Pneumatic rubber cutting device

A rubber and cutting technology, which is applied in transportation and packaging, metal processing, winding strips, etc., can solve the problems of poor flexibility, high energy consumption, and poor cutting length accuracy, so as to improve production efficiency and high cutting accuracy , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

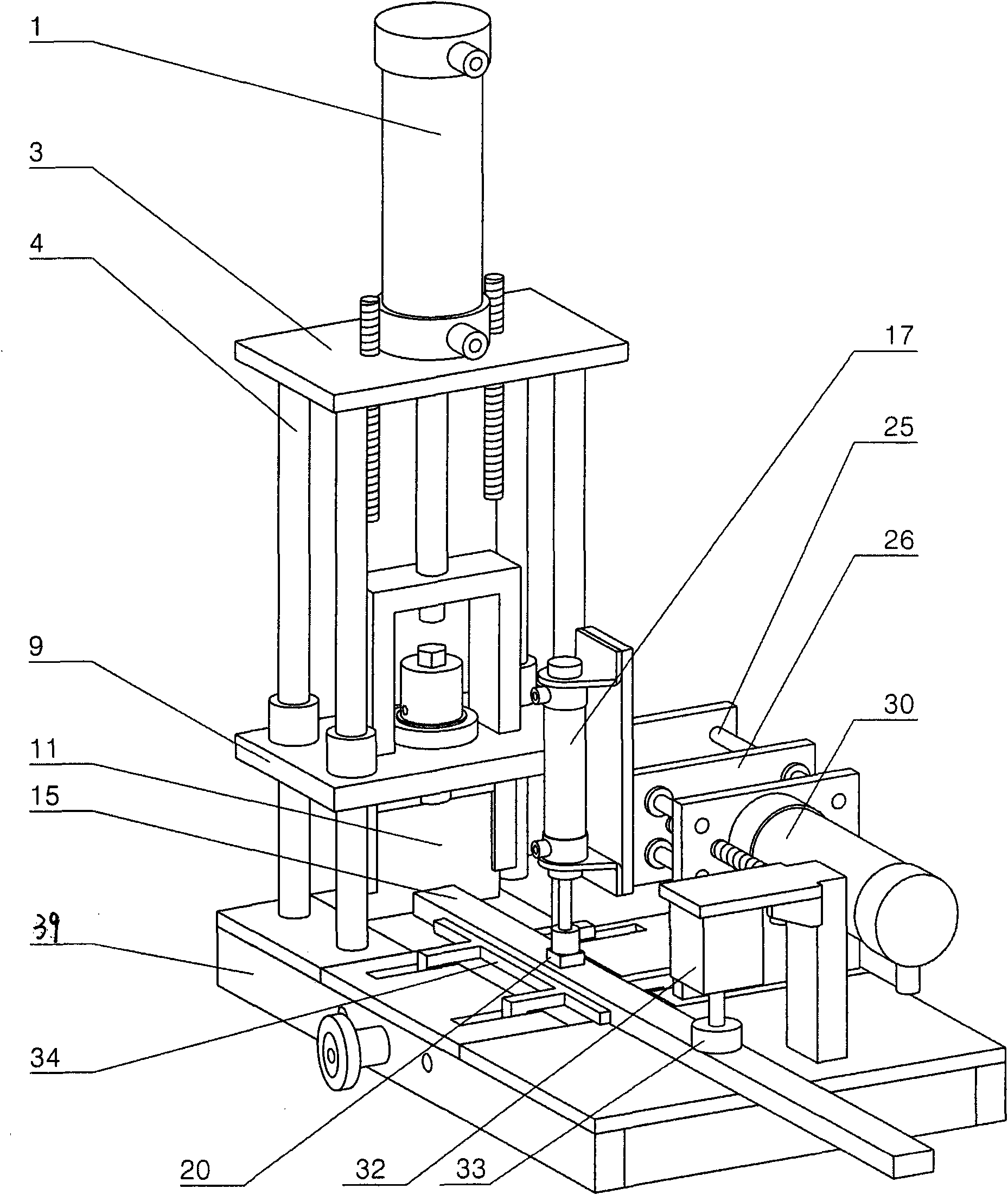

[0021] Such as figure 1 As shown, the present embodiment consists of a frame, a frame panel, a cutter mechanism, a push structure, a pressing mechanism, a limit mechanism, a base, an air control system, and an electric control system. The above-mentioned cutter mechanism bottom plate 13, air distribution Panel 18 , cover plate 21 , pushing mechanism bottom plate 22 and pressing mechanism bottom plate 23 constitute the frame panel together, and are installed on the frame 39 together. The power sources are respectively corresponding cylinders.

