Method and device for industrialized recycling of waste tires based on ultra-high pressure water jet technology

A waste tire, ultra-high pressure technology, applied in plastic recycling, recycling technology, solid waste removal and other directions, can solve problems such as poor economy, high jet pressure, secondary environmental pollution, etc., to improve the separation of rubber threads, reduce The effect of jet pressure and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In this embodiment, the method for industrialized recovery of waste tires based on ultra-high pressure water jets is carried out as follows:

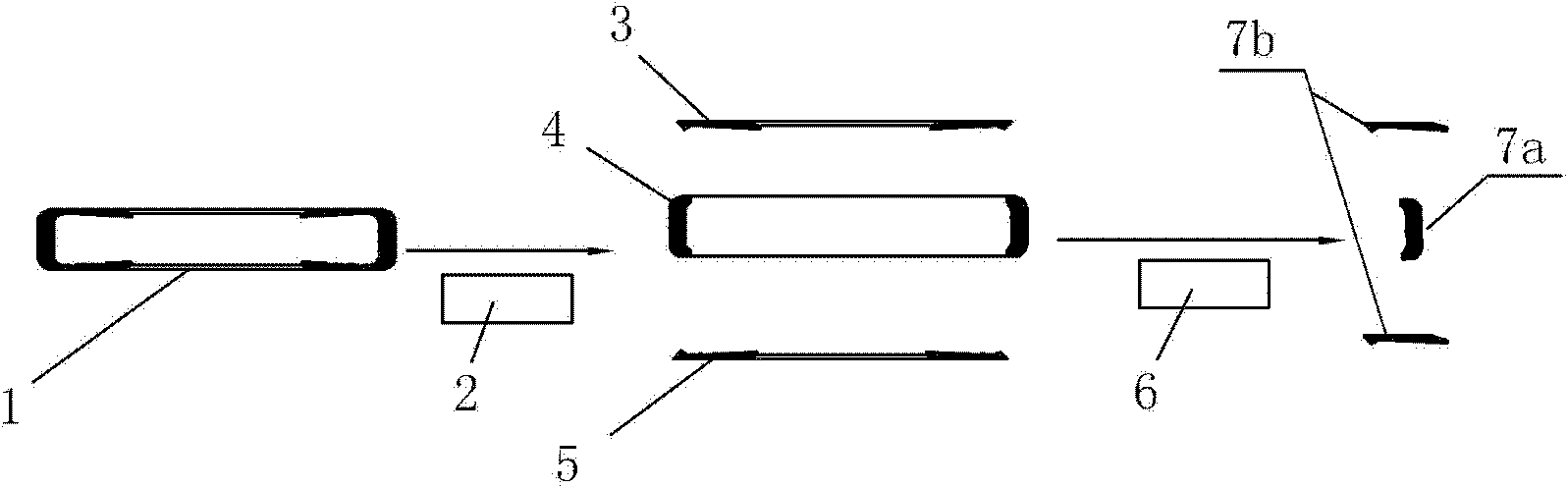

[0035] see figure 1 First, the waste tire 1 with the wheel hub removed is divided into tread rubber 4, upper bead rubber 3 and lower bead rubber 5 by a ring cutting machine 2, and the tread rubber 4 is cut into 1 / 4, 1 by a cutting machine 6 / 8 or 1 / 16 tread arc rubber blocks 7a, the upper bead rubber 3 and the lower bead rubber 5 are respectively cut into 1 / 4, 1 / 8 or 1 / 16 bead arc rubber blocks 7b, the tread The size of the arc rubber block 7a and the bead arc rubber block 7b can be formulated according to the width of the mesh conveyor belt 8;

