Patents

Literature

86results about How to "Complicated to make" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Can

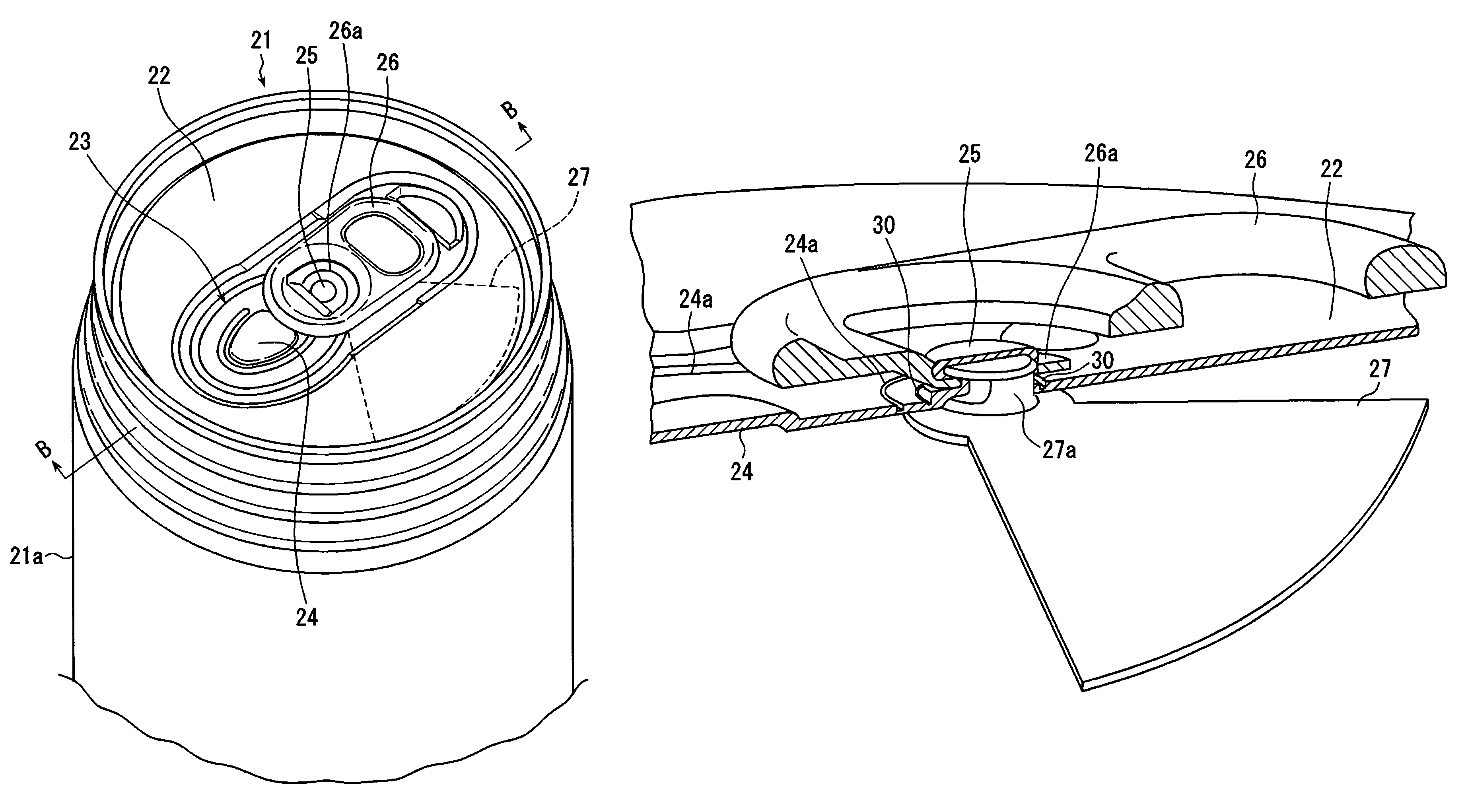

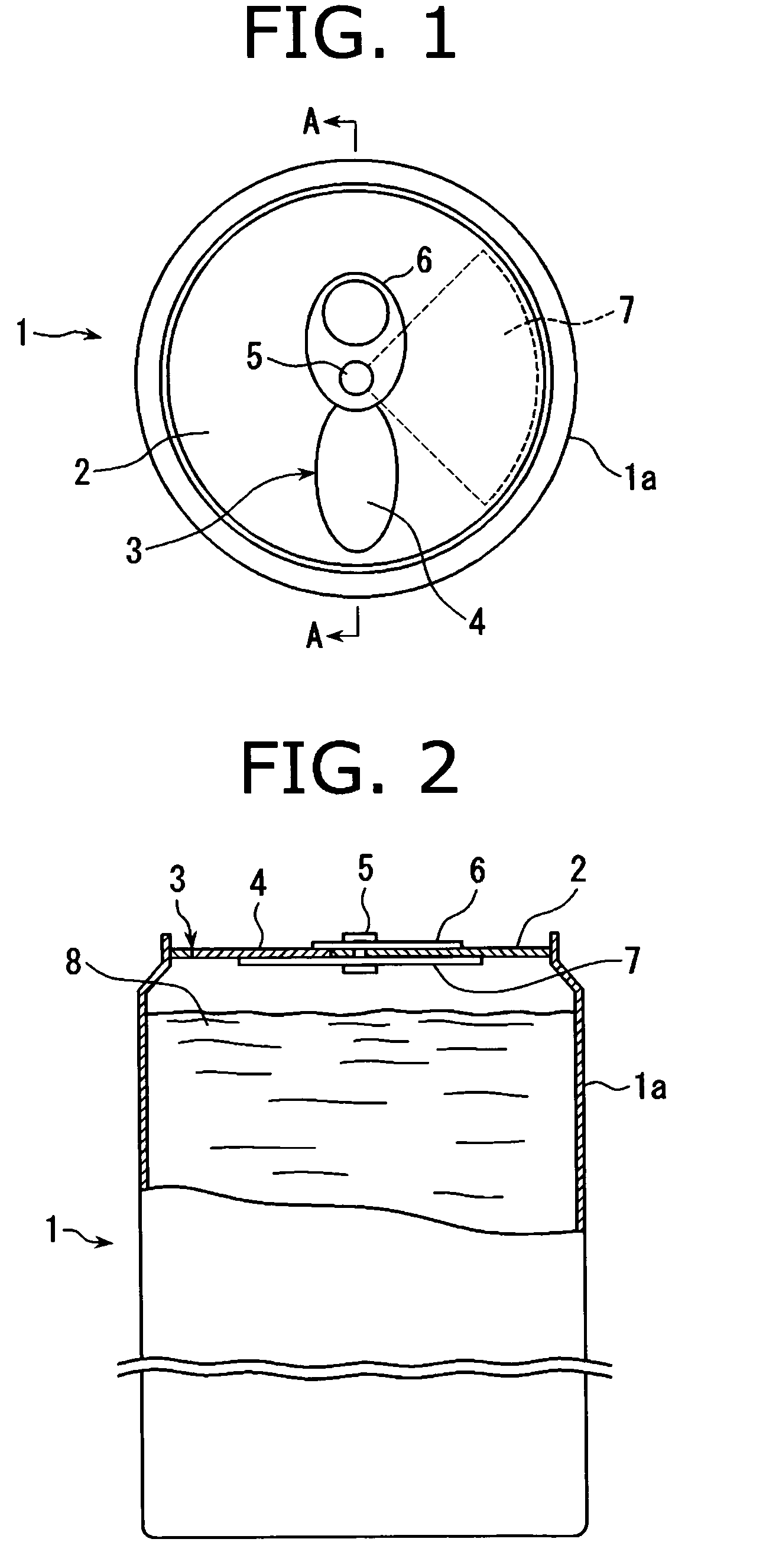

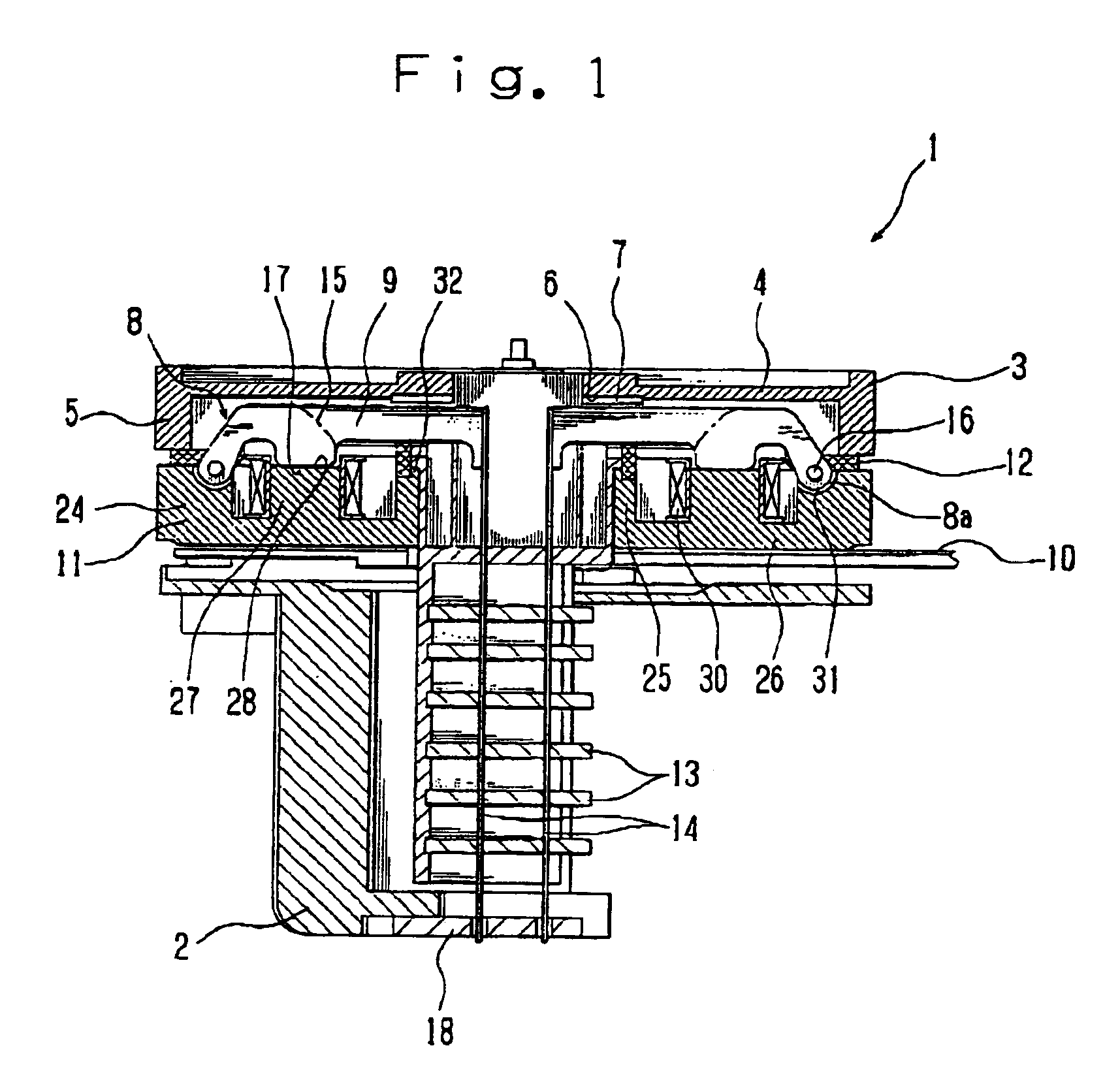

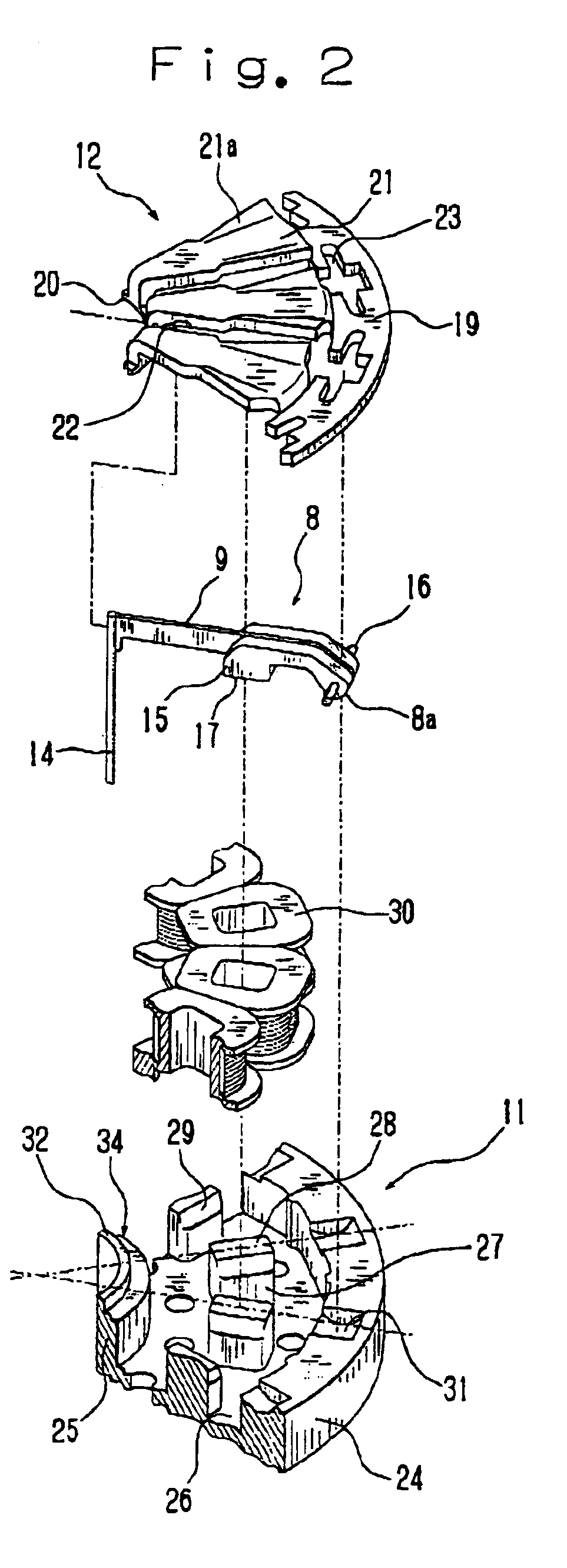

InactiveUS7198168B2Heat exchangerAvoid heat exchangeLiquid flow controllersRefuse receptaclesEngineeringRivet

A can (1) having a spout that can, after opening, be securely resealed and can be opened and closed with an easy operation. The can (1) has a spout (3) that is opened by lifting and pulling a pull-ring (6) fixed on a top wall (2) of a can body (1a) with a rivet (5) to bend a sealing tongue portion (4) toward the inside of the can. Inside the top wall (2) and away from the spout (3), an internal sealing member (7) having a fan shape with its pivot mounted to the rivet and a size capable of sealing the spout (3) is disposed so as to be fixed to the rivet (5). After opening the spout (3), by rotating the pull-ring (6) around the rivet (5), the internal sealing member (7) is also rotated at the same time. As an interlocking mechanism therefor, the rivet (5) is rotatably supported by the top wall (2), and a base end of the pull-ring (6) and the pivot of the internal sealing member (7) are fixed to the rivet (5), respectively.

Owner:MIZUMA JYUNZI +5

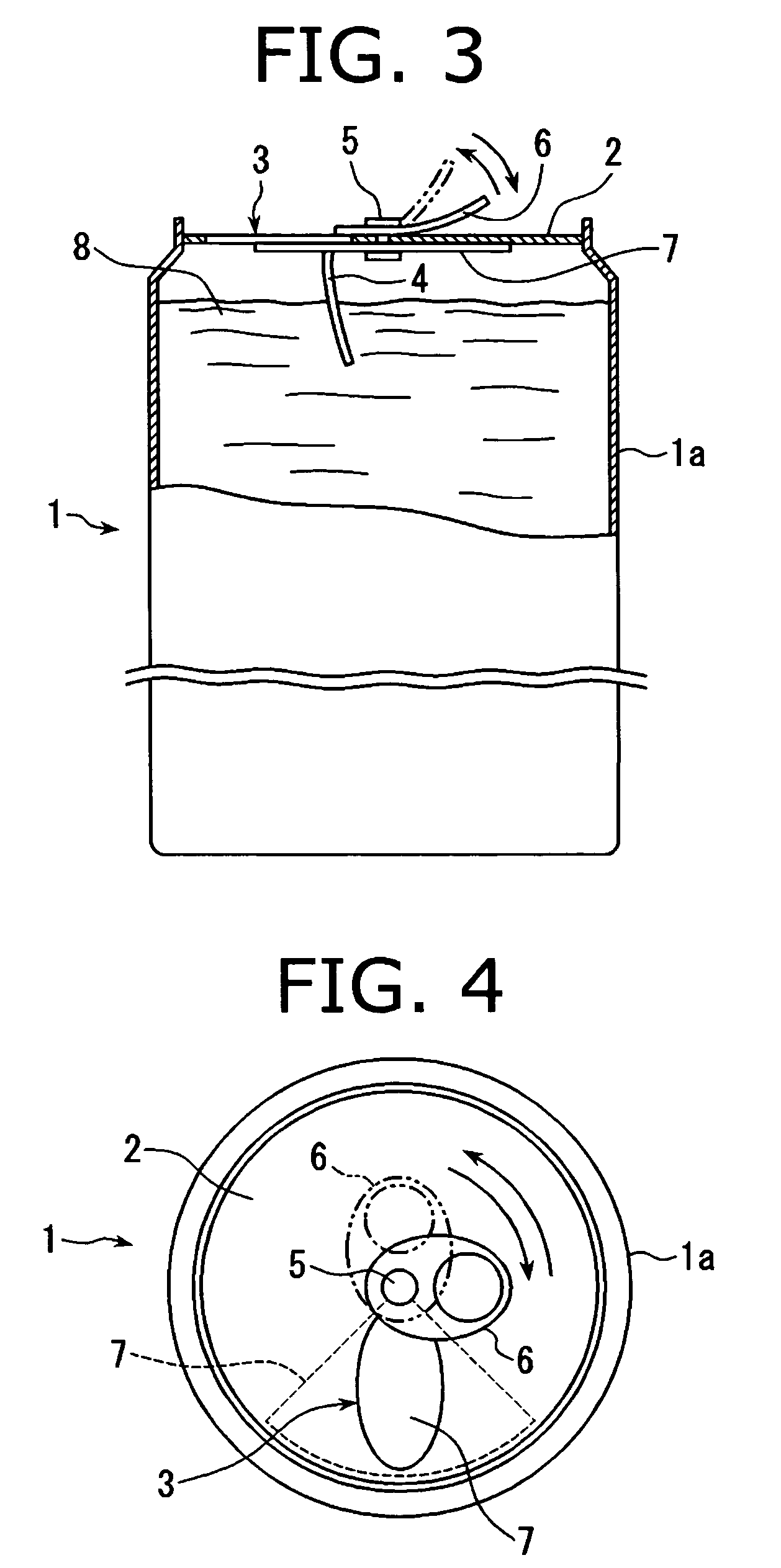

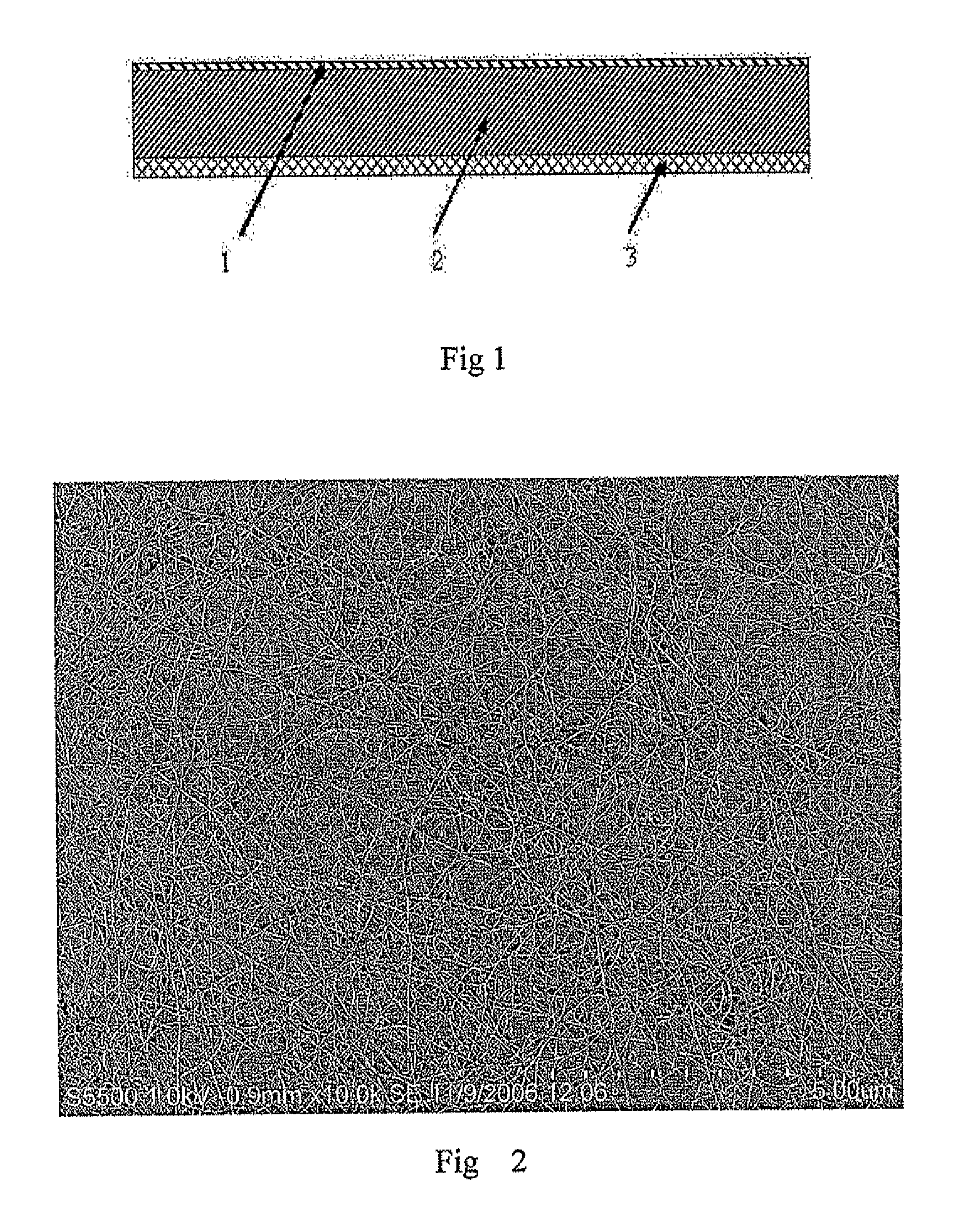

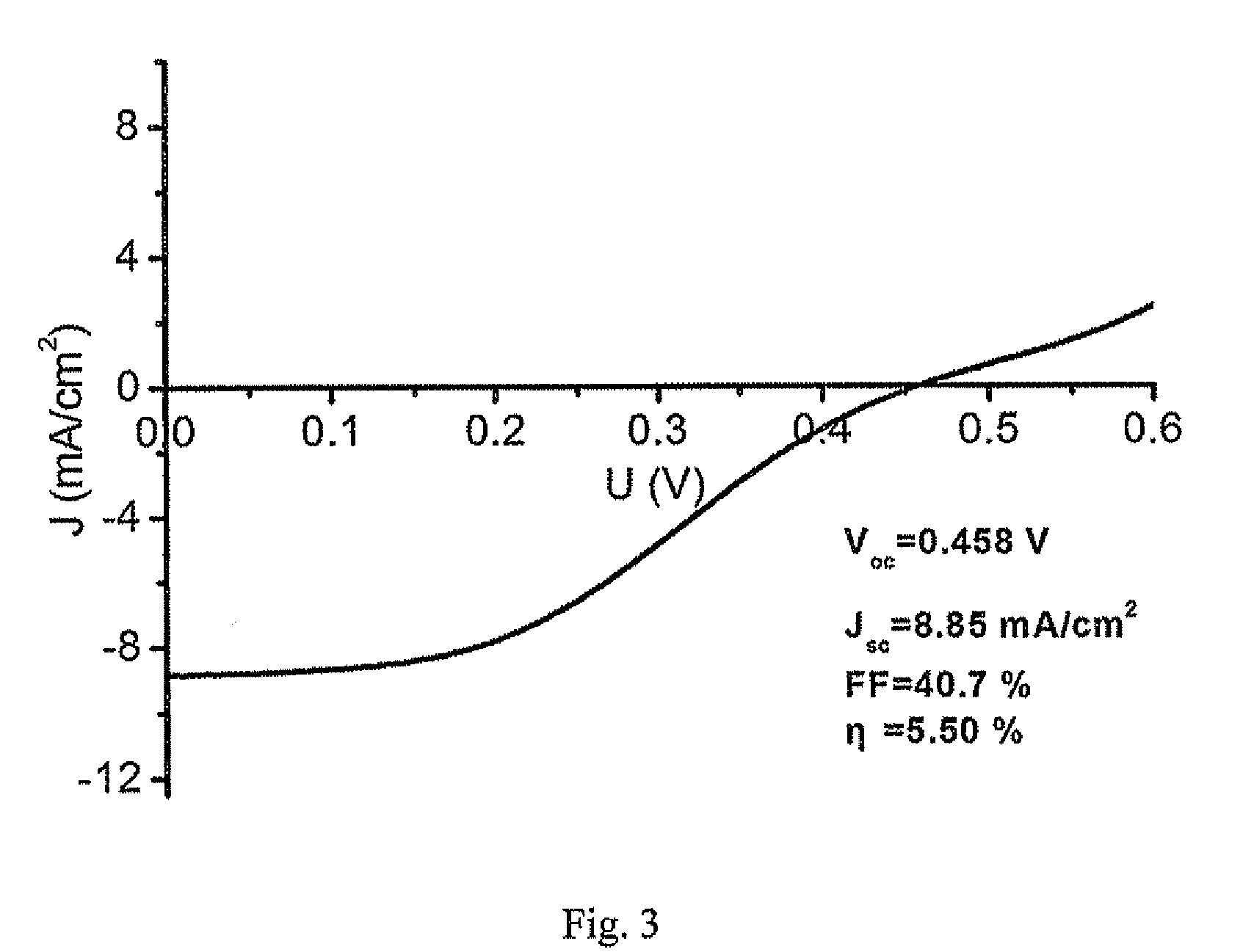

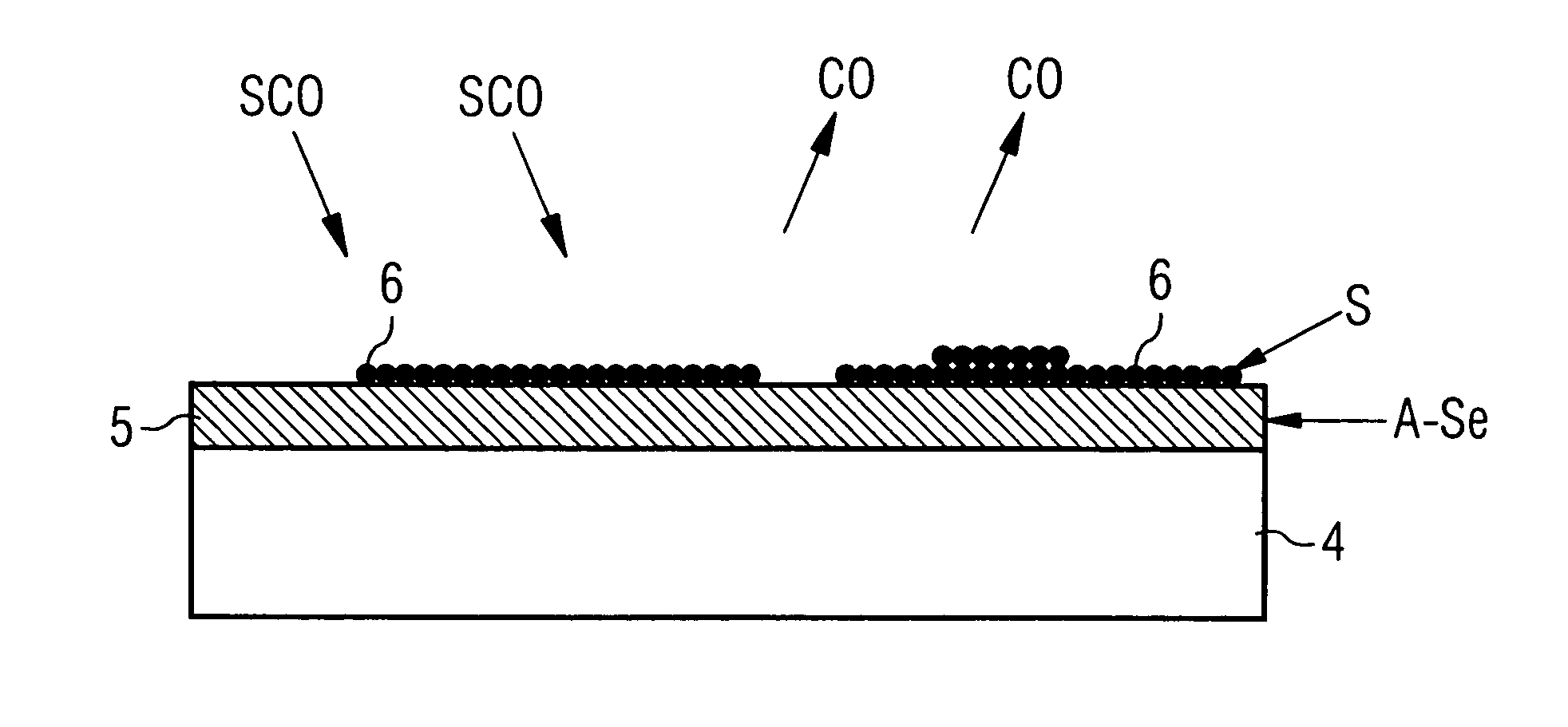

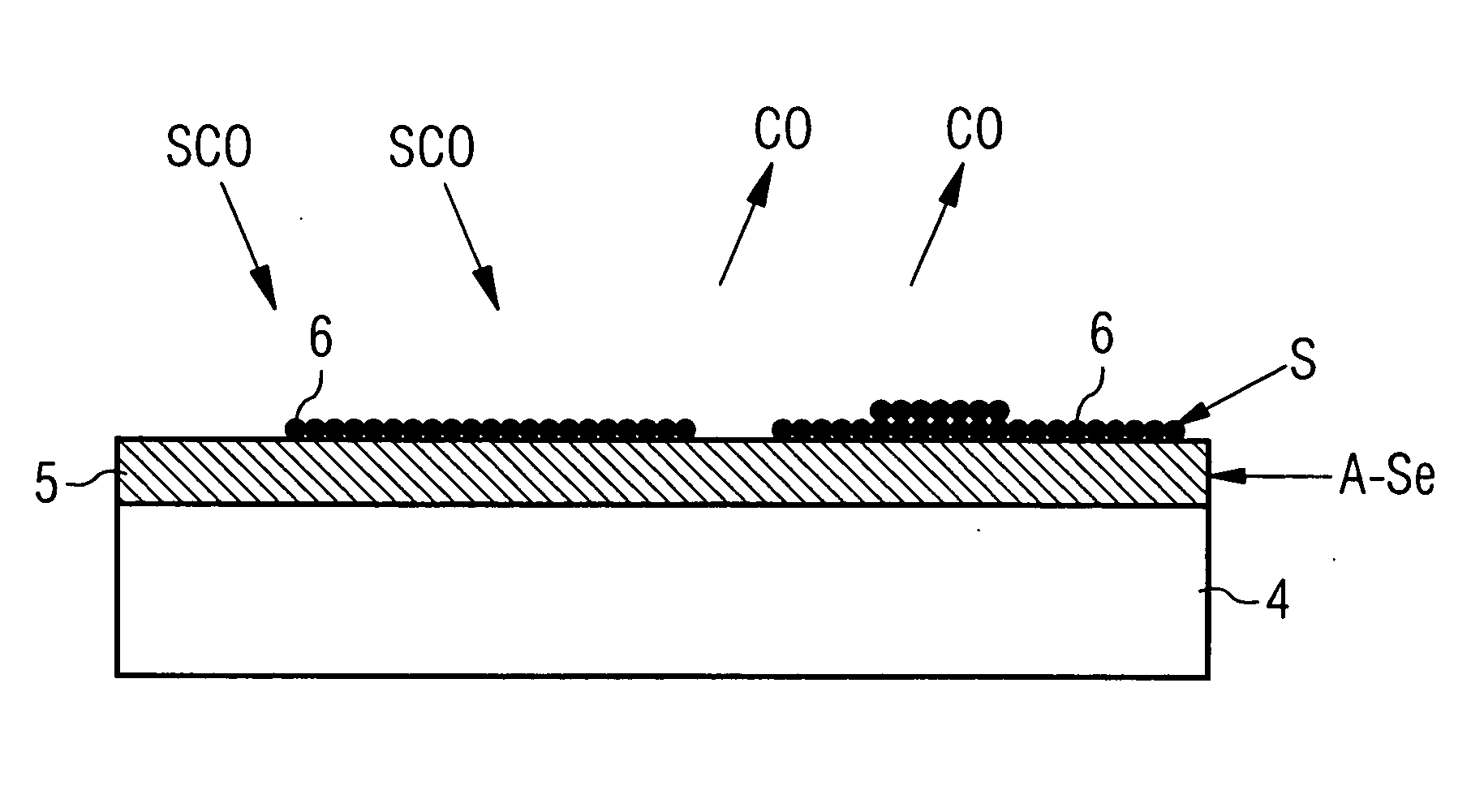

Carbon nanotube film based solar cell and fabricating method thereof

InactiveUS20100078067A1Improve conversion efficiencyWide rangeFinal product manufactureNanoinformaticsFilm baseCarbon nanotube

A carbon nanotube-based solar cell and fabricating method thereof are provided. The method is achieved by applying carbon nanotube film (1) photoelectric conversion material and an upper electrode simultaneously. The method improves photoelectric conversion efficiency and life time of the solar cell, the fabricating method of the solar cell is simple, and the fabricating cost is low.

Owner:TSINGHUA UNIV

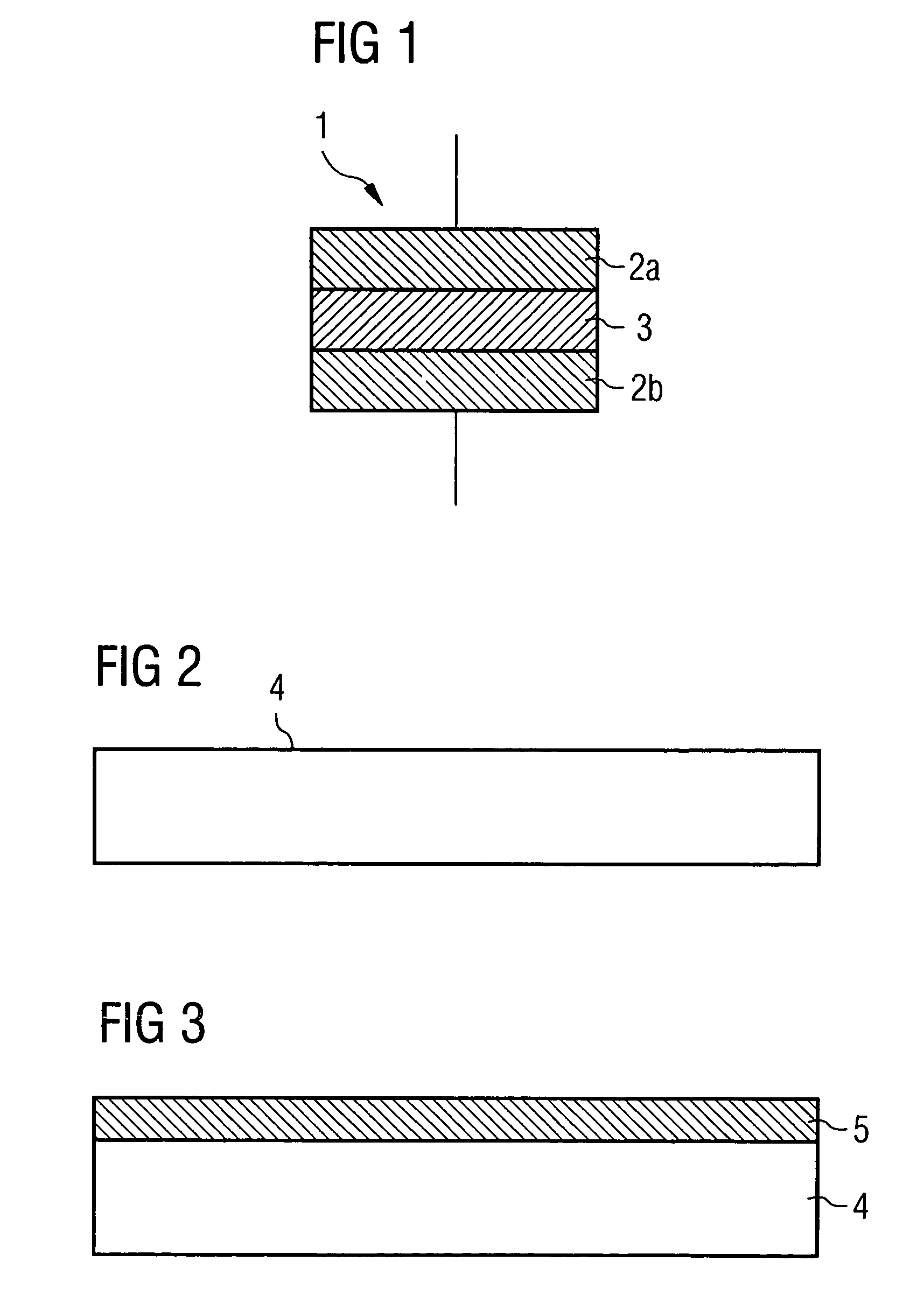

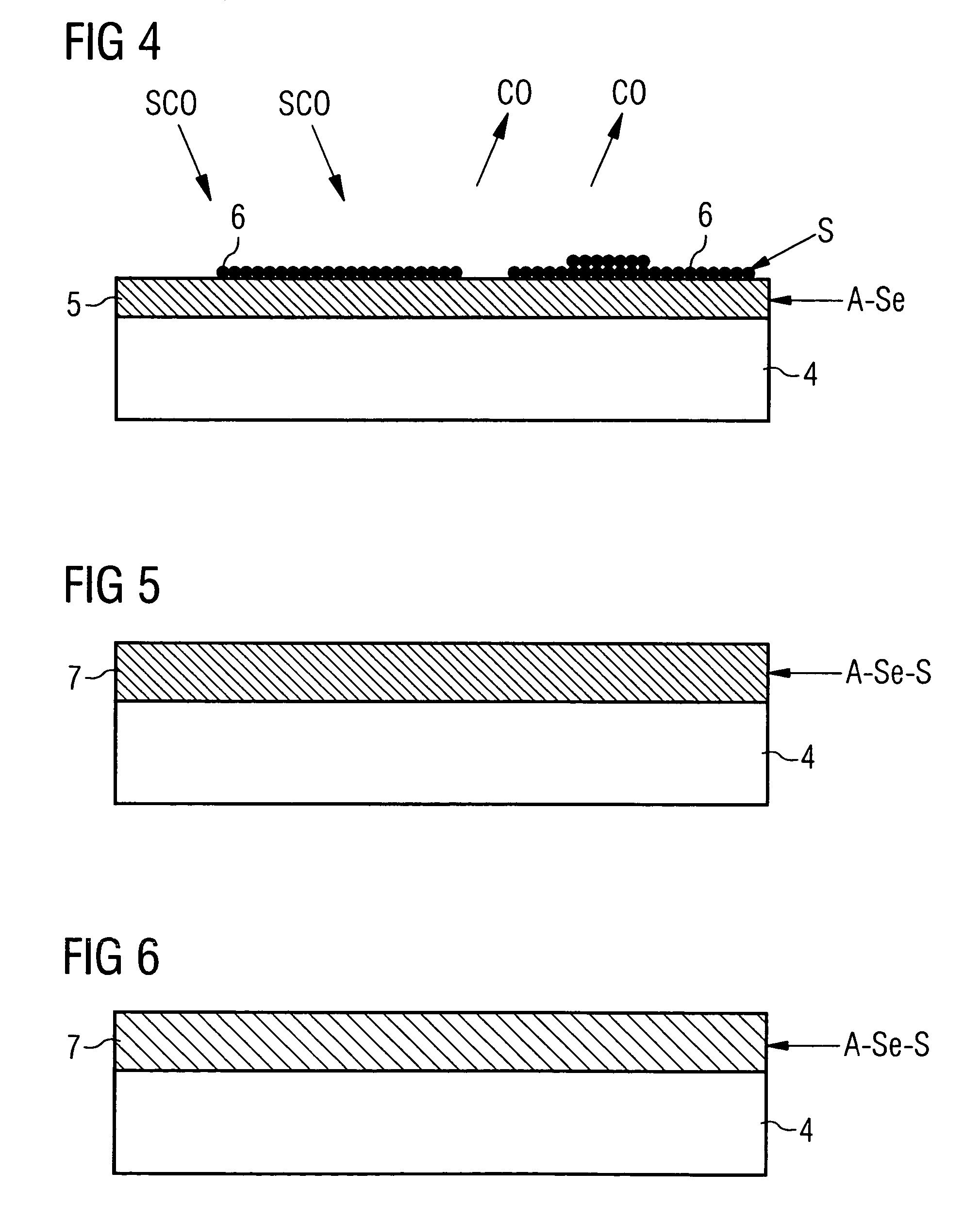

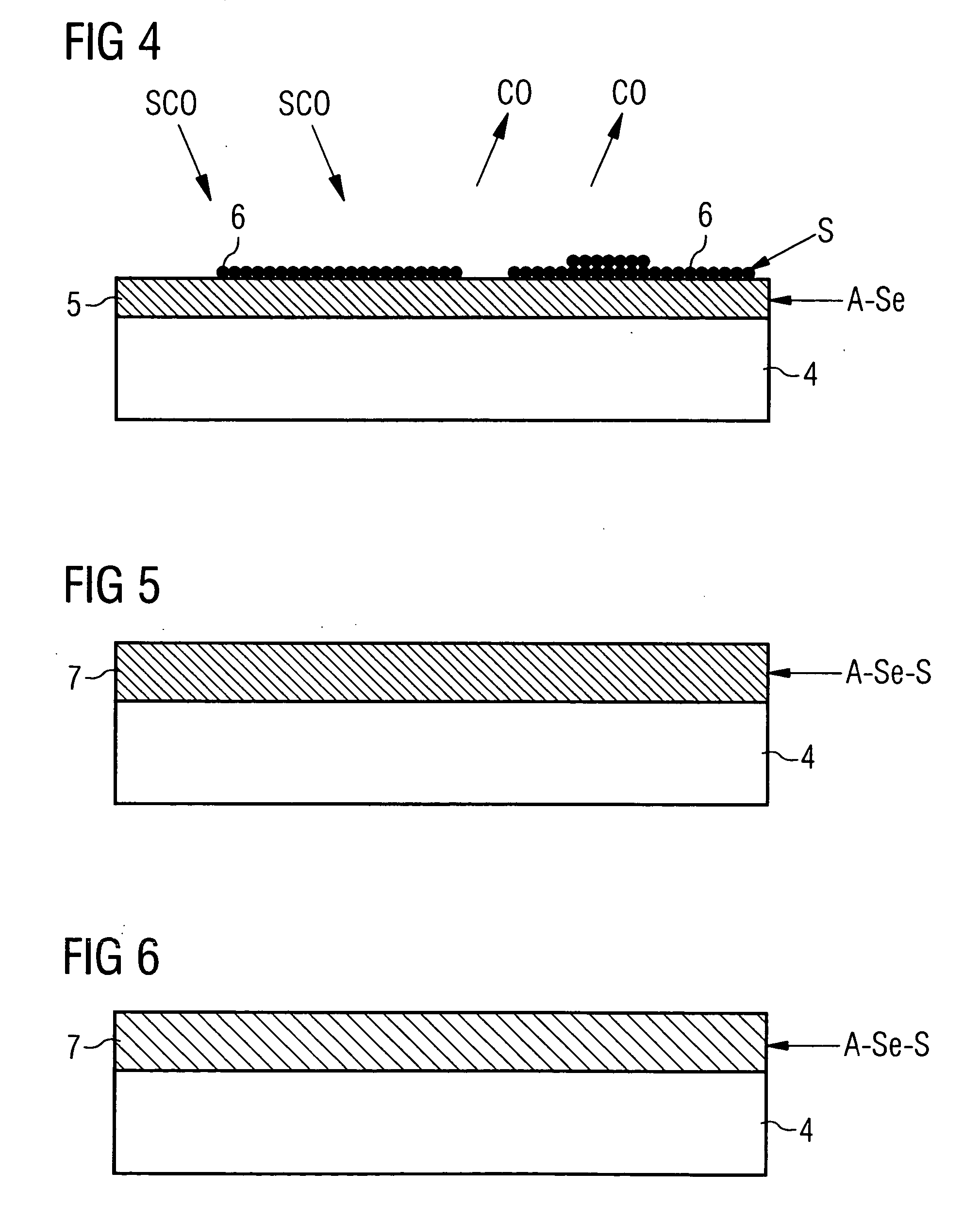

Method for manufacturing an integrated circuit including an electrolyte material layer

InactiveUS7749805B2Fast, scalable, low-voltage switching mechanismHigh switching enduranceSemiconductor/solid-state device manufacturingDigital storageEngineeringTernary chalcogenide

A method for manufacturing an electrolyte material layer with a chalcogenide material incorporated or deposited therein for use in semiconductor memory devices, in particular resistively-switching memory devices or components. The method comprises the steps of producing a semiconductor substrate, depositing a binary chalcogenide layer onto the semiconductor substrate, depositing a sulphur-containing layer onto the binary chalcogenide layer, and creating a ternary chalcogenide layer comprising at least two different chalcogenide compounds ASexSy. One component A of the chalcogenide compounds ASexSy comprises materials of the IV elements main group, e.g., Ge, Si, or of a transition metal, preferably of the group consisting of Zn, Cd, Hg, or a combination thereof.

