Waste tire recycling method and device

A waste tire and recycling device technology, applied in the field of recycling, can solve problems such as frequent maintenance, secondary pollution, and complicated processing process, and achieve the effects of reducing downtime for maintenance, saving processing costs, and simplifying the processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

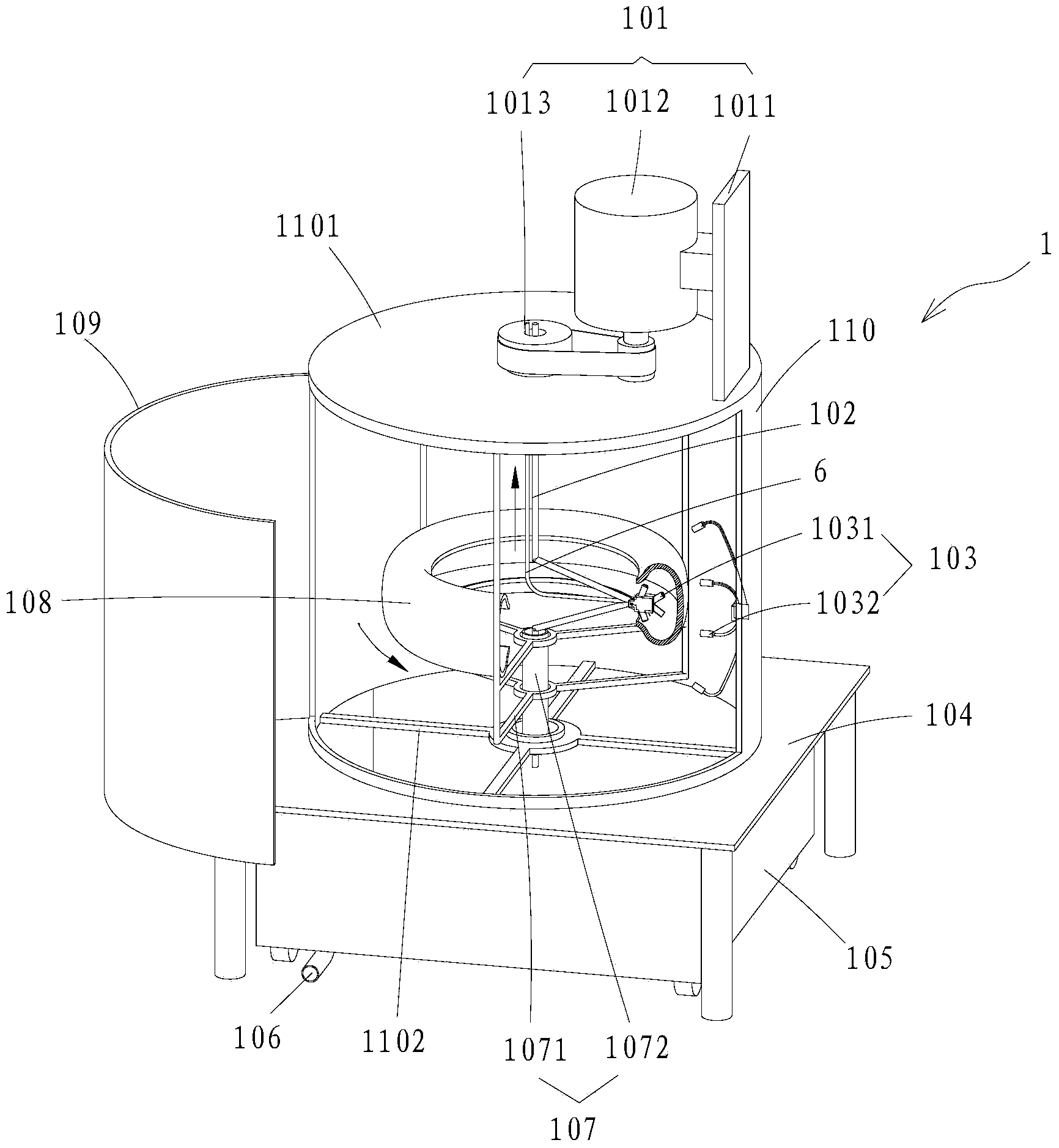

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

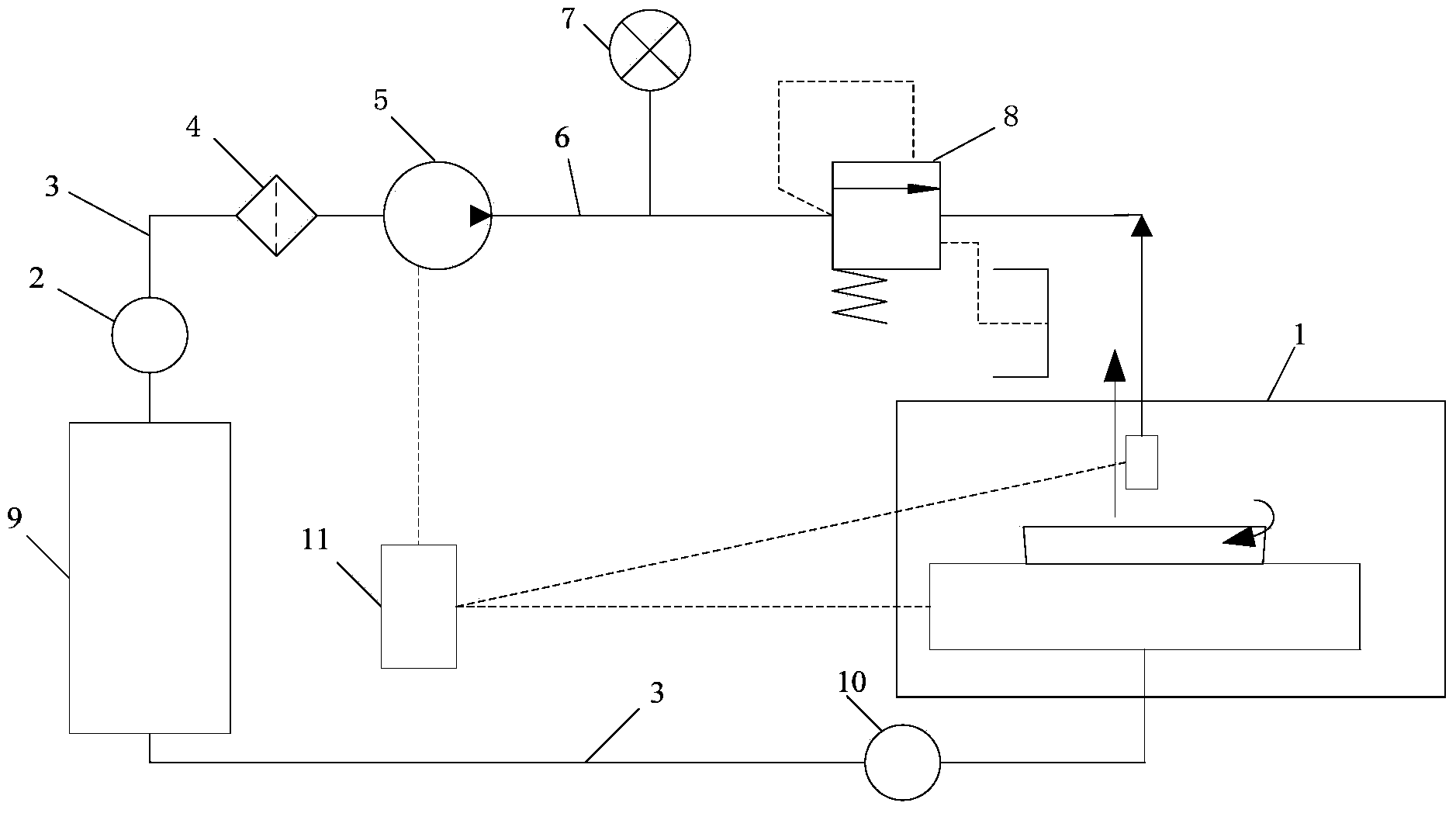

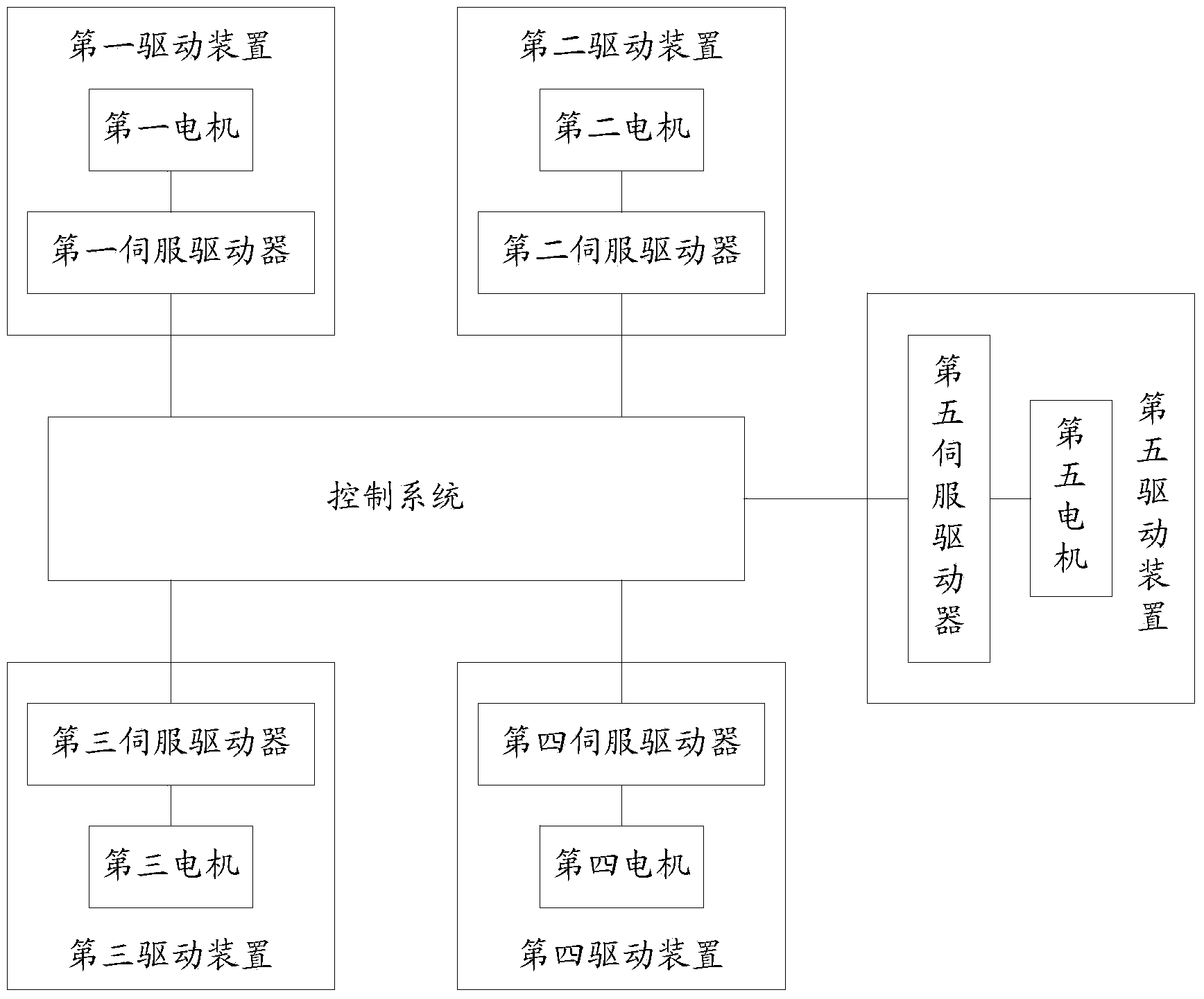

[0033] The present invention firstly provides a method, which is to soak and clean the waste tires, then place them on the workbench, and rotate them at a low speed under the drive of the driving device; It has at least two nozzles that can be connected to high-pressure water jets and are rotatable. When the nozzles are in the working position corresponding to the waste tires to be recycled, start the high-pressure water pump to make high-pressure water jets from each nozzle to form a high-pressure water jet. The surface of the recovered waste tires is subjected to impact cutting, so that the waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com