, and at the same time realizes the sealing of the connection between the crushing groove 3 and the extension rod 25, so as to avoid the overflow of grain feed.

[0030] Further, the surface of the rotating shaft 19 is fixedly equipped with a helical blade 18, and the helical blade 18 can rotate along with the rotating shaft 19. On the one hand, it can promote the dispersion of the grain feed at the bottom of the crushing tank 3, improve fluidity, and on the other hand, it is convenient for the grain to feed. The lateral movement of the feed is convenient to discharge through the discharge pipe 15, so as to realize the collection of broken grain feed.

[0031] Further, the drive motor 12 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com