Owner:ADESTO TECH

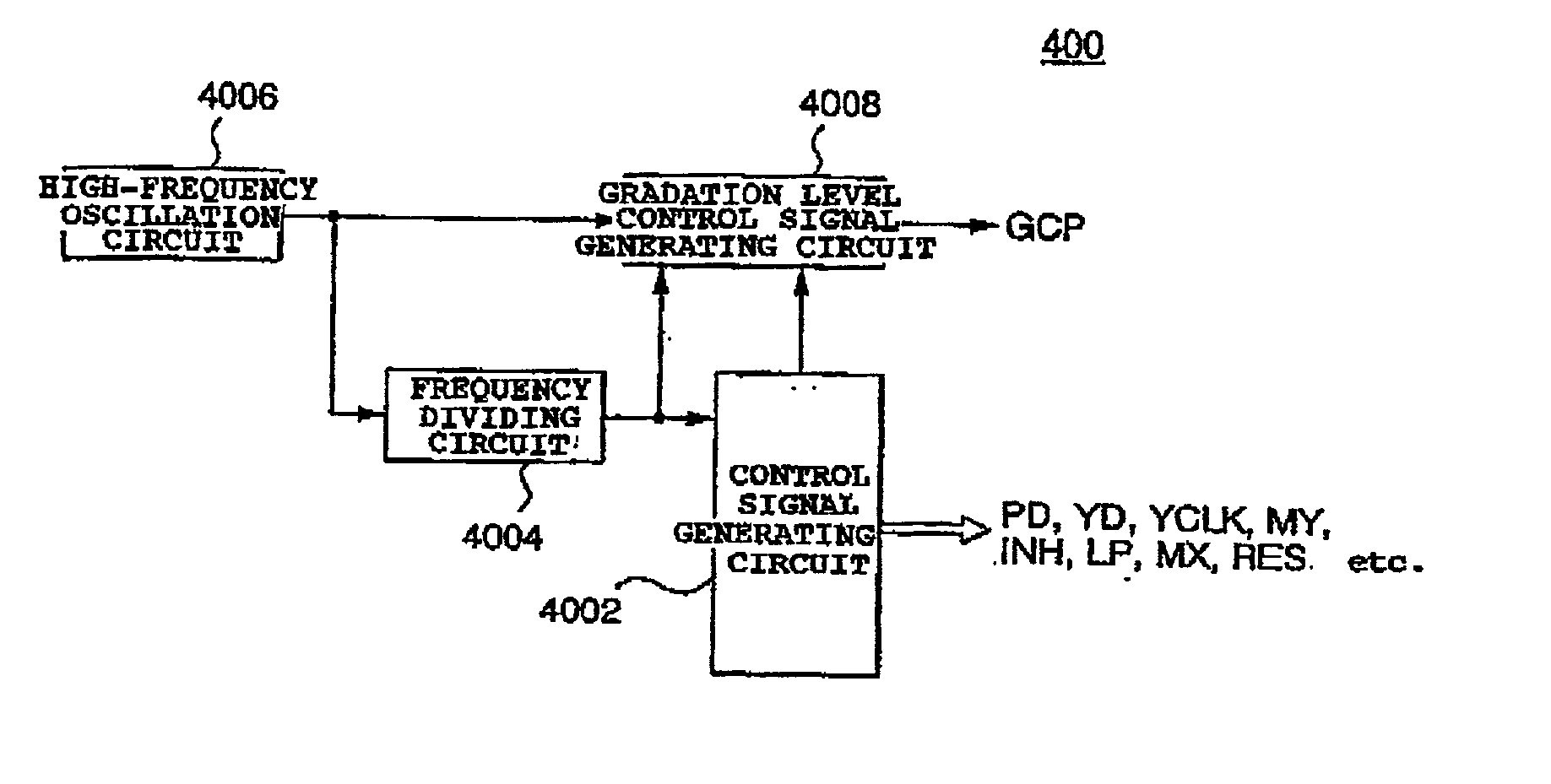

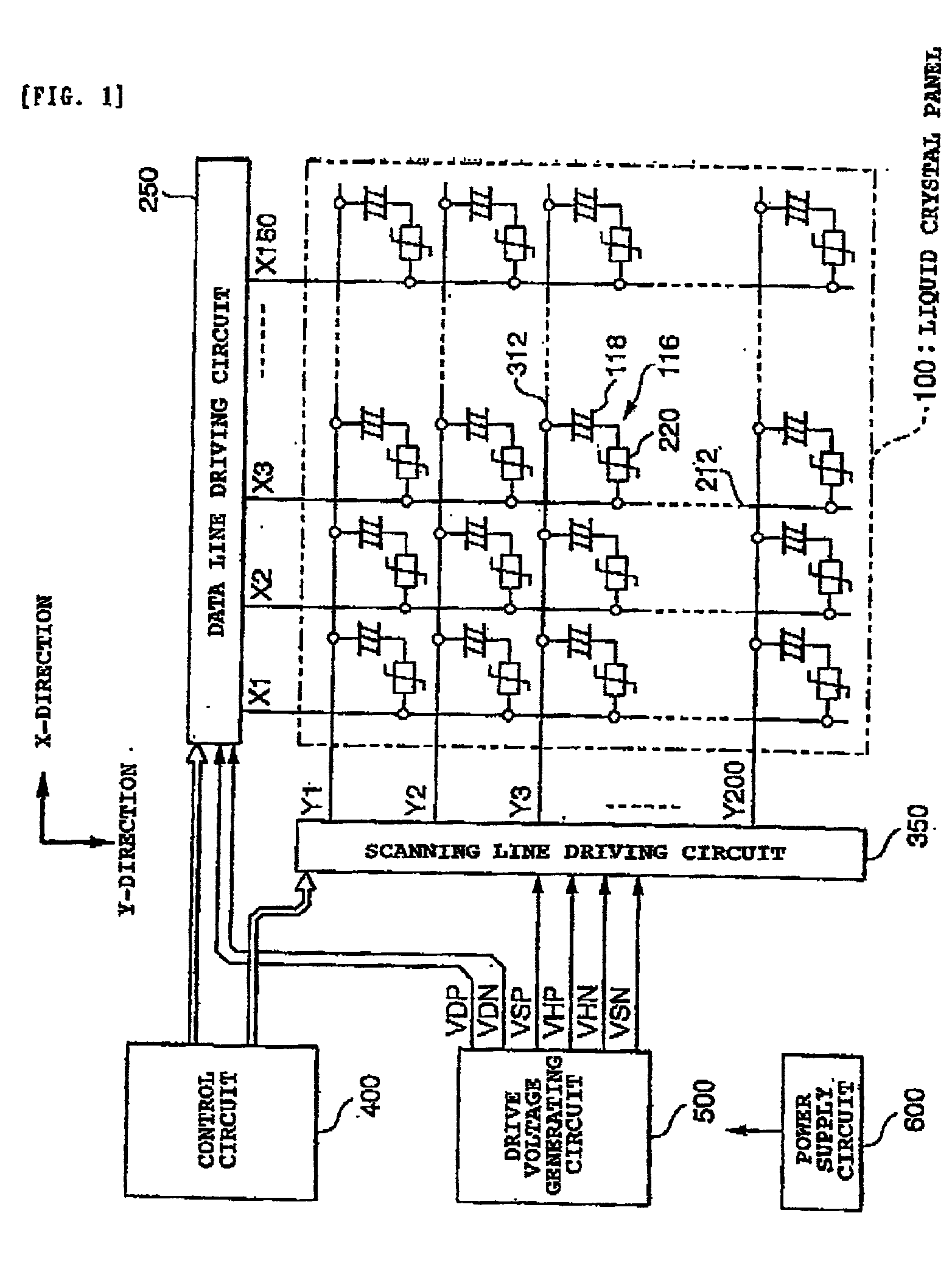

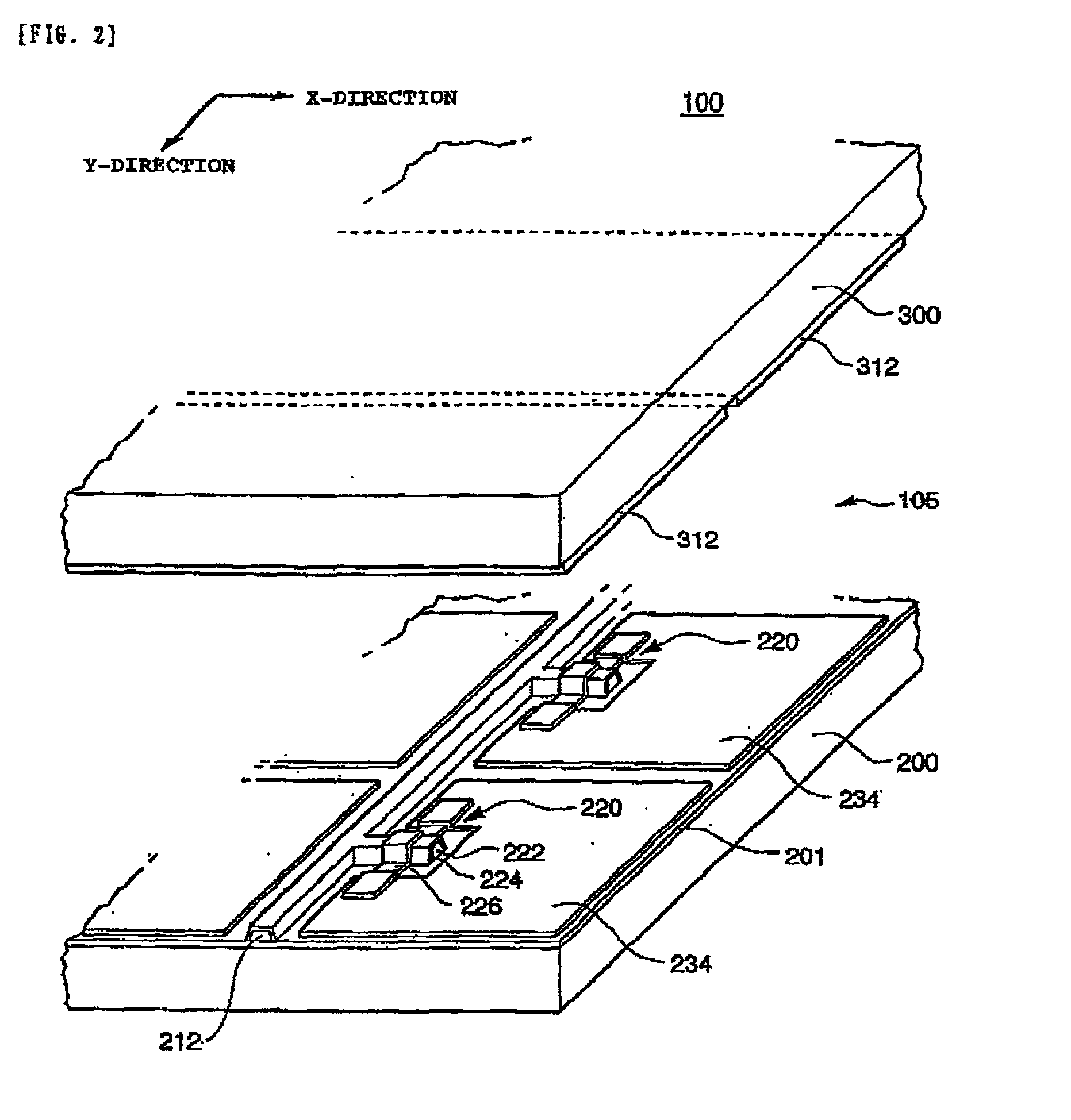

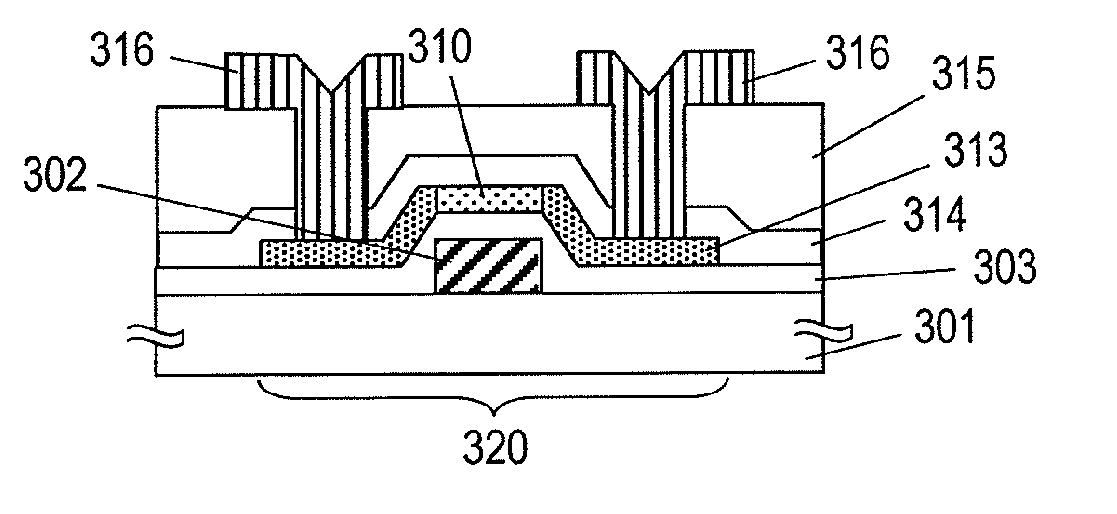

Method of driving matrix type display apparatus, display apparatus and electronic equipment

InactiveUS20020126107A1Reduce power consumptionStop operationCathode-ray tube indicatorsNon-linear opticsElectrical polarityEngineering

It is to manage both the reduction of power consumption and the enhancement of quality of picture when a partial display operation is performed. A scanning line driving circuit 350 supplies each of scanning lines 312 in a display region with selection signals in a second half part of one horizontal scanning time period and with non-selection signals in the rest thereof by inverting the polarity every vertical scanning time period. Further, the scanning line driving circuit 350 supplies each of scanning lines 312 in a non-display region with non-selection signals by inverting the polarity every one or more vertical scanning time periods. A data line driving circuit 250 supplies each of data lines 212 with a signal representing a positive-side voltage level VDP and a signal representing a negative-side voltage level VDN in first and second half parts of a horizontal scanning time period, respectively, for a period of time of the same length in the case that a scanning line 312 in a display region is selected. Furthermore, the data line driving circuit 250 supplies each of data lines 212 alternately with a signal representing the positive-side voltage level VDP and a signal representing the negative-side voltage level VDN every one or more horizontal scanning time period.

