Tire recycling device for smashing waste tire based on high-pressure water jet

A technology of high-pressure water jetting and waste tires, applied in plastic recycling, recycling technology, mechanical material recycling, etc., can solve the problems of low degree of thermal oxidation, high exhaust gas, large processing capacity, etc., and achieve a clean and environmentally friendly recycling method and easy installation and the effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

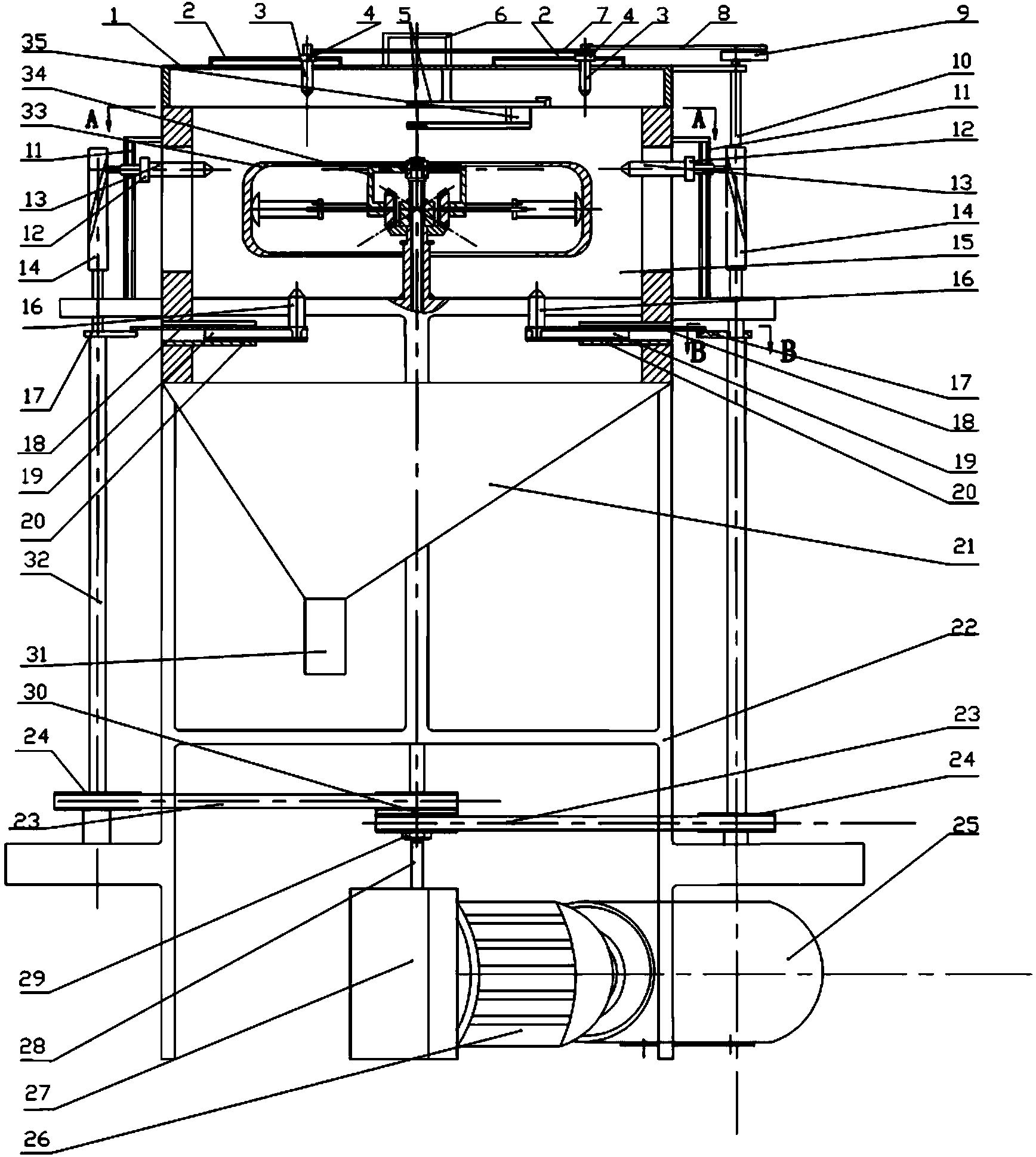

