Method for recovering high-pelitic and high-iron copper oxide ore hard to treat

A technology of copper oxide ore recovery method, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of low recovery rate of copper minerals, high production cost, and low recovery rate of flotation, and achieves increased The effect of resource utilization, improved recycling rate, and smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

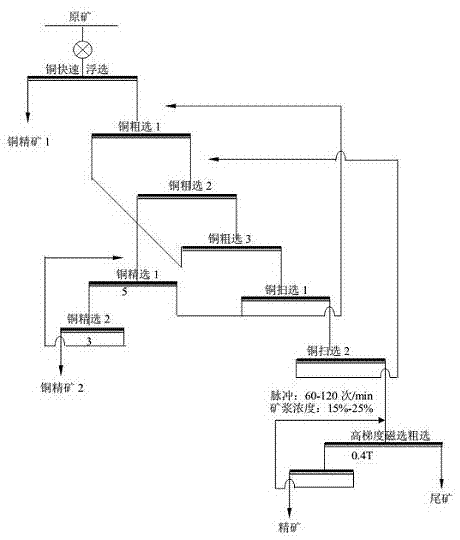

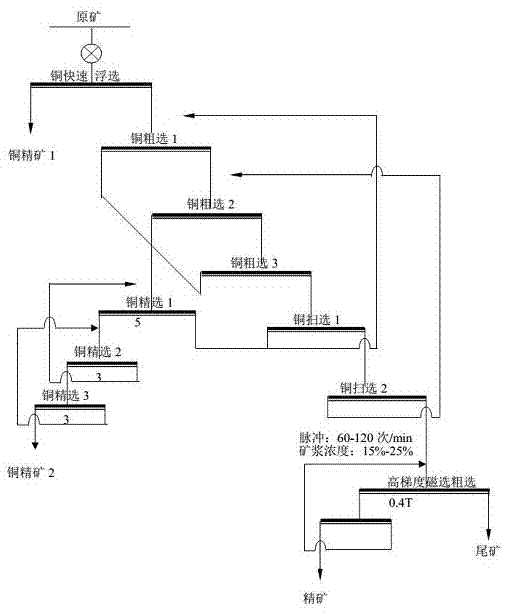

Method used

Image

Examples

Embodiment 1

[0026] The raw ore is selected from a high-grade copper oxide mine in Tibet, containing 4.40% copper and 20.76% iron. It is mainly limonite and contains a small amount of hematite. The copper oxidation rate is about 75%. Copper ore, cuprite, azurite, manganite, and some copper minerals are mixed into iron minerals by adsorption or mechanically. The occurrence state of copper in the ore is complicated, mainly in free copper oxide and secondary copper sulfide, with distribution rates of 41.50% and 34.31% respectively; secondly, in the form of bound copper oxide, with a distribution rate of 27.83%. The gangue minerals are mainly clay minerals.

[0027] The mine copper mineral recovery includes the following steps:

[0028] (1) Grinding: Raw ore is ground to a fineness of -0.074mm, accounting for 84%;

[0029] (2) Perform rapid flotation on the ore pulp after grinding, the concentration of the pulp is: 27%, add 1000g / t ammonium sulfate and 3000g / t sodium sulfide as vulcanizing a...

Embodiment 2

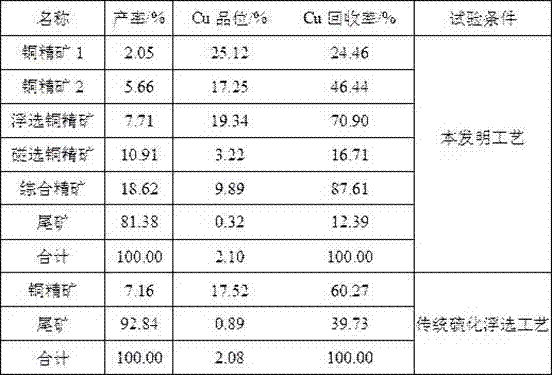

[0039]A copper mine in Yunnan has high iron content and large slime content. The ore contains 2.1% copper, 14.85% iron, 20.3% kaolinite, and a copper oxidation rate of about 78%. The copper minerals are mainly malachite and bluestone. Copper ore, goatite, manganite, and some copper minerals are mixed into limonite and kaolinite by adsorption or mechanically, which is difficult to recover. The occurrence state of copper in the ore is complicated, and it mainly occurs in copper sulfide, free copper oxide and bound copper oxide, and the distribution rates are 22%, 57.31%, and 20.69%, respectively. The gangue minerals are mainly clay minerals such as kaolinite.

[0040] The mine copper mineral recovery includes the following steps:

[0041] (1) Grinding: Raw ore is ground to a fineness of -0.074mm, accounting for 80%;

[0042] (2) Perform rapid flotation on the ore pulp after grinding, add 1200g / t ammonium sulfate and 2800g / t sodium sulfide as vulcanizing agents, and stir for 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com