Thermal cracking treatment device for waste tires

A processing device and a technology for waste tires, which are used in the processing of hydrocarbon oil, the petroleum industry, the preparation of liquid hydrocarbon mixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

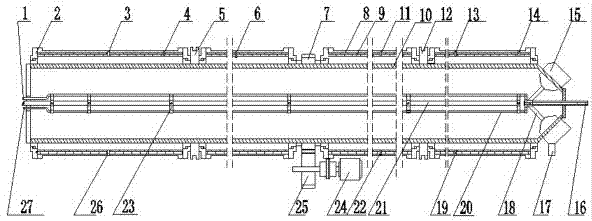

[0008] The specific embodiment of the present invention is described in conjunction with accompanying drawing, as figure 1 As shown, the waste tire thermal cracking treatment device includes a cracking furnace, an internal heating system, and an external heating system.

[0009] The cracking furnace includes a support shaft 21, a hollow shaft 16, and a rotary kiln shell 10. The support shaft 21 is fixed on the outer wall of the hollow shaft 16 through a fixing mechanism 23; the support shaft 21 and the hollow shaft 16 are installed in the rotary kiln shell 10, and the support shaft 21. The hollow shaft 16 and the rotary kiln shell 10 are coaxial, and have an inclination angle of 0°~5° with the horizontal position; the support shaft 21 and the hollow shaft 16 do not rotate with the rotary kiln shell 10, and the rotary kiln shell Front wheel belt 5, rear wheel belt 12 and gear ring 7 are installed on 10 outer walls, and gear ring 7 is meshed with transmission gear 25, and transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com