Owner:SEIKO EPSON CORP

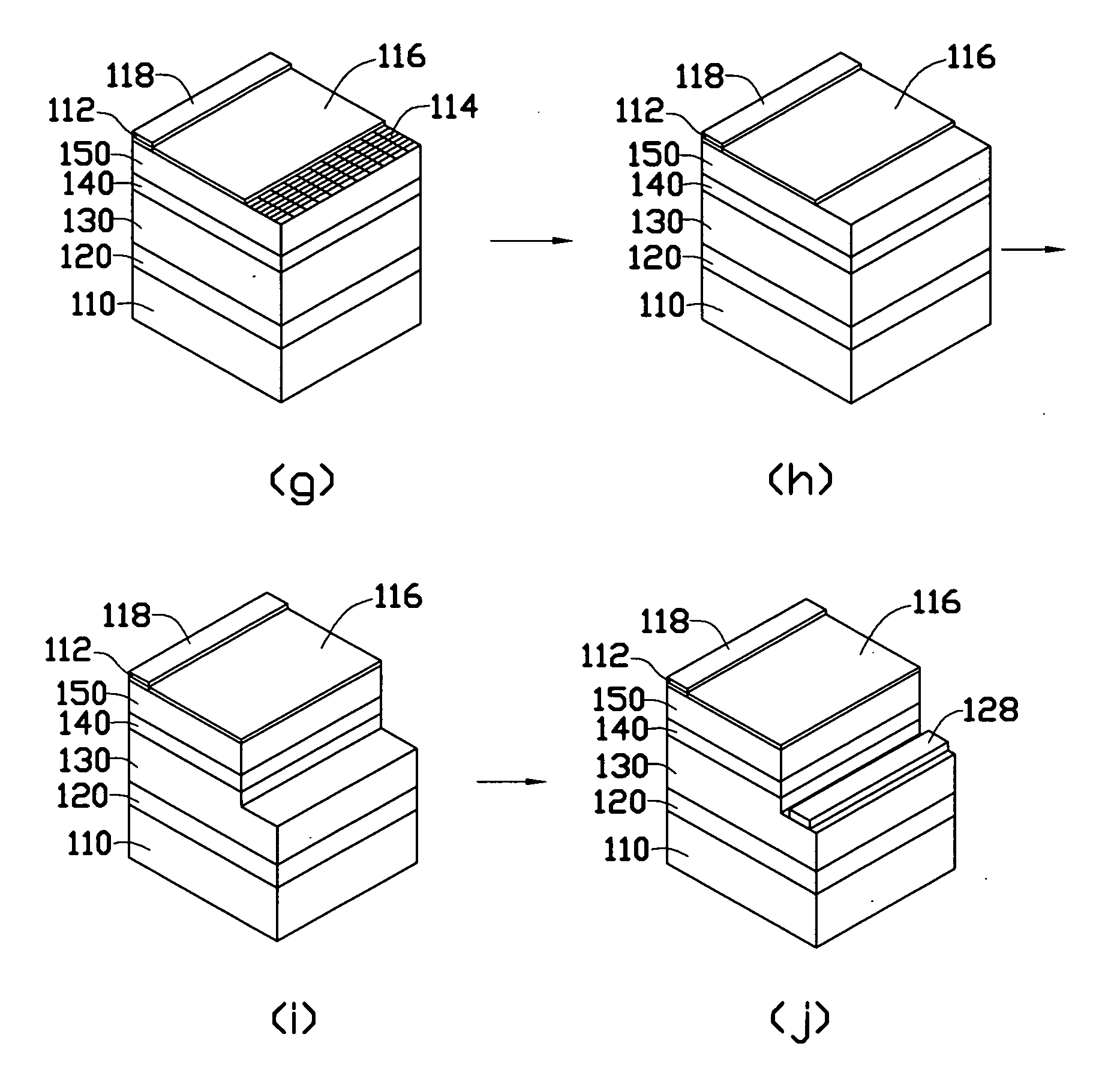

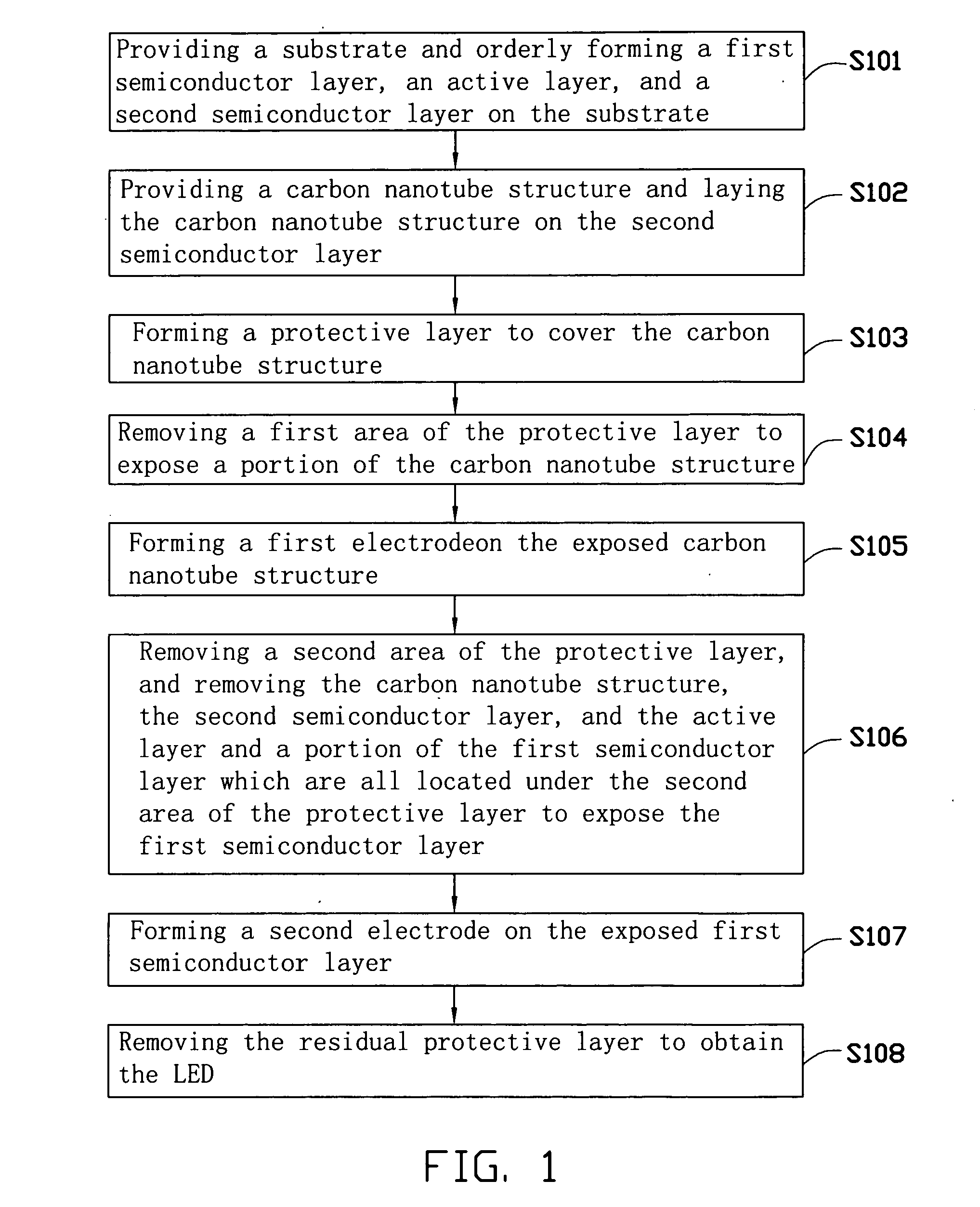

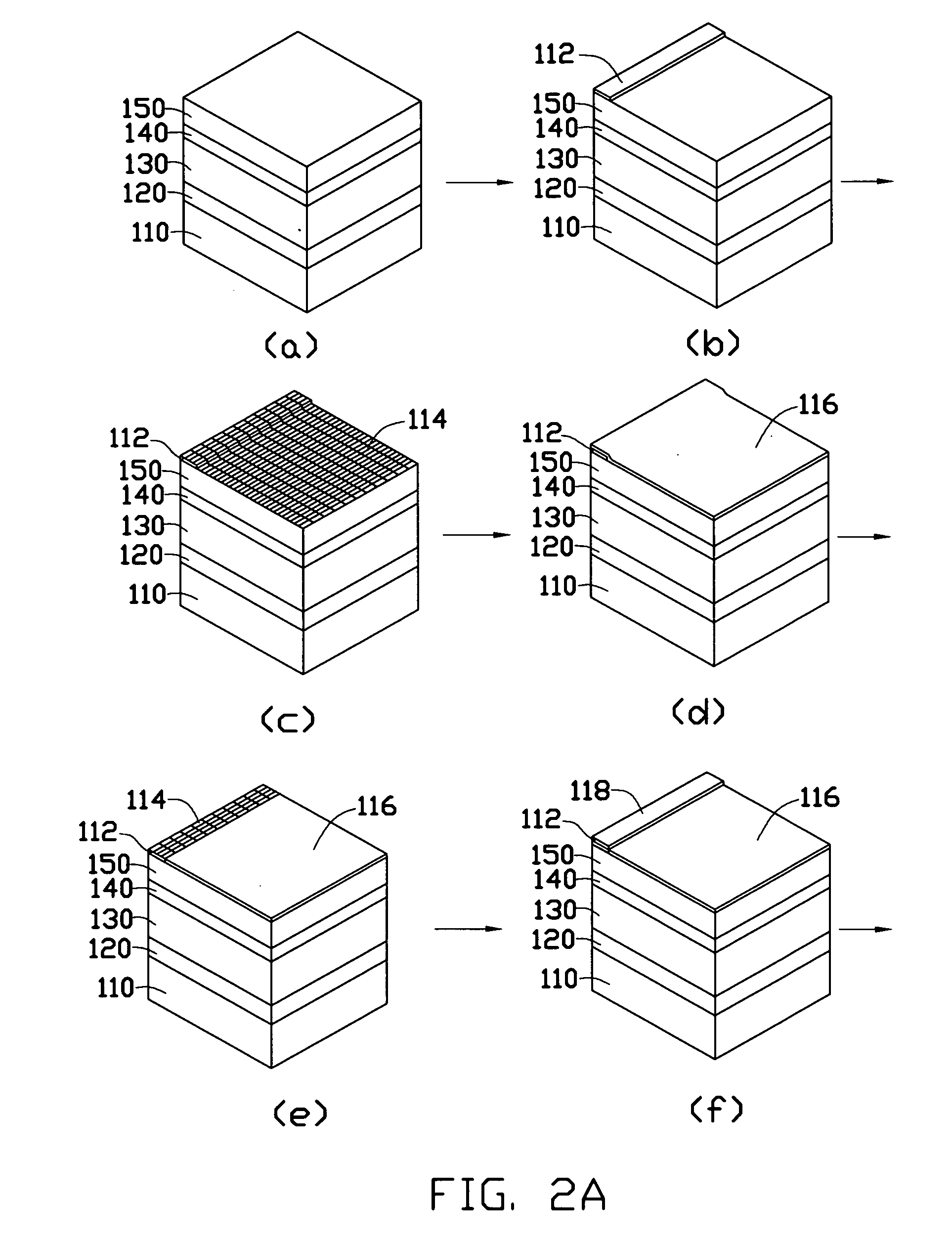

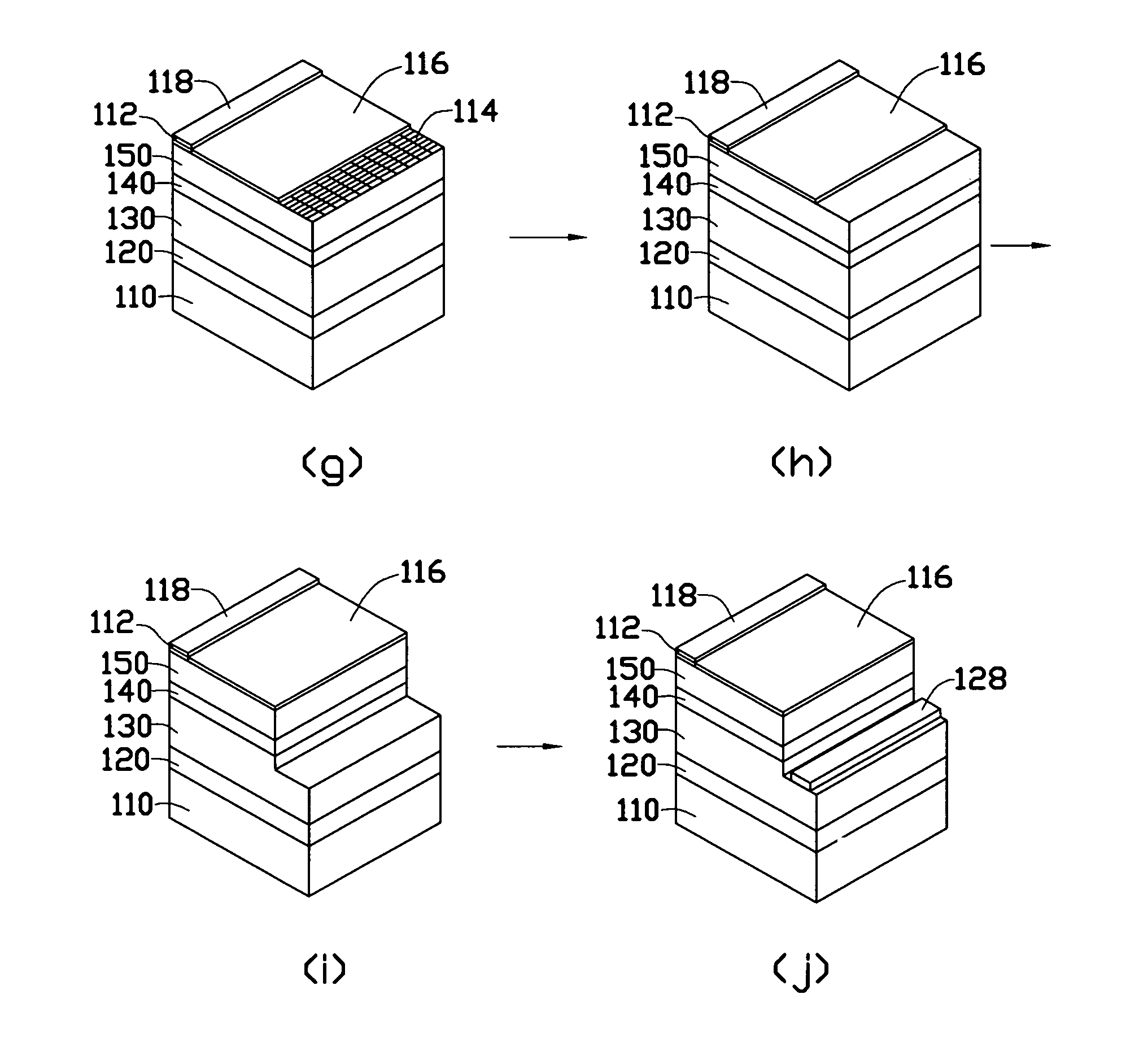

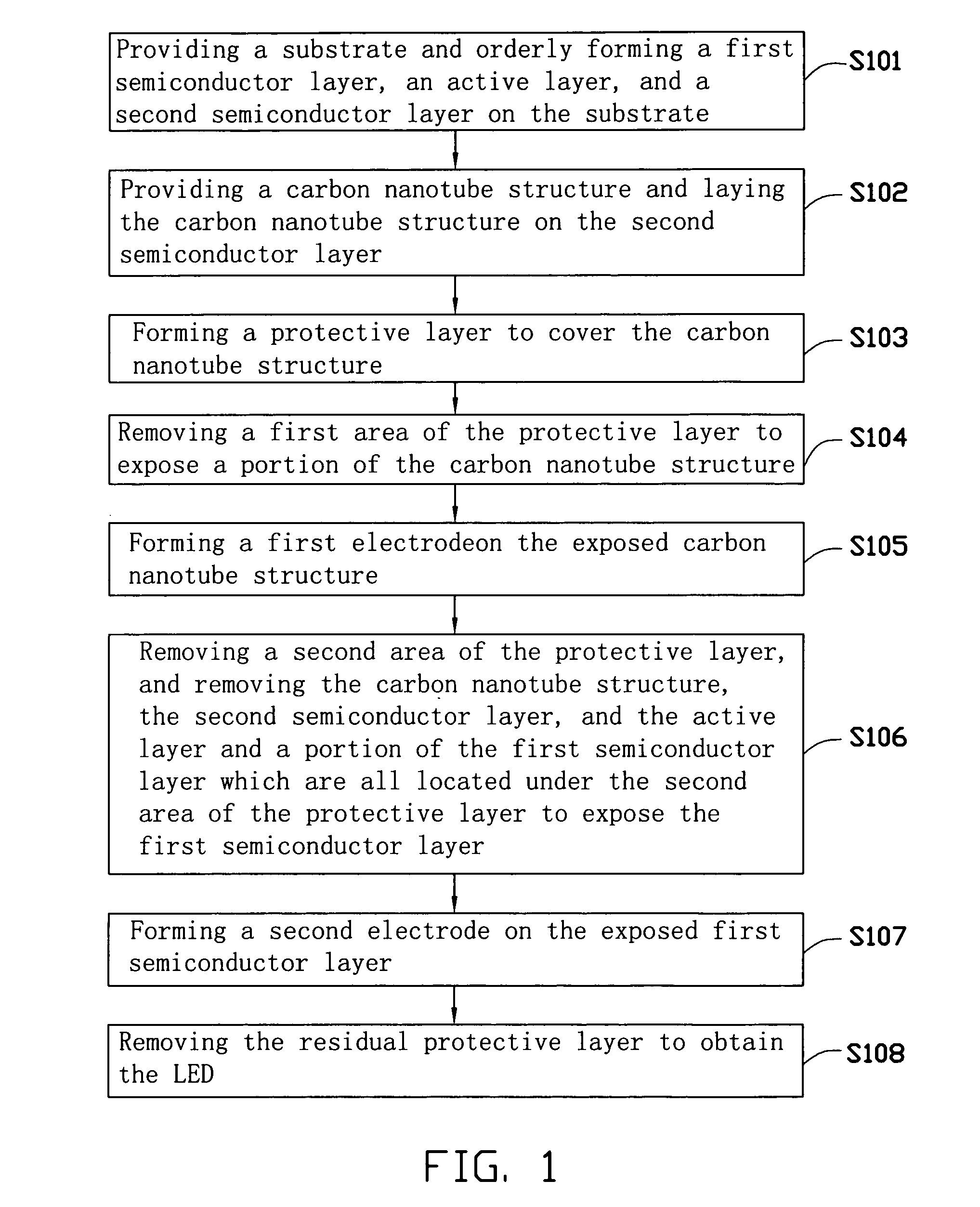

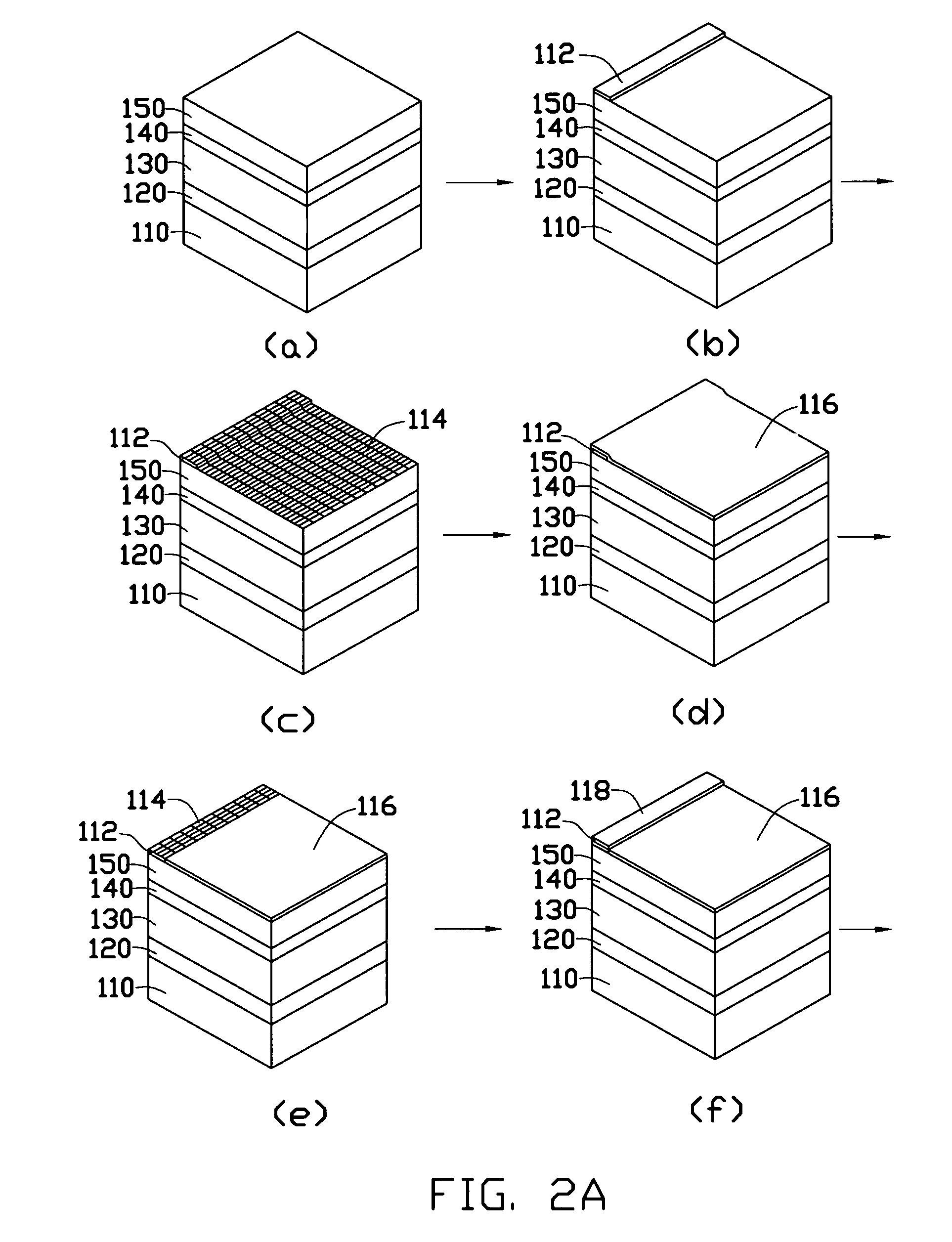

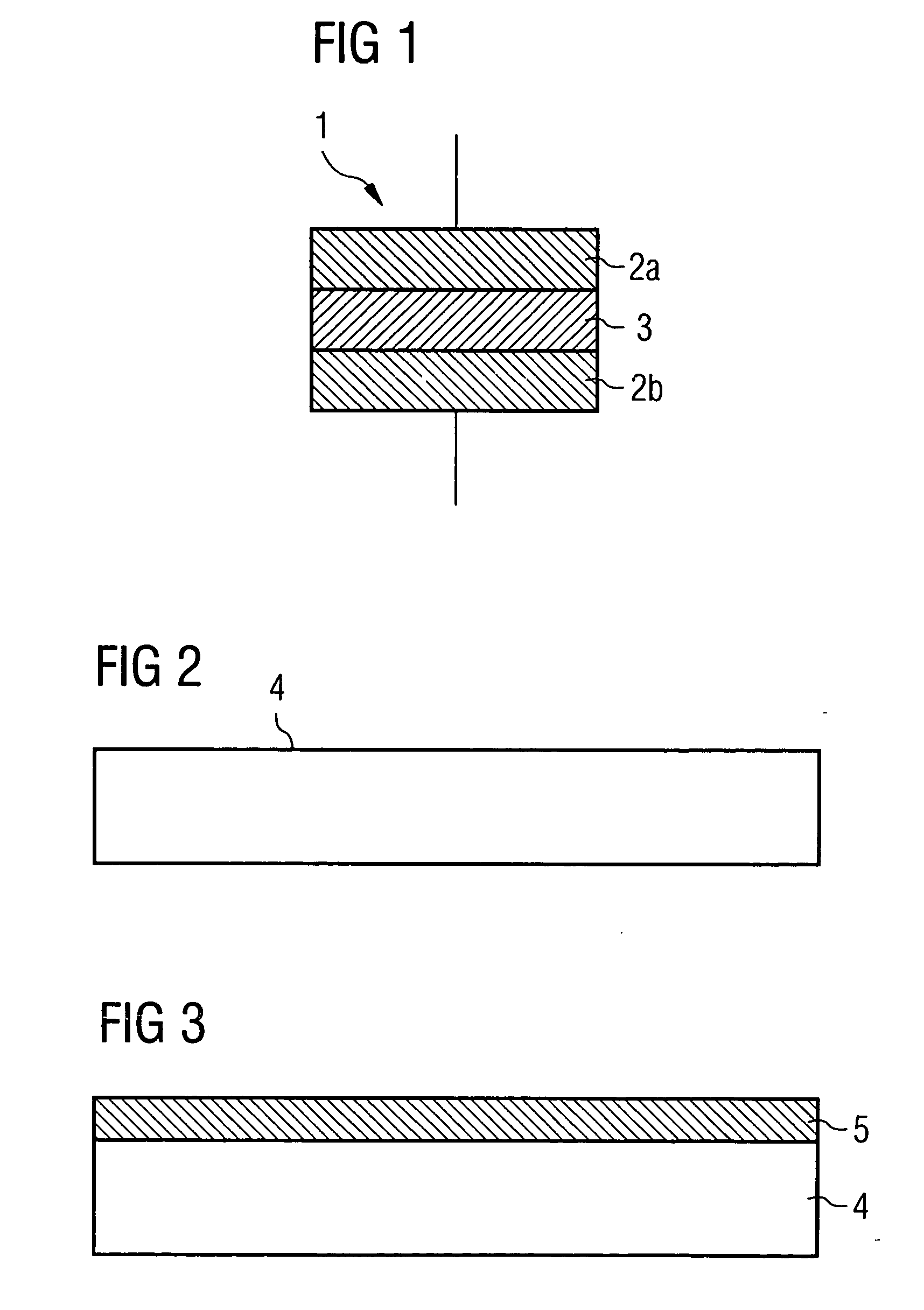

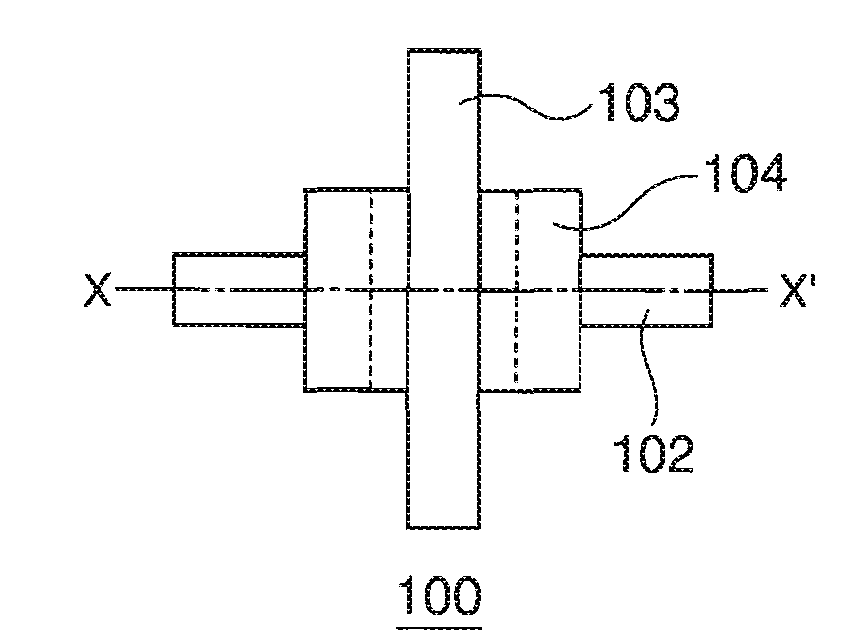

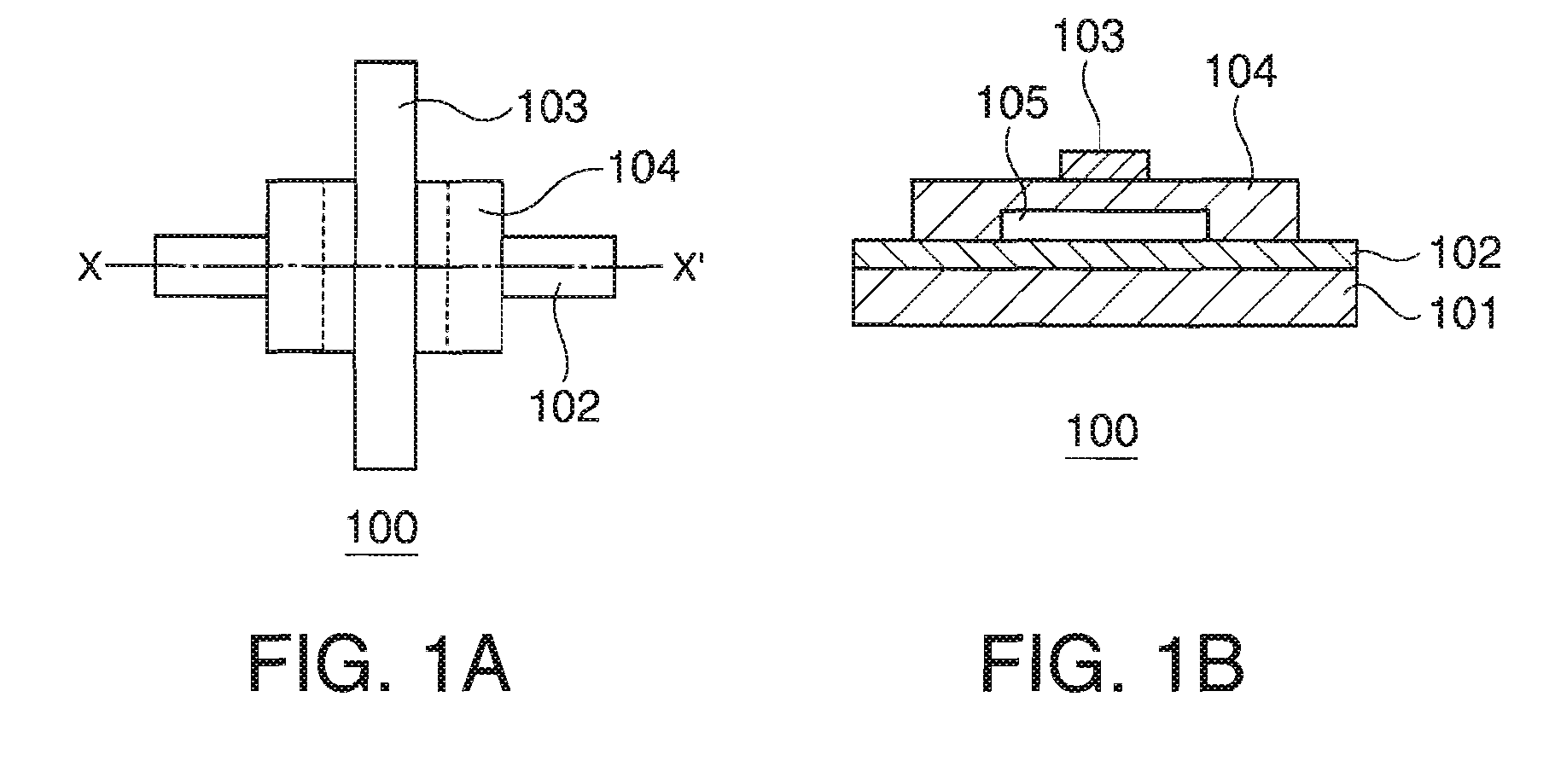

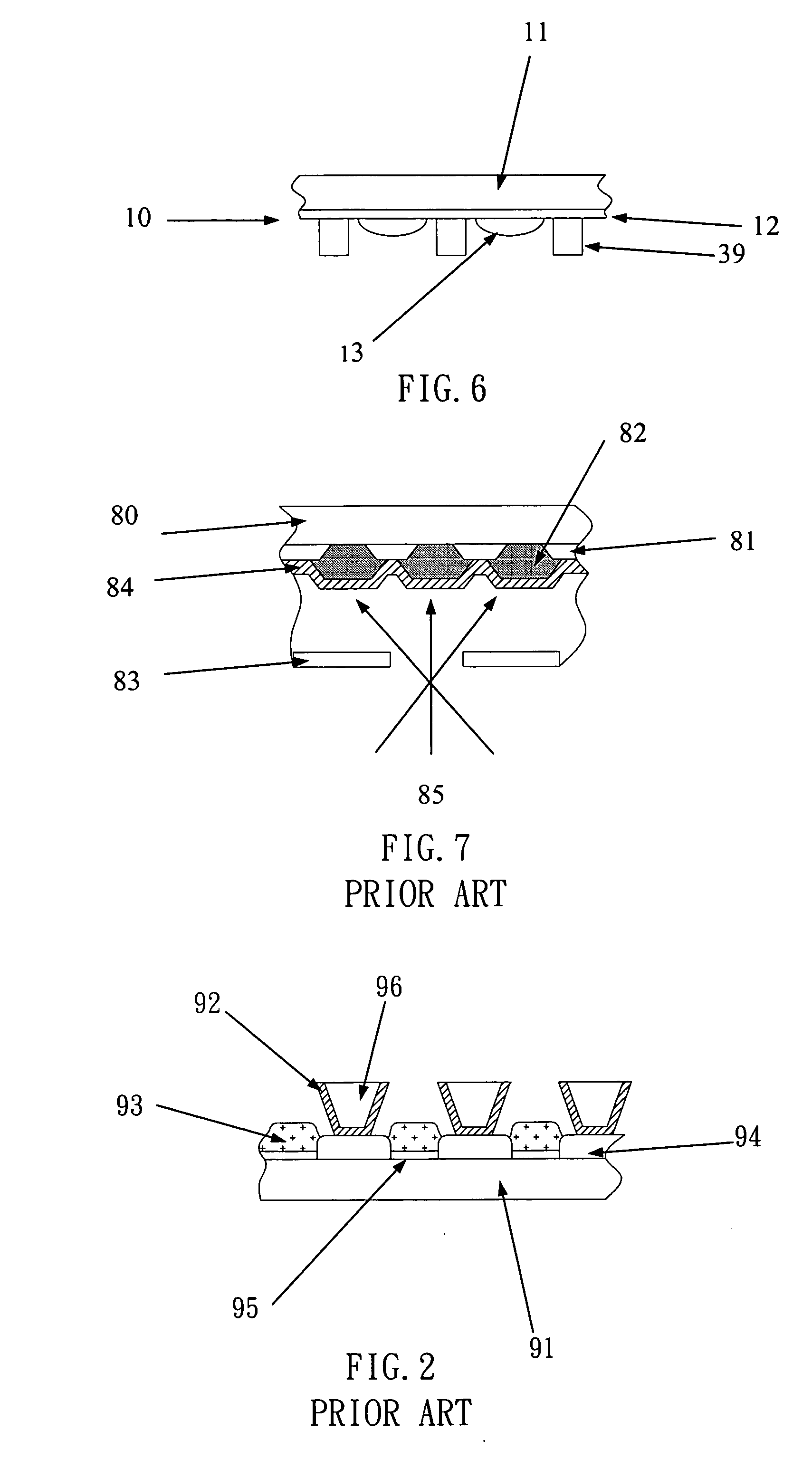

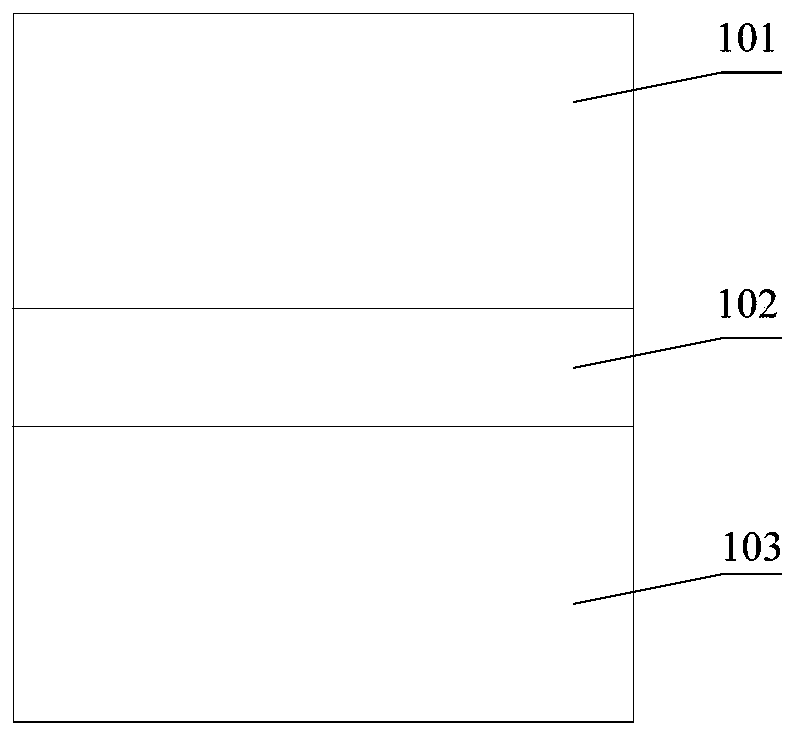

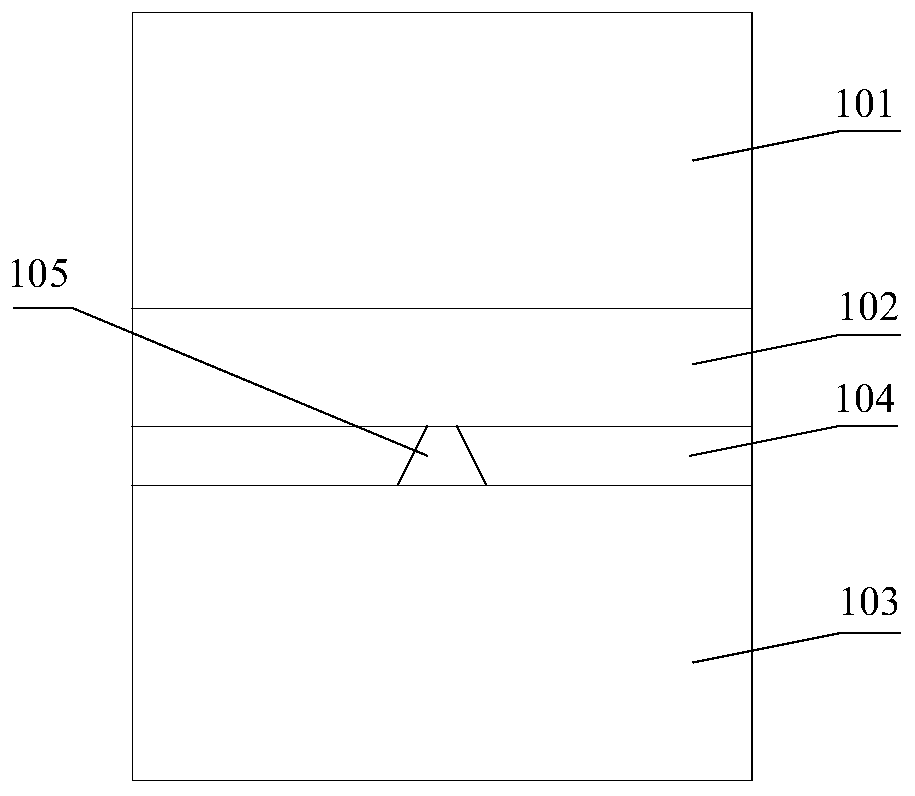

Method for fabricating light emitting diode

ActiveUS20100221852A1Light extraction efficiency can be improvedComplicated to makeMaterial nanotechnologySolid-state devicesElectrical conductorCarbon nanotube

A method of fabricating a light emitting diode includes the following steps. A substrate is provided and a first semiconductor layer, an active layer, and a second semiconductor layer are placed on the substrate. A carbon nanotube structure is provided and the carbon nanotube structure is lie on the second semiconductor layer. A first electrode is formed on the carbon nanotube structure. A portion of the first semiconductor layer is exposed and a second electrode is formed on the exposed portion of the first semiconductor layer to obtain the light emitting diode.

Owner:TSINGHUA UNIV +1

Transverse control arm, and method for producing a transverse control arm

A transverse control arm for installation in a motor vehicle is being configured as a single-piece malleable structure of uniform material and includes two bearing mounts for receiving elastic bearings and an arcuate center portion which extends between the bearing mounts and has a hollow cross section. The center portion includes in cross section a web and side panels respectively extending from the web in spaced-apart confronting relationship, in particular in parallel relationship.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

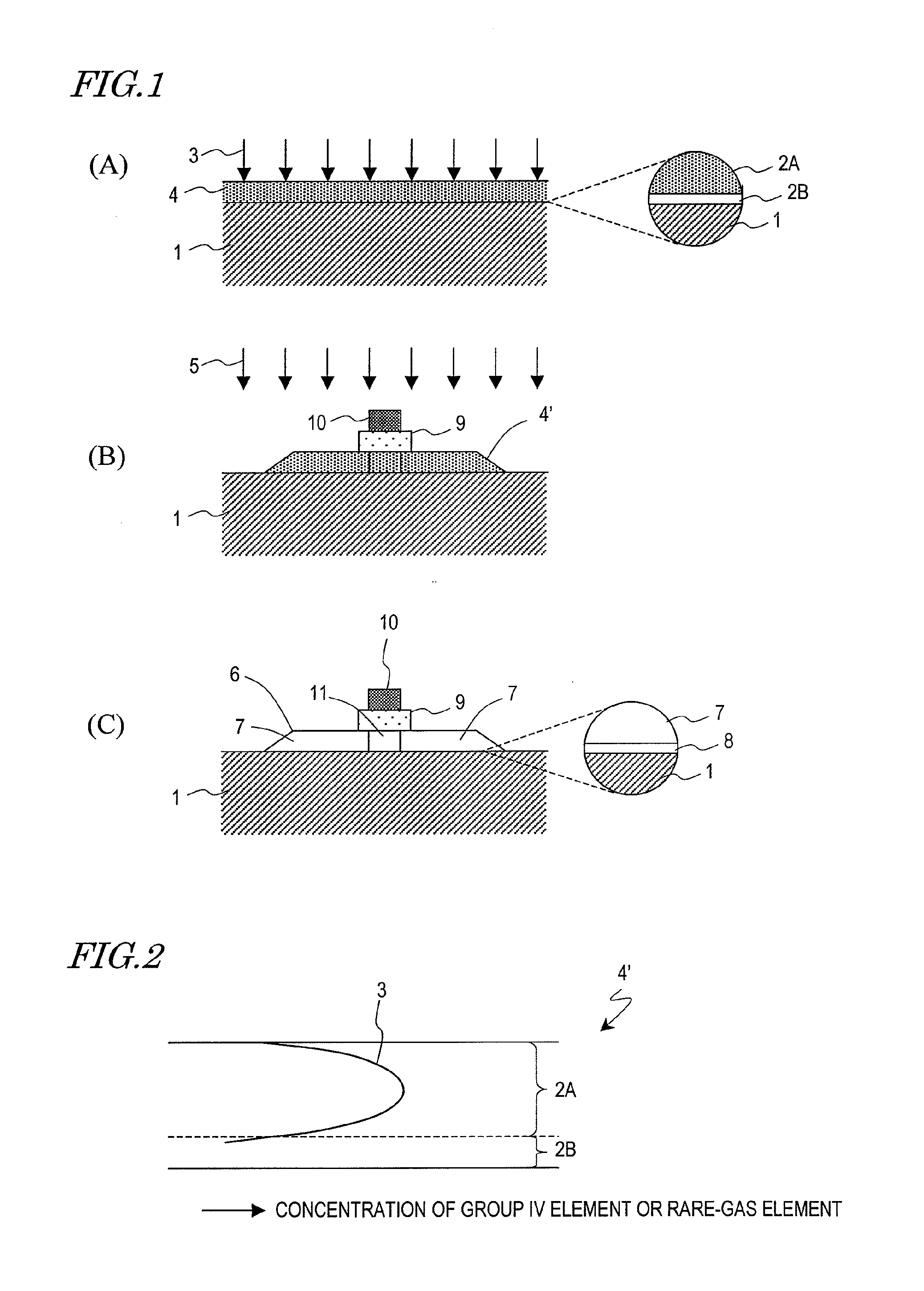

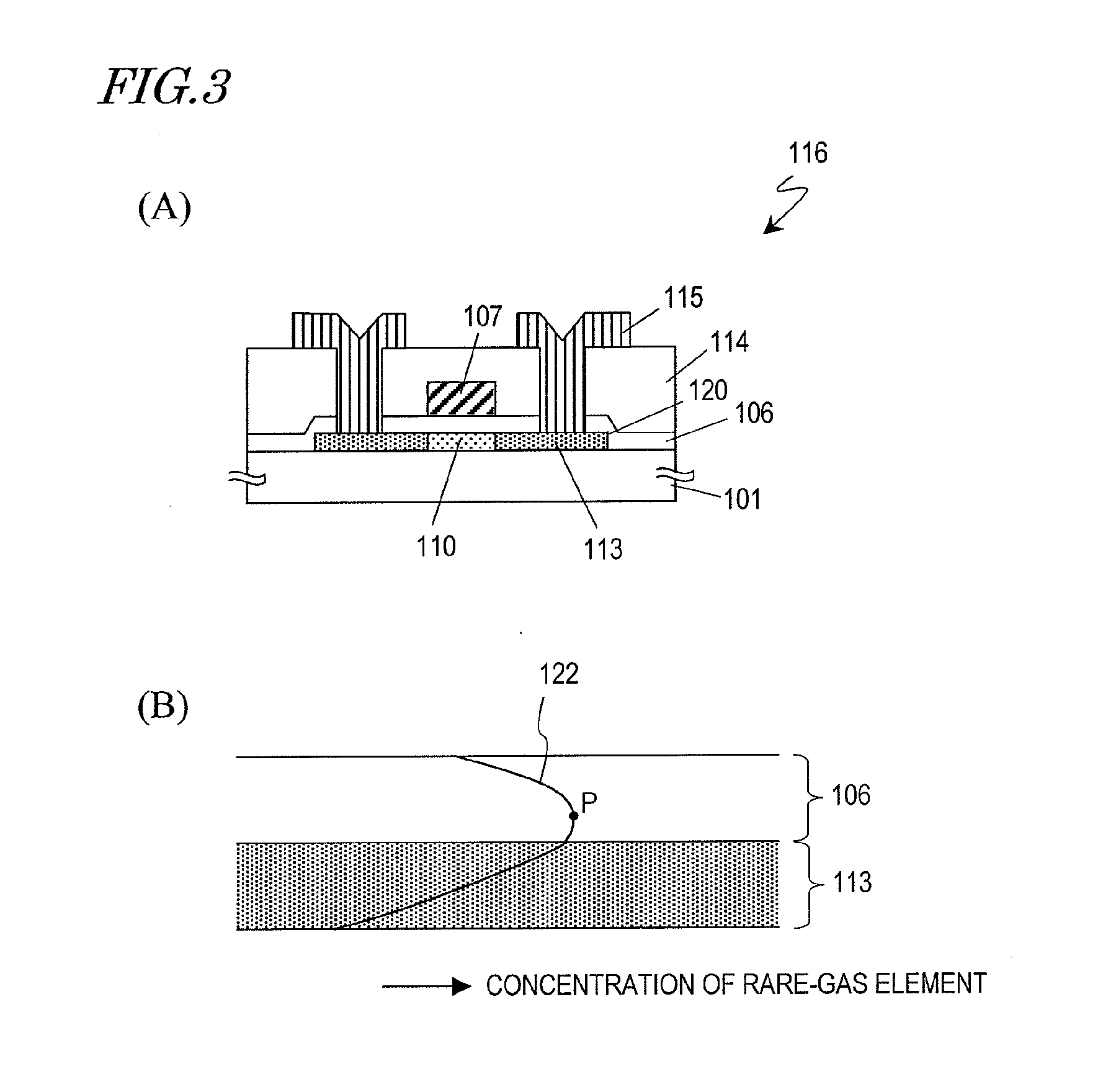

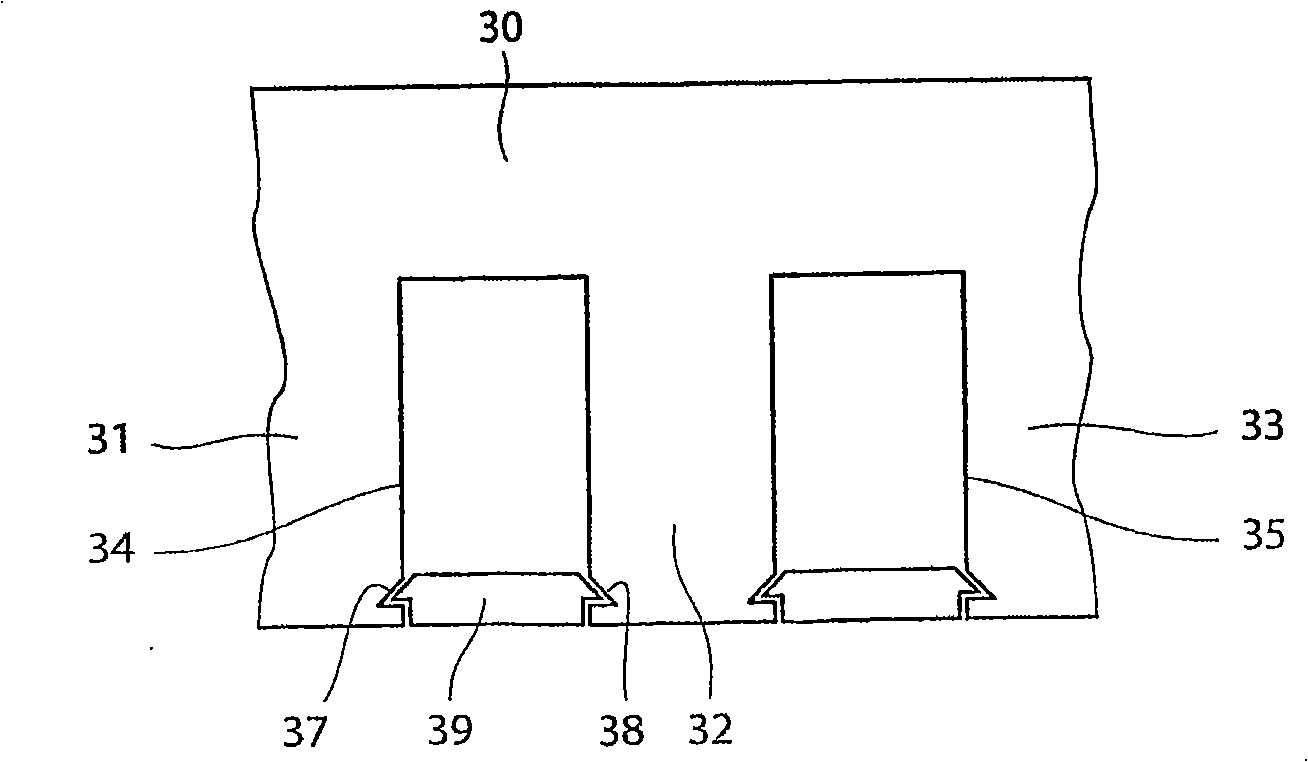

Semiconductor device provided with thin film transistor and method for manufacturing the semiconductor device

InactiveUS20100181575A1Reduce resistanceHigh performanceTransistorSolid-state devicesCrystalline semiconductorTransistor

A semiconductor device includes at least one thin-film transistor 116, which includes: a crystalline semiconductor layer 120 including a region 110 to be a channel region and source and drain regions 113; a gate electrode 107 for controlling the conductivity of the region 110 to be a channel region; a gate insulating film 106 arranged between the semiconductor layer 120 and the gate electrode 107; and source and drain electrodes 115 connected to the source and drain regions 113, respectively. At least one of the source and drain regions 113 contains an element to be a donor or an acceptor and a rare-gas element, but the region 110 to be a channel region does not contain the rare-gas element. The atomic weight of the rare-gas element is greater than that of the element to be a donor or an acceptor. The concentration of the rare-gas element in the at least one region as measured in the thickness direction thereof decreases continuously from the upper surface of the at least one region toward its lower surface.

