Waste tire recycling system

a waste tire and recycling technology, applied in the field of waste tire recycling system, can solve the problems of waste tire use as fuel, waste of resources, waste of resources, etc., and achieve the effect of stable and reliable system operation and enhanced convenience in initial operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The above and other objects and advantages of the present invention will become readily apparent by reference to the following detailed description.

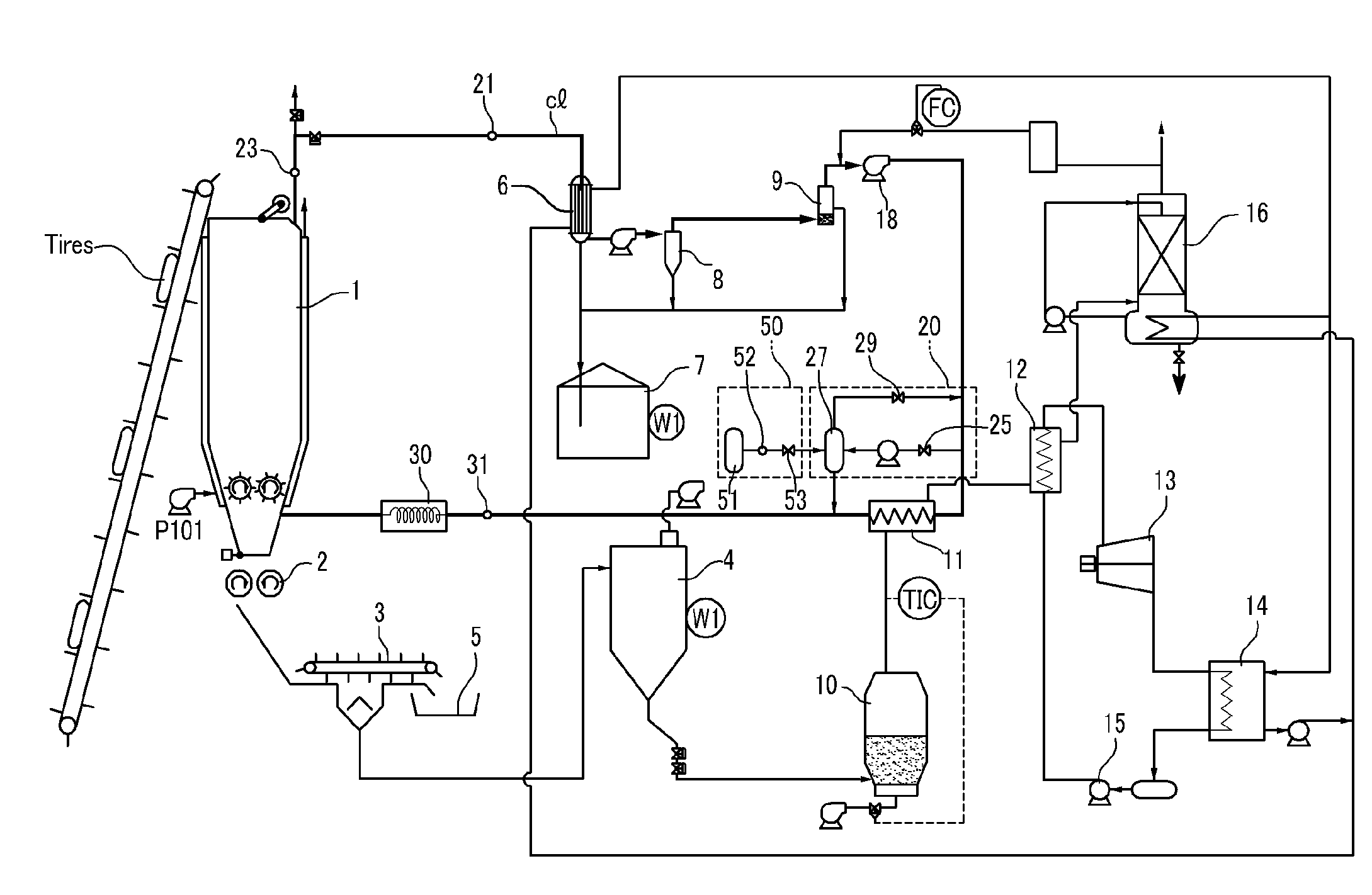

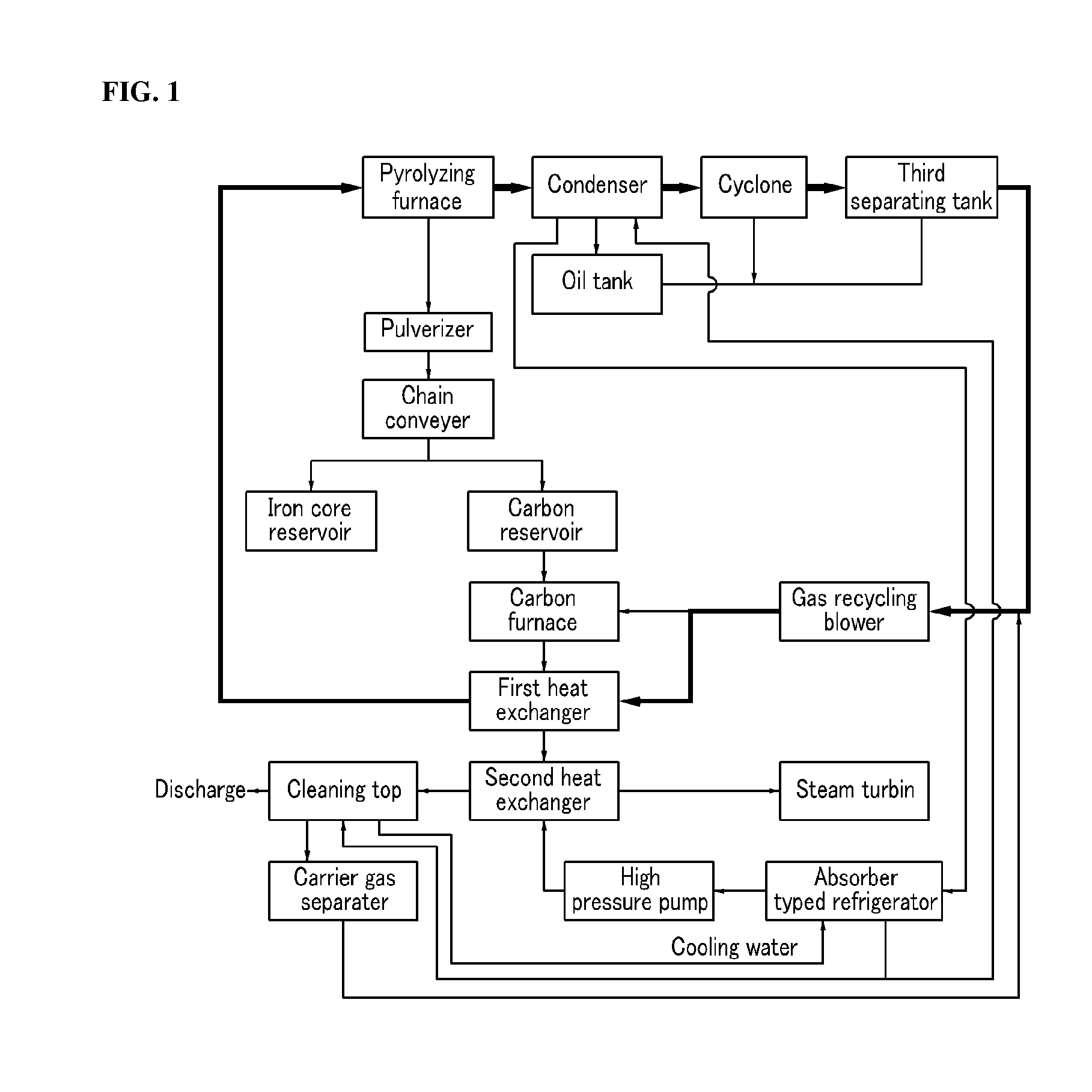

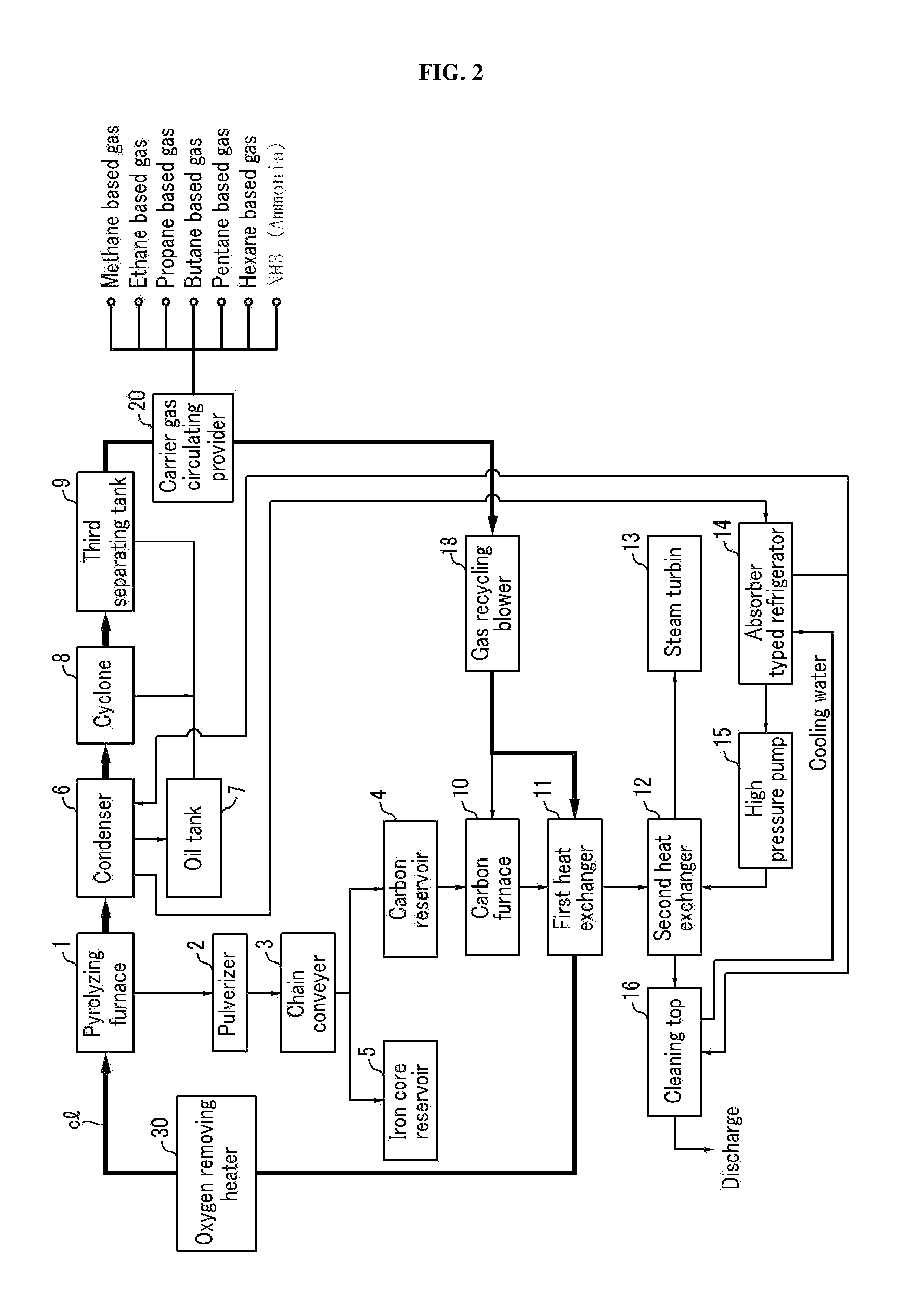

Hereinafter, a system for recycling waste tires according to preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

Note that the same components or parts are shown to have same reference numbers in the drawings. In describing the present invention, any related known function or structures are not described in detail so as to not vague the gist of the present invention.

FIG. 2 is a block view schematically illustrating a structure of a system for recycling waste tires according to a preferred embodiment of the present invention.

Firstly, the main elements of the present invention are explained as follows.

Reference numeral (1) is a pyrolyzing furnace (1) for pyrolyzing waste tires by a direct heating method using gas such as carbon dioxide (CO2) or nitrogen (N2) as a carrier gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com