Treatment process for wastewater generated during recycling process of waste tire

A waste tire and waste water treatment technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as pollution and air pollution, and achieve high transparency and safety High and wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

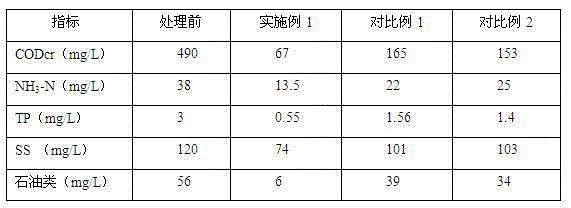

Embodiment 1

[0051] The waste tire recycling wastewater treatment process includes the following steps:

[0052] (1) Add acid to the wastewater to neutralize its pH to 6.9-7.2;

[0053] (2) Add defoamer to the wastewater in step (1), and then undergo aeration and defoaming treatment for 3 hours. The defoamer accounts for 0.12% of the body weight of the wastewater;

[0054] (3) Add flocculating water purifying agent to the wastewater in step (2), polyaluminum chloride 16, polyacrylamide 12, ferrous sulfate 8, aluminum sulfate 10; flocculating water purifying agent accounts for 0.08% of the total weight of wastewater ; Then add the microbial water purifier, the added amount accounts for 0.1% of the total weight of the wastewater;

[0055] The weight parts of the microbial water purifying agent are: nitrifying bacteria powder 1.2, denitrifying paracoccus powder 0.9, sulfur bacteria powder 0.6, aniline degrading bacteria powder 0.8, and flocculating bacteria powder 0.9;

[0056] (4) Add enzyme preparat...

Embodiment 2

[0065] The waste tire recycling wastewater treatment process includes the following steps:

[0066] (1) Add acid to the wastewater to neutralize its pH to 6.9-7.2;

[0067] (2) Add a defoamer to the waste water in step (1), and then undergo aeration and defoaming treatment for 5 hours. The defoamer accounts for 0.05% of the weight of the waste water;

[0068] (3) Add flocculating water purifying agent to the wastewater in step (2), polyaluminum chloride 4, polyacrylamide 4, ferrous sulfate 2, aluminum sulfate 3; flocculating water purifying agent accounts for 0.01% of the total weight of wastewater ; Then add microbial water purifier;

[0069] The weight parts of the microbial water purifying agent are: nitrifying bacteria powder 0.5, denitrifying paracoccus powder 0.4, Pseudomonas aeruginosa powder 0.2, Candida lipolytica powder 0.2, Bacillus megaterium 0.2, which The added amount accounts for 0.02% of the total weight of wastewater;

[0070] (4) Add enzyme preparation to the wastewa...

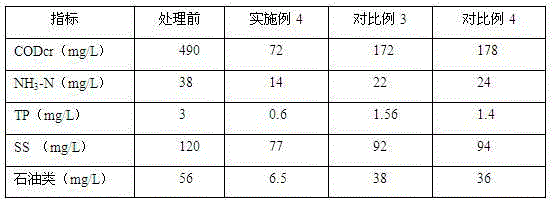

Embodiment 3

[0073] The waste tire recycling wastewater treatment process includes the following steps:

[0074] (1) Add acid to the wastewater to neutralize its pH to 7.2;

[0075] (2) Add a defoamer to the wastewater in step (1), and then undergo aeration defoaming treatment for 6 hours. The defoamer accounts for 0.3% of the weight of the wastewater;

[0076] (3) Add flocculating water purifying agent to the wastewater in step (2), polyaluminum chloride 16, polyacrylamide 16, ferrous sulfate 12, aluminum sulfate 16; flocculating water purifying agent accounts for 0.3% of the total weight of wastewater ; Then add the microbial water purifier, the added amount accounts for 0.3% of the total weight of the wastewater;

[0077] The weight parts of the microbial water purifying agent are: nitrifying bacteria powder 2.0, denitrifying paracoccus powder 1.5, Pseudomonas aeruginosa powder 1.2, Candida lipolytica powder 0.8, Bacillus megaterium 0.8;

[0078] (4) Add enzyme preparation to the wastewater in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com