Owner:SHARP KK

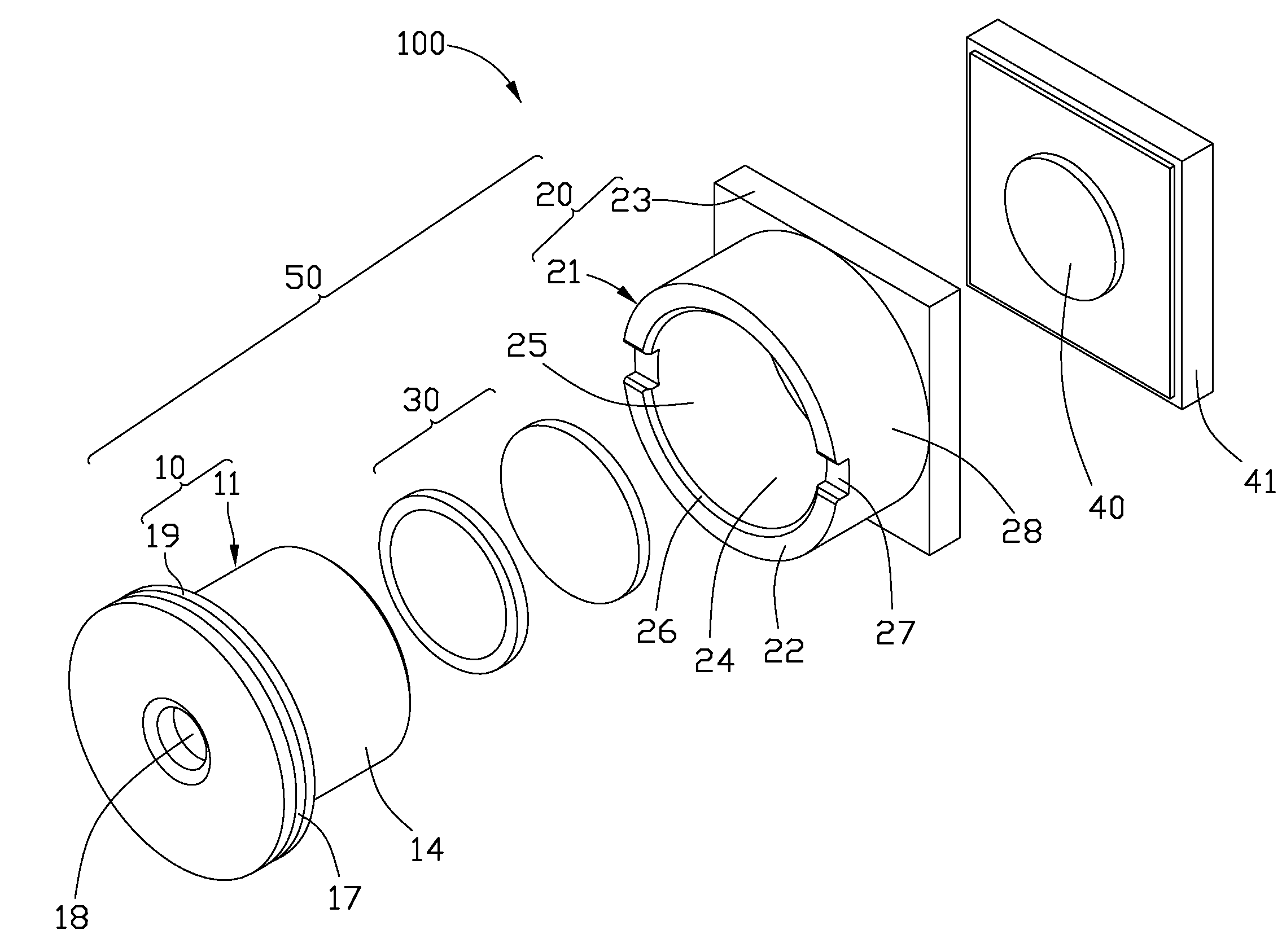

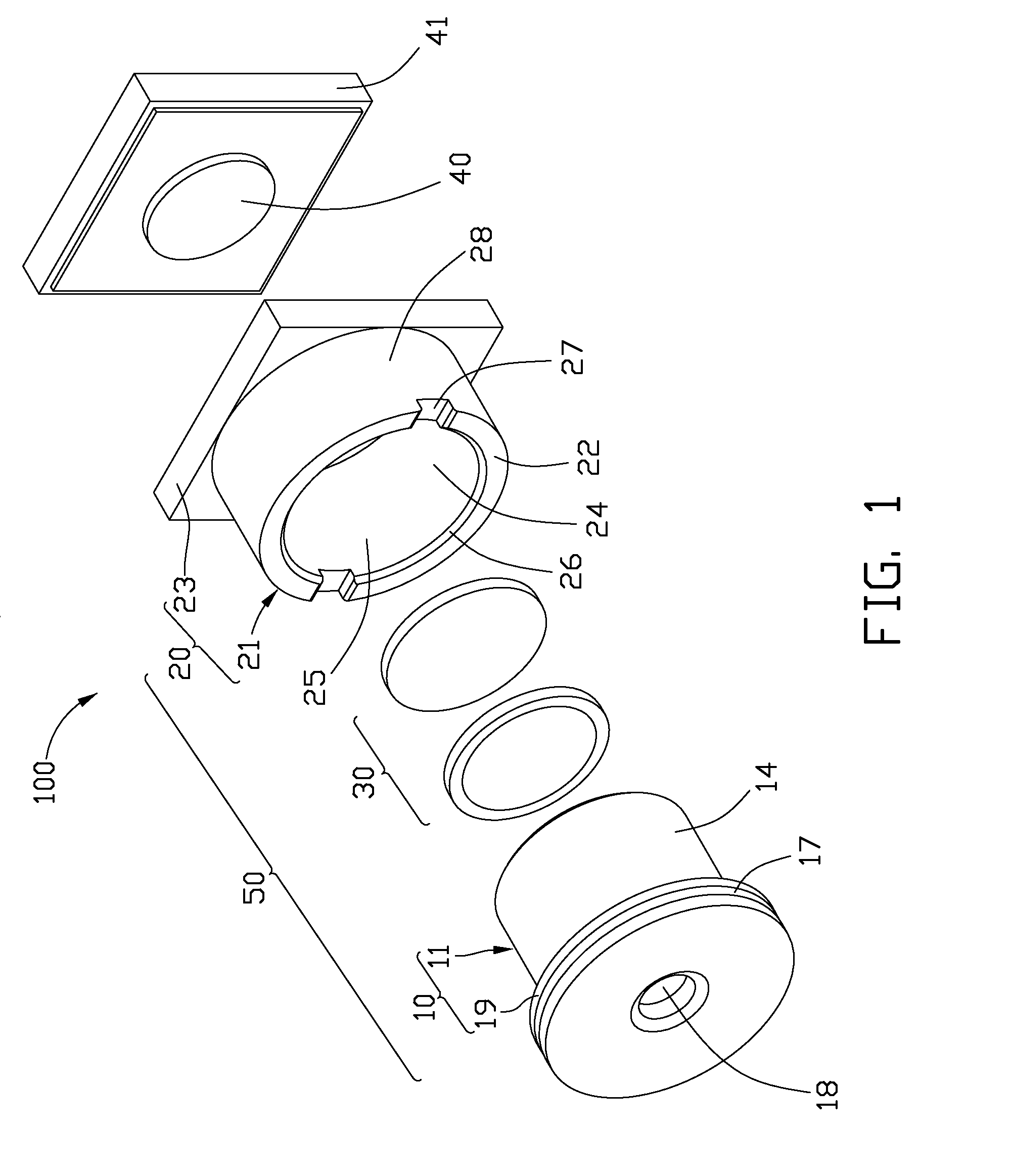

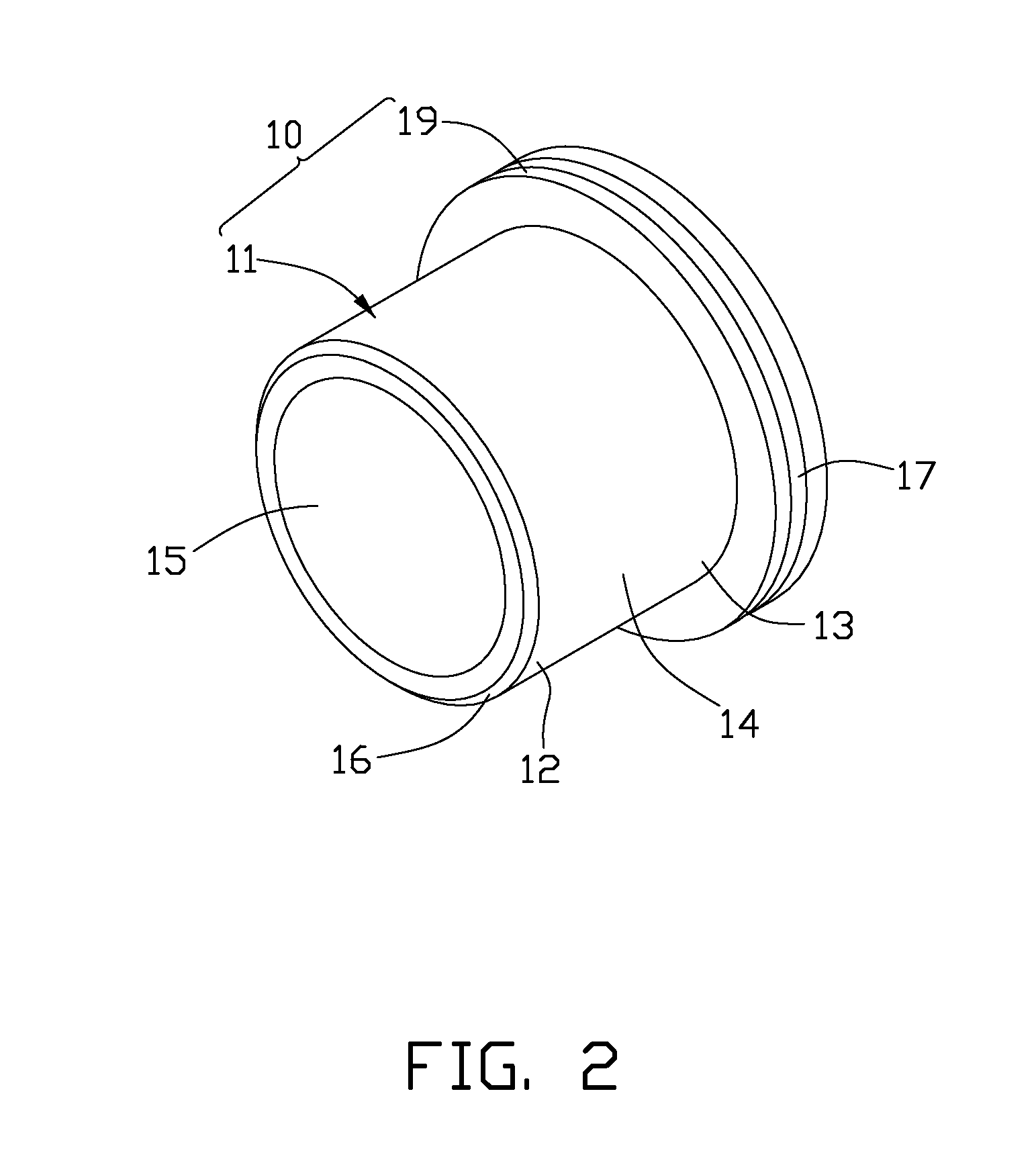

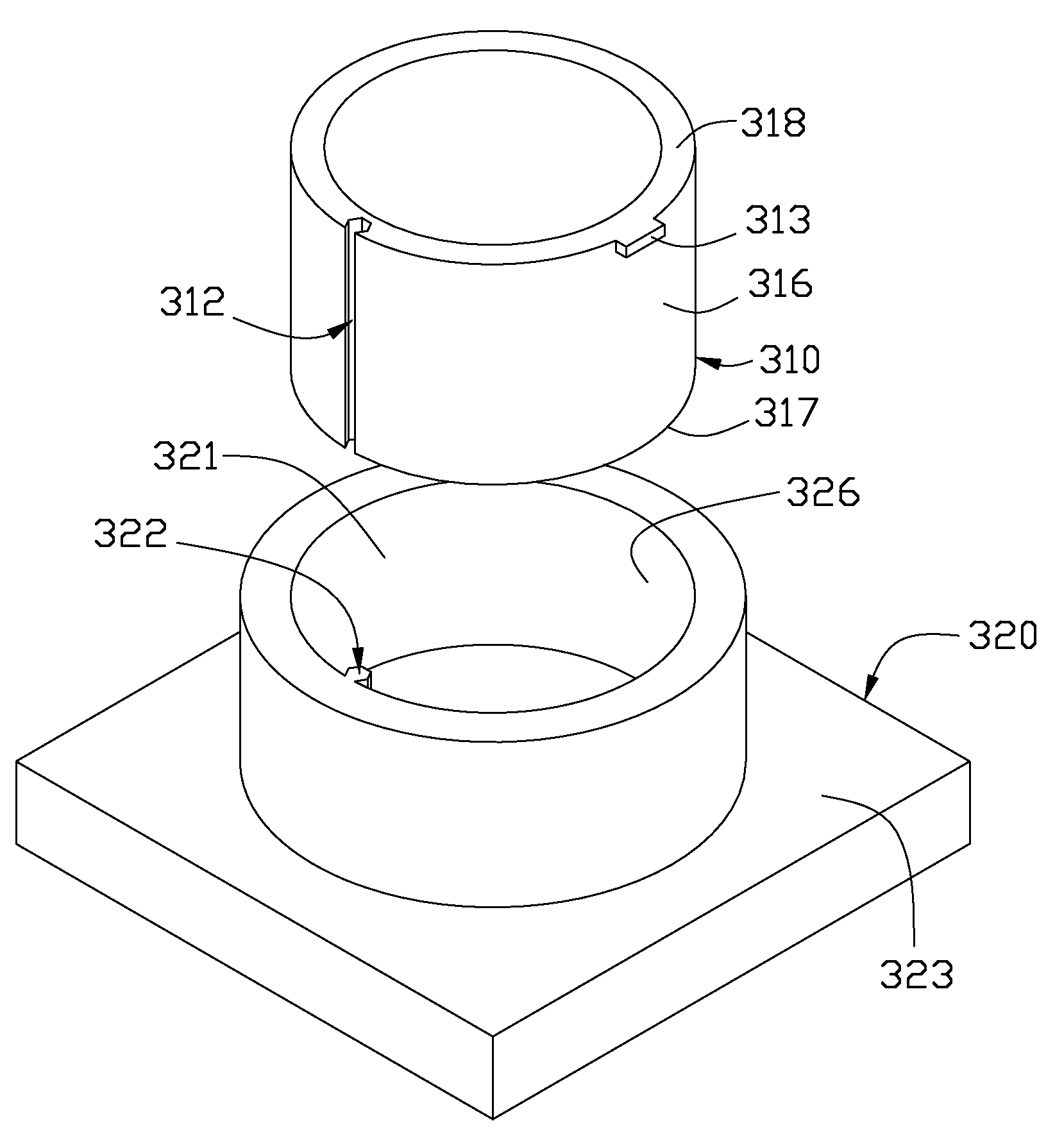

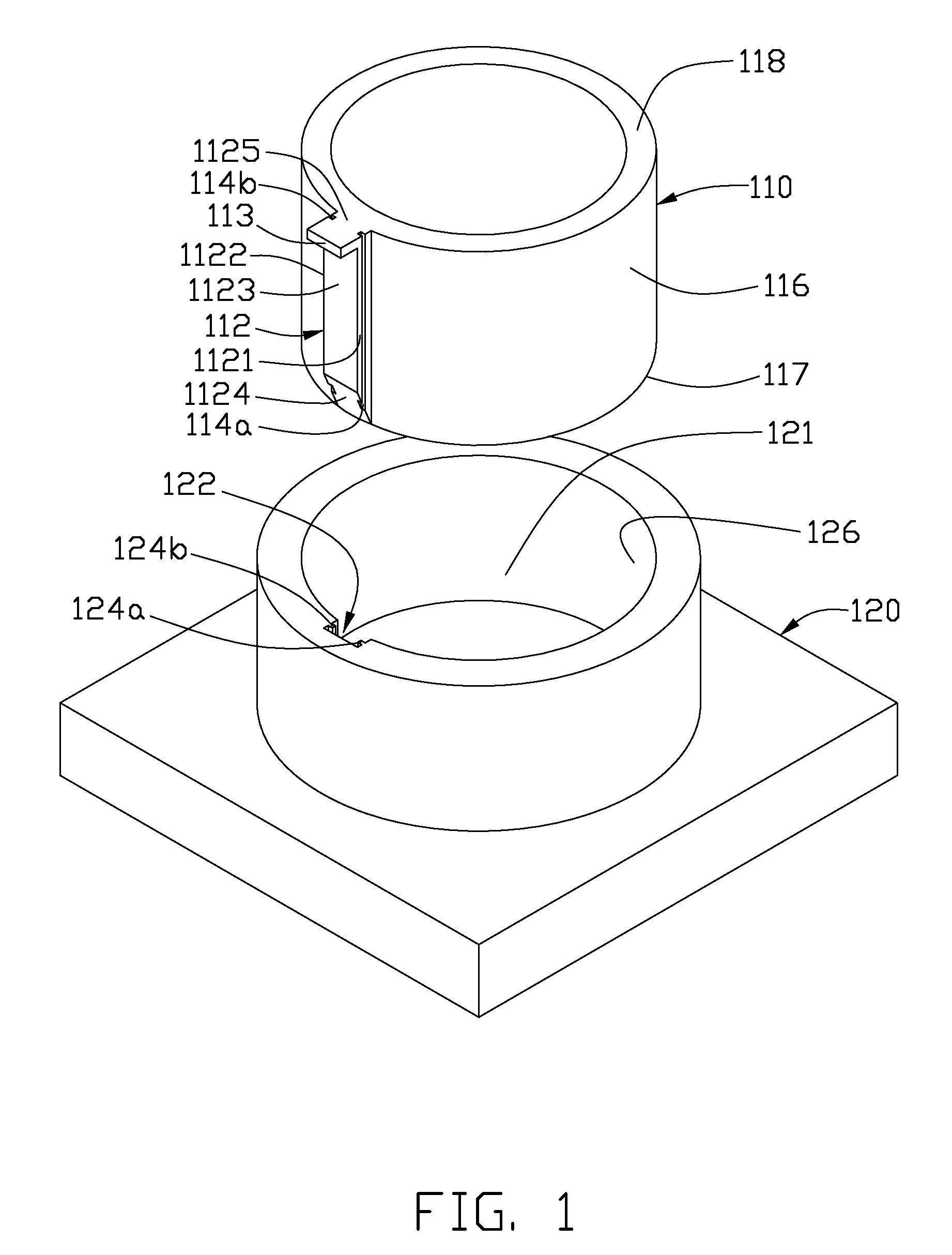

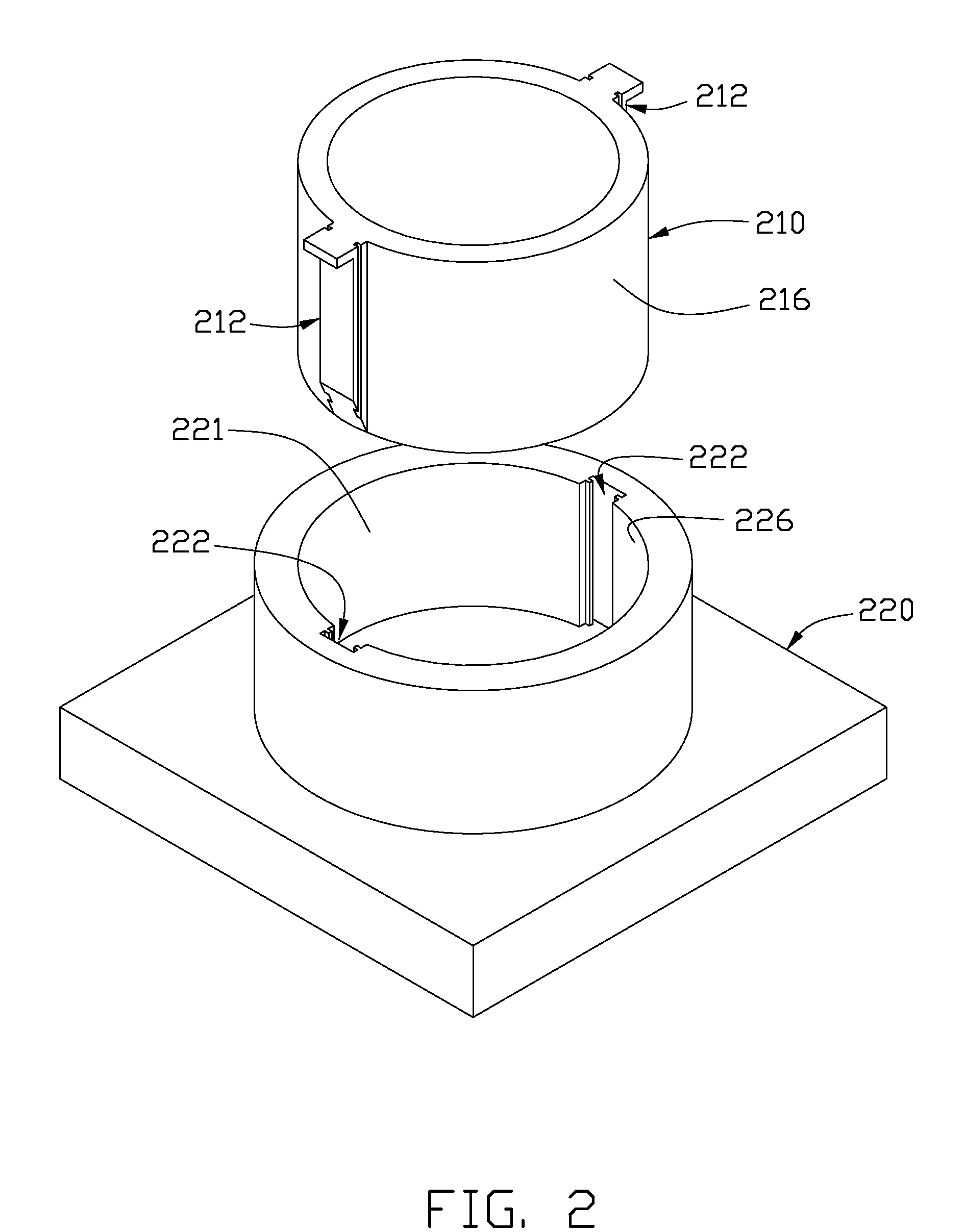

Lens module and camera having same

InactiveUS20090169198A1Easy to insertSpeed up preparationMountingsCamera body detailsScrew threadBiomedical engineering

A lens module includes a lens, a lens module and a base. The lens barrel receives the lens therein. The lens barrel includes a hollow cylindrical body, a beveled distal end and a flange. The hollow cylindrical body includes a smooth peripheral side surface free of thread formed thereon. The flange extends outwardly from the cylindrical body. The flange defines an annular groove in a peripheral surface thereof. The base includes a hollow cylindrical holding body coaxially receiving the cylindrical body therein. The holding body has a first distal end, a second distal end and an inner smooth surface. The beveled distal end is configured for facilitating insertion of the cylindrical body in the cylindrical holding body. The flange is configured for being clamped by a tool and being moved toward or away from the base using the tool.

Owner:HON HAI PRECISION IND CO LTD

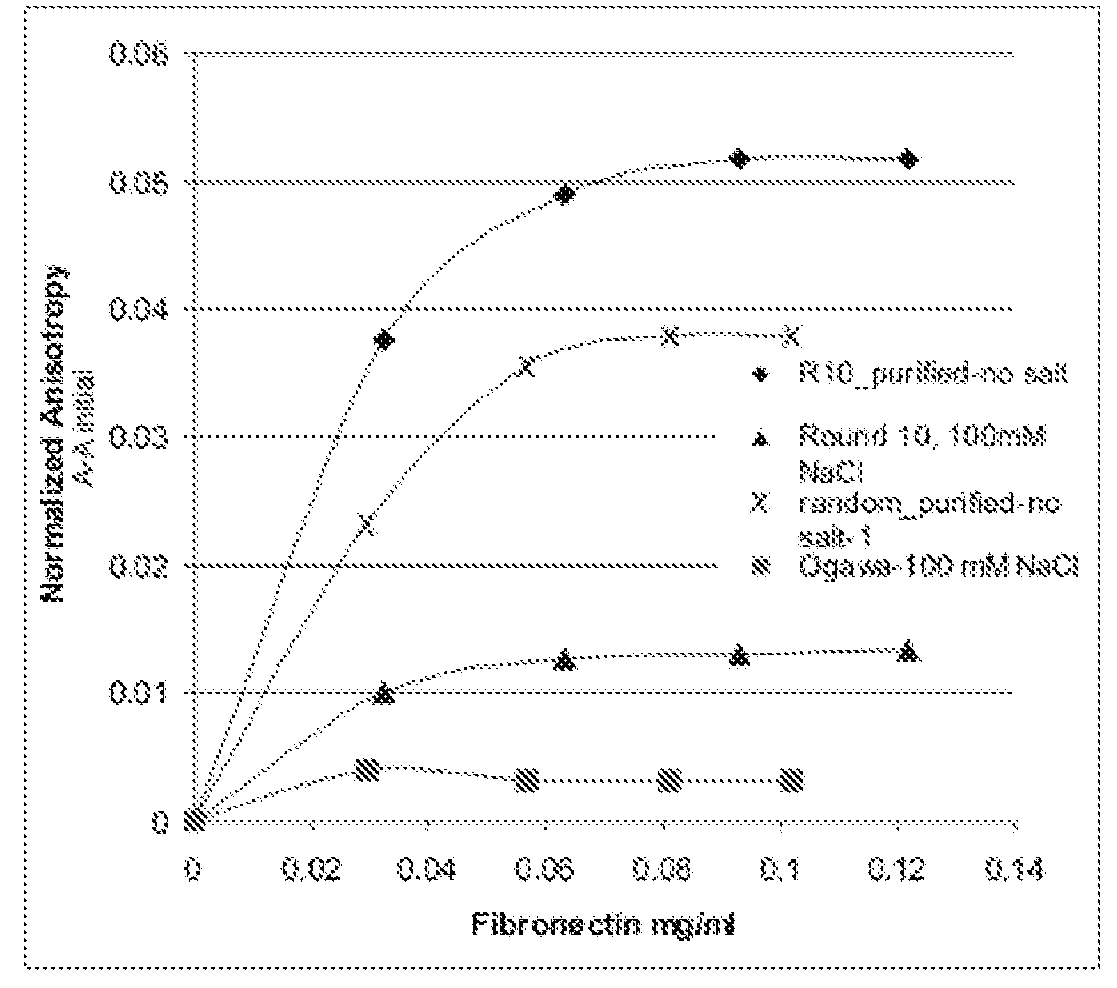

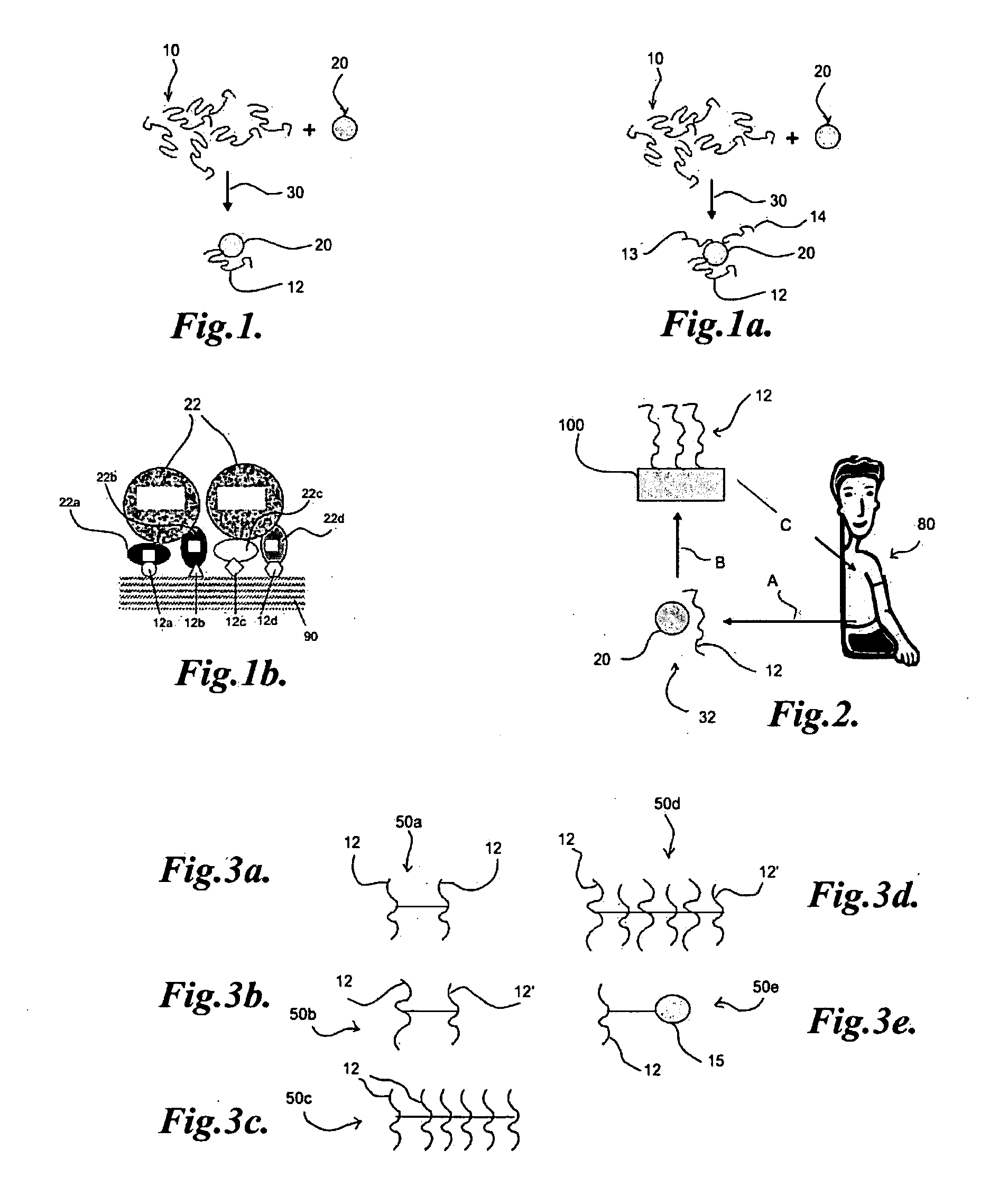

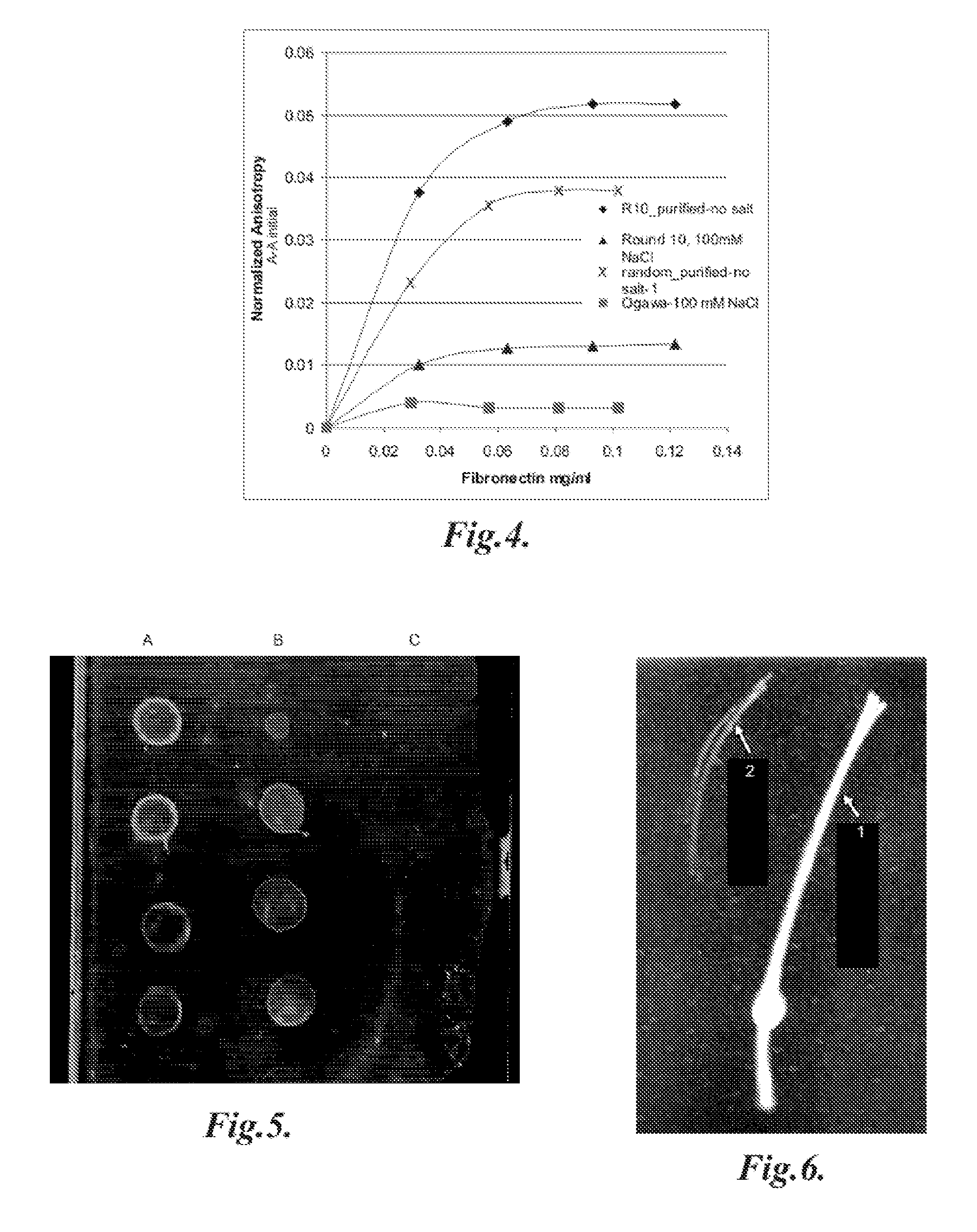

Methods and devices for enhanced biocompatibility

InactiveUS20090148493A1Good biocompatibilityLower immune responseOrganic active ingredientsGenetic material ingredientsBiocompatibility TestingIon release

The present invention is directed to devices with enhanced biocompatibility and methods for generating and utilizing such devices. The present invention is further directed to enhanced biocompatibility utilizing oligonucleotide functionalization. In one aspect, a device for implantation and / or prolonged exposure to the body tissues includes a functionalized surface. The functionalized surface generally enhances the biocompatibility of the device with body tissues. In some embodiments, the functionalized surface includes substances for controlling interaction between the device and the body tissues. Substances for controlling interactions may include, but are not limited to, polymeric materials, biomolecules, ions and / or ion-releasing substances, and / or any other appropriate substance or combination thereof. In exemplary embodiments, the functionalized surface includes oligonucleotides for controlling interaction between the device and the body tissues. In some exemplary embodiments, the oligonucleotides are aptamers.

Owner:BIOTEX

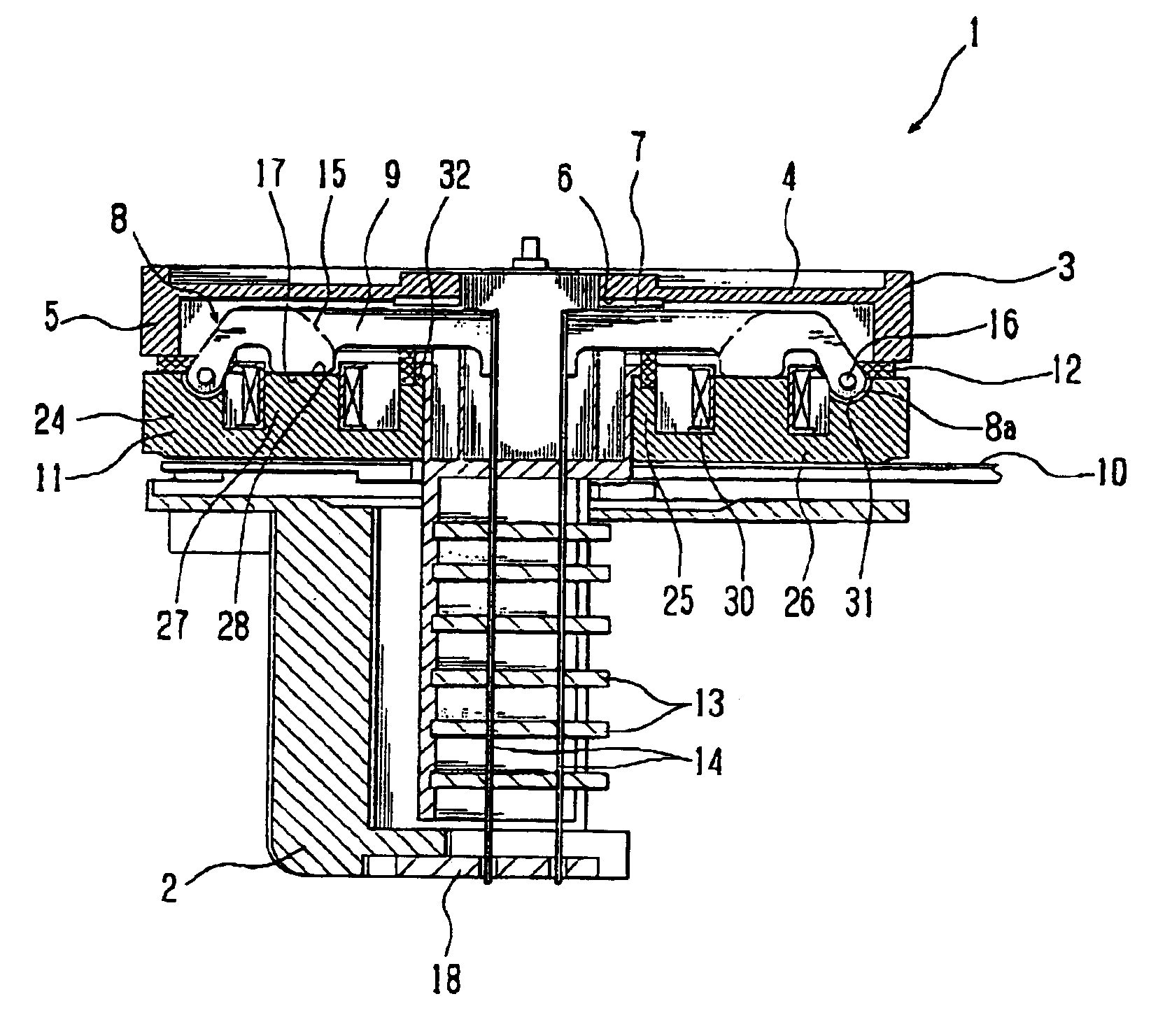

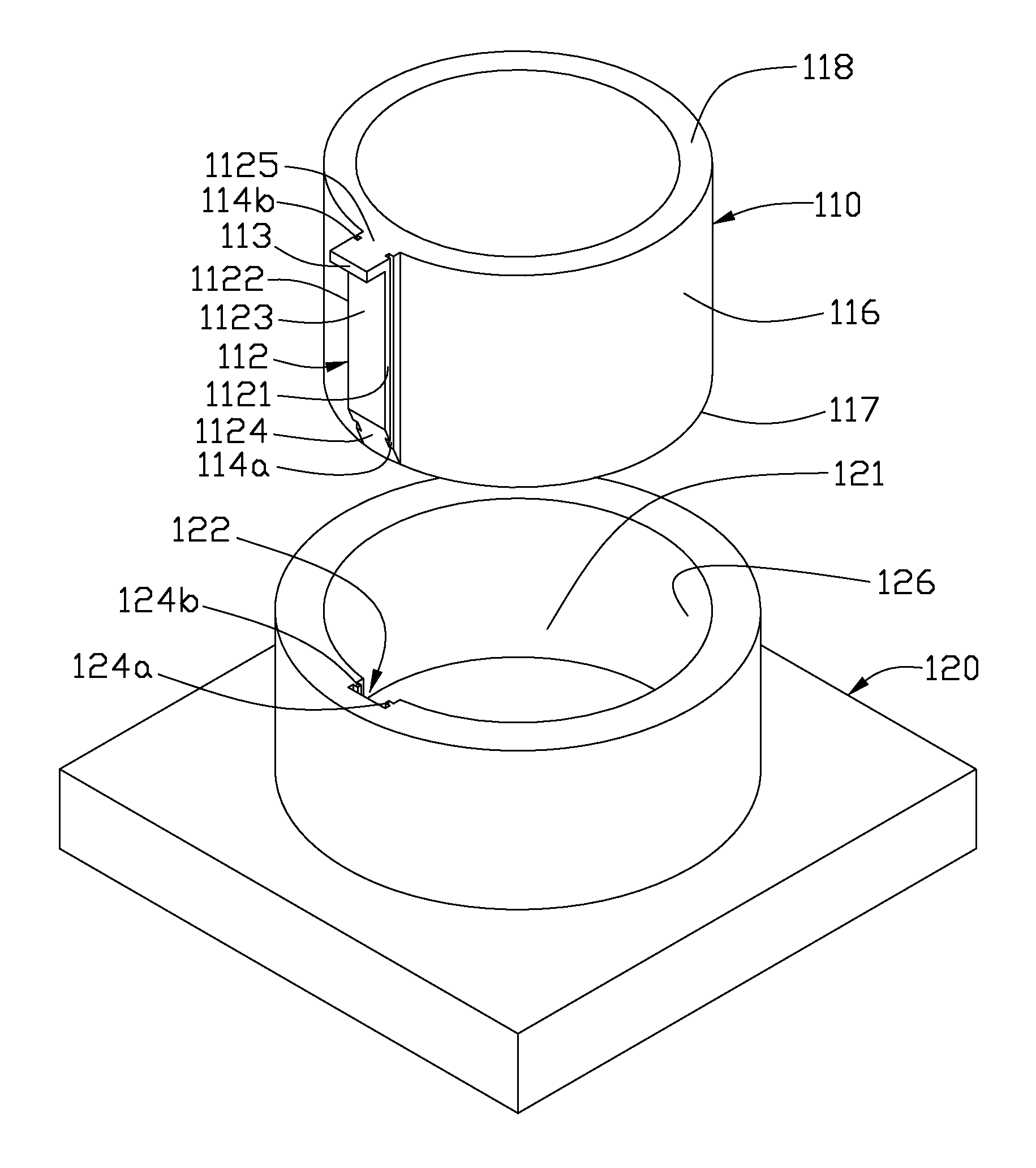

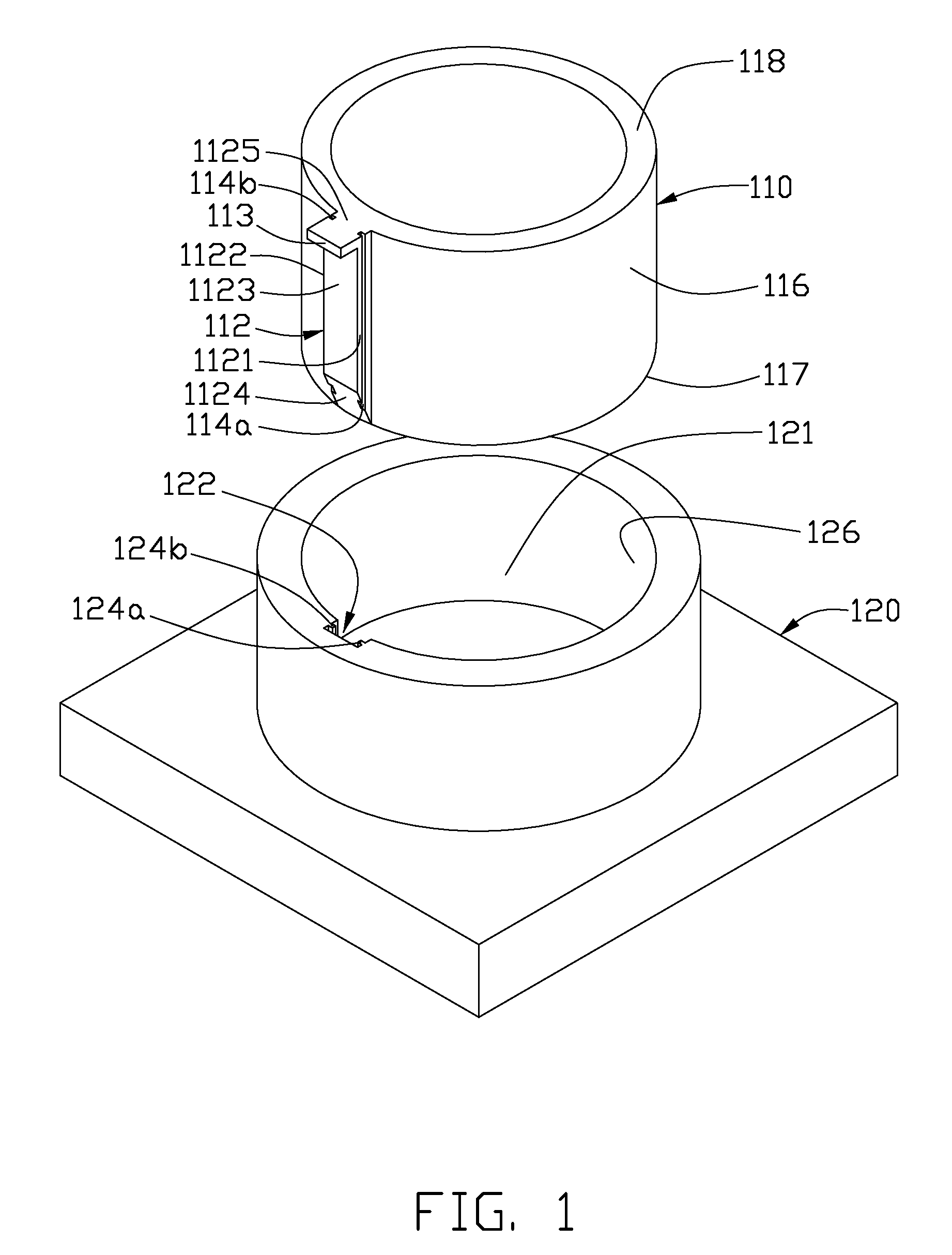

Impact dot print head and a printer including the same

InactiveUS6872016B2Ensure efficient flowIncrease printing speedOther printing apparatusAssembly structureEngineering

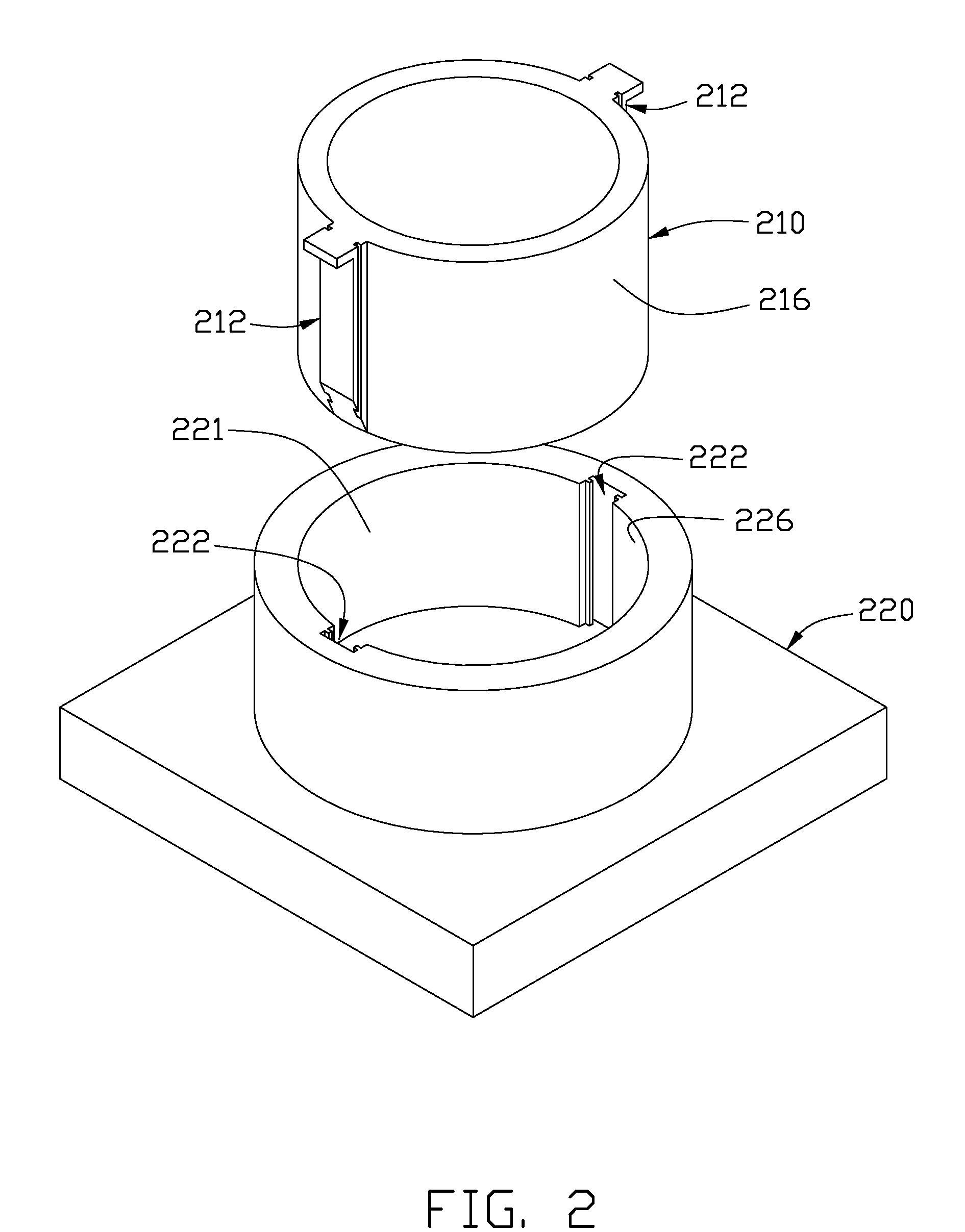

In an impact dot print head there is provided a fitting structure for fitting an inner periphery-side cylindrical portion of a yoke and an inner periphery-side ring-shaped portion of an armature spacer with each other so that the inner periphery-side cylindrical portion of the yoke and the inner periphery-side ring-shaped portion of the armature spacer push against each other, thereby permitting a magnetic flux to flow efficiently between the armature spacer and the yoke through the contact face between the inner periphery-side cylindrical portion of the yoke and the inner periphery-side ring-shaped portion of the armature spacer.

