Scrap tire pyrolytic carbon black micro-oxidation and activation method

An activation method and technology for waste tires, applied in the field of waste resource utilization, can solve problems such as affecting the surface activity of carbon black, unfavorable tire commercialization, unfavorable finishing, etc., to increase porosity and surface activity, and reduce commercialization costs. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

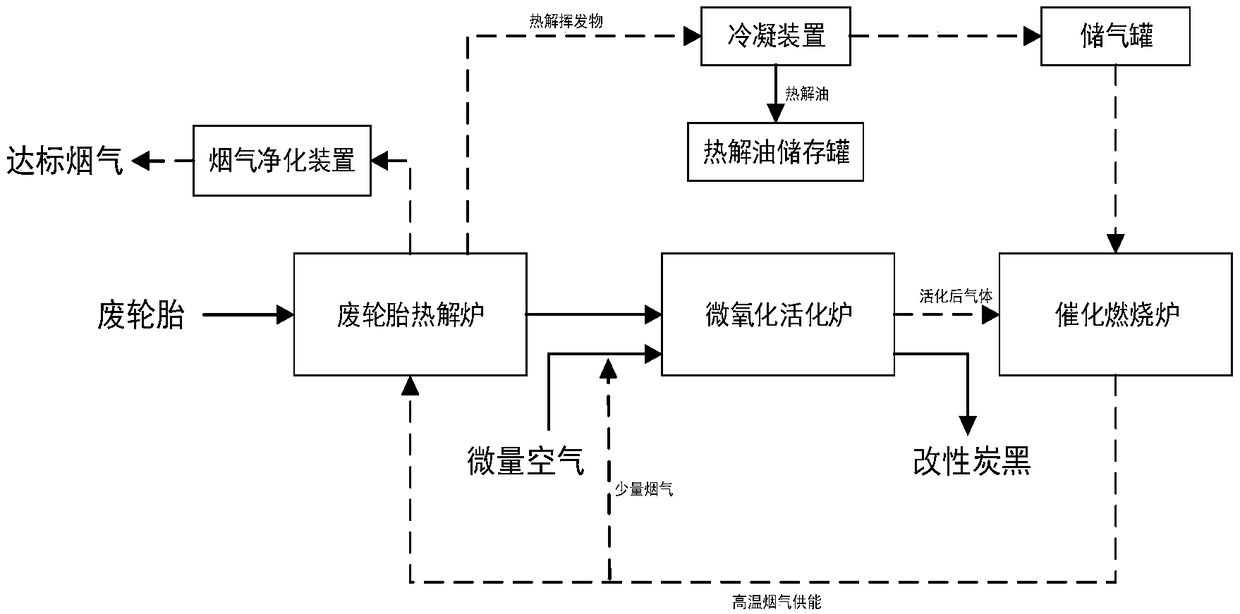

[0013] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0014] refer to figure 1 . The waste tire pyrolysis carbon black micro-oxidation activation method of the present invention mainly includes waste tire pyrolysis furnace, micro-oxidation activation furnace, gas storage tank, catalytic combustion furnace, condensation device, pyrolysis oil storage tank and flue gas purification device;

[0015] Waste tires are crushed and screened and then sent to the waste tire pyrolysis furnace for low-temperature pyrolysis at 400 to 500°C. At the same time, the pyrolysis volatiles generated during the pyrolysis process are sent to the condensing device, and the condensed pyrolysis oil is sent to the heat sink. The pyrolysis gaseous products are sent to the catalytic combustion furnace through the gas storage tank; the pyrolysis carbon black formed in the pyrolysis furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com