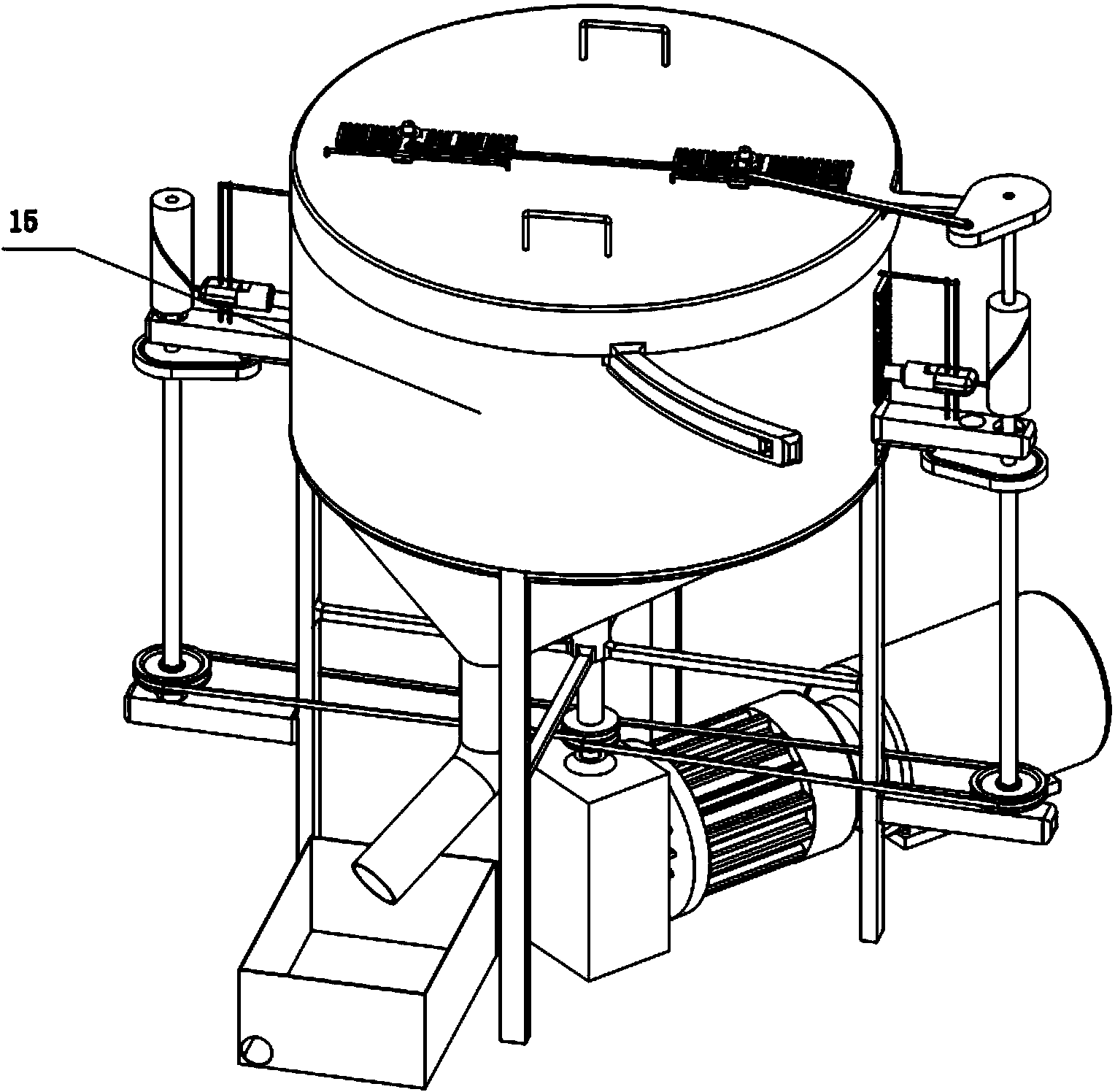

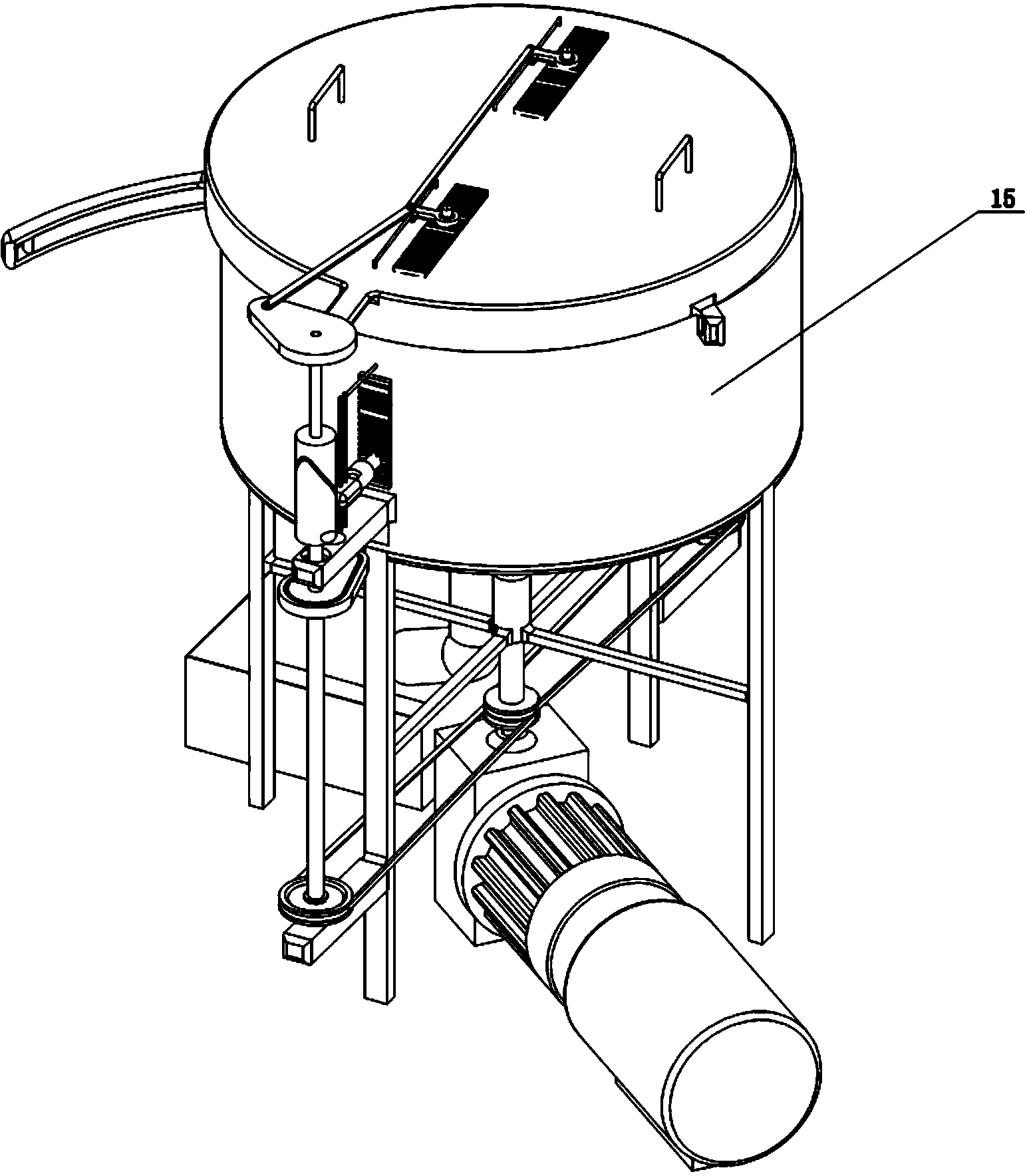

[0033] The technical solutions of the present invention will be further explained and illustrated through specific embodiments below in conjunction with the accompanying drawings.

[0034] As shown in the figure, the tire recovery device includes a frame 22, and the upper part of the frame 22 is provided with a crushing chamber 15 which can be opened by the top cover 1. The crushing chamber 15 is provided with a tire clamping mechanism, and the crushing chamber 15 is upper and lower. , The left and right directions are equipped with mobile jet nozzles that spray high-pressure water to the clamped tires;

[0035] The above-mentioned clamping mechanism includes a main shaft 28, a clamping frame 34, a radial expansion arm, an electromagnetic chuck 44, a small bevel gear 40 and a large bevel gear 41. The main shaft 28 vertically penetrates into the crushing chamber 15, and its bottom end is connected with the driving mechanism. The top is rigidly connected to the clamping frame 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com