Owner:TOSHIBA TEC KK

Method for fabricating light emitting diode

ActiveUS8021902B2Light extraction efficiency can be improvedComplicated to makeMaterial nanotechnologySolid-state devicesElectrical conductorCarbon nanotube

A method of fabricating a light emitting diode includes the following steps. A substrate is provided and a first semiconductor layer, an active layer, and a second semiconductor layer are placed on the substrate. A carbon nanotube structure is provided and the carbon nanotube structure is lie on the second semiconductor layer. A first electrode is formed on the carbon nanotube structure. A portion of the first semiconductor layer is exposed and a second electrode is formed on the exposed portion of the first semiconductor layer to obtain the light emitting diode.

Owner:TSINGHUA UNIV +1

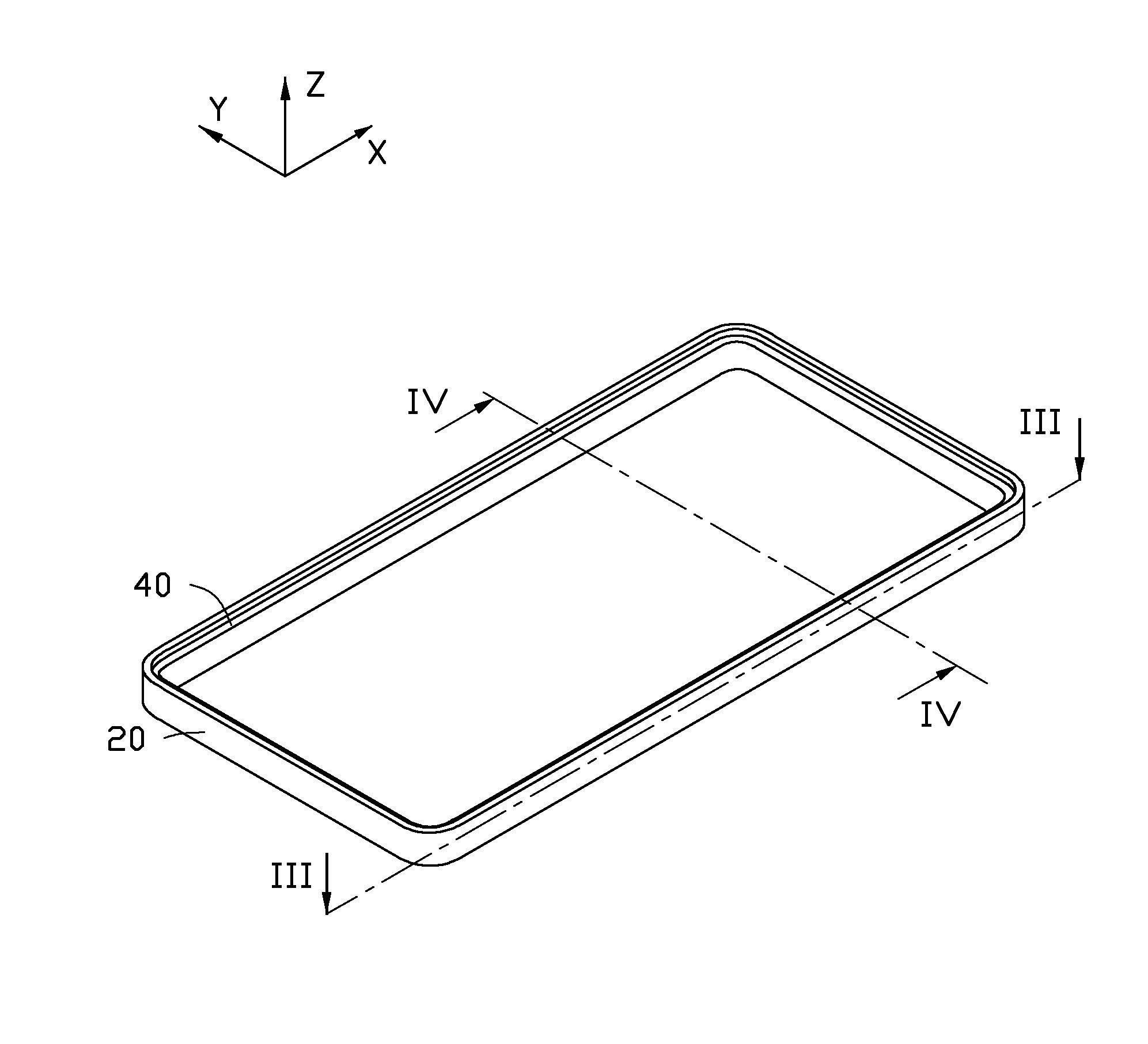

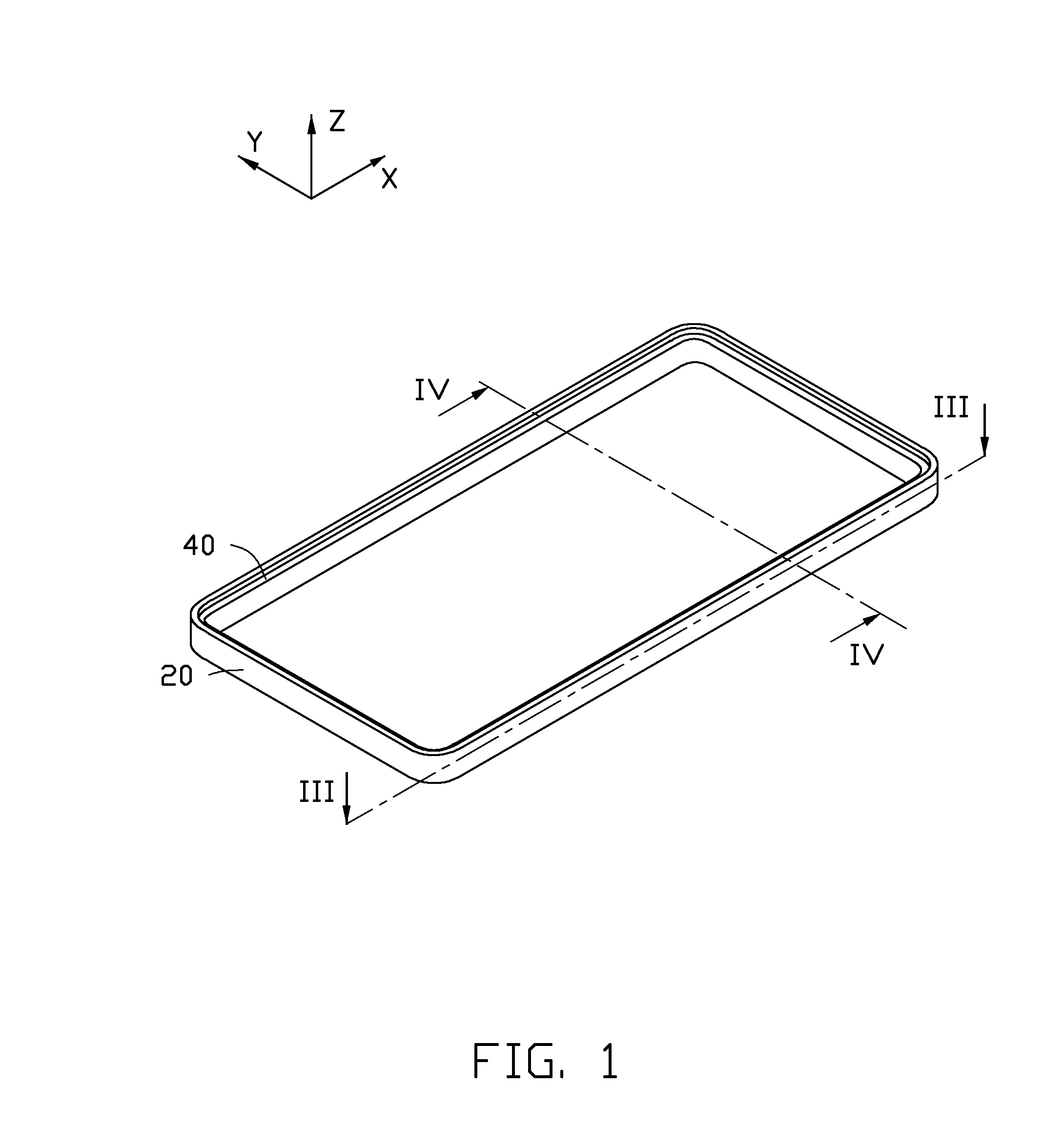

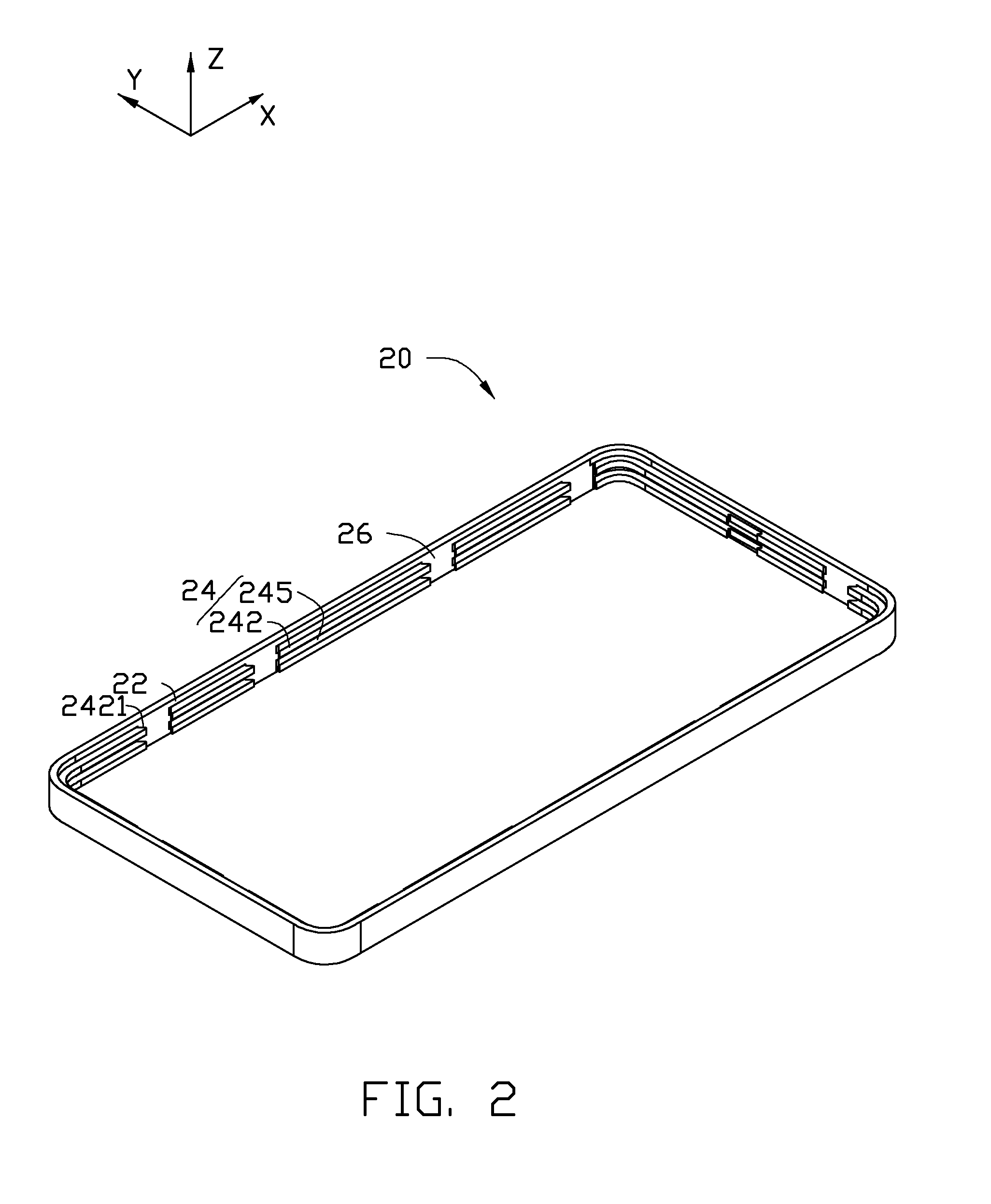

Metallic housing of electronic device and manufacturing method thereof

InactiveUS20150021064A1Light weightImprove scalabilityFoundry mouldsMetal casingsMetal alloyDie casting

A metallic housing of an electronic device, includes a metallic outer frame and an inner structural member. The metallic outer frame comprises a plurality of latching portions protruding, and a plurality of latching grooves. The inner structural member is made from metal-alloy and embedded in the outer frame by die-casting. The inner structural member comprises a peripheral sidewall, a plurality of engaging portions, and a plurality of matching portions. The plurality of engaging portions and the plurality of matching portions protrude from the peripheral sidewall outwardly. Each latching portion comprises at least two parallel latching ribs, and forms a receiving groove between two adjacent latching ribs. The plurality of engaging portions is respectively embedded in the plurality of receiving grooves, and the plurality of matching portions is respectively embedded in the plurality of latching grooves. The present disclosure further provides a manufacturing method for the metallic housing.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

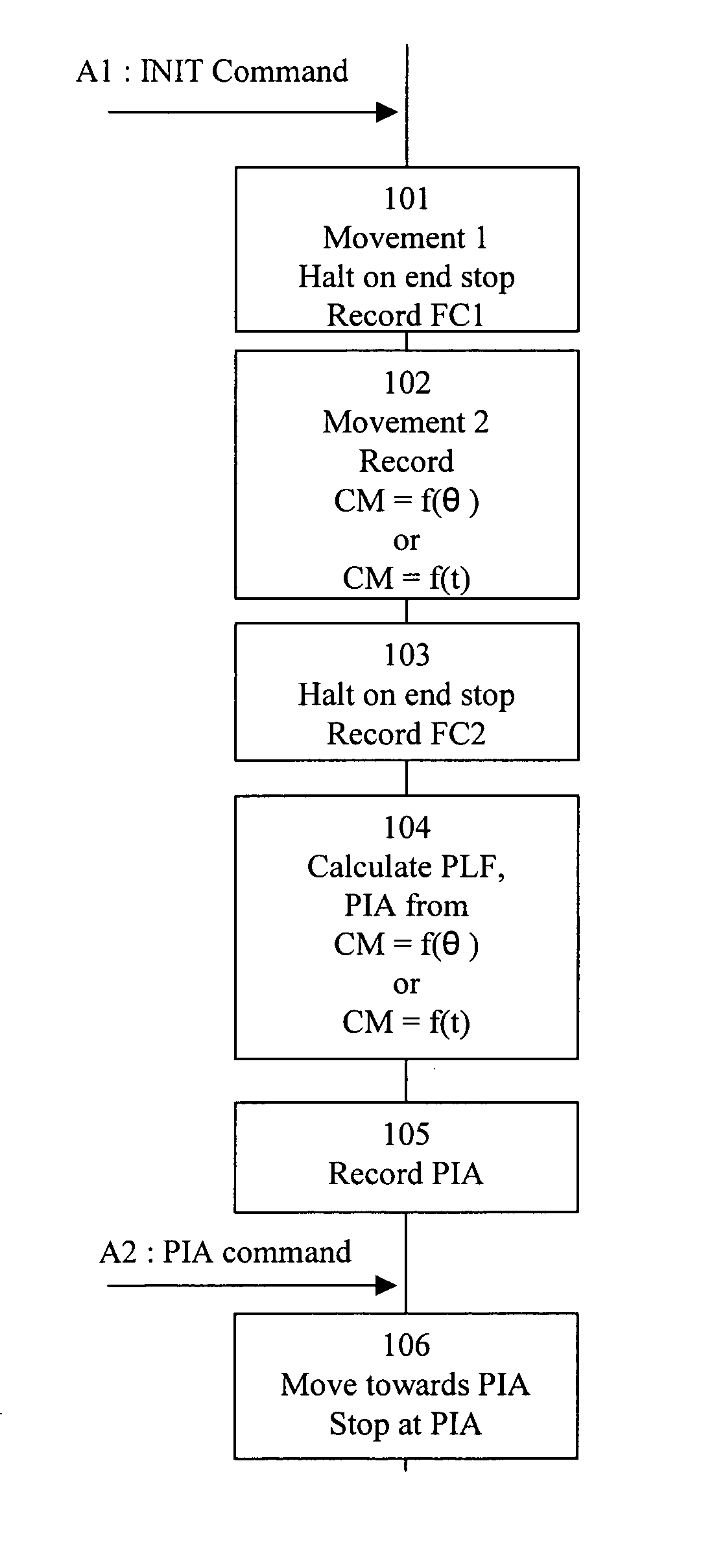

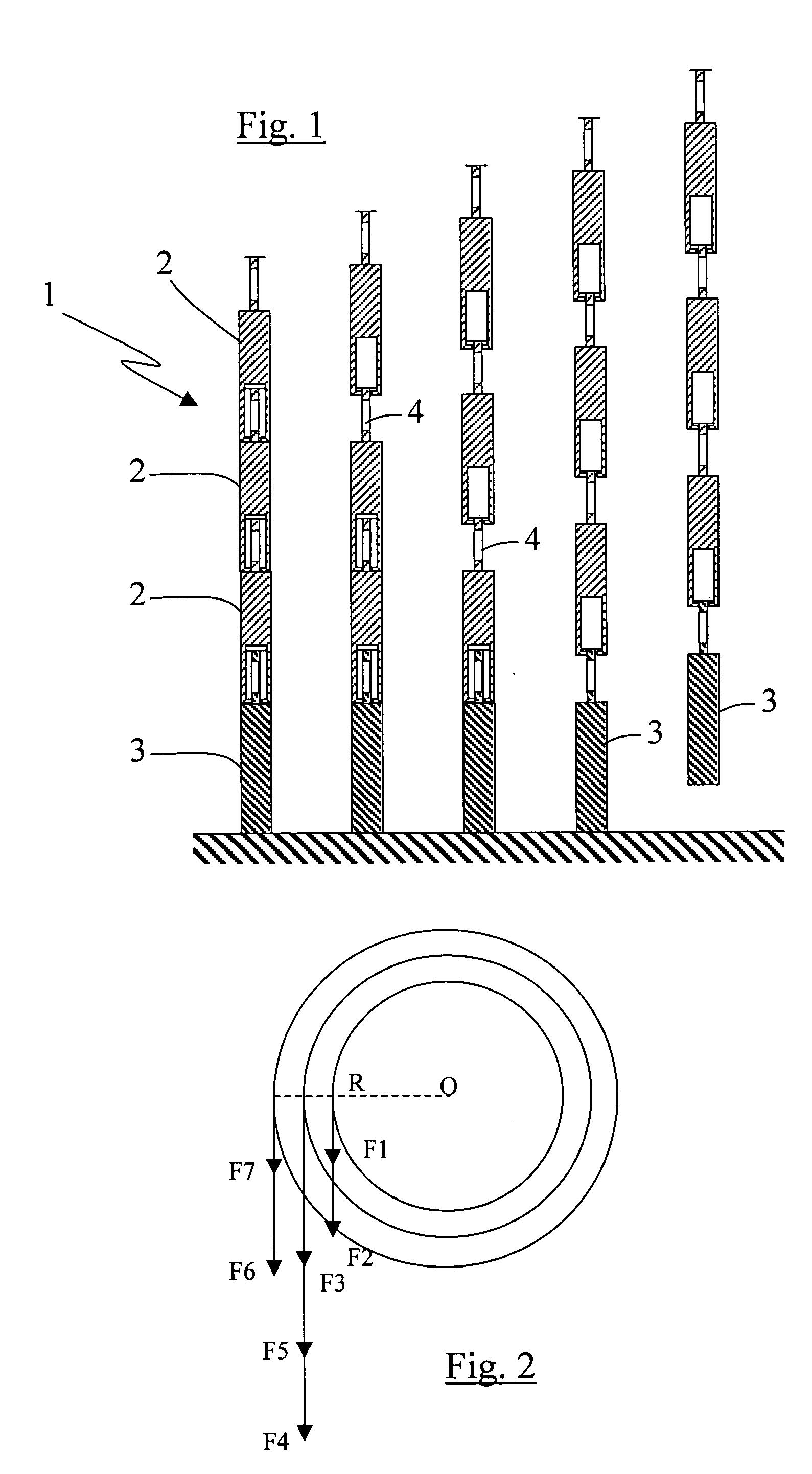

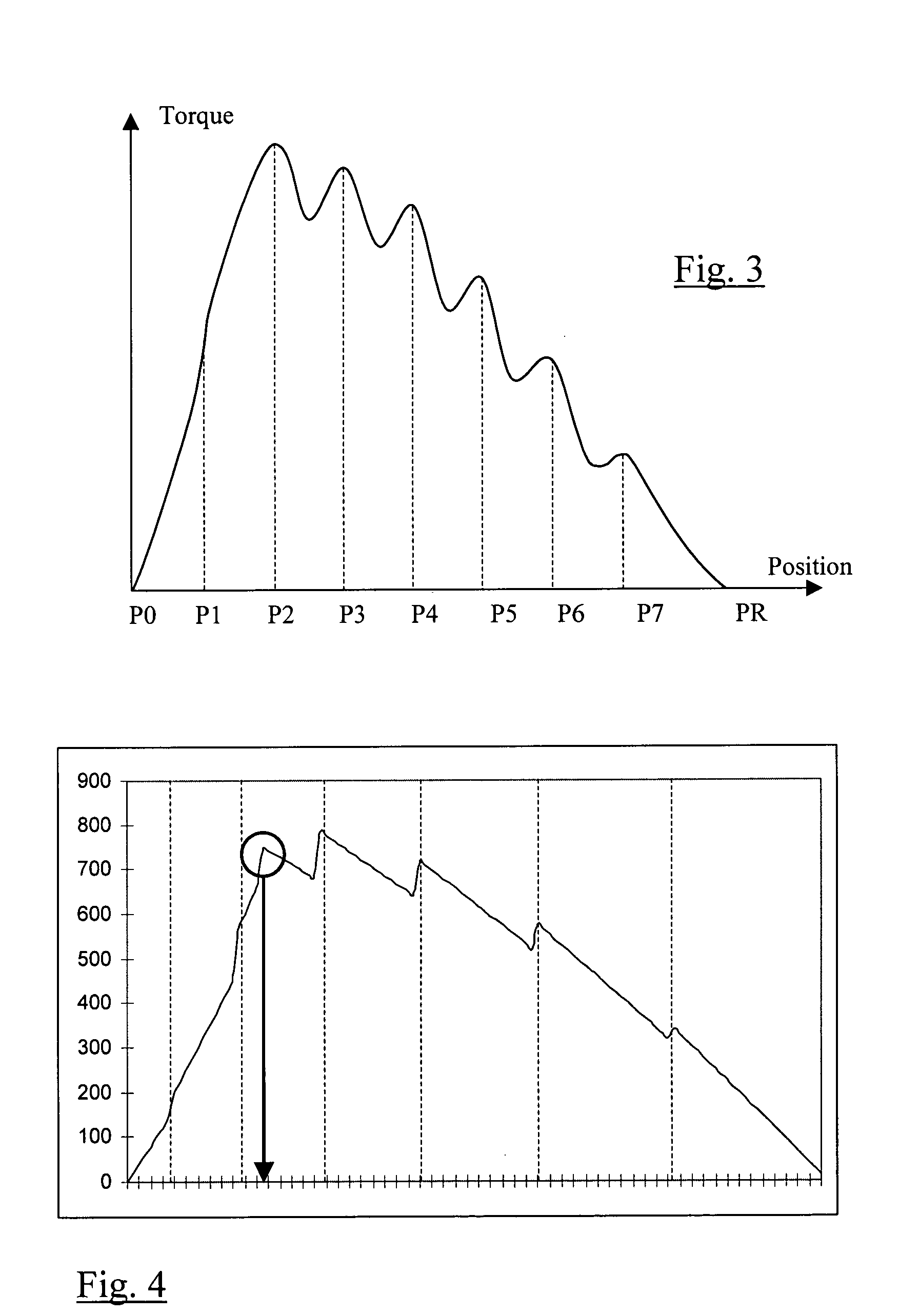

Method of determining an intermediate open position for a roller blind

InactiveUS20050119792A1Production is complicatedComplicated to makeScreensSampled-variable control systemsControl systemWindow shutter

The method of determining a shading and ventilation position in a control system of an actuator which is used to move a roller blind with stackable slats, is characterized in that it comprises the following steps: identifying, by analysing the torque exerted on the actuator, the final slat position in which the bottom slat is at the limit of contact with the bottom end stop of the blind, assigning to this final slat position a data defining said position, calculating a shading and ventilation position data defining the shading and ventilation position from the data of the final slat position, and storing the shading and ventilation position data in a shading and ventilation position memory. This method makes it possible to store the best shading and ventilation position without storing it in memory at the site of manufacture.

Owner:SOMFY SAS

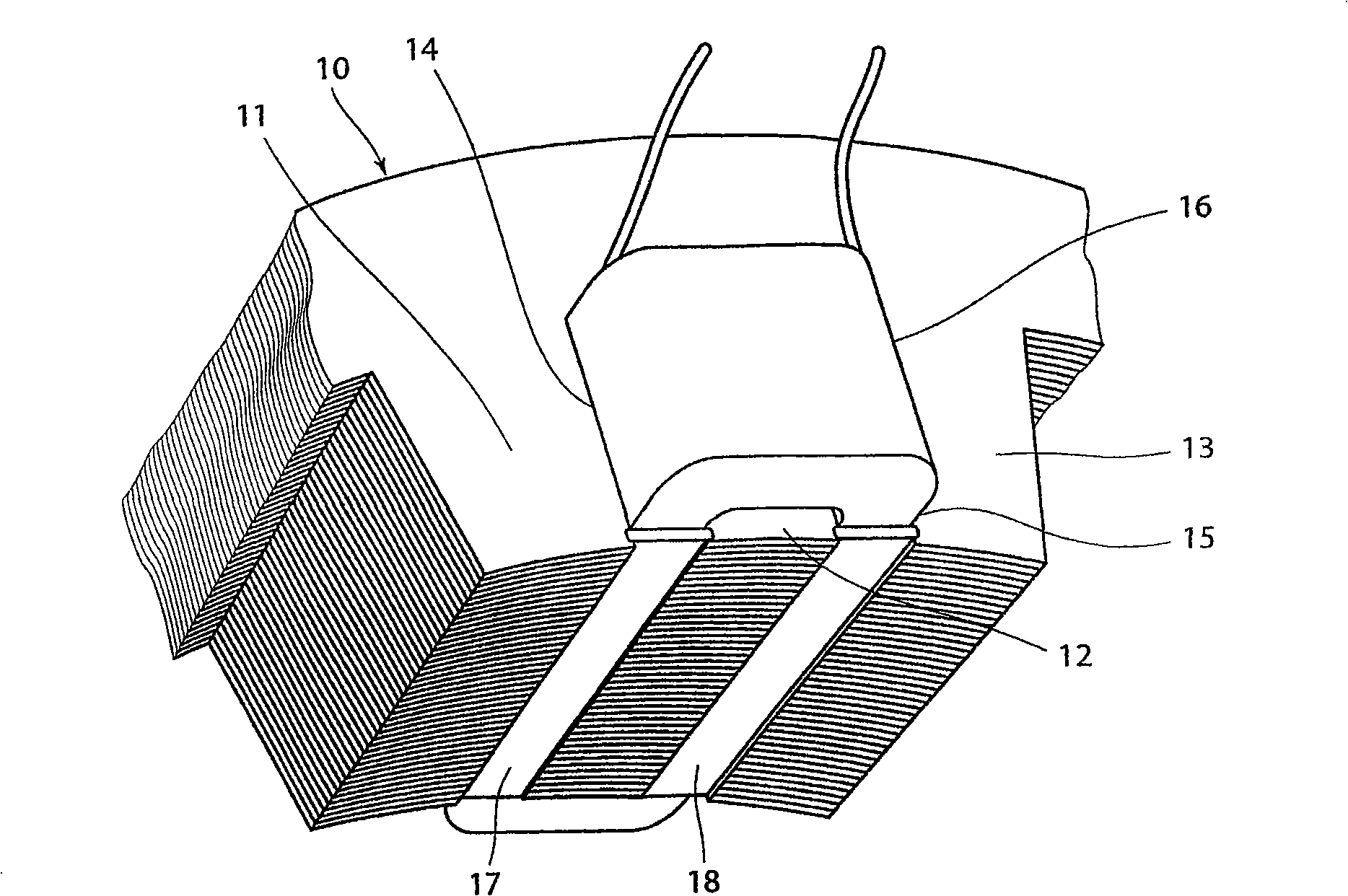

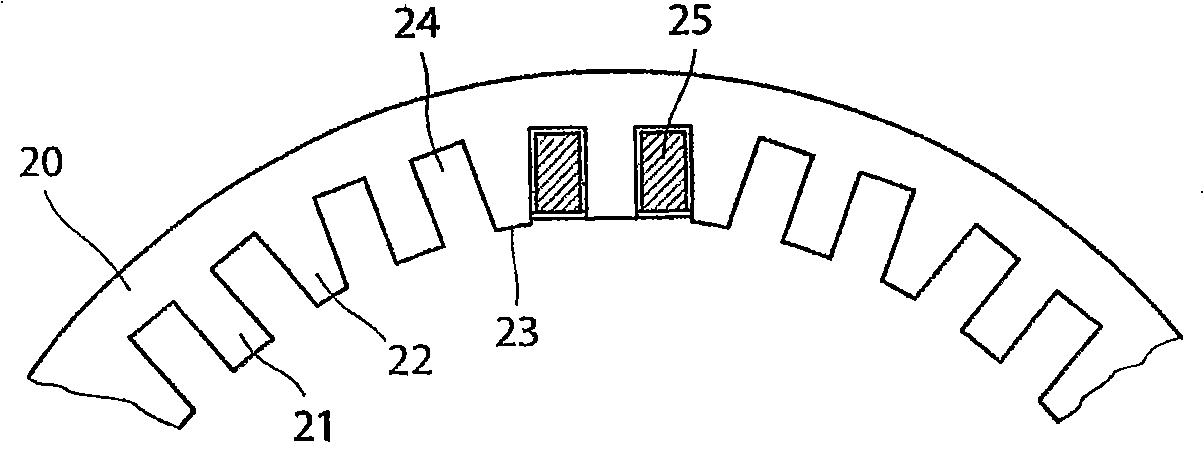

An electrical machine having a stator with rectangular and trapezoidal teeth

InactiveCN101411036AEasy to installLarge conductor cross sectionWindingsMagnetic circuit stationary partsElectric machineActuator

Arrangement at an electric machine, particularly motor, generator, or actuator, with a stator with teeth (11, 12) carrying coils (15), particularly one layer, for concentrated windings. A permanent magnetic rotor is movable relatively to the stator (11, 12). The teeth of the stator are arranged for receiving coils (15) with generally rectangular opening. Advantages are achieved if the stator teeth (11, 12) are provided to receive generally identical coils (15) closing the grooves (14, 16). The teeth (11, 12) may be alternating rectangular and converging / diverging toward the top, to provide grooves (14, 16), with parallel sides to enter the coils (15). The converging teeth (22) have preferably a shortened top (23). The grooves are preferably provided to make room for a semi magnetic groove wedge (17, 18) between adjacent teeth.

Owner:SMART MOTOR AS

Method for manufacturing an electrolyte material layer in semiconductor memory devices

InactiveUS20060205110A1High switching enduranceFast, scalable, low-voltage switching mechanismSemiconductor/solid-state device manufacturingDigital storageEngineeringElectrolyte

A method for manufacturing an electrolyte material layer with a chalcogenide material incorporated or deposited therein for use in semiconductor memory devices, in particular resistively-switching memory devices or components. The method comprises the steps of producing a semiconductor substrate, depositing a binary chalcogenide layer onto the semiconductor substrate, depositing a sulphur-containing layer onto the binary chalcogenide layer, and creating a ternary chalcogenide layer comprising at least two different chalcogenide compounds ASexSy. One component A of the chalcogenide compounds ASexSy comprises materials of the IV elements main group, e.g., Ge, Si, or of a transition metal, preferably of the group consisting of Zn, Cd, Hg, or a combination thereof.