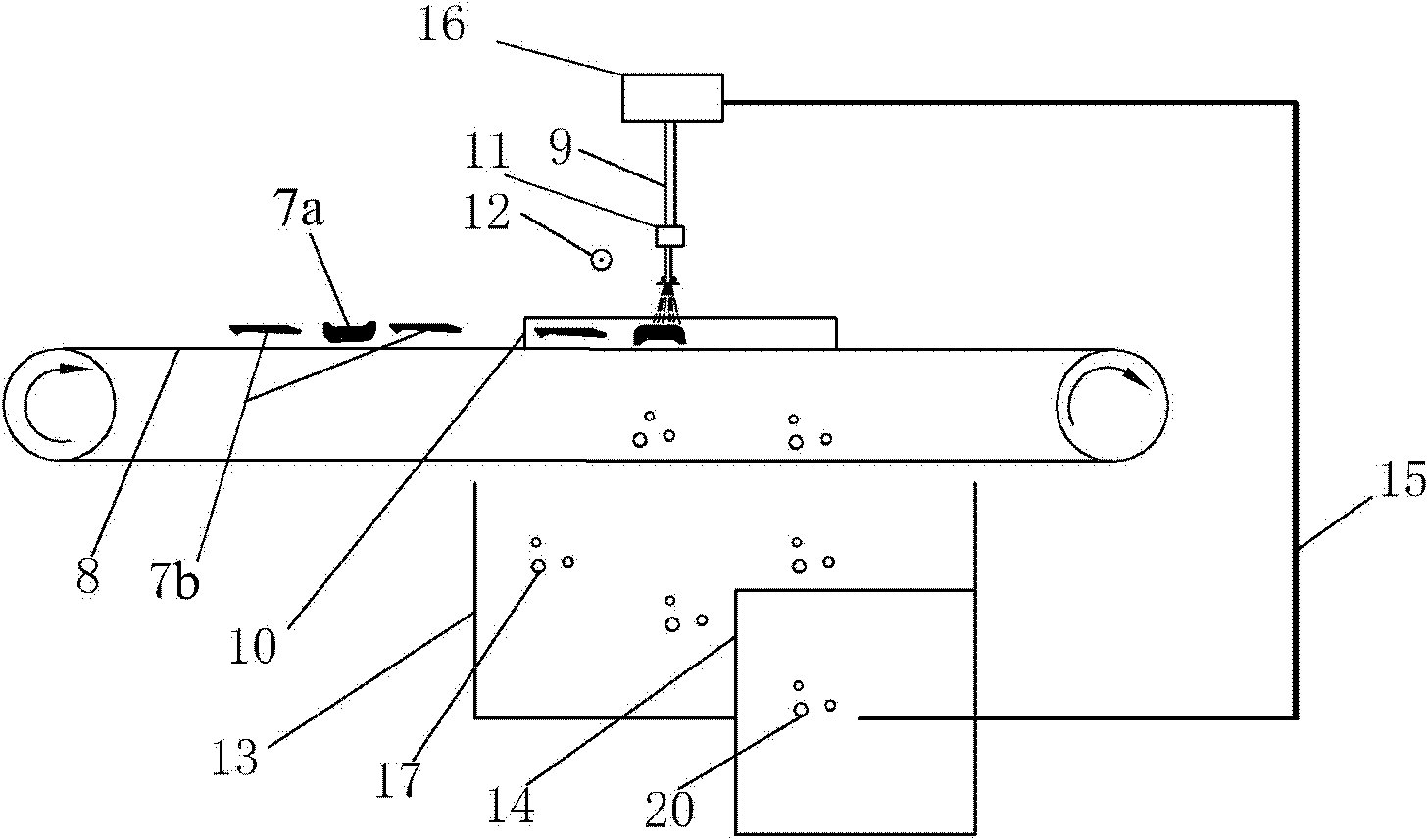

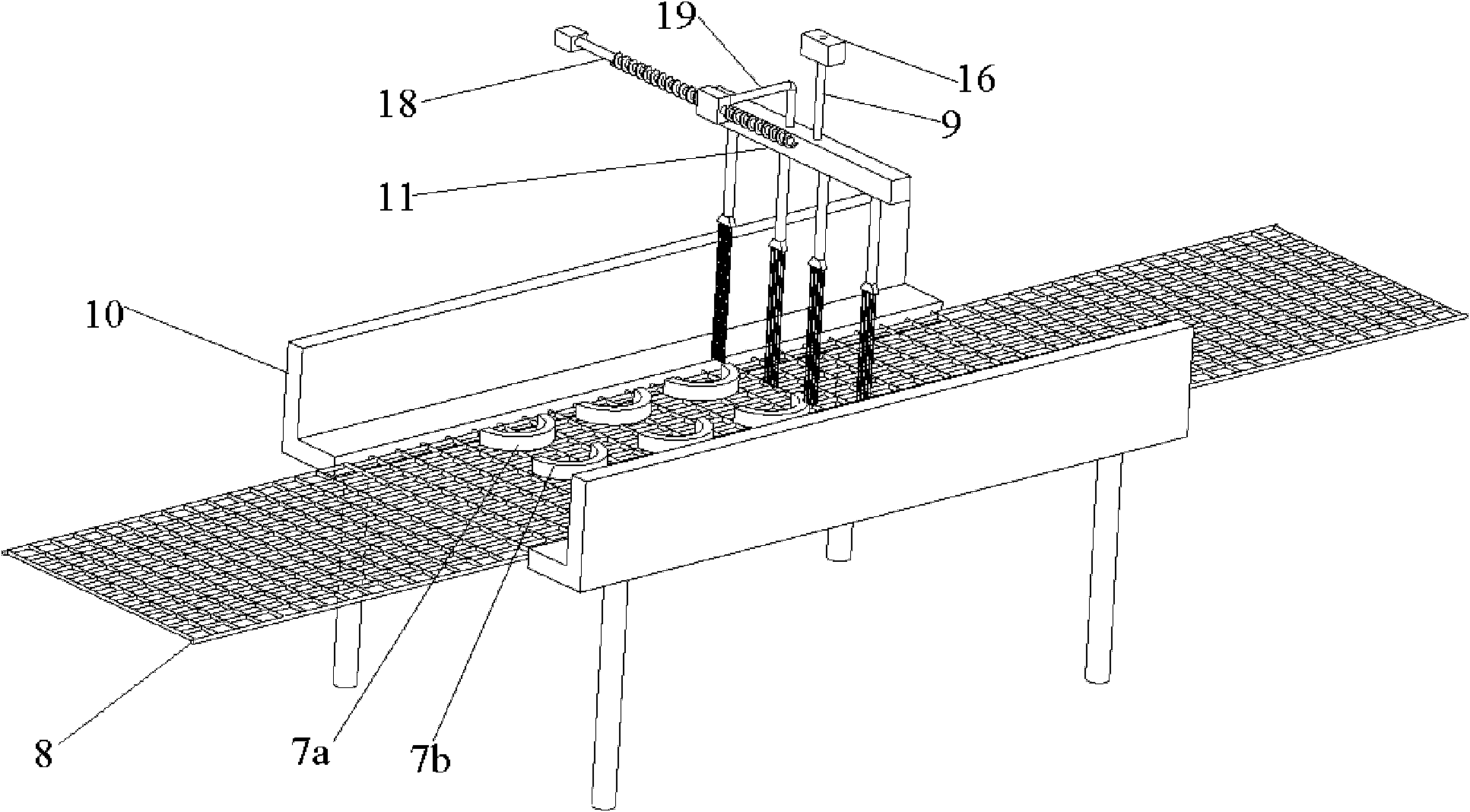

[0036] see figure 2 Place the tread circular arc rubber block 7a and the bead edge circular arc rubber block 7b on the mesh conveyor belt 8, and place the row-type waterjet nozzle 11 with a water pressure between 150Mpa-400Mpa on the tread circular arc rubber block 7a , 6-60mm above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com