Cutter spacing optimizing method for cydariform knife tool multiple coordinates line width processing

A tool position optimization, wide-row machining technology, applied in the direction of comprehensive factory control, digital control, electrical program control, etc., can solve problems such as unfavorable non-toroidal knife expansion, non-convergence, unfavorable tool path, etc., to increase the degree of programming automation , the effect of reducing acceleration requirements and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

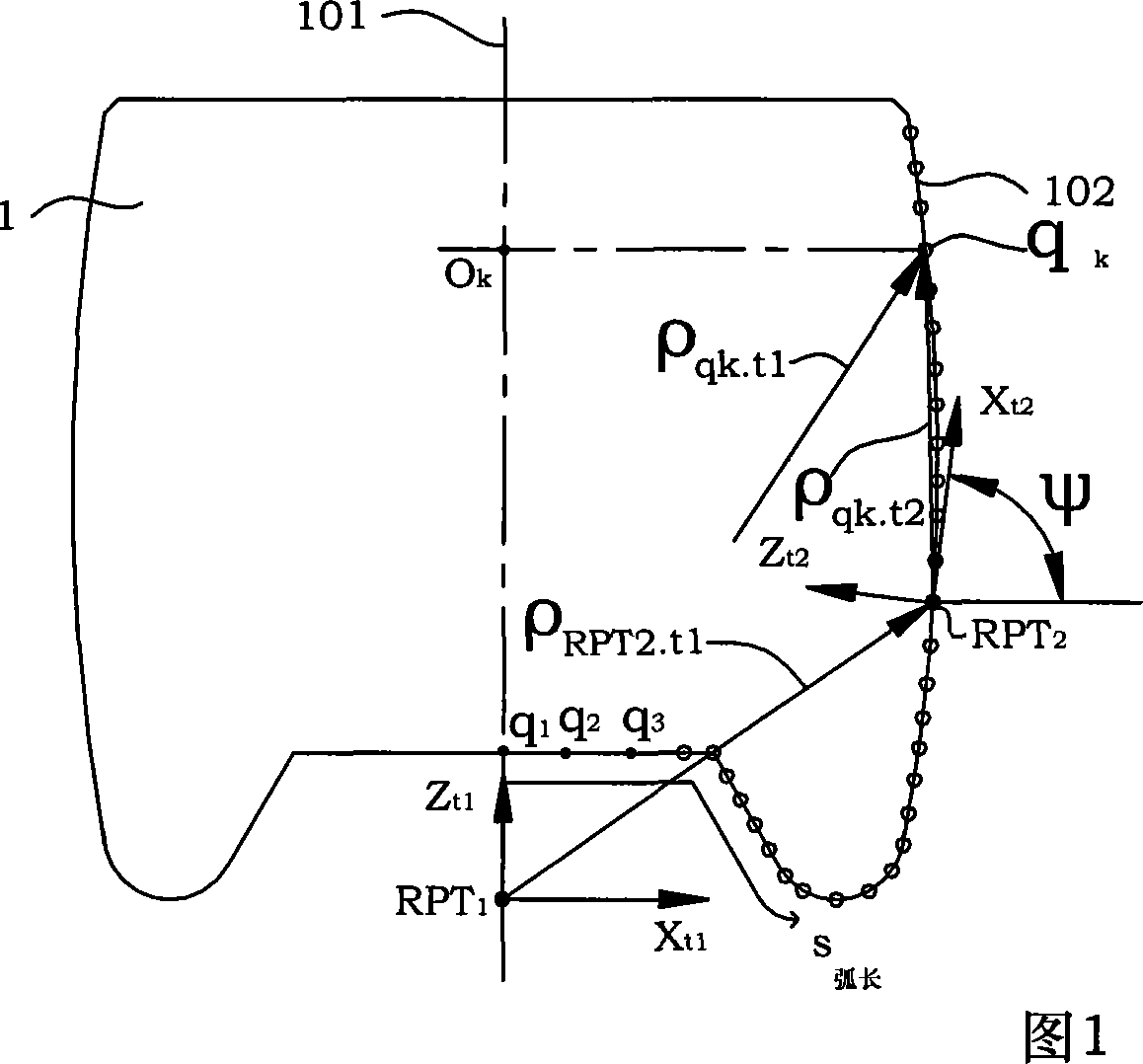

[0027] The present invention is a tool position optimization method for multi-coordinate wide row machining of a drum-shaped tool, which has the following optimization steps:

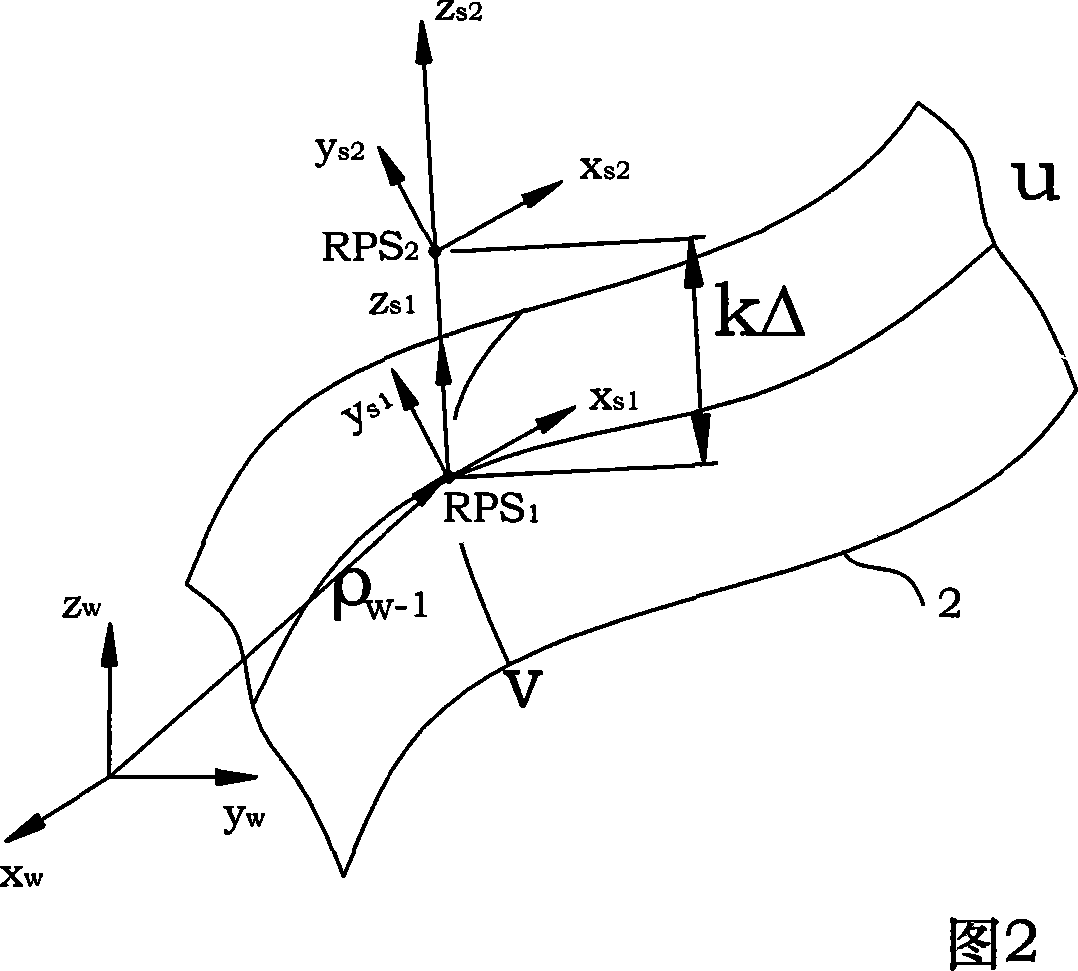

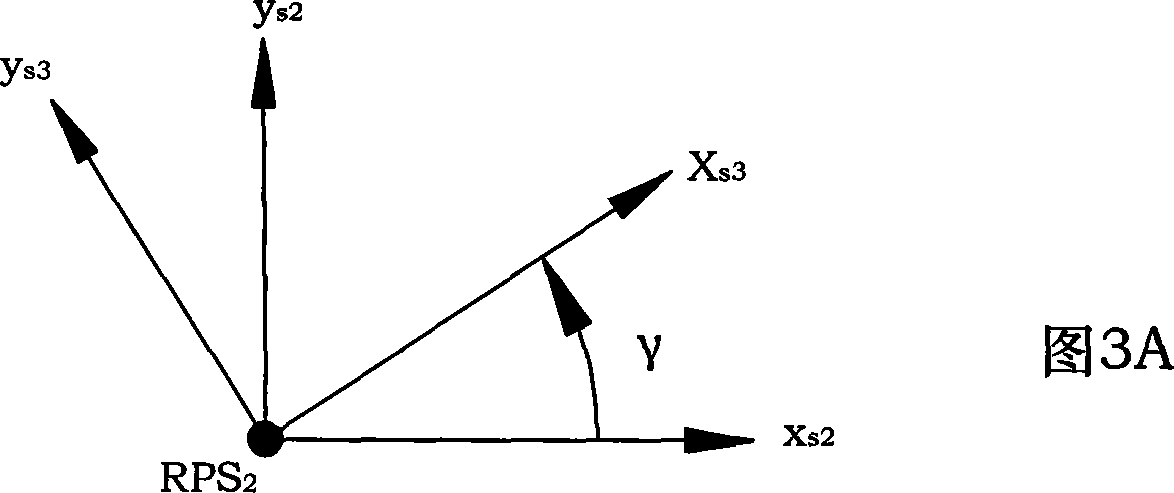

[0028] (1) Select the first reference point RPS of the workpiece on the workpiece design surface 1 , at the first reference point RPS of the workpiece 1 The first coordinate system S of the workpiece is established on s1 (x s1 -y s1 -z s1 ); Then pick up the second reference point RPS of the workpiece in the direction of the normal line outside the point 2 , and at the workpiece second reference point RPS 2 The second coordinate system S of the workpiece is established on s2 (x s2 -y s2 -z s2 ), and the workpiece first coordinate system S s1 and workpiece second coordinate system S s2 Parallel; the second coordinate system S of the workpiece s2 around z s2 Rotate the axis counterclockwise by γ angle to obtain the third coordinate system S of the workpiece s3 (X s3 -y s3 -z s3 ) coordina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com