Owner:ADESTO TECH

Optical lens module

Owner:GOLD CHARM LTD

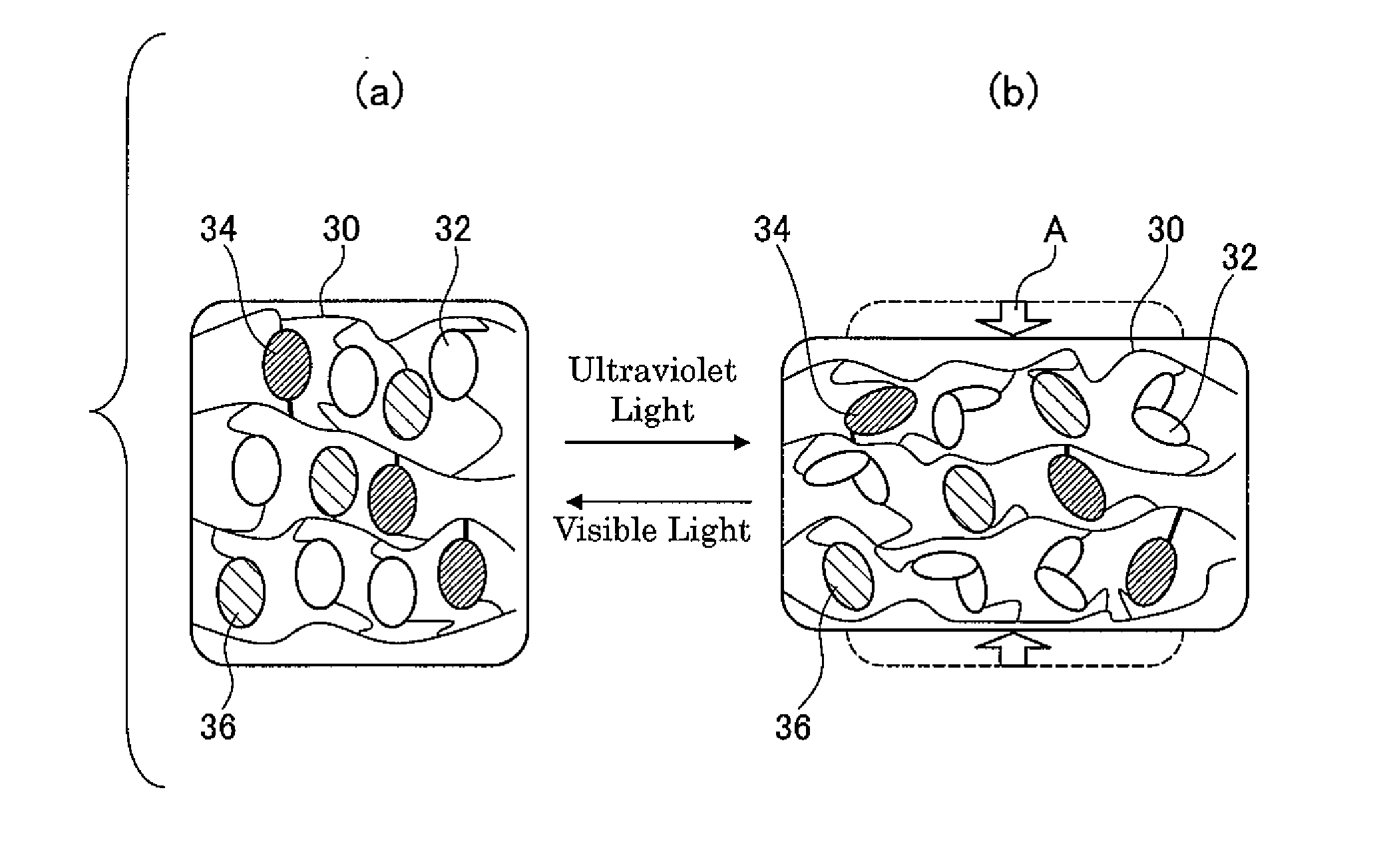

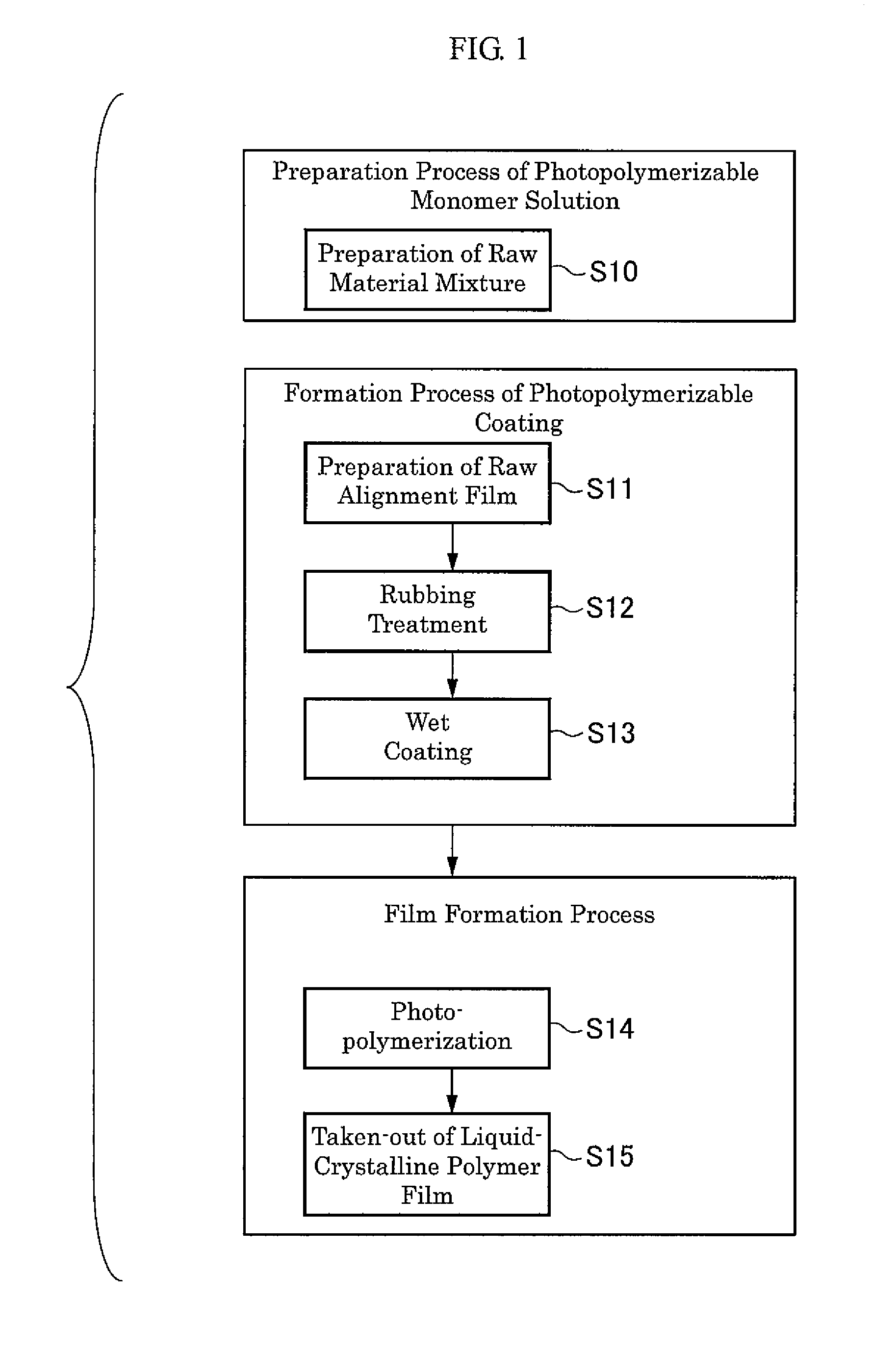

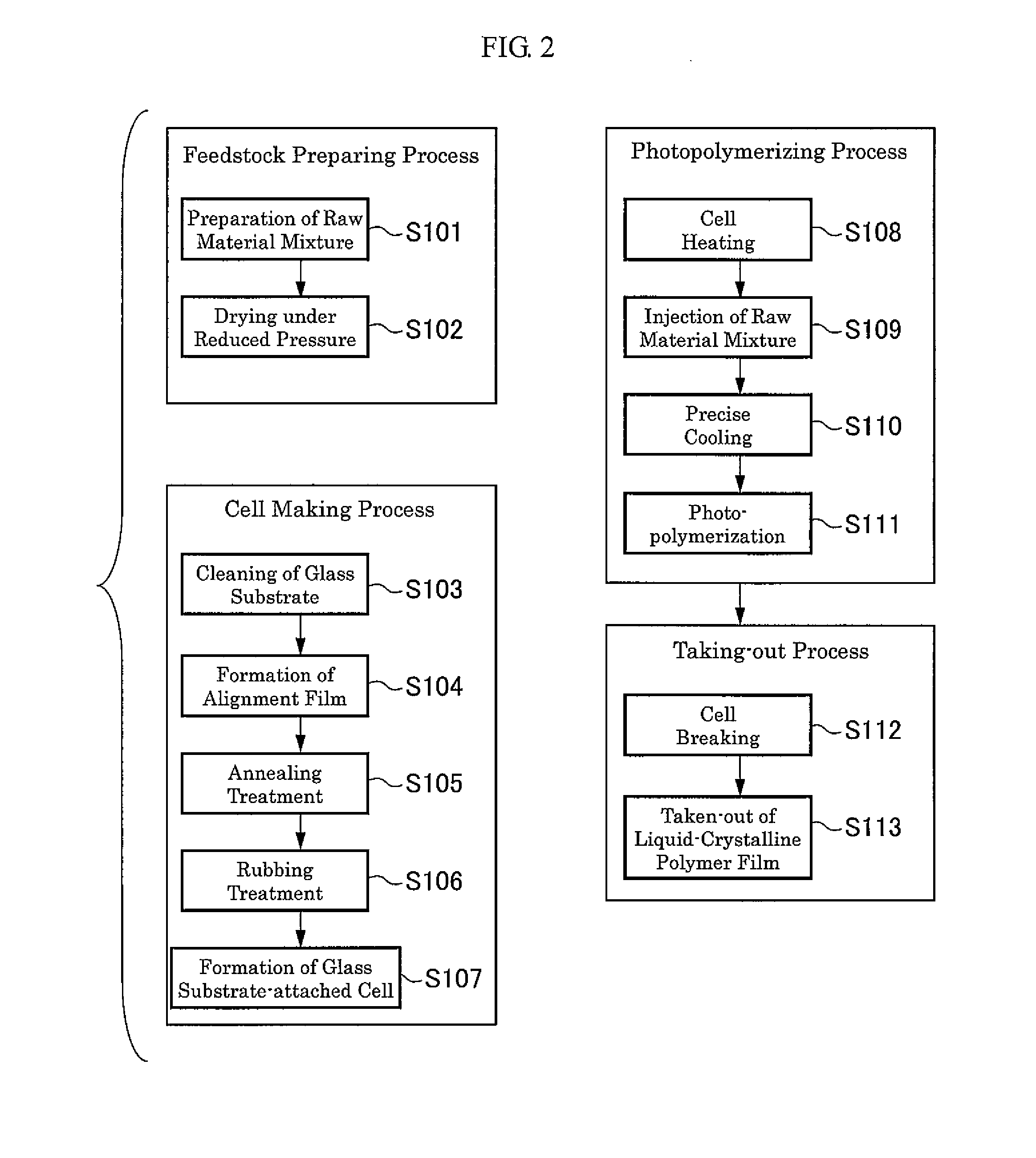

Method for manufacturing photo-responsive cross-linked liquid-crystalline polymer film

ActiveUS20150218409A1Simple and short-time and satisfactory control of film thicknessLow degree of freedomLiquid crystal compositionsSynthetic resin layered productsLiquid crystallineCross-link

The present invention relates to a method for manufacturing a photo-responsive cross-linked liquid-crystalline polymer film, containing: a process of preparing a photopolymerizable monomer solution by dissolving in a solvent a polyfunctional liquid-crystalline monomer, a monofunctional liquid-crystalline monomer, a polyfunctional photo-responsive monomer and a photopolymerization initiator; a process of forming a photopolymerizable coating by applying the photopolymerizable monomer solution to a surface of an alignment film by means of a wet coating method and performing removal of the solvent; and a process of forming a film by photopolymerizing the monomers through light irradiation of the photopolymerizable coating under a non-oxygen atmosphere.

Owner:NITTO DENKO CORP

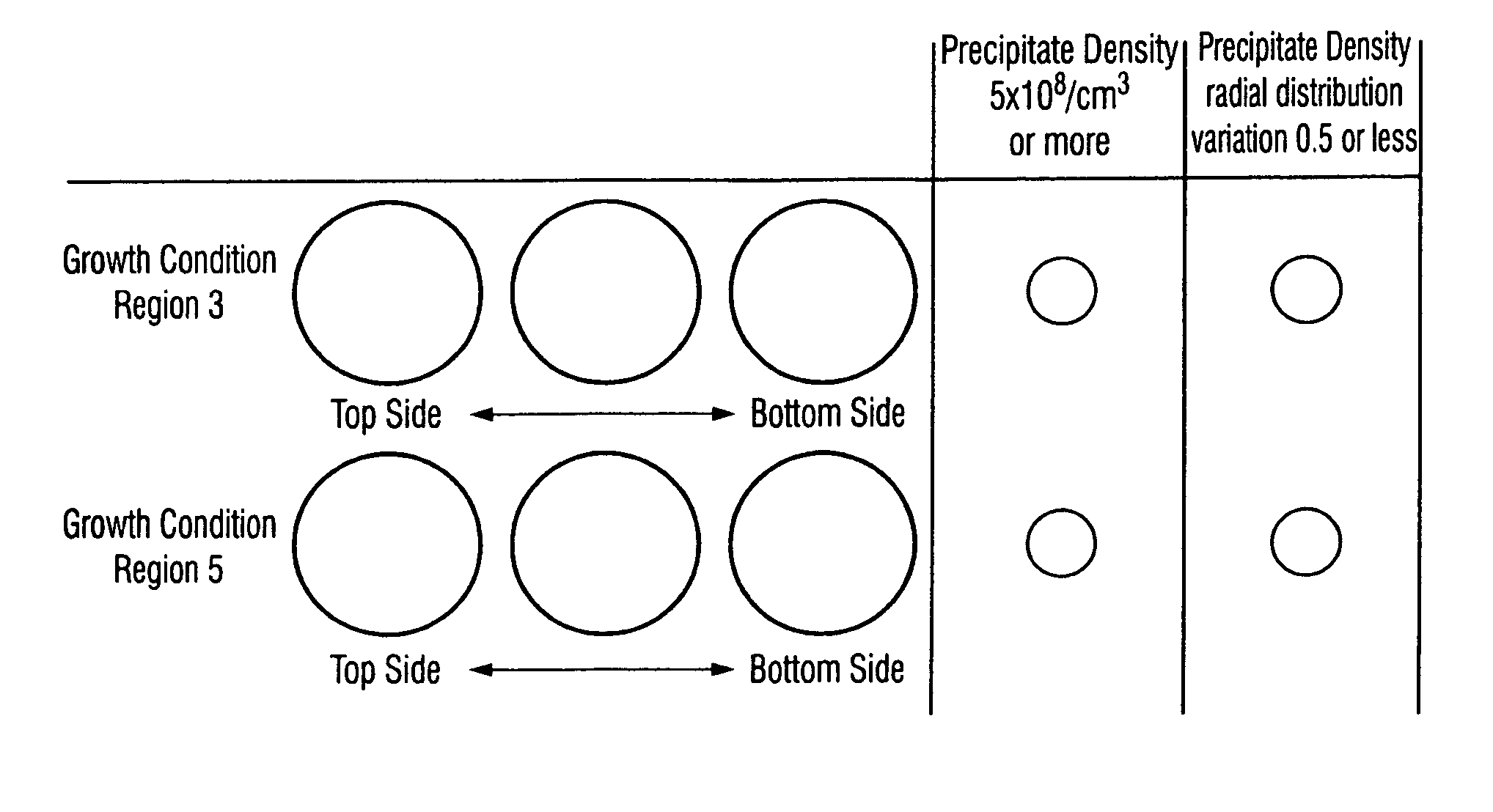

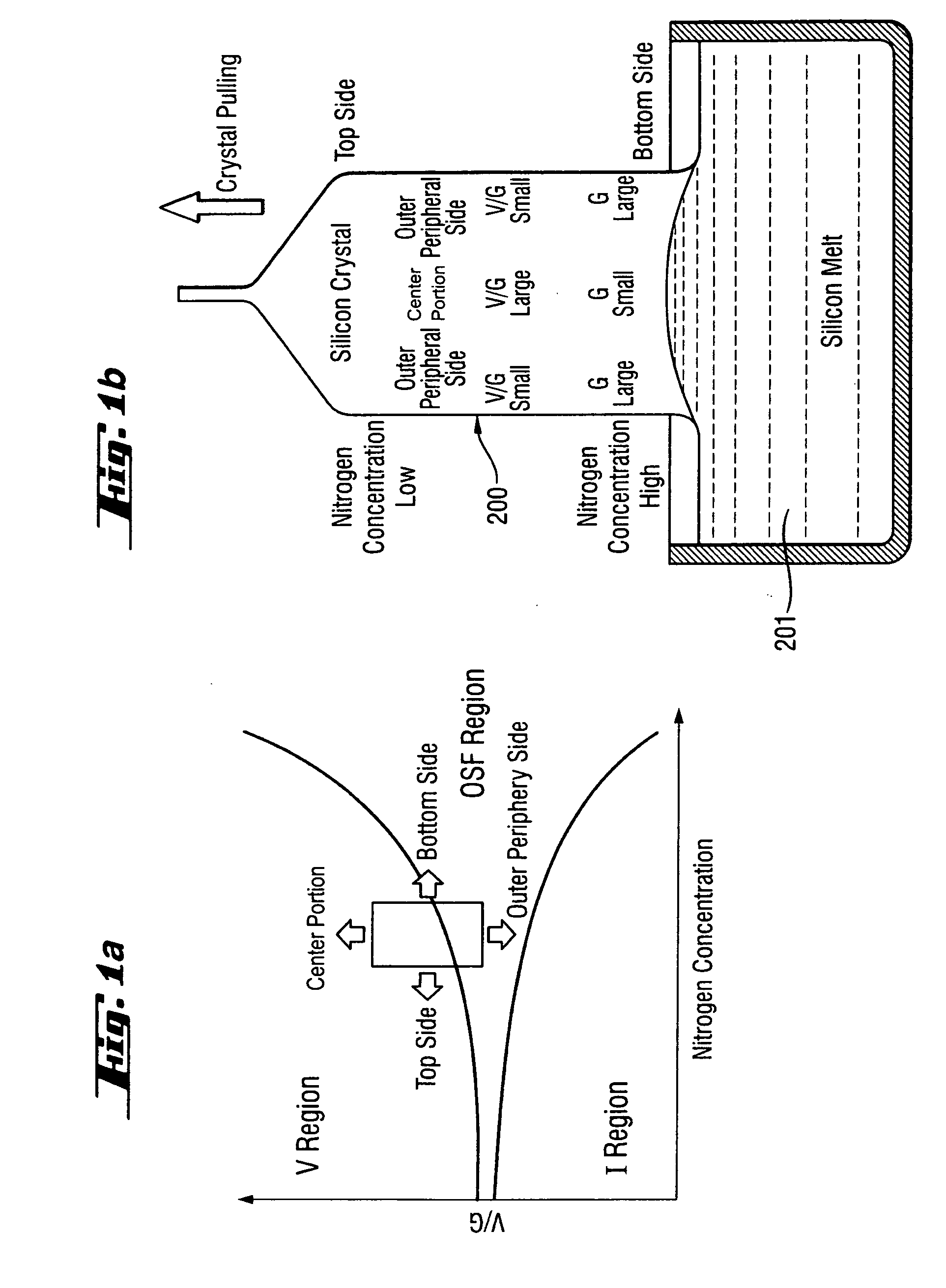

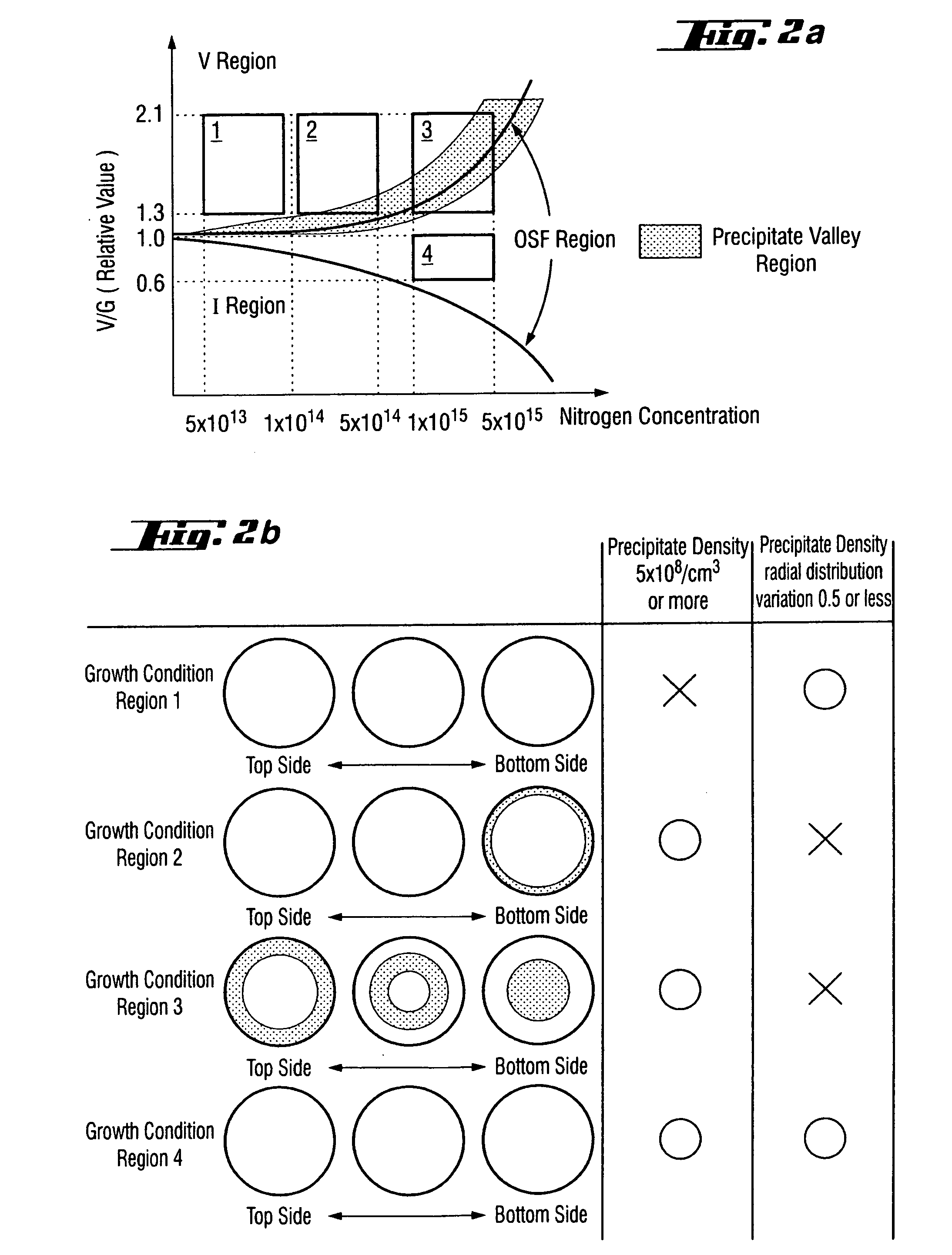

Annealed wafer and manufacturing method of annealed wafer

ActiveUS20070155134A1Reliable supplyIncreasing costPolycrystalline material growthAfter-treatment detailsSingle crystal substrateSingle crystal

An annealed wafer in which oxygen precipitation is uniform in the substrate plane and a manufacturing method thereof are provided. A nitrogen-doped silicon single crystal substrate pulled at the cooling rate of 4° C. / minute or more during crystal growth between 1100 and 1000° C. wherein the nitrogen concentration is 1×1014 to 5×1015 atoms / cm3 and V / G satisfies predetermined conditions serves as a substrate, and the substrate is subjected to heat treatment in a non-oxidative atmosphere.

Owner:SILTRONIC AG

Optical lens module

An optical lens module includes a lens barrel and a barrel base. The lens barrel includes an external wall. The barrel base has a receiving housing for receiving the lens barrel therein. The receiving housing includes an internal wall. The lens barrel defines at least a first positioning block or at least a second positioning slot at the external wall along a longitudinal axis of the lens barrel. The receiving housing defines at least a first positioning slot corresponding to the first positioning block or at least a second positioning block corresponding to the first positioning slot at the internal wall of the receiving housing.

Owner:GOLD CHARM LTD

Wiring substrate, electro-optic device, electric apparatus, method of manufacturing wiring substrate, method of manufacturing electro-optic device, and method of manufacturing electric apparatus

InactiveUS20070023899A1Improve performanceComplicated to makeSemiconductor/solid-state device detailsSolid-state devicesEngineering

Owner:SEIKO EPSON CORP

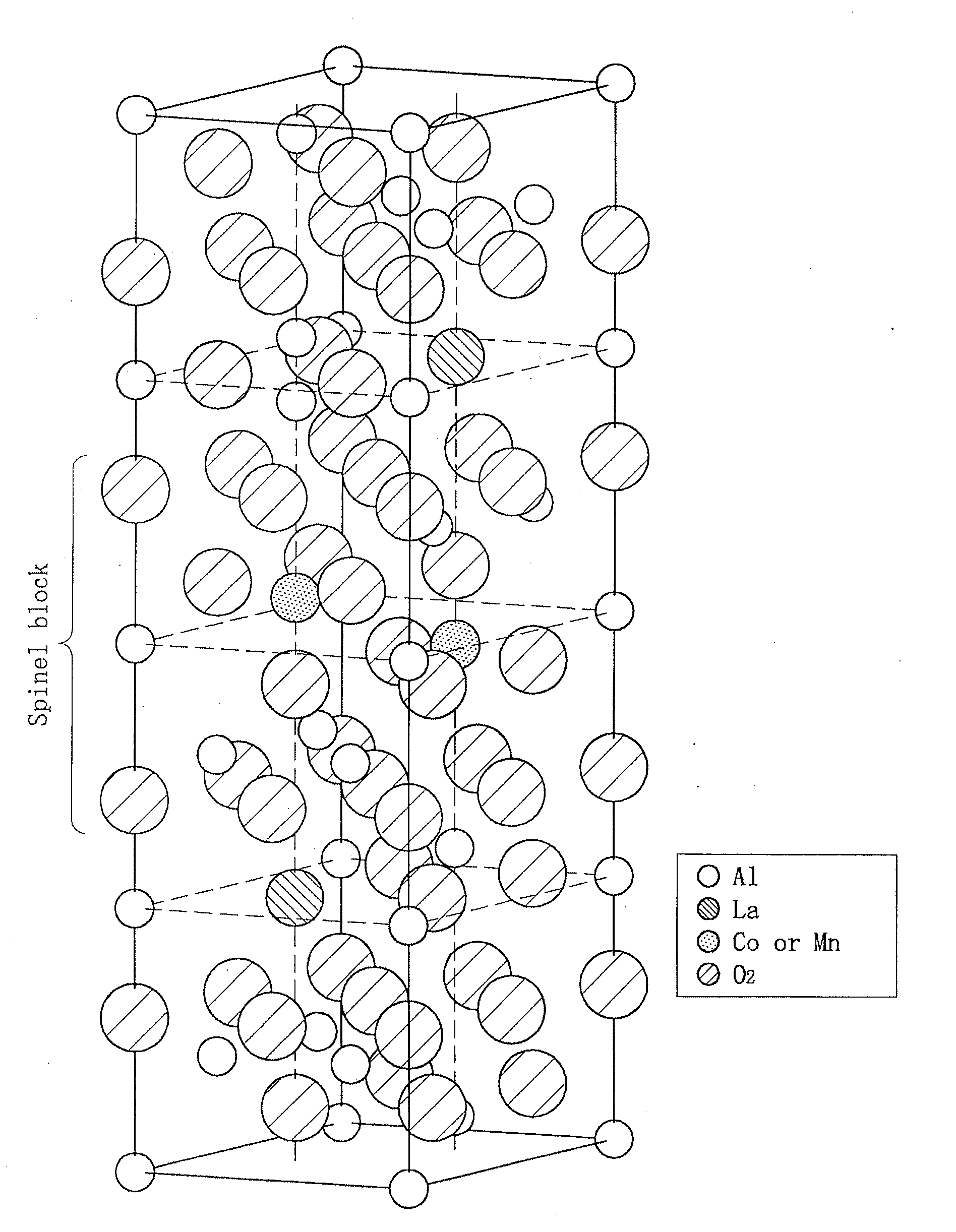

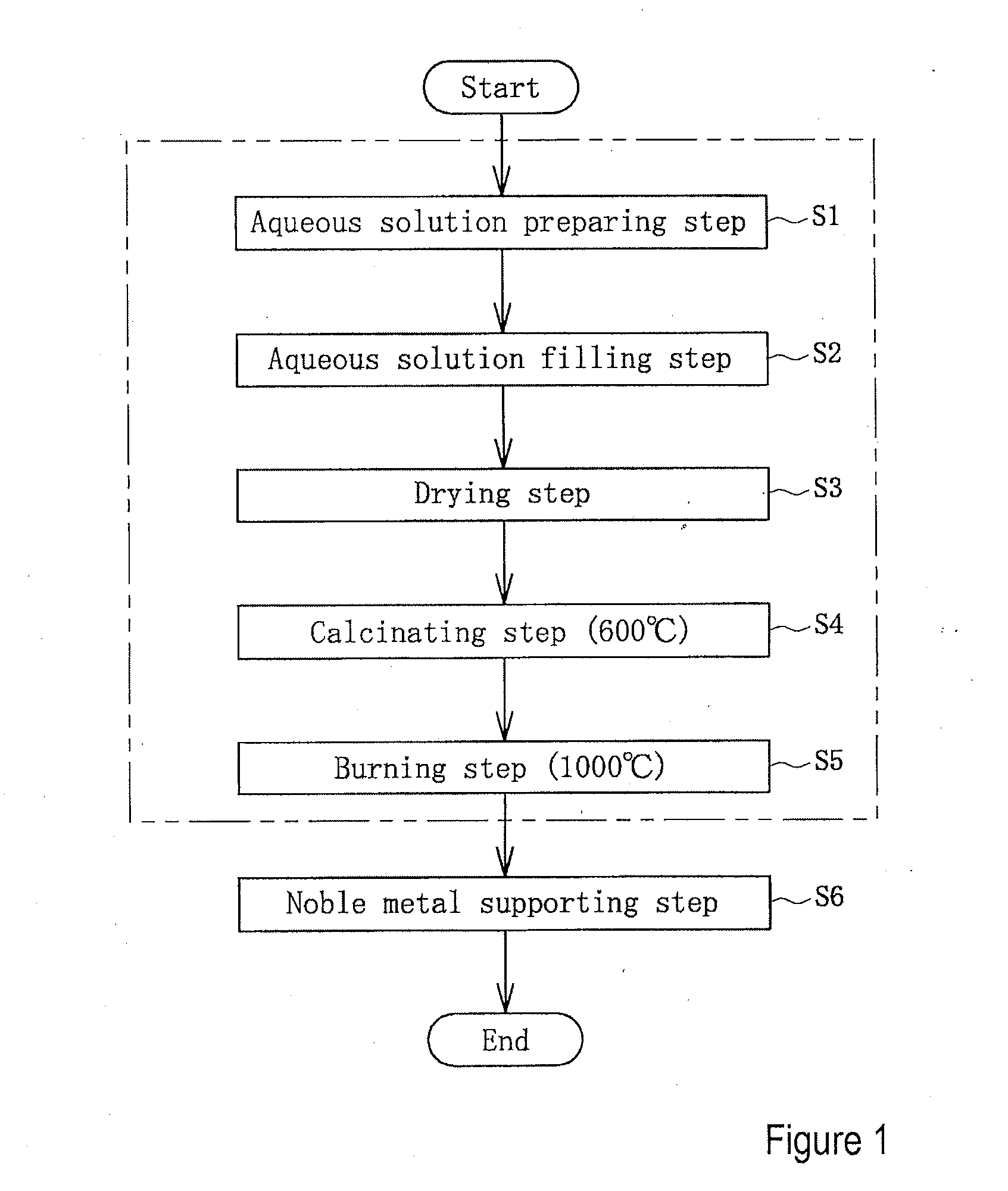

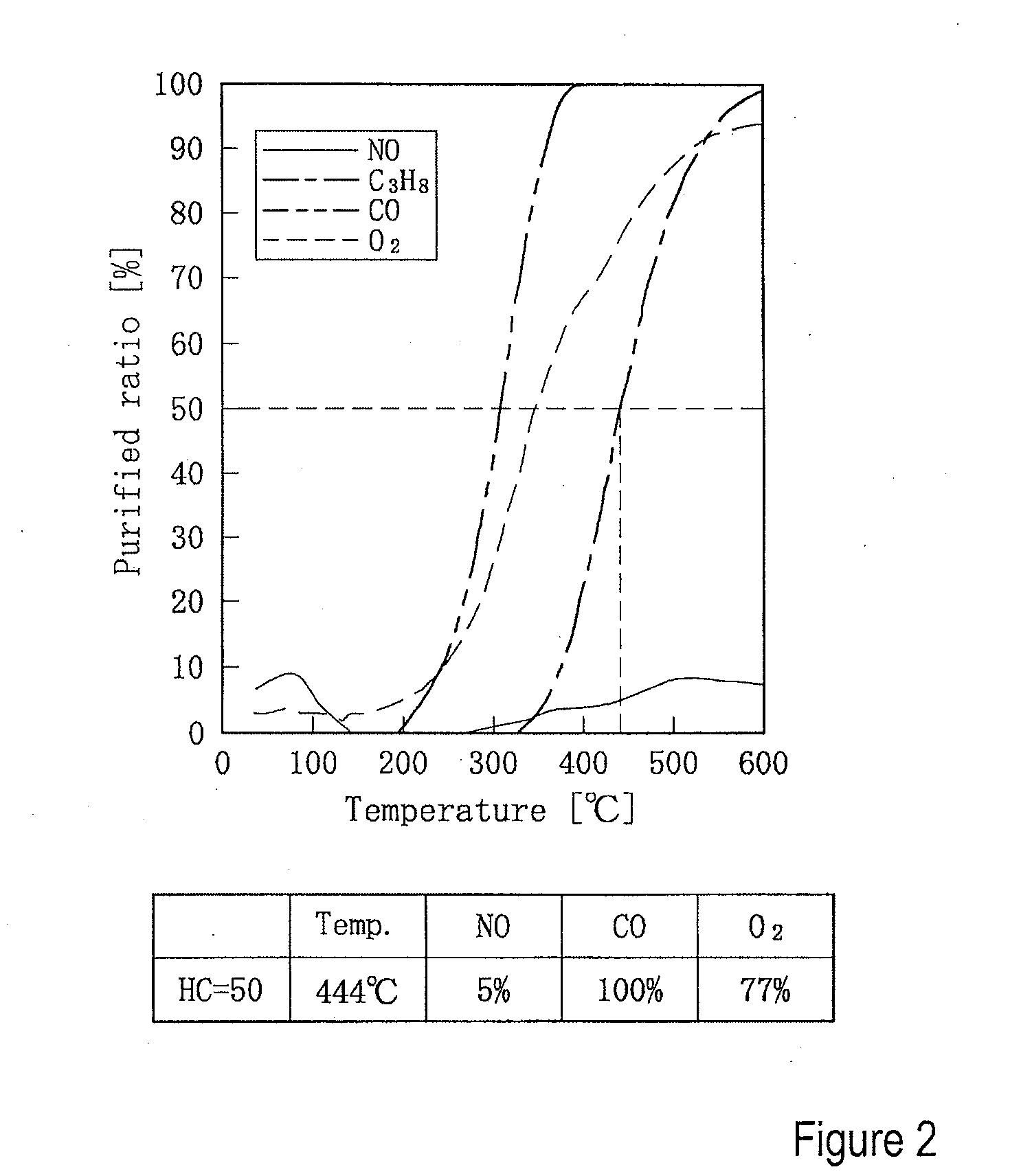

Catalyst support and method of producing same

InactiveUS20110039691A1Easy to produceImprove low temperature combustion activityAluminium compoundsInternal combustion piston enginesAqueous solutionLanthanum Ion

An object of the present invention is to provide a catalyst support which can maintain the purifying ability of HC, CO and NO even after being exposed to a high temperature atmosphere such as about 1000° C. for a long term and a method which can easily produce the catalyst support. According to the present invention there is provided a method for producing a catalyst support of porous alumina formed with pores within which magneto-plumbite type complex oxide ((La.M) Al11O19 (wherein M is Mn or Fe)) is formed and a noble metal is supported on the magneto-plumbite type complex oxide comprising an aqueous solution preparing step for preparing aqueous solution containing lanthanum ions and either manganese ions or iron ions; an aqueous solution filling step for filling the pores of porous alumina with the aqueous solution obtained in the aqueous solution preparing step by a pore-filling method using the capillarity caused in the pores; a drying step for drying the porous alumina of which pores are filled with aqueous solution in the aqueous solution filling step, and a burning step for forming the magneto-plumbite type complex oxide by burning the porous alumina obtained in the drying step.

Owner:FCC KK

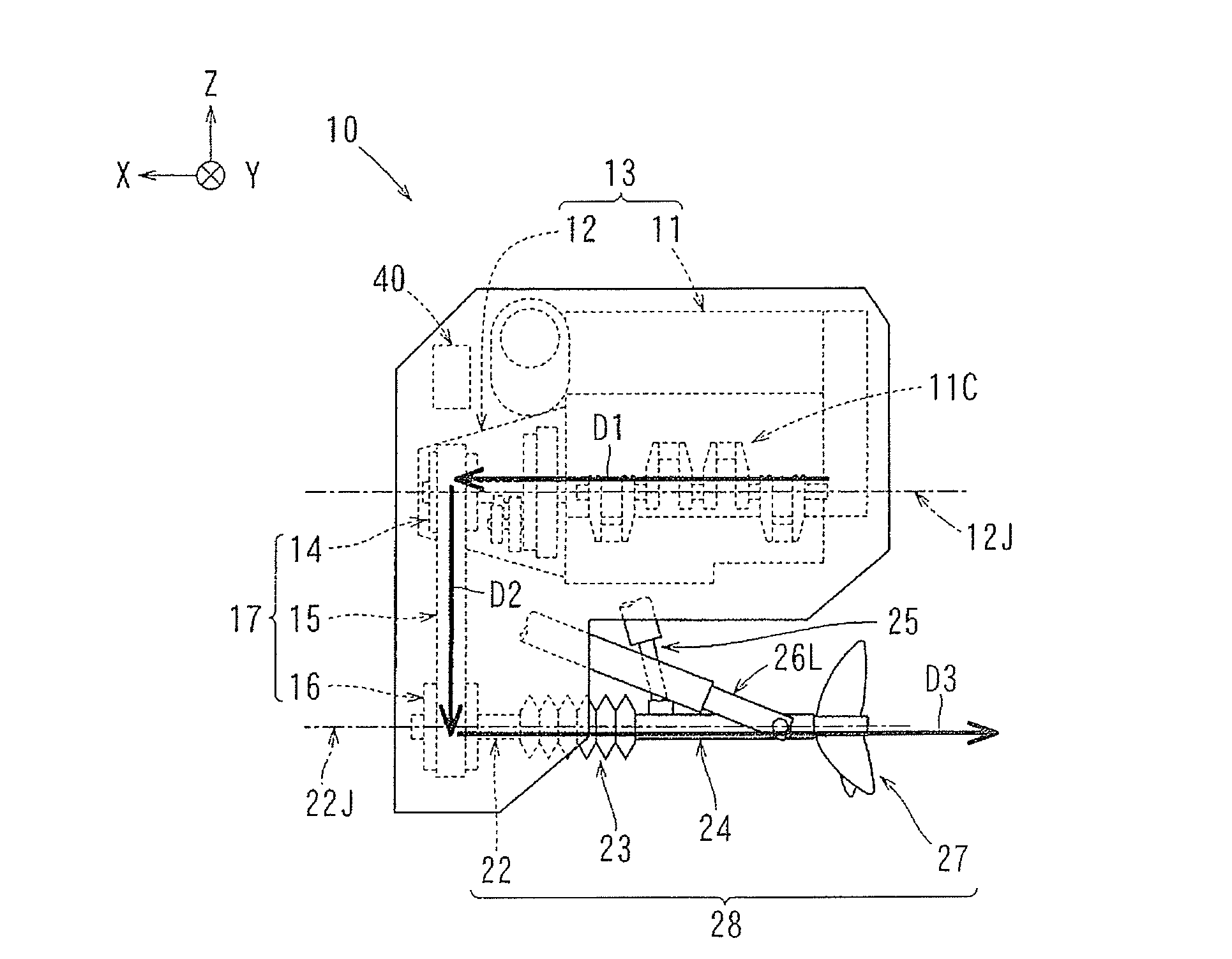

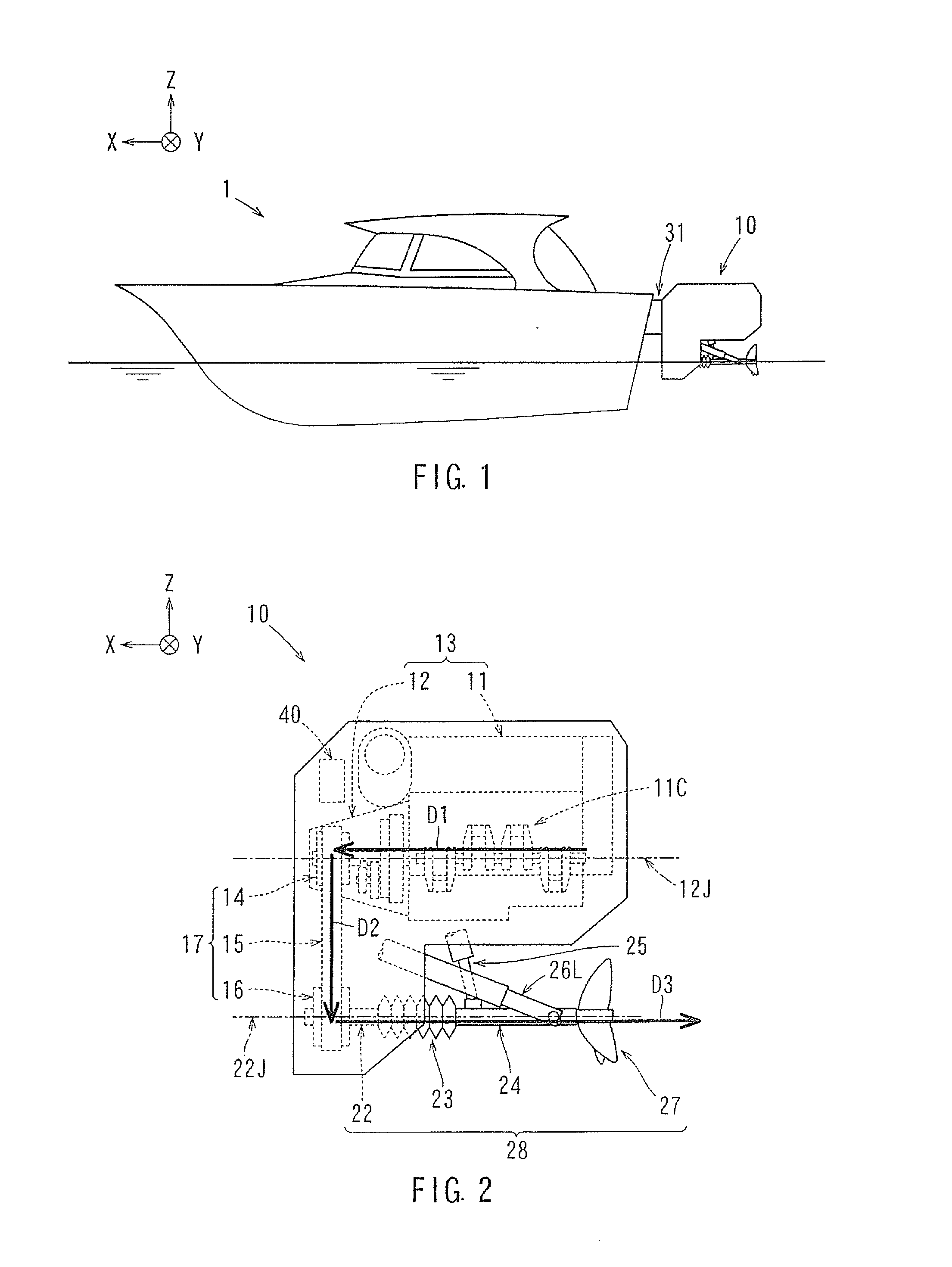

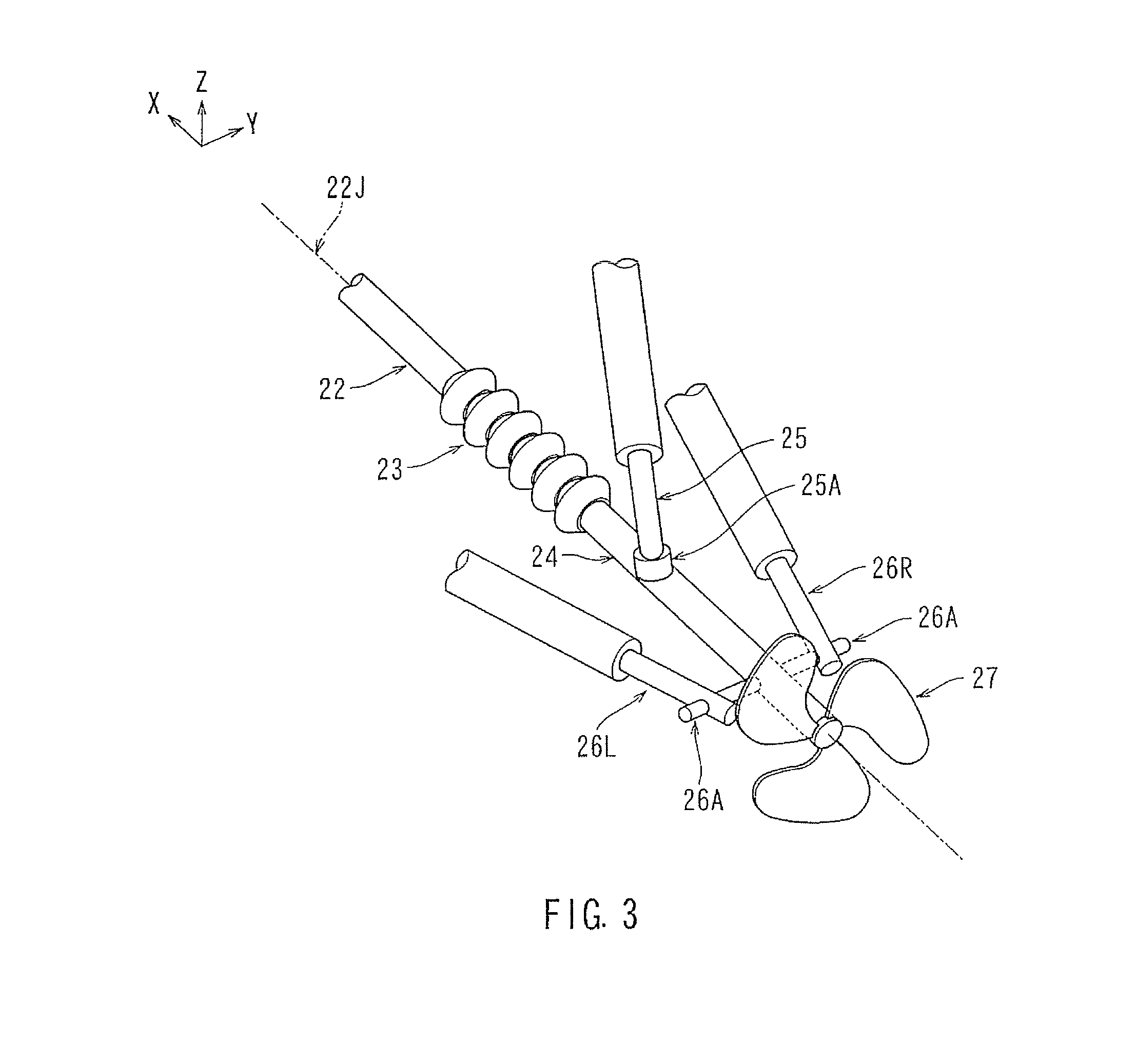

Marine engine propelling apparatuses

ActiveUS20170043853A1Easy maintenanceEasy to useSteering ruddersRotary propellersPropellerEngineering

A marine engine propelling apparatus (10) is mounted to an outboard portion at a rear end of a boat. The engine propelling apparatus (10) has a power generating portion (13), a power transmitting portion (17) provided below the power generating portion (13), a propelling force generating portion (28) provided below the power transmitting portion (17), and a height adjustment mechanism (25). The power generating portion (13) includes an engine (11) equipped with a crankshaft (11C), and the crankshaft (11C) is arranged substantially parallel to a front-rear direction of the boat and is substantially horizontal. The power transmitting portion (17) has a power transmission mechanism forming a linear power transmission route (D2) extending from the vicinity of a front end of the crankshaft (11C) to the vicinity of a front end of the propelling force generating portion (28). The propelling force generating portion (28) includes a propeller shaft (22) extending rearwards from the power transmitting portion (17), and a propeller (27) provided at a rear portion of the propeller shaft (22). The height adjustment mechanism (25) is configured to vary inclination of a part of the propeller shaft (22) with respect to the boat to thereby vary height of the propeller (27) with respect to the boat.

