Scrap tire recycling plant

a recycling plant and scrap tire technology, applied in the field of scrap tire recycling plant, can solve the problems of reducing the marketability of scrap tires, unable to address the problem of recovering other components, and unable to meet the needs of replacement of tires, etc., and achieves the effect of high commercial value and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

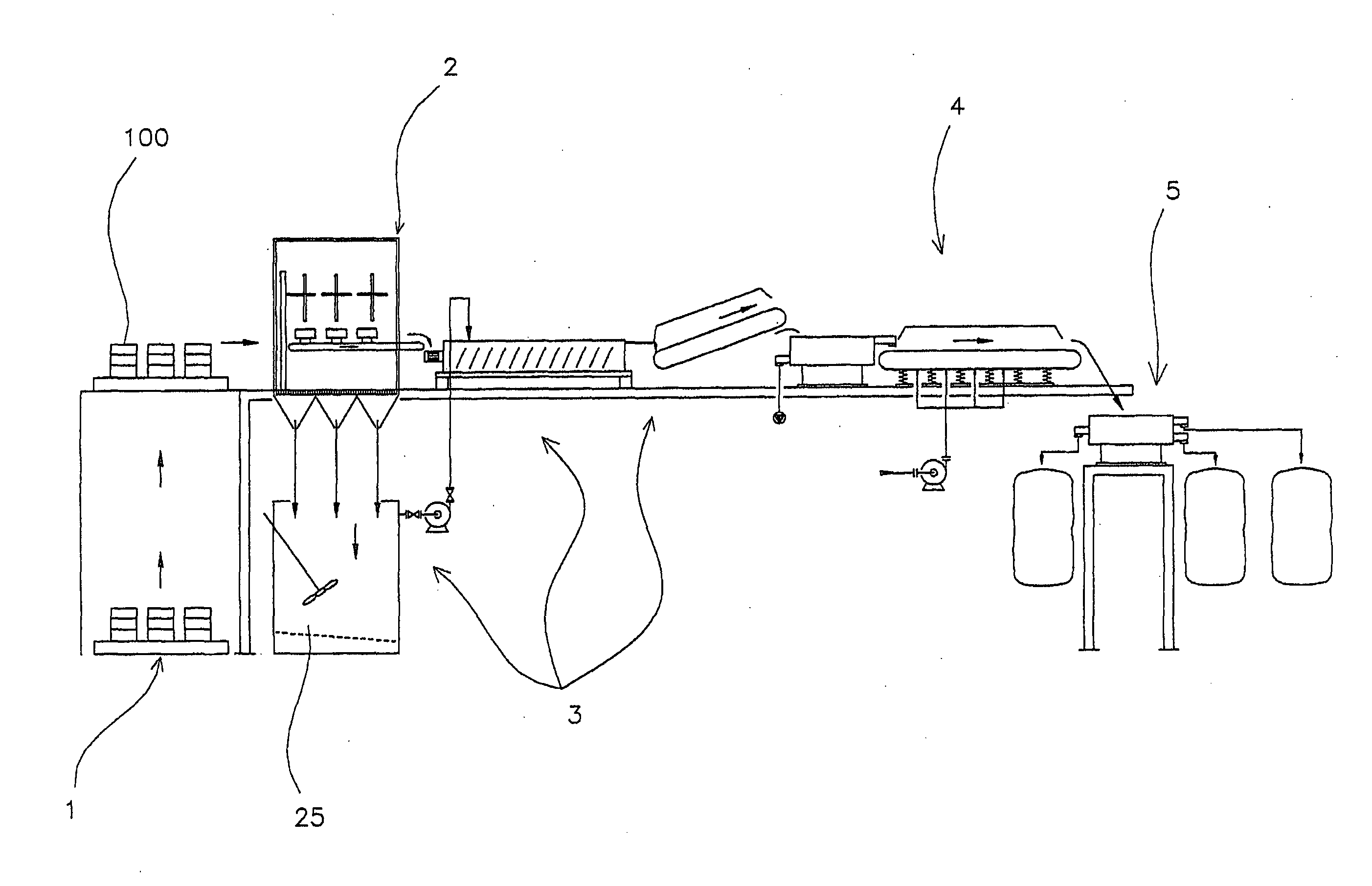

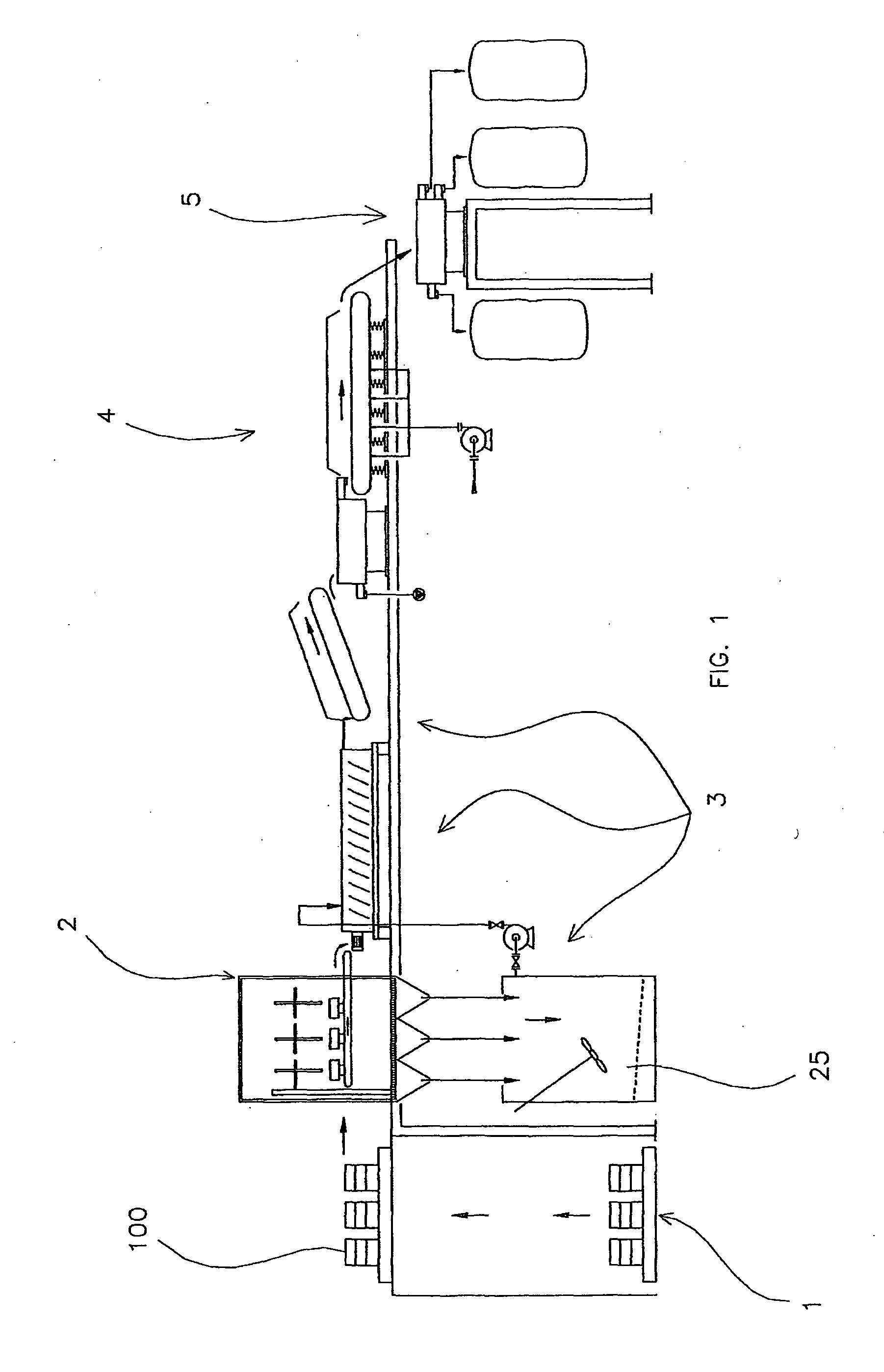

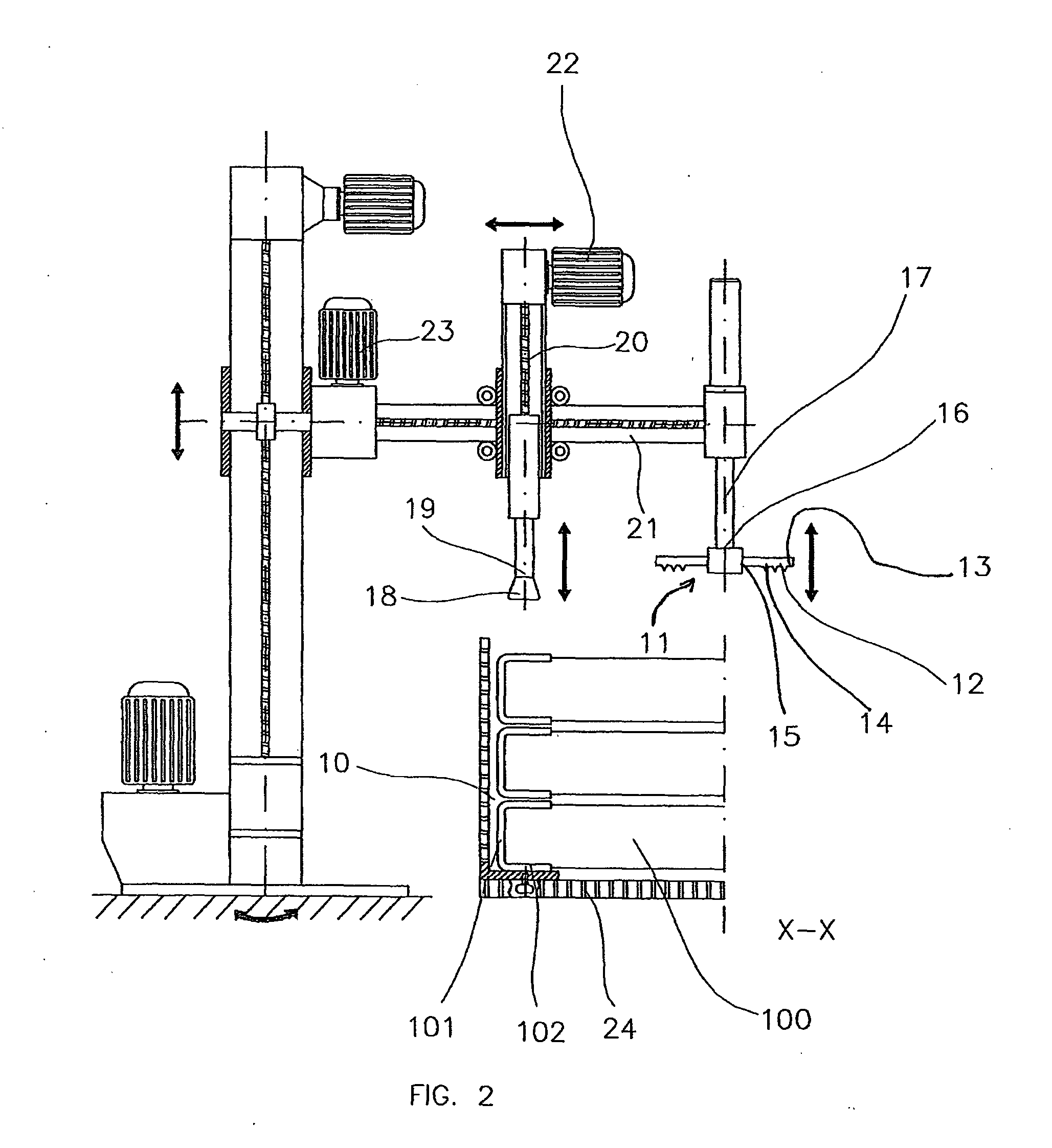

[0019]Referring to FIG. 1, the plant may comprise a plurality of workstations: the first station 1 may be an “intelligent” station in which scrap tires 100 are pre-selected and loaded into the second station 2, which may be a scrap tire 100 disgregating station, possibly having a device, e.g., a Water Jet device, for disgregating the rubber and fabric of the tread 101 and / or the shoulder 102 and / or means for separating the residual metal material.

[0020]The rubber and fabric disgregated into crumbs and fibers by the second station 2 may be collected with the Water Jet pump liquids in a third station 3 which provides, possibly at a later time, a (rubber or fiber) powder having a very low moisture content.

[0021]A fourth station 4 separates the rubber crumbs from the textile particles while further drying the product and conveys the rubber crumbs to a fifth screening station 5, in which the crumbs are separated according to their size.

[0022]A plant of this type provides an unprecedented...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shape | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com