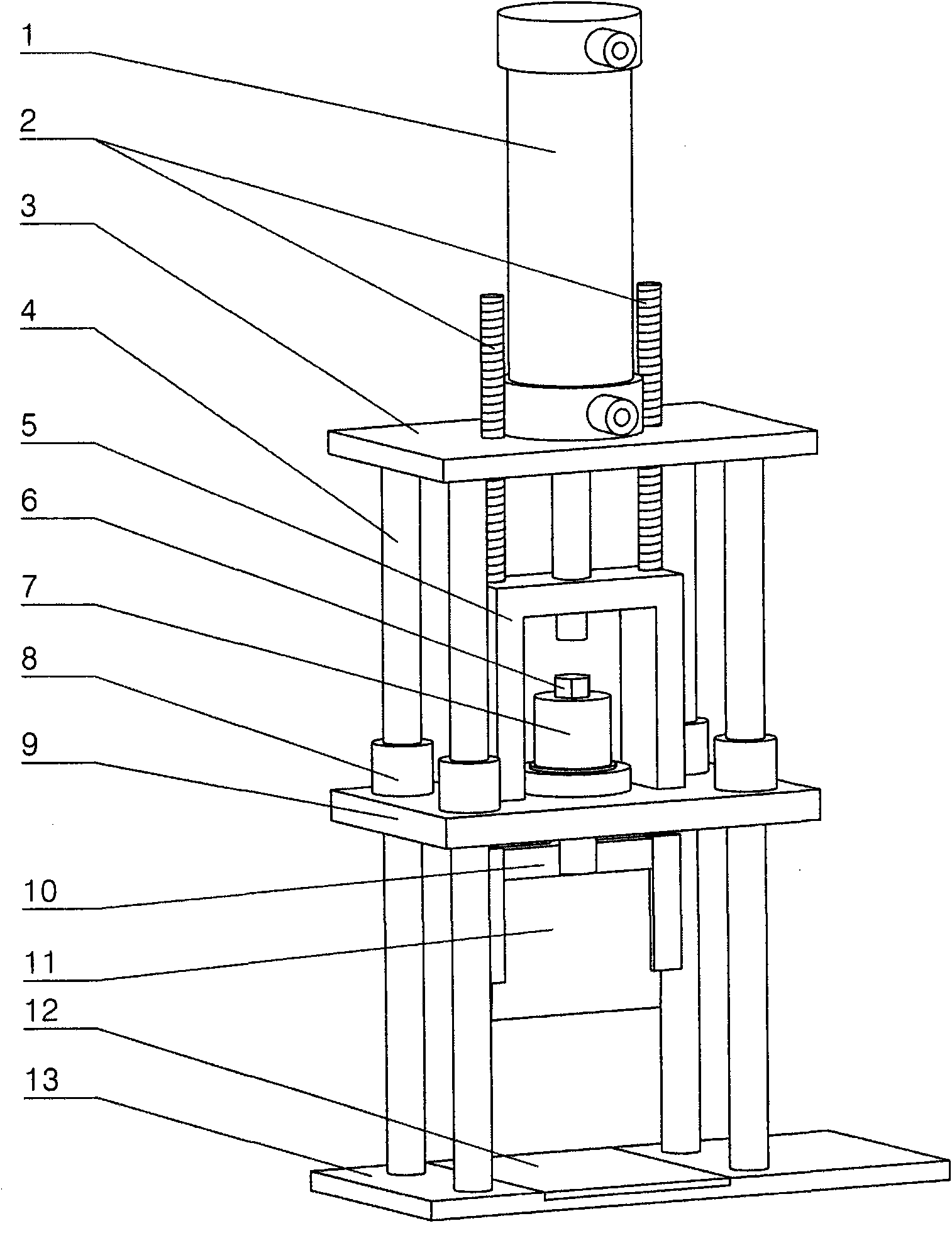

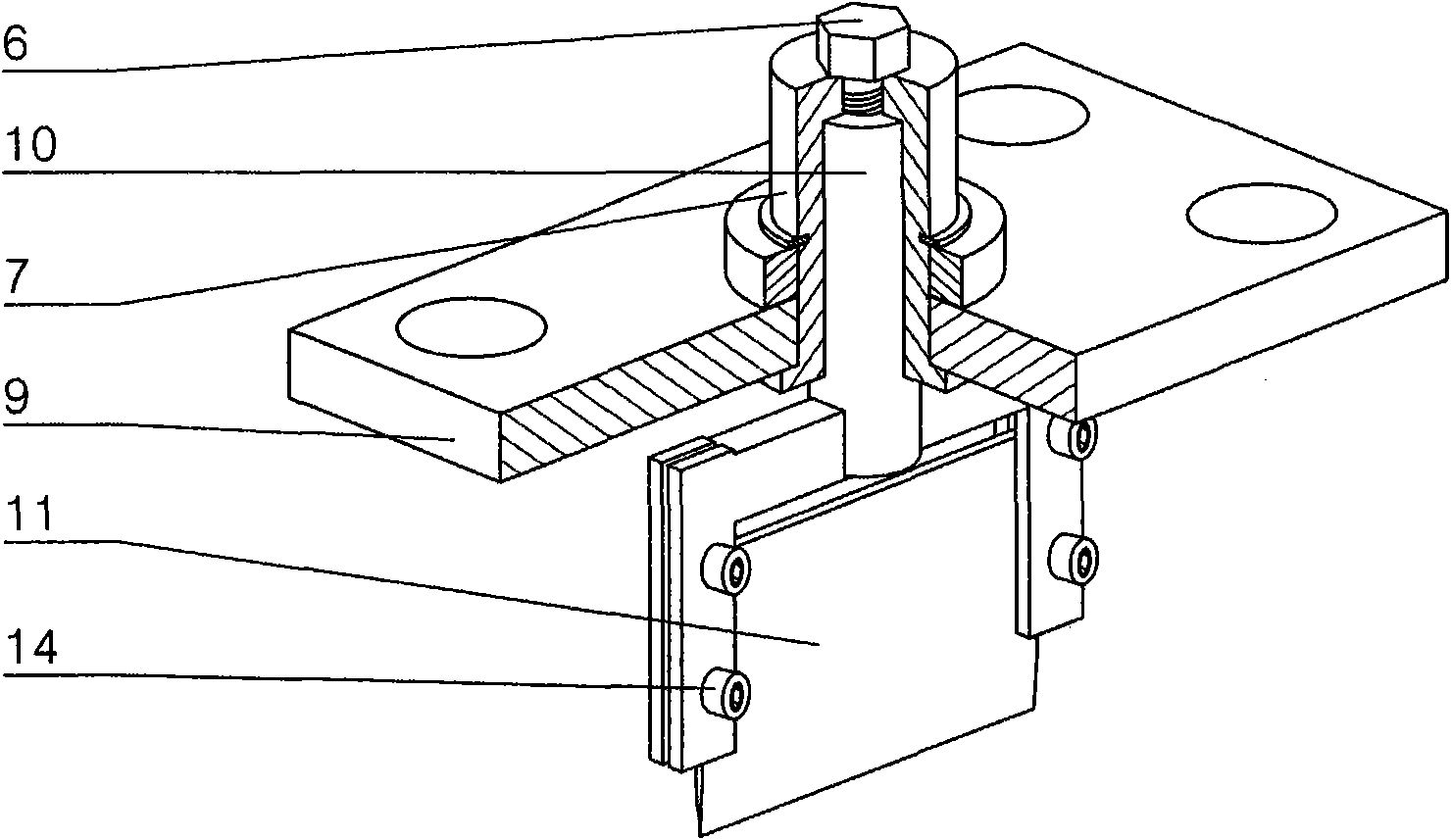

[0022] Such as figure 2 As shown, the described cutter mechanism is: the cutter cylinder frame is fixed on the frame panel, the cutter cylinder 1 is fixed on the cutter cylinder frame, and the piston head of the cutter cylinder 1 fixes the cutter 11. Specifically, the cutter mechanism includes a cutter cylinder 1, and the cutter cylinder 1 is fixed on the cutter cylinder fixed plate 3, and its cutter cylinder piston rod stretches out ...

Embodiment 2

[0044] In this embodiment, a polyurethane rubber or polytetrafluoroethylene material cutter backing plate 12 is fixed on the bottom plate 13 of the cutter mechanism facing the cutter 11. When the cutter cylinder 1 stretches out to the limit, the cutter 11 should Can cut into the thickness of cutter backing plate 12 about 0.2-1mm.

[0045] Other technical features and working principles are the same as in Embodiment 1.

Embodiment 3

[0047] In this example, if Figure 5 As shown, the limiting mechanism includes two symmetrically arranged limiting plates 34, two circular holes are respectively arranged on the two limiting plates 34, and two round rods 35 pass through the circular holes, and the two round rods 35 have two circular holes. End is fixed on the frame 39. Also respectively have a threaded hole on the two limiting plates 34, one end of the adjusting screw mandrel 38 is screwed in to cooperate with it, and its other end passes through the round hole at the corresponding position on the frame 39, and the adjusting handwheel 37 and the retaining ring are installed. 36, thereby constraining the axial position of the adjusting screw rod 38, and turning the adjusting hand wheel 37 can drive the limit plate 34 to adjust its axial position on the round rod 35.

[0048] Other technical features and working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com