Owner:TOYOTA IND CORP +1

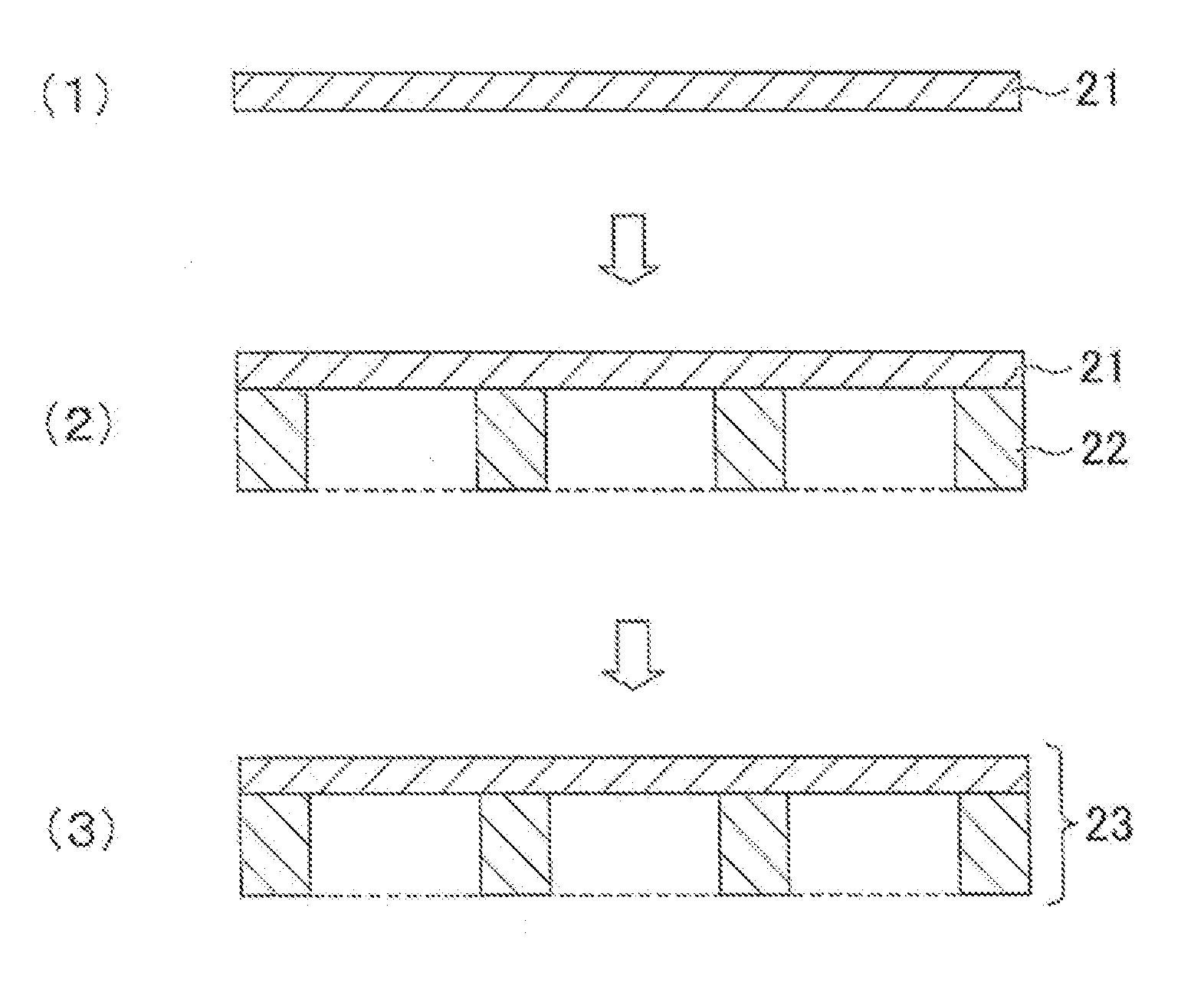

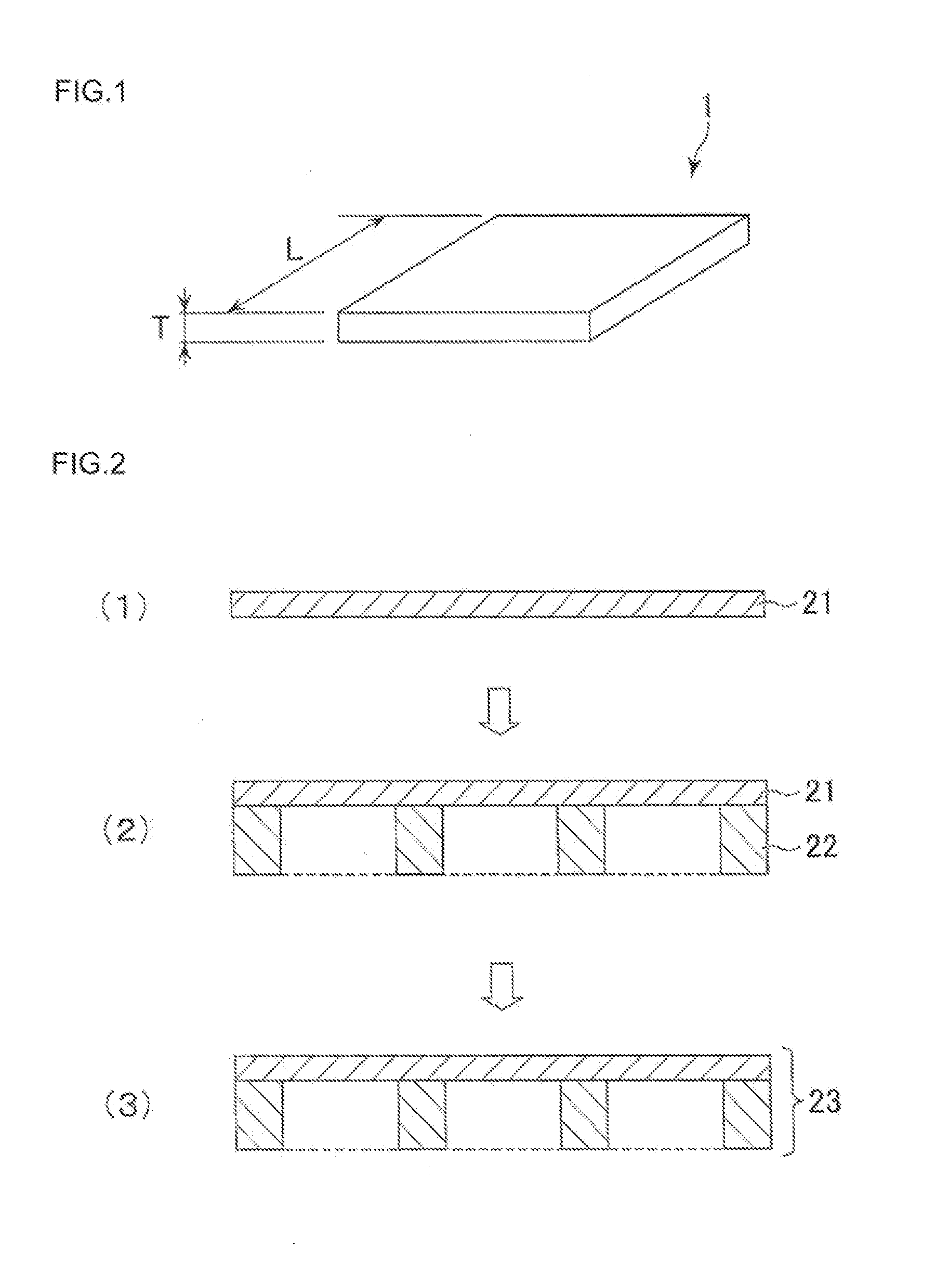

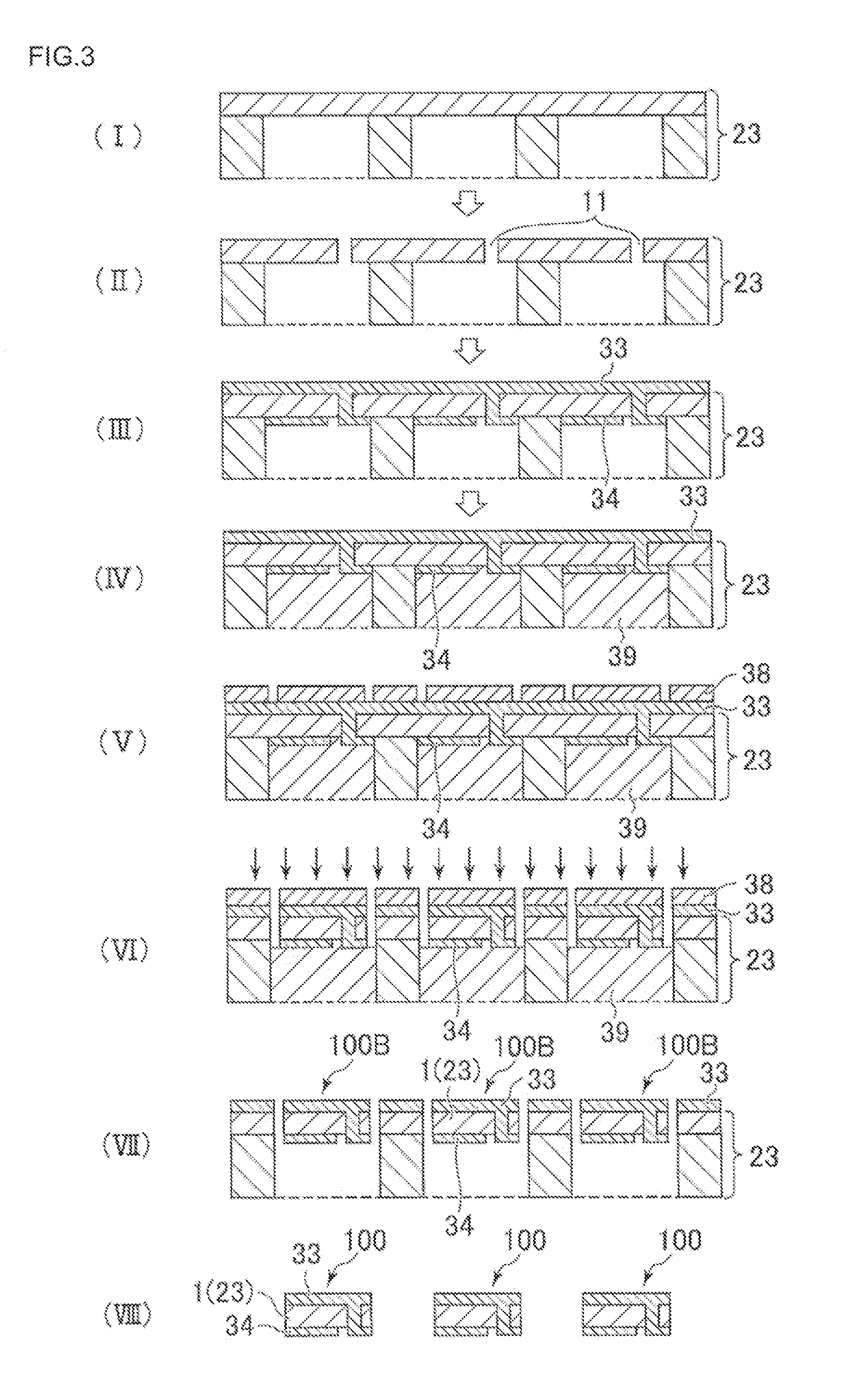

Method for manufacturing piezoelectric element

InactiveUS20120117769A1Warpage is hardlyAvoid damagePiezoelectric/electrostrictive device manufacture/assemblyOperating means/releasing devices for valvesEngineeringMechanical engineering

Owner:NGK INSULATORS LTD

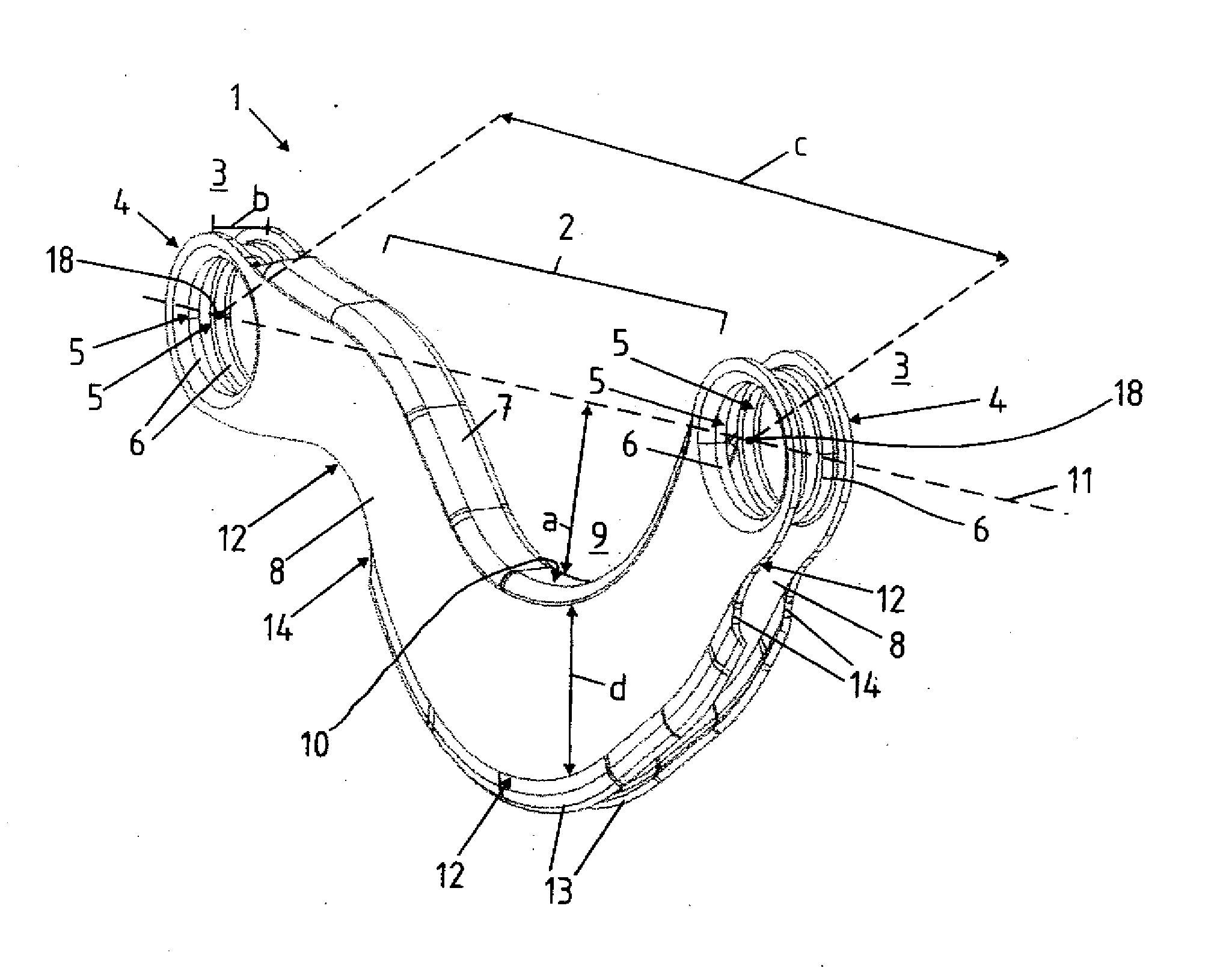

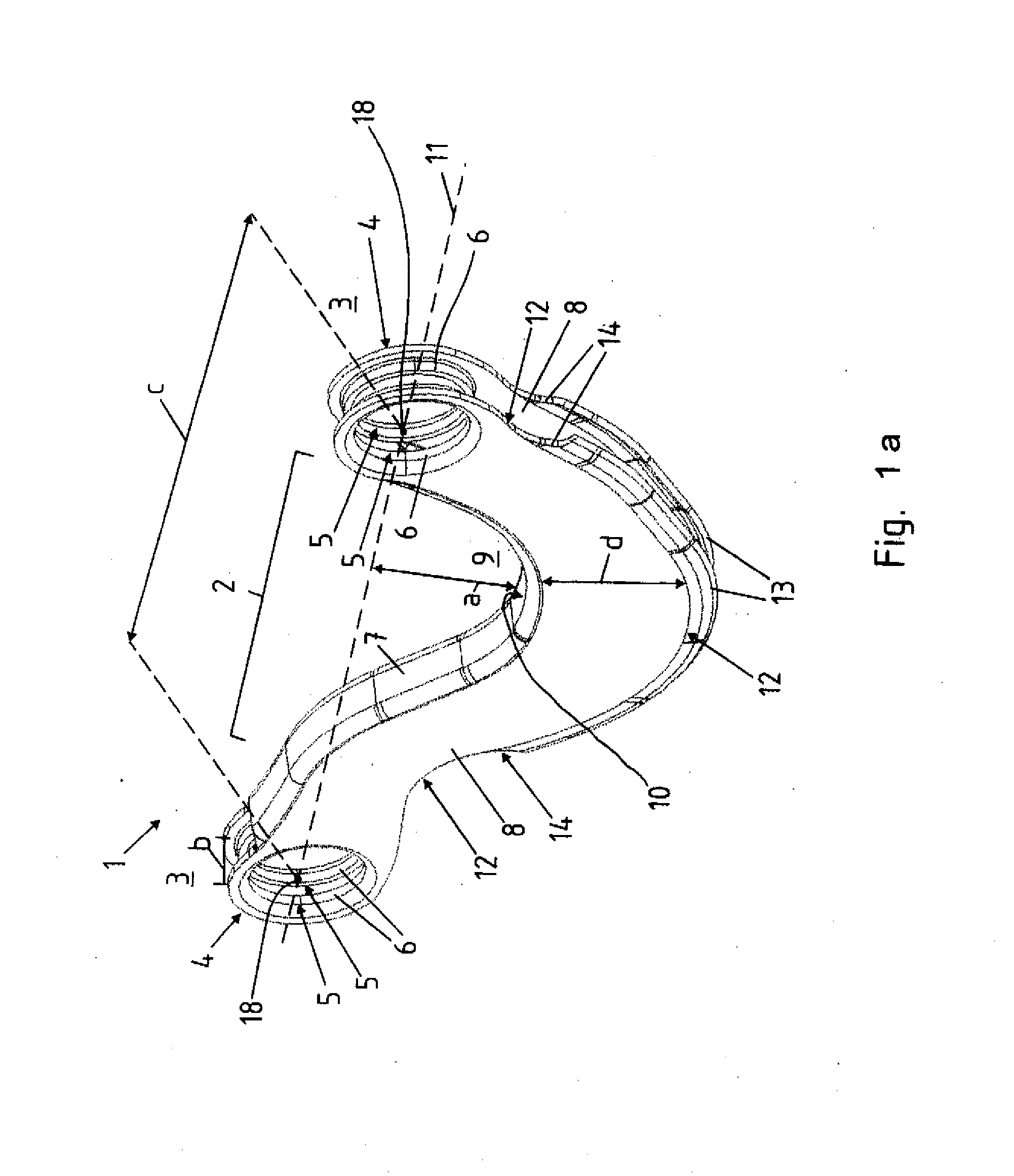

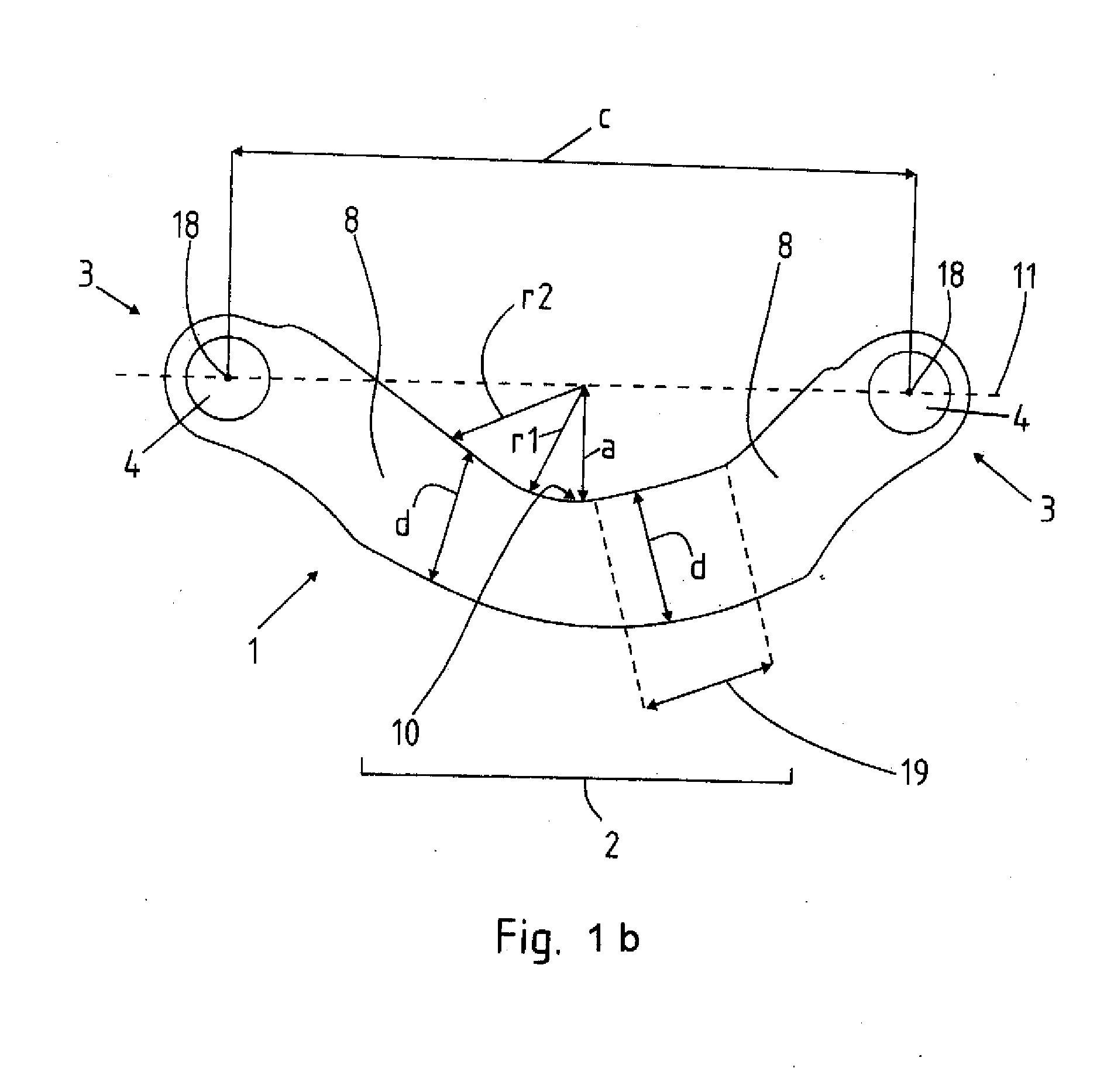

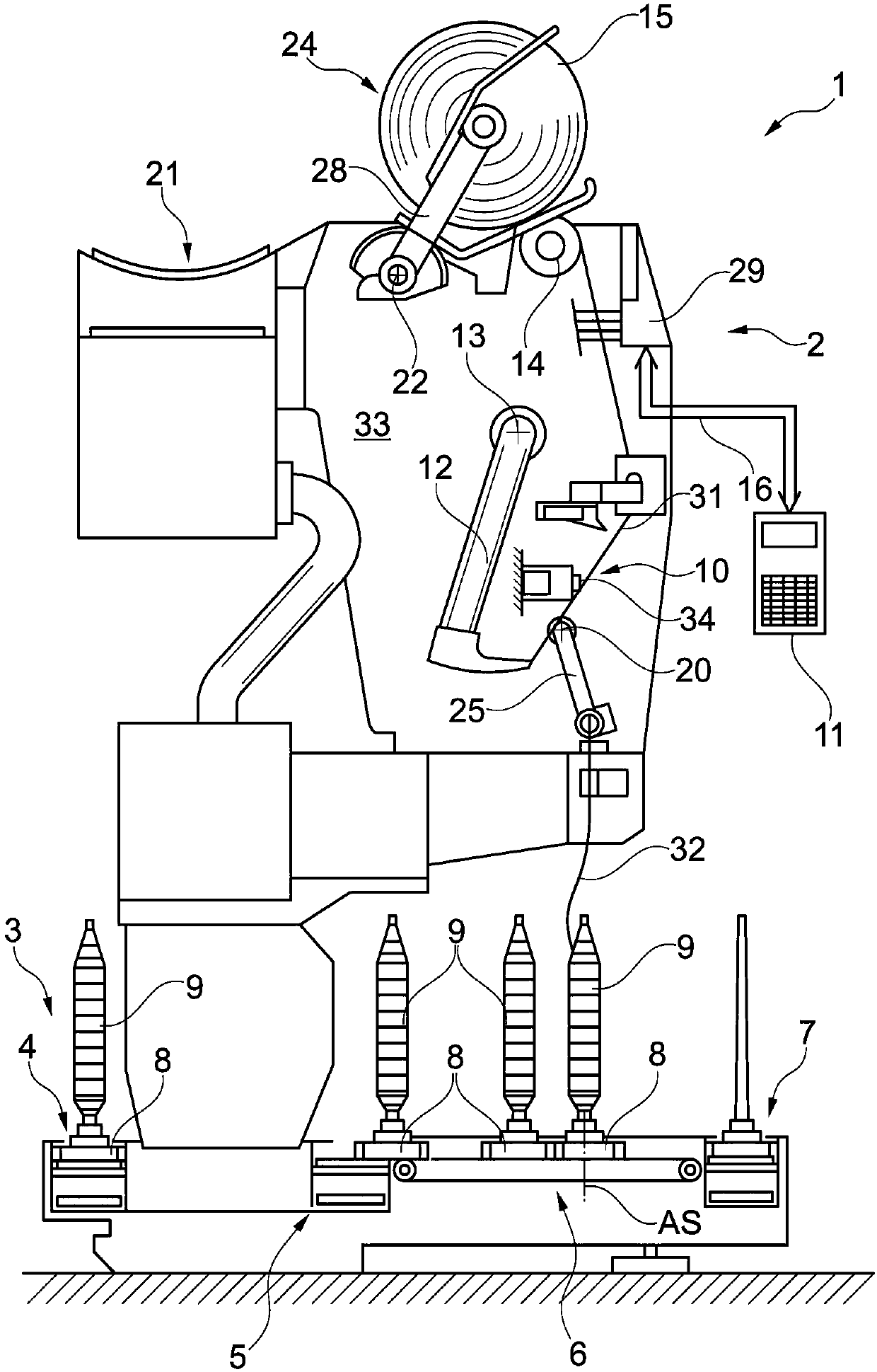

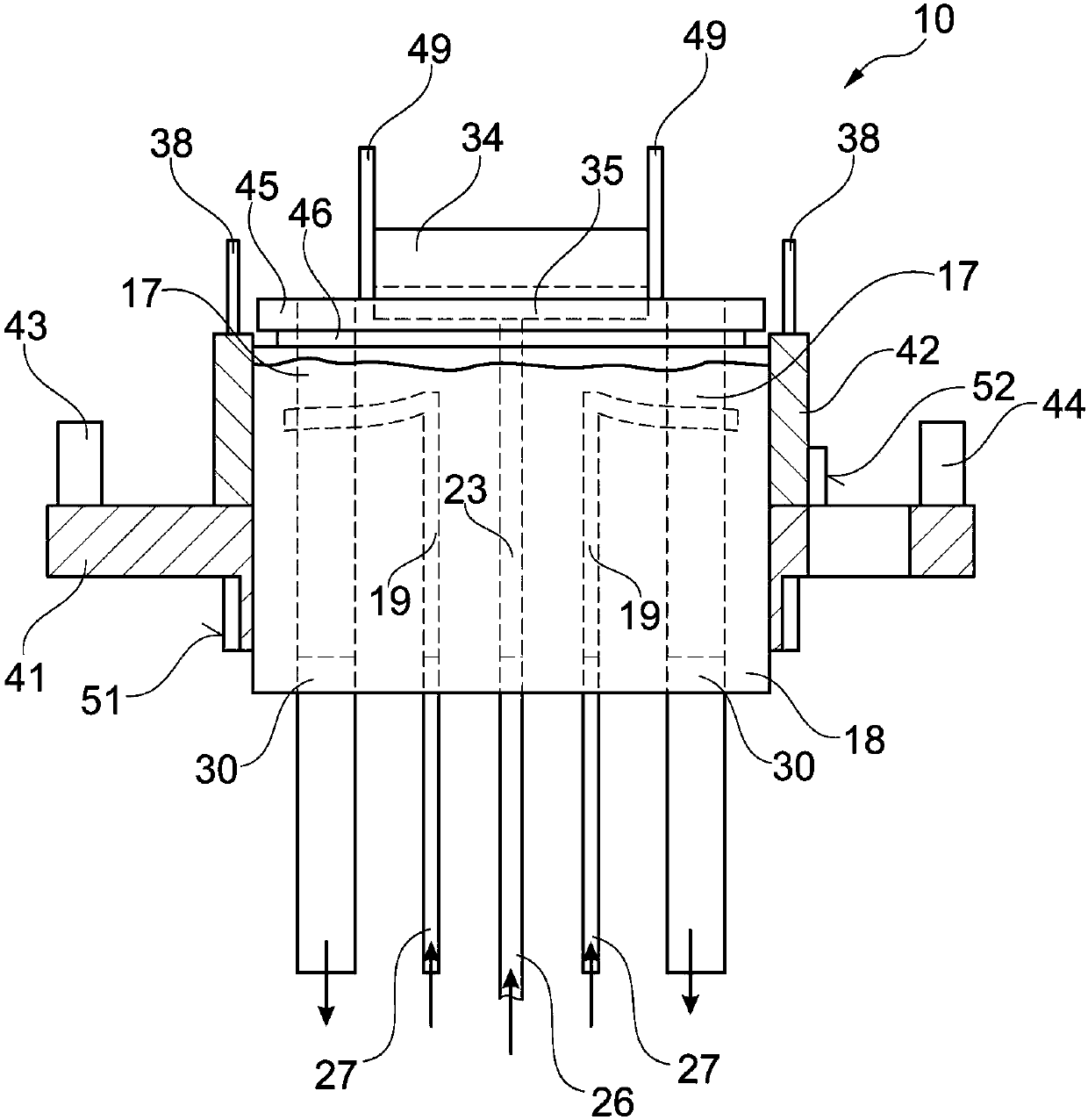

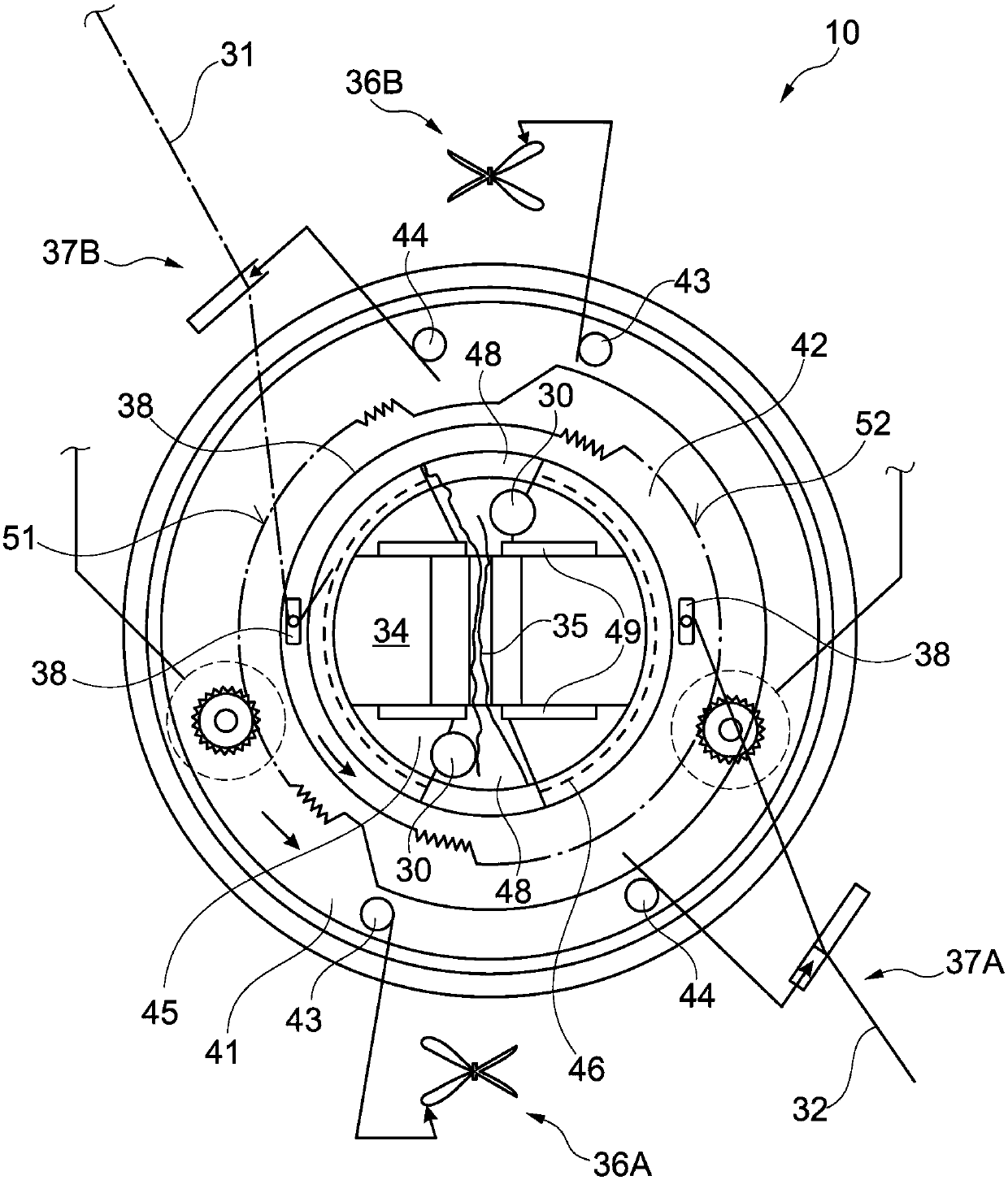

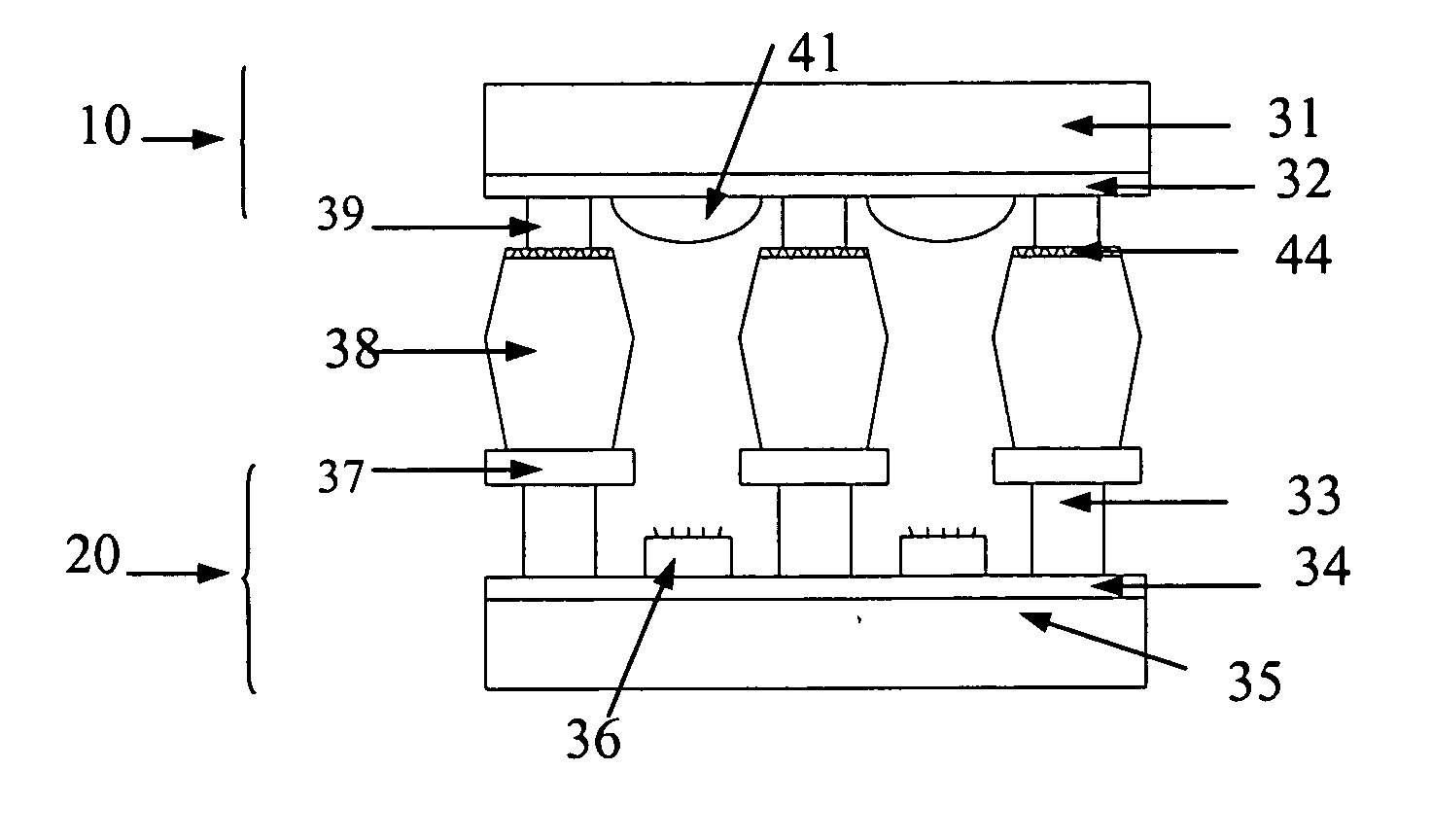

Yarn splicing device for a workstation of a textile machine producing cross-wound bobbins

The invention relates to a yarn splicing device (10) for a workstation (2) of a textile machine (1) producing cross-wound bobbins. The yarn splicing device (10) includes a yarn splicing prismoid (34)and a yarn feeder (38), wherein the yarn splicing prismoid (34) is fastened to an air distributor (18) and is provided with a yarn receiving channel (35) which can receive compressed air. The yarn feeder is arranged at a distance from the yarn splicing prismoid (34) and is limited-rotatably installed. According to the invention, there is a yarn guiding trough (46) for receiving yarn headers of upper yarns (31) and lower yarns (32) in the zone of the yarn splicing prismoid (34). A tunnel outlet (48) is arranged at each outlet side of the yarn receiving channel (35) of the yarn splicing prismoid(34). Each outlet (48) is provided with an accommodating hole (30) which is used for holding an opening small tube (17).

