Waste tire recovery processing equipment

A technology for recycling and processing waste tires, applied in grain processing, plastic recycling, mechanical material recycling, etc., can solve the problems of easy winding of steel wire, reduced production efficiency, affecting wire drawing work, etc., to achieve smooth wire drawing work, improve work efficiency, and work. Efficient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

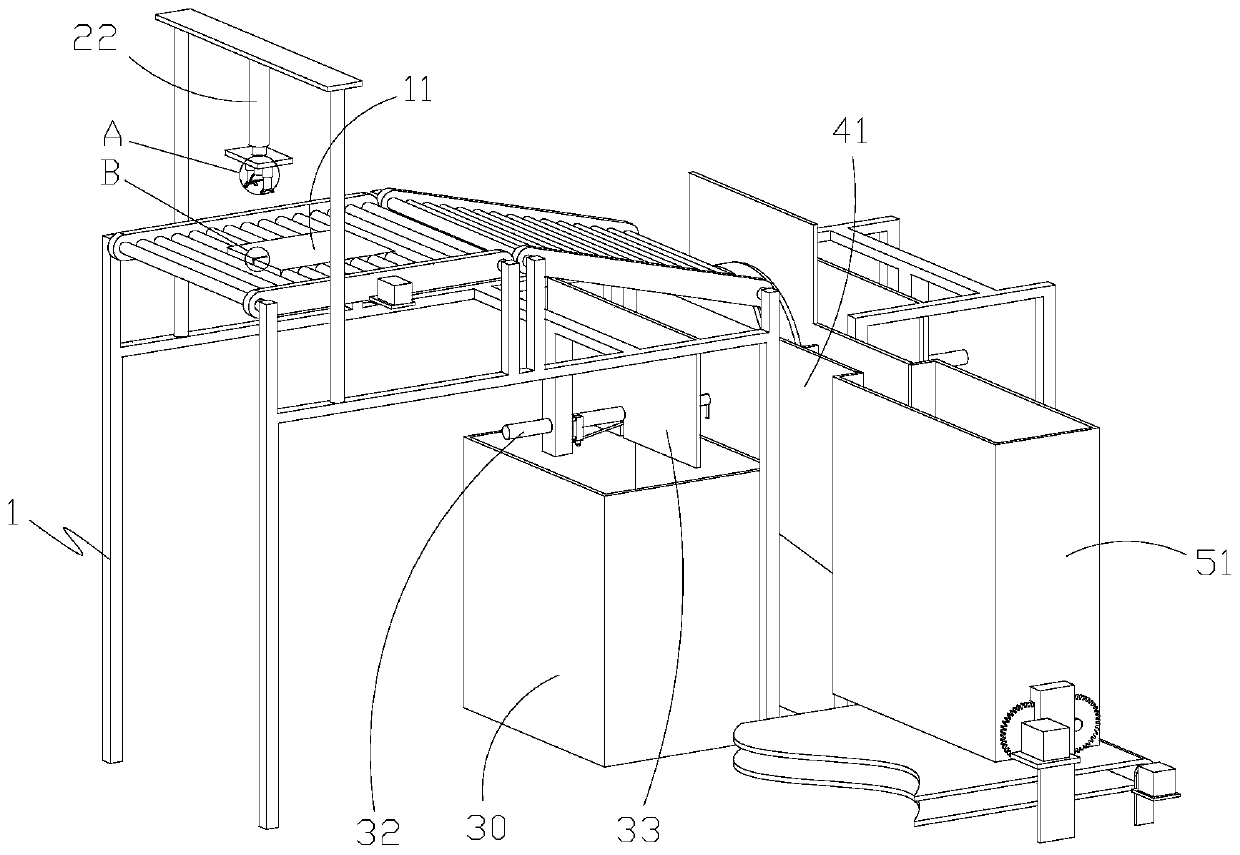

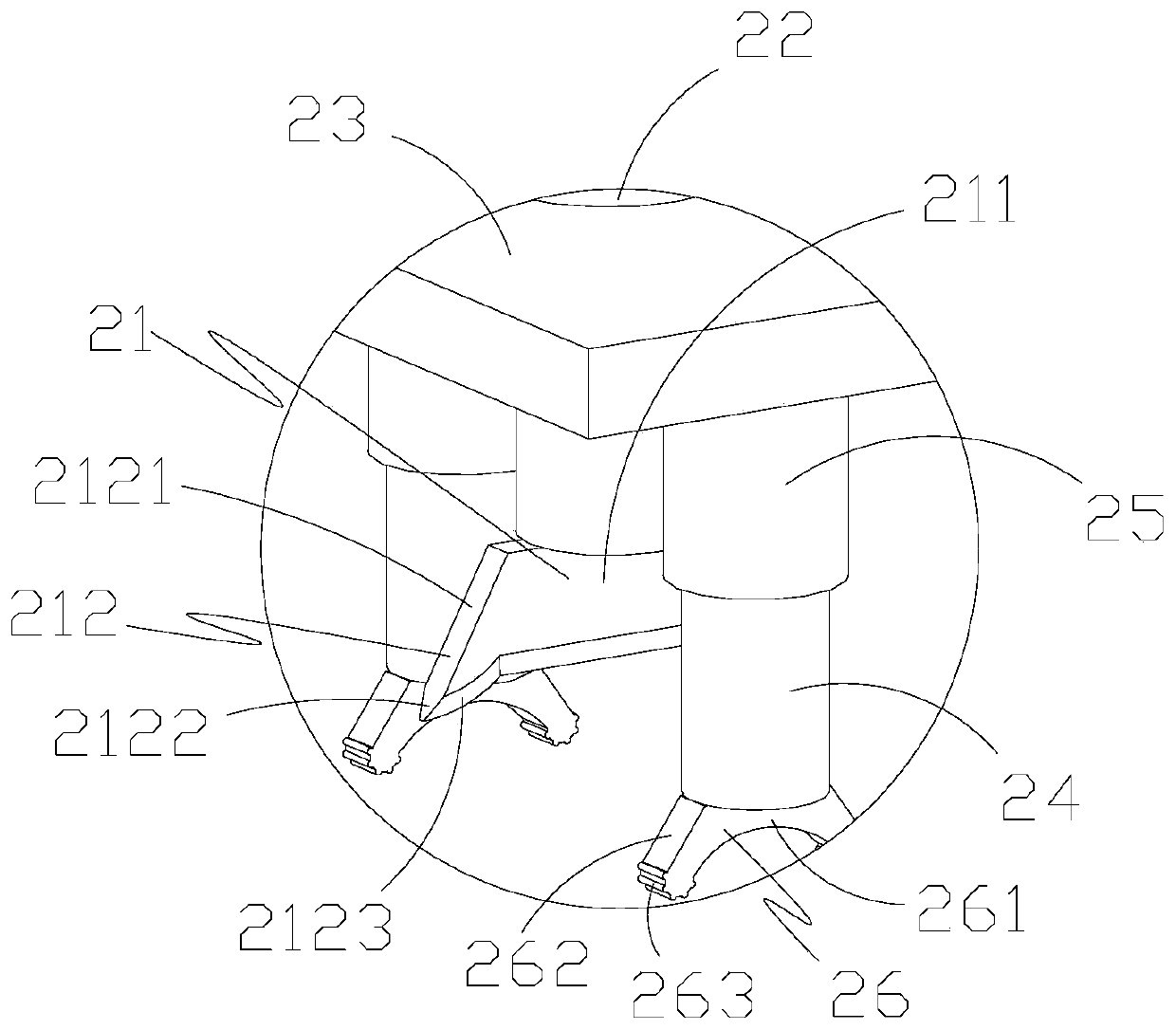

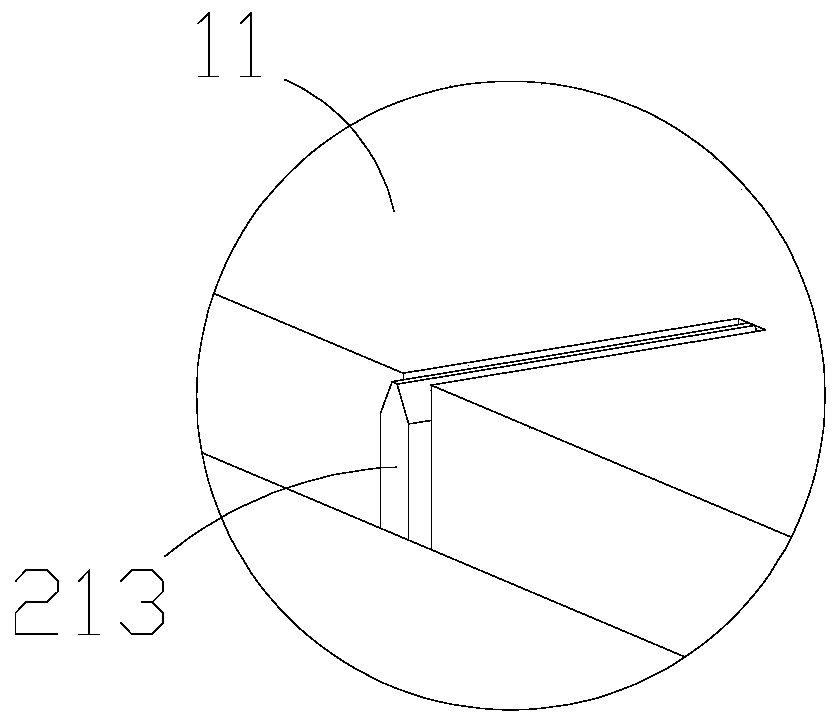

[0030] Such as Figure 1-13 As shown, a waste tire recovery processing equipment includes a frame 1, a cutting device, a spinning device and a crushing device; wherein, the cutting device includes a cutting part 21, a first driving part 22, a synchronous plate 23 and a pressing structure; A driving member is a cylinder purchased on the market, hereinafter referred to as the No. 1 cylinder, which is the prior art, so it will not be described in detail here; a cutting frame is installed on the frame, and the No. 1 cylinder is bolted to the cutting frame. ;The synchronous plate is installed on the output shaft of the No. 1 cylinder, which can be driven up and down by the No. 1 cylinder; the cutting parts and the pressing structure are installed on the synchronous plate, so that the two can move together with the lifting of the synchronous plate. Lifting ensures that the cutting part and the pressing structure can cooperate stably; a cutting table 11 matched with the cutting part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com