Beneficiation process for refractory micro-fine particle-graded iron-copper ore

A fine-grained, copper ore technology, applied in the field of mineral processing, can solve the problems of poor selectivity, difficulty in comprehensive recovery, and ineffective development, etc., and achieve good economic benefits and eliminate hidden dangers of environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

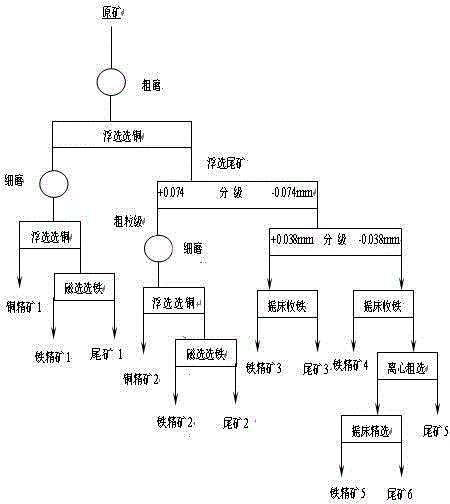

Image

Examples

Embodiment 1

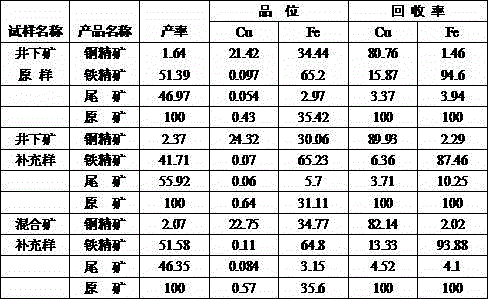

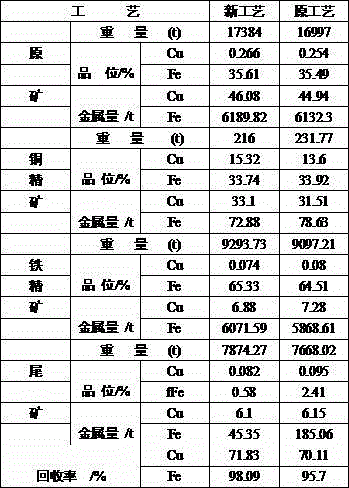

[0022] Example 1: (1), the first flotation: before the first flotation, the raw ore should be crushed and sieved first, the particle size of the product under the sieve should be controlled at -12mm, and the product of -12mm should be rod milled once. Finally, the particle size of the product is controlled by a hydrocyclone so that it reaches -0.074mm, accounting for 63-68%, and then flotation is carried out. The collector uses Z-200, and the dosage is: 4-6g / t. The foam product is mainly yellow Copper ore, but because the monomer dissociation is not very deep, there is still a part of magnetite in the foam product. Therefore, the foam product must be subjected to secondary rod milling, and -0.074mm is controlled to account for 68-75%, while the primary flotation tailings product is sieved by a high-frequency sieve, and the particle size of the sieving control is 0.074mm. The +0.074mm product is rod milled again, and the -0.074mm product is sieved by a high-frequency sieve. The...

Embodiment 2

[0028] Preferred embodiment 2: The flow process of embodiment 1 is basically the same, the difference is that the temperature is controlled at 10-15°C during the first flotation, and 15-22wt% industrial paraffin and 10- 20wt% talcum powder, as we all know, the greater the concentration of the collector, the greater the adsorption capacity, the higher the flotation recovery, but when the concentration of the agent reaches a certain value, that is the amount of Z-200 in the present invention: 4-6 g / During t, the rate of recovery declines with the rise of medicament concentration and adsorption capacity, for this reason the present invention adds 15-22wt% industrial paraffin and 10-20wt% talcum powder while adding the Z-200 of 4-6 g / t And maintaining the flotation temperature in the lower range of 10-15°C can stabilize the flotation recovery rate so that it does not drop in the range of 4-6g / t, which ensures both the adsorption capacity and the flotation recovery rate.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com