Owner:SAURER GERMANY GMBH & CO KG

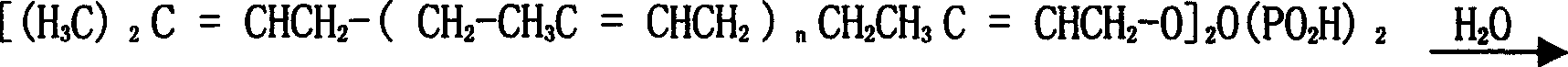

Method for synthesizing polypren phosphate

InactiveCN1709894AComplicated to makeConvenient sourcePhosphorus organic compoundsEmulsionOrganic solvent

This invention has disclosed a manufacturing method for polypentenyl phosphate. Put oil of plant polyprenol into nonpolar organic solvent, formed a mix solution, under the nitric organic alkali catalysis, put phosphorylation agent into above-mentioned mix solution, mix, get mixture contained reaction products, put hydrolysis liquid into the mixture, mixing for 1-2 hours, then evaporation, retrieve the organic solvent, the hangover is mainly emulsion of polypentenyl phosphate. Extract above-mentioned emulsion with the solvent to separate, volume ratio of emulsion and solvent is 1:(5-100), the solvent is mixture of nonpolar organic solvent and water, ratio of nonpolar organic solvent and water is (1-10):1, mixing for 1-10 hours, then wait 1-10 hours quietly for delamination, wash the supernatant with saturated inorganic sodium salt solution again and again to neutrality, recovery nonpolar organic solvent in the supernatant, gained yellow oil of polypentenyl phosphate.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

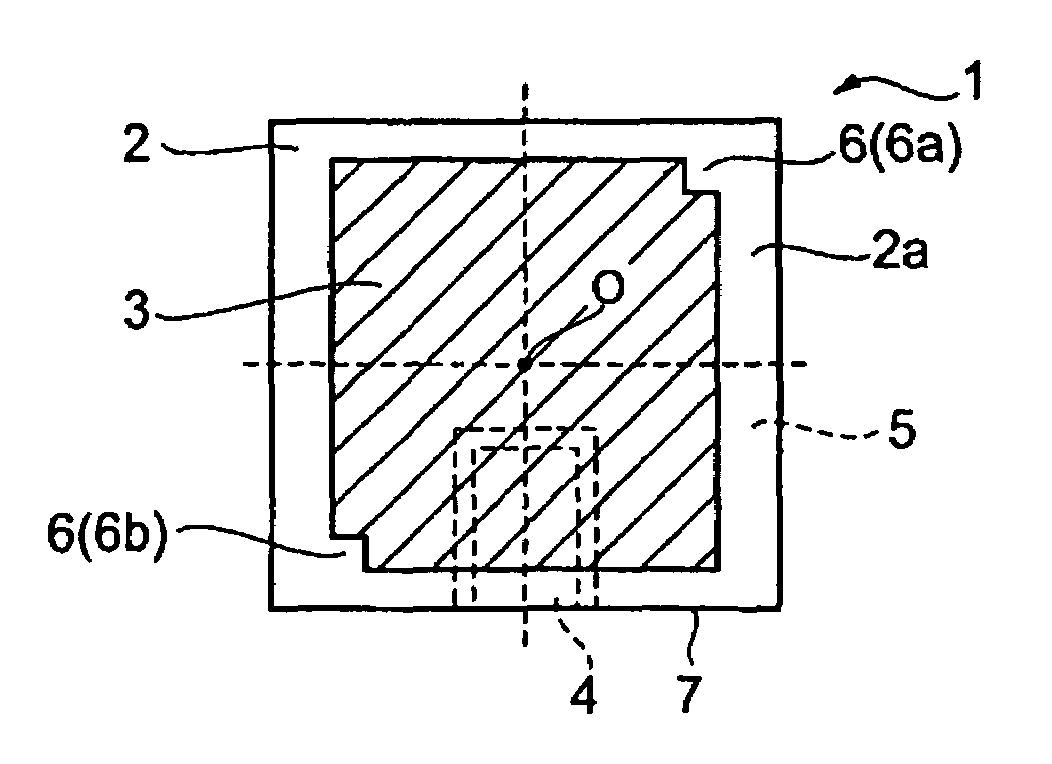

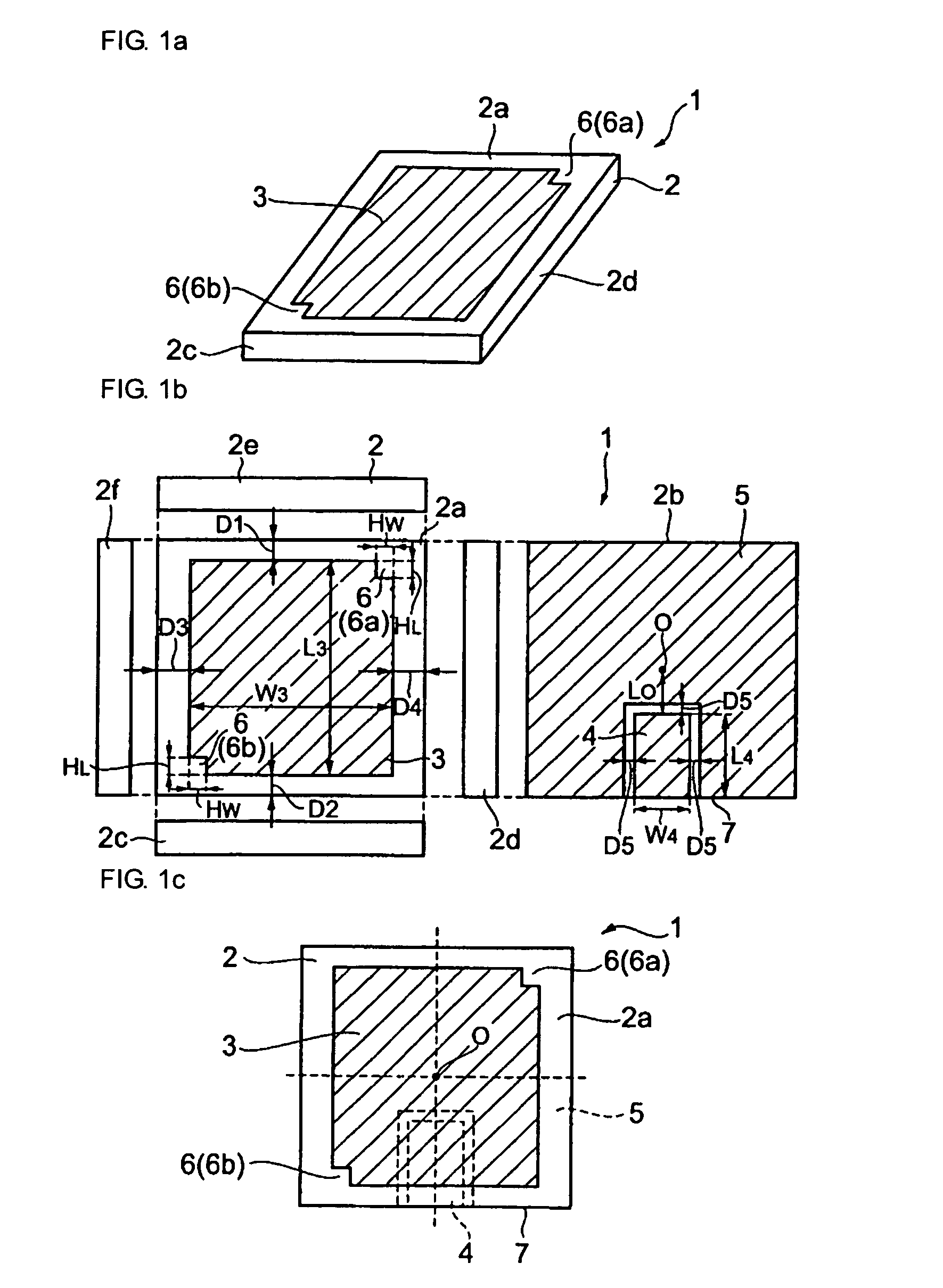

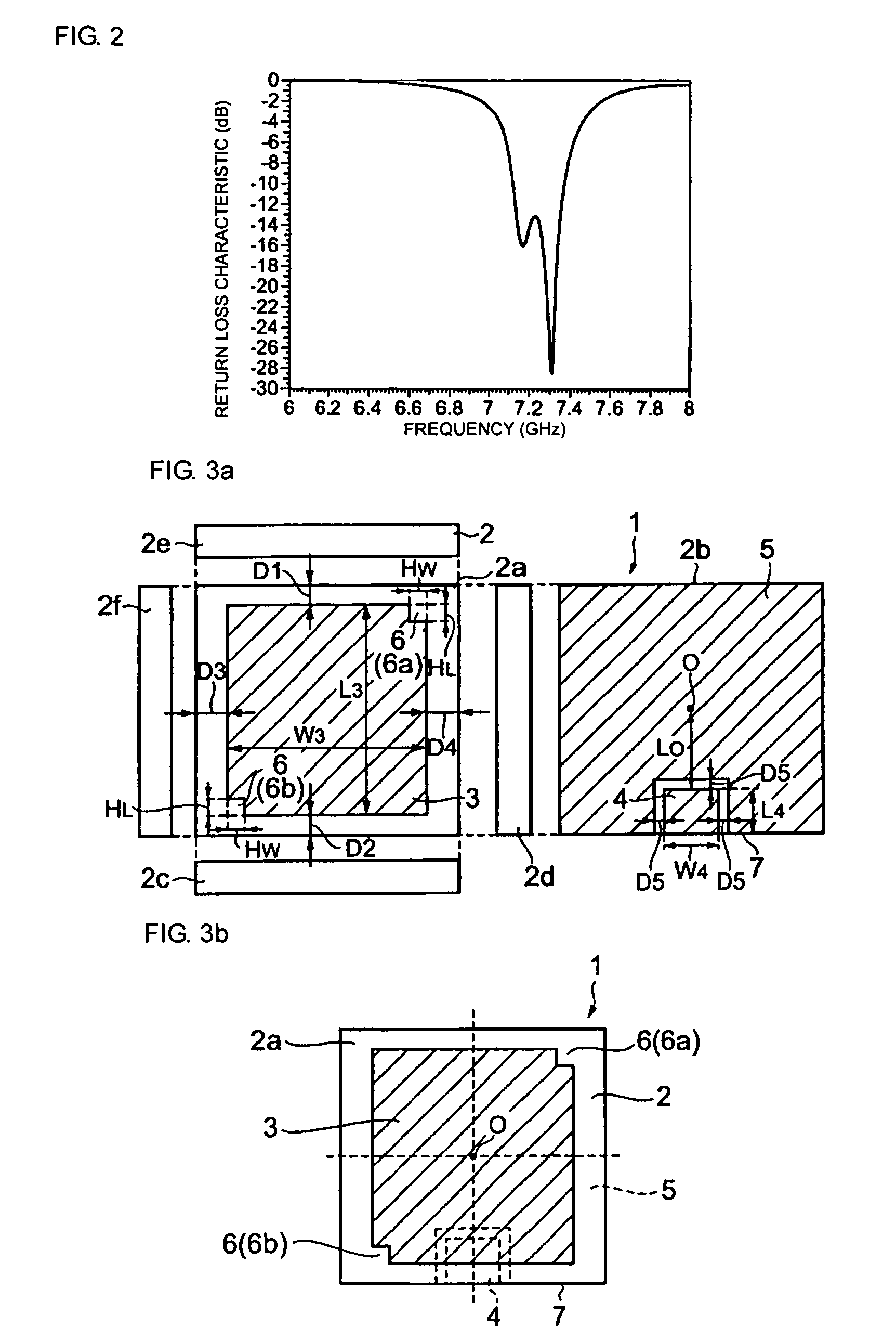

Circularly polarized microstrip antenna and radio communication apparatus including the same

InactiveUS7369088B2Shorten the lengthComplicated to makeSimultaneous aerial operationsRadiating elements structural formsDielectric substrateOptoelectronics

A circularly polarized microstrip antenna includes a dielectric substrate having only an emitting electrode for generating circularly polarized waves on a front surface of the dielectric substrate and a coplanar signal line for feeding the emitting electrode and a ground electrode on a back surface of the dielectric substrate. The ground electrode covers the entire area of the back surface of the dielectric substrate excluding a region in which the signal line is provided. The signal line extends from an edge of the back surface of the dielectric substrate to an intermediate position between the edge of the back surface of the dielectric substrate and a center position O of the emitting electrode on the back surface of the dielectric substrate. Thus, a circularly polarized microstrip antenna whose circular polarization characteristic can be easily improved and whose manufacturing cost and size can be easily reduced is provided.

Owner:MURATA MFG CO LTD

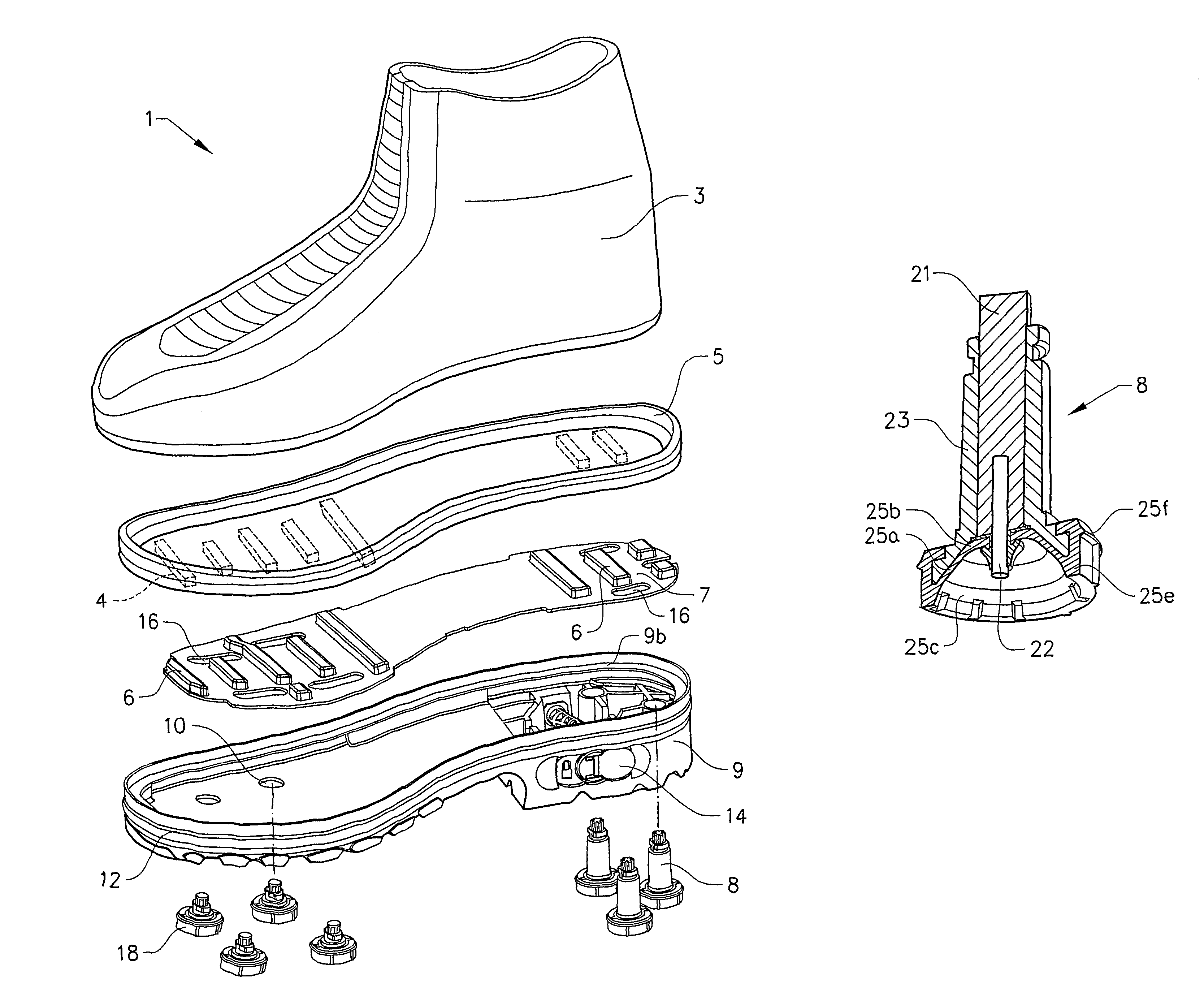

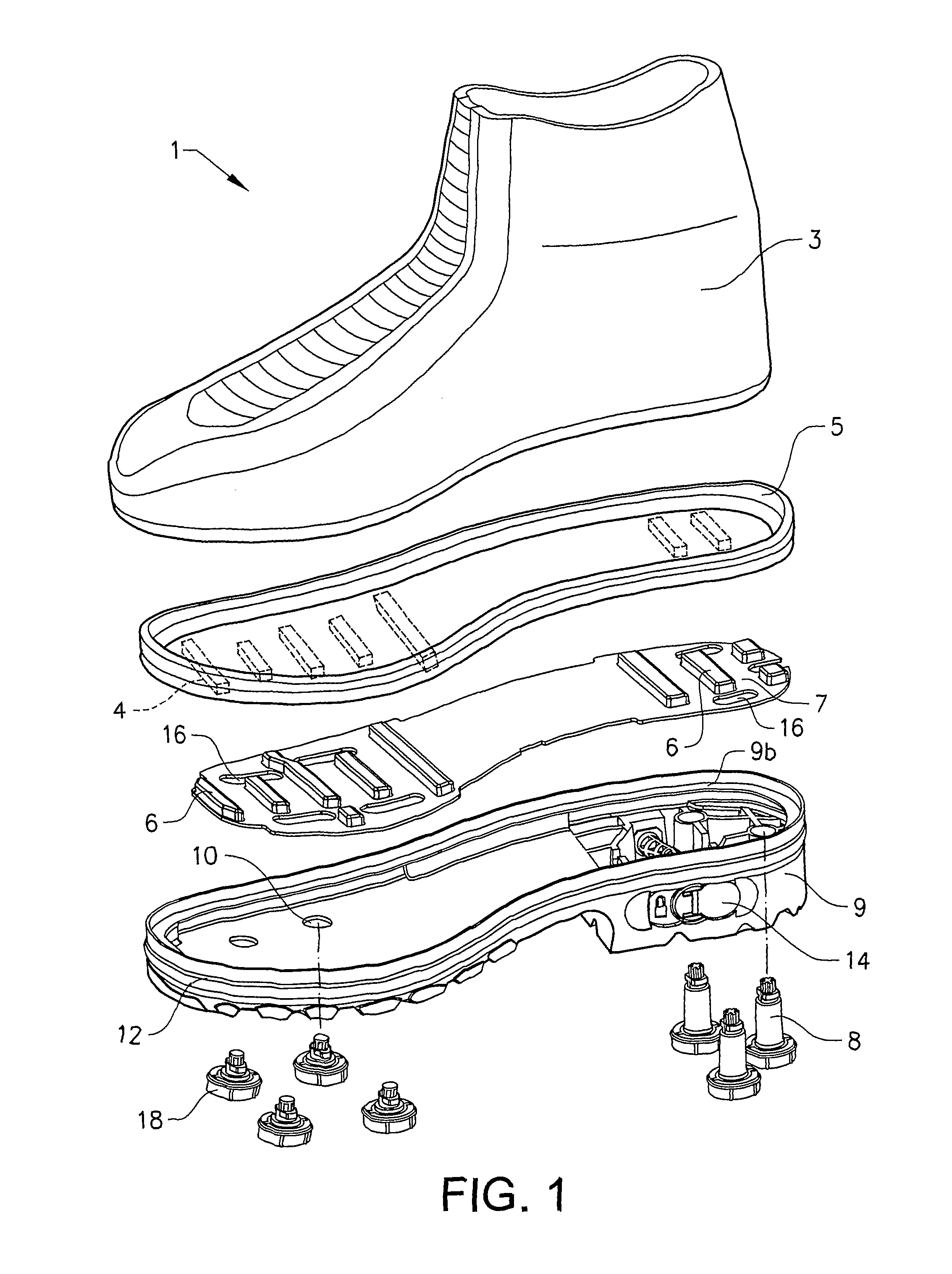

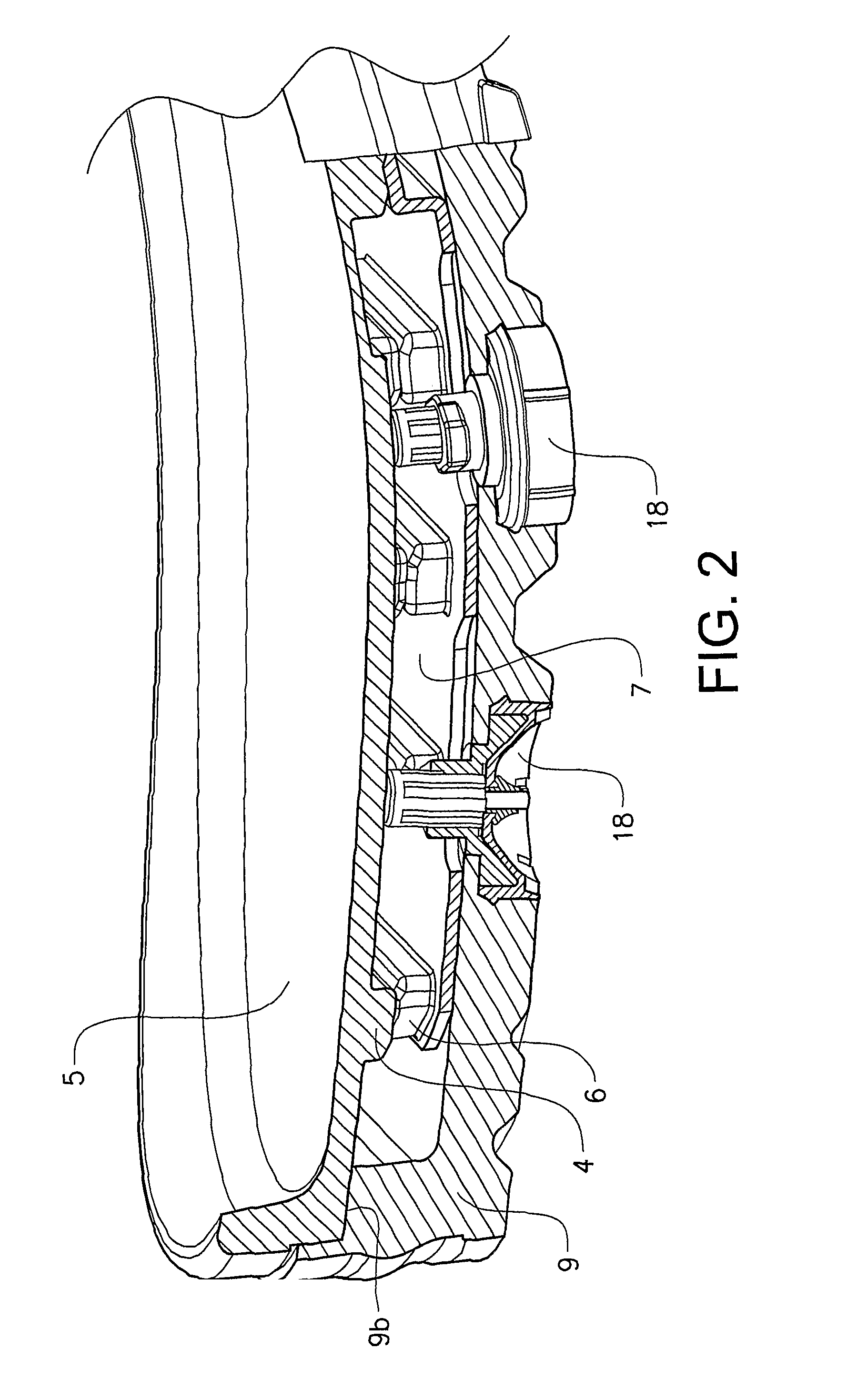

Spike device for an anti-slid shoe

ActiveUS8607477B2Less complexComplicated to makeFasteningsDrying machines with non-progressive movementsEngineering

Owner:GRIP FORCE TECH

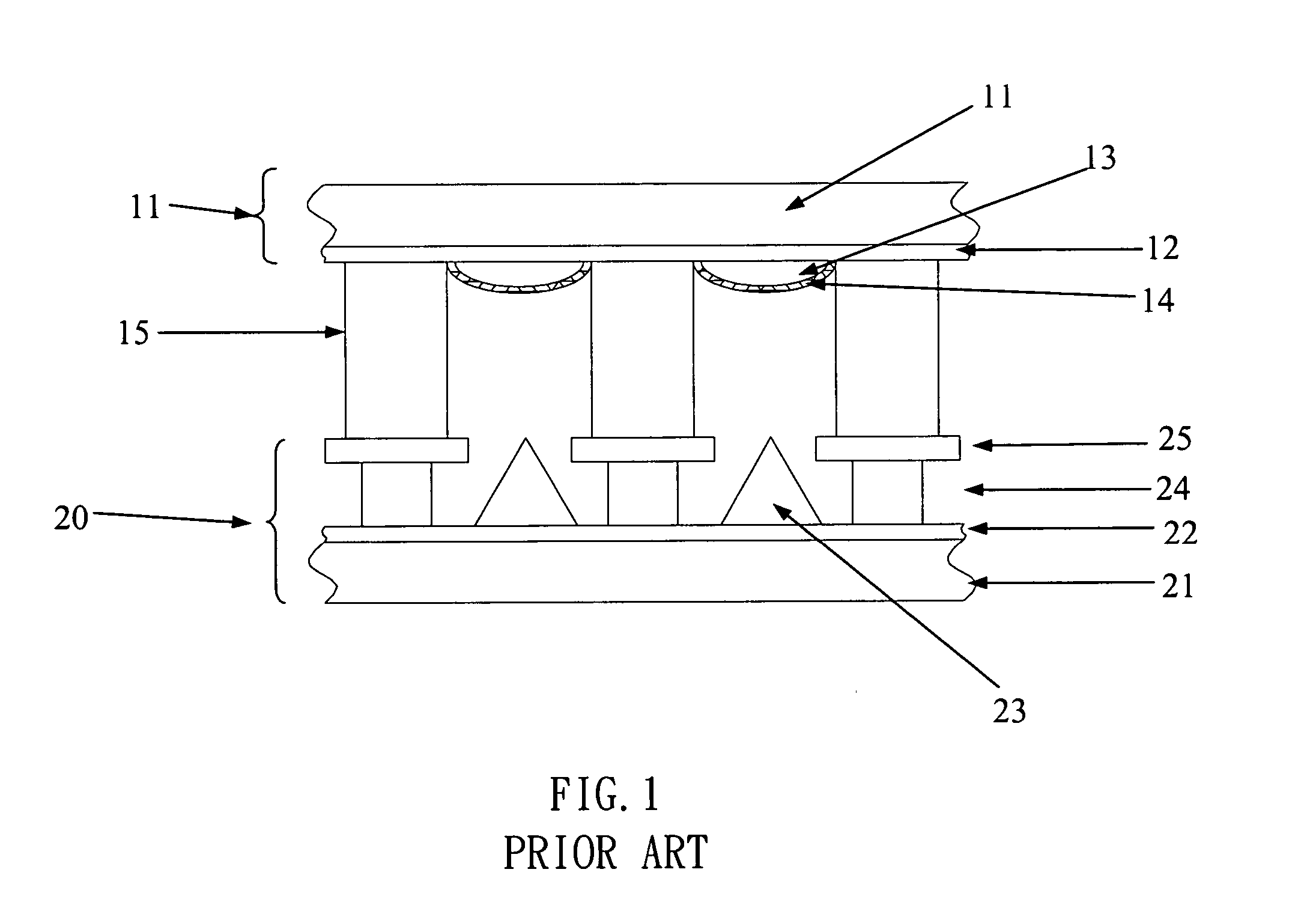

Field emission display with reflection layer

InactiveUS20050194886A1Improve lighting efficiencyComplicated to makeIncadescent screens/filtersDischarge tube luminescnet screensPhosphorField emission display

A field emission display with reflection layer has an improved insulating supporting device. The major feature is to place a reflection layer on the insulating supporting device. From the special structure, the insulating supporting device can enhance the emission efficiency of the phosphors powder rather than the primary function of the insulating support. The field emission display with reflection layer has an anode structure, a cathode structure and the supporting device.

Owner:TECO NANOTECH CO LTD

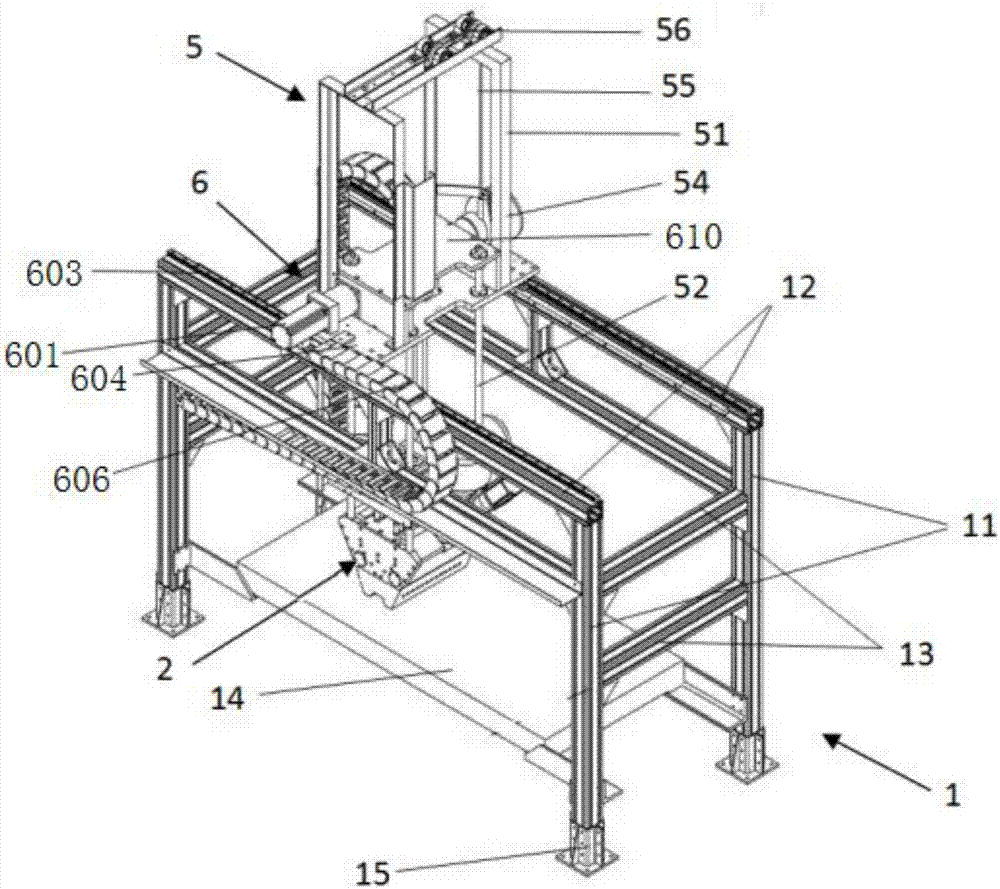

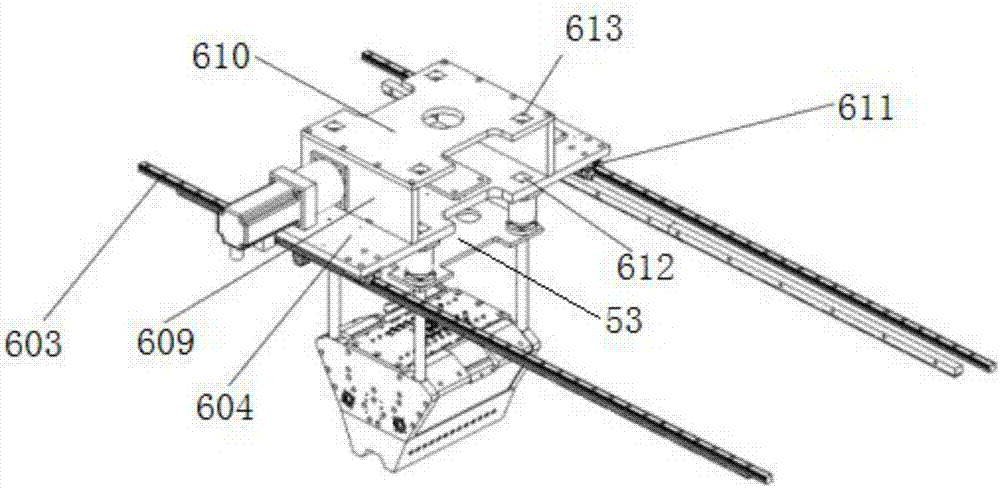

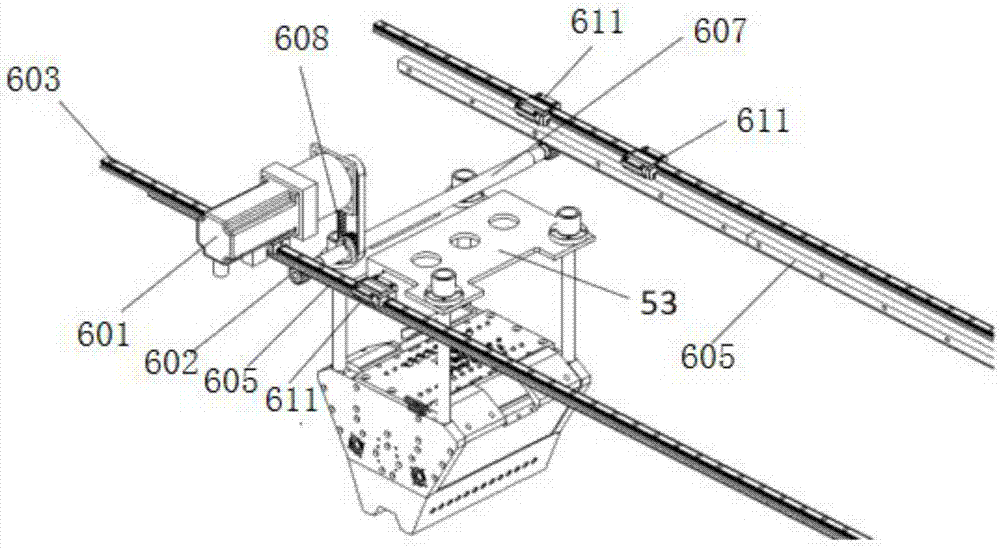

Array type 3D printer for cement-based material

PendingCN107571371ARealize simultaneous printingRealize the purpose of 3D printingAdditive manufacturing apparatusCeramic shaping apparatusControl system3d printer

The invention relates to an array type 3D printer for a cement-based material. The 3D printer is characterized by comprising a main frame, array type shower nozzles, a material storage and transportation mechanism, a control system, a longitudinal lifting mechanism and a horizontal moving mechanism; the main frame is of a main body supporting structure of the 3D printer; the array type shower nozzles are connected to the material storage and transportation mechanism and are mounted on the longitudinal lifting mechanism; the longitudinal lifting mechanism is connected to the horizontal moving mechanism and is assembled on the main frame; driven by the control system, horizontal and vertical movements of the array type shower nozzles are achieved by interaction; and the array type shower nozzles have a plurality of nozzles. The printer adopts the array type shower nozzles, and is matched with the horizontal moving mechanism and the longitudinal lifting mechanism, so that the array type shower nozzles can stably move horizontally up and down, and the printer can be applied to 3D fine printing of the cement-based material and has a very good application prospect in the field of geotechnical engineering and geological engineering.

Owner:HEBEI UNIV OF TECH

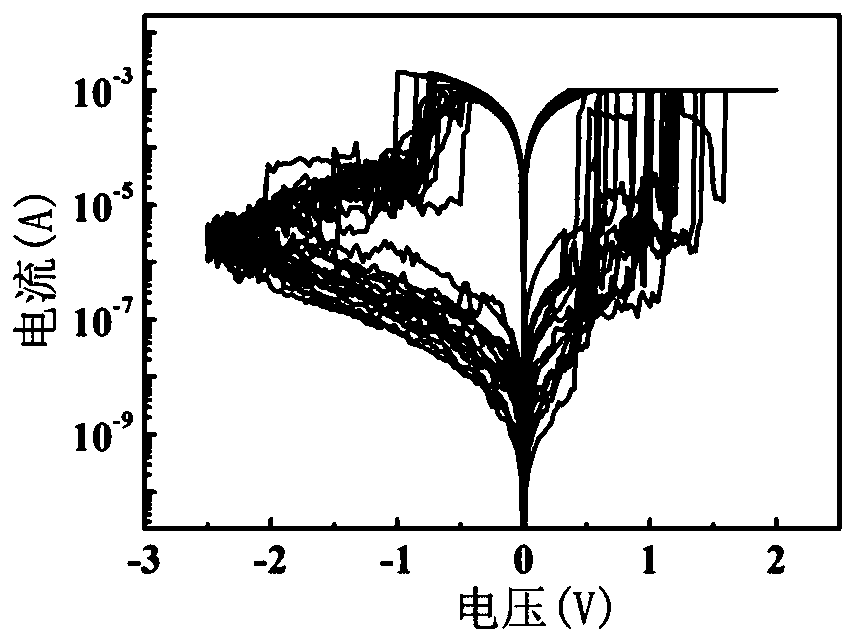

Method for preparing resistive random access memory

ActiveCN109920911AEasy to makeComplicated to makeElectrical apparatusStatic random-access memoryLow mobility

The invention discloses a method for preparing a resistive random access memory. The method comprises the following steps of providing a substrate; depositing a first metal layer on the upper surfaceof the substrate; depositing a resistive functional layer on the upper surface of the first metal layer; depositing a material layer having a low mobility on the upper surface of the resistive functional layer; preparing one or more via holes on the material layer having the low mobility; and depositing a second metal layer on the upper surface of the material layer having the low mobility. According to the method for preparing a resistive random access memory provided by the invention, the resistive random access memory prepared can control the size of conductive filaments. Since the growth