Technology for treating spent tyre and its used equipment

A waste tire and process technology, applied in grain processing, lighting and heating equipment, applications, etc., can solve the problems of high-purity rubber, not providing practical guarantee, not being specific enough, and not providing high-purity fine rubber powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

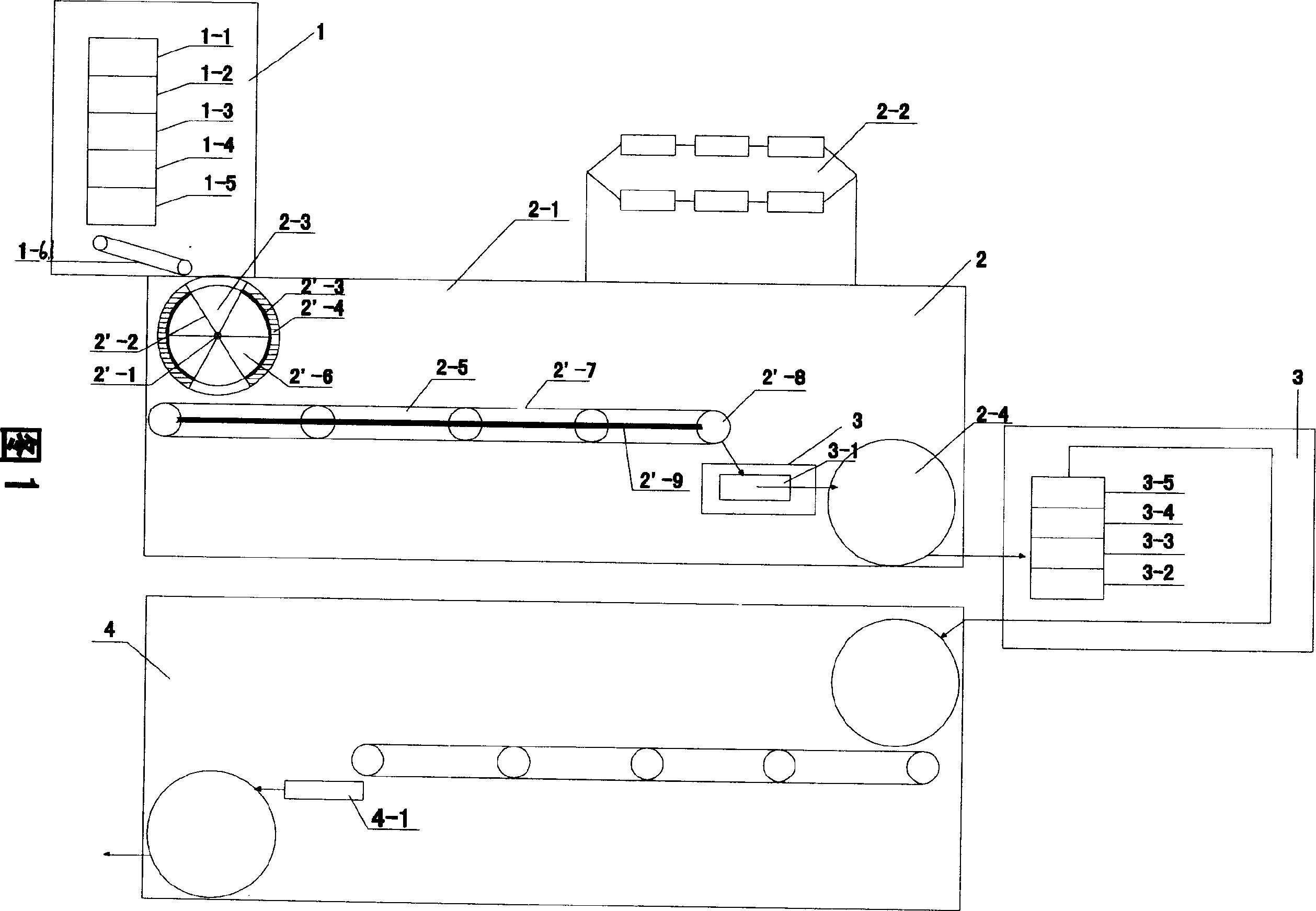

[0053] The present invention is specifically described below in conjunction with accompanying drawing:

[0054] Referring to Fig. 1, the waste tires collected are put into the cleaning machine 1-1 of the pretreatment station 1 for cleaning. The washing machine for processing waste tires of the present invention is preferably a dry-cleaning washing machine controlled by a manipulator. The structure of the robot-type cleaning machine is similar to that used in car washes. A wire-nylon composite brush is mounted on the arm of the robotic washer. Longer nylon fibers are arranged on the outer circle of the composite brush, and shorter steel wires are arranged on the inner circle of the composite brush. The steel wire-nylon composite brush stretches to the inner and outer surfaces of the vertically placed waste tires under the control of the manipulator, and as the composite brush rotates, the steel wires will firmly adhere to the foreign matter on the tire surface, such as soil ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com