Rubber tyre recycling device

A recycling device and technology for rubber tires, applied in the field of rubber tire recycling, can solve the problems of inclusion of sand and gravel, damage to the cutter head of a pulverizer, and inability to clean the sand and gravel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

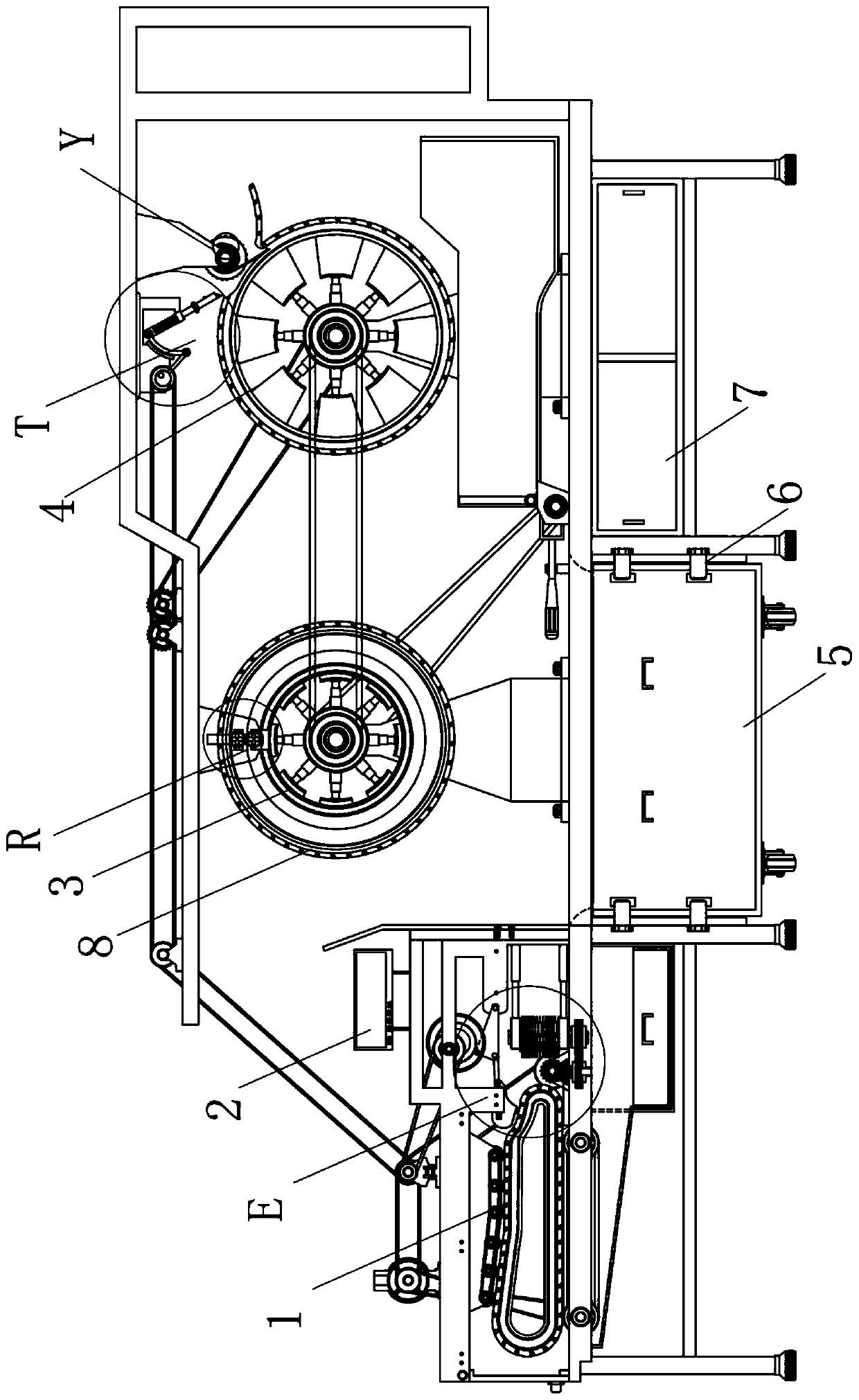

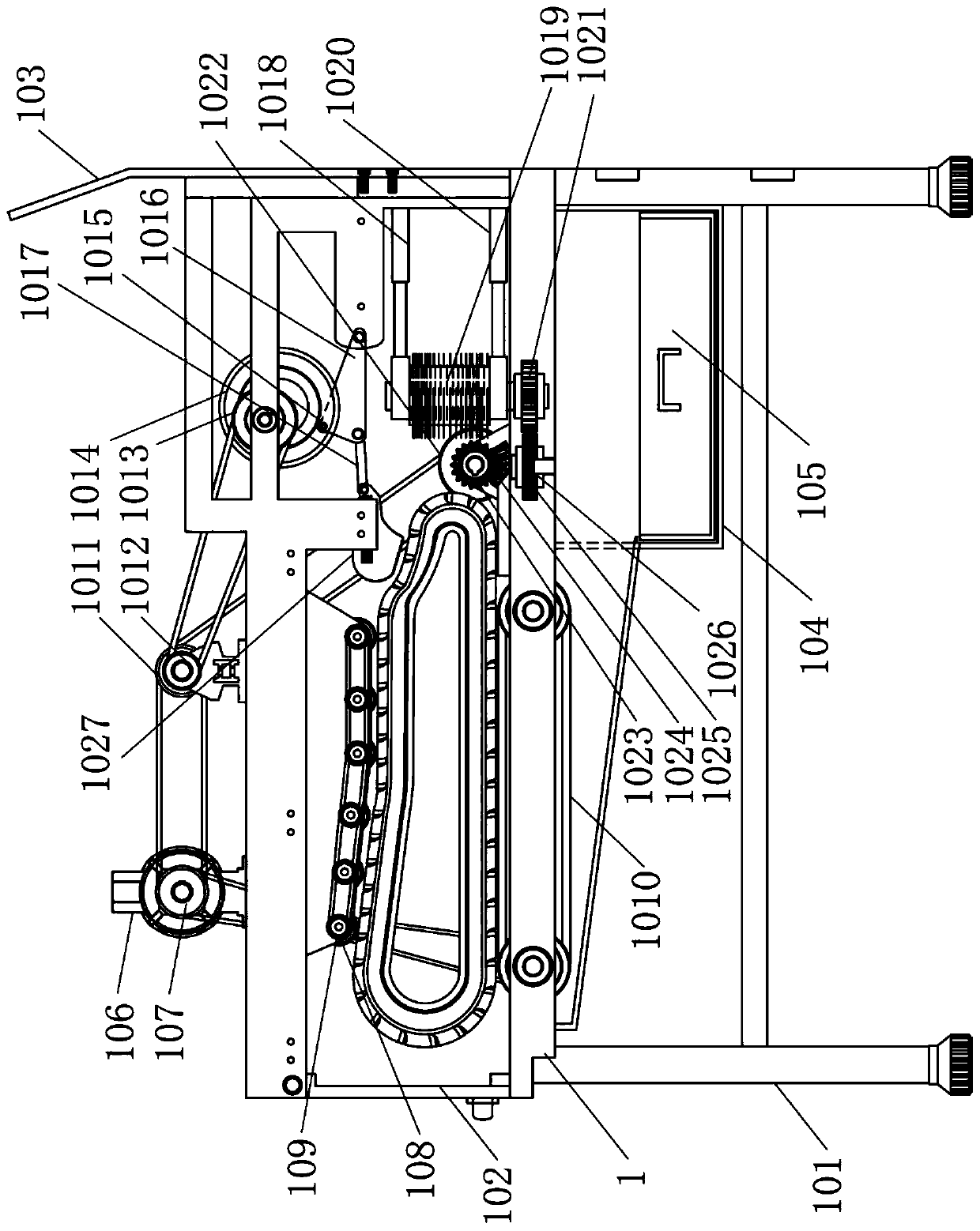

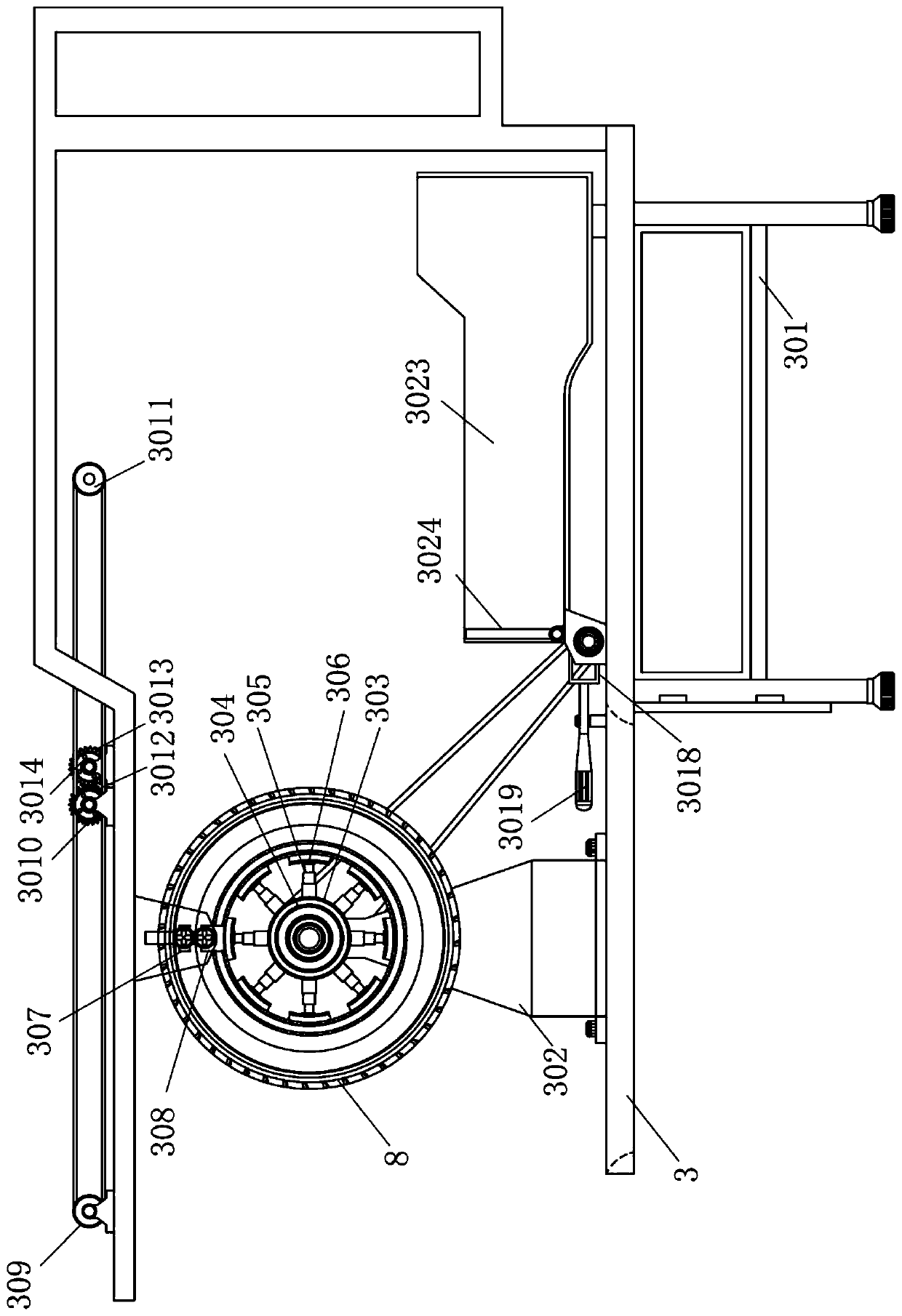

[0032] A rubber tire recovery device, comprising a sandstone removal mechanism 1, a control panel 2, a steel ring separation mechanism 3, a steel wire mesh separation mechanism 4, a collection vehicle 5, buckles 6, a storage cabinet 7 and waste tires 8; the sandstone removal mechanism 1. A control panel 2 is set on the right side of the top; a steel ring separation mechanism 3 is set on the right side of the sand removal mechanism 1; a steel wire mesh separation mechanism 4 is set on the middle right side of the steel ring separation mechanism 3; A collection cart 5 is provided; a buckle 6 is provided at the bottom middle of the front end of the steel ring separation mechanism 3, and the left side behind the buckle 6 is connected with the collection cart 5; a storage cabinet 7 is arranged on the right side of the bottom of the steel ring separation mechanism 3; the steel ring Discarded tires 8 are arranged on the left side in the separation mechanism 3 .

[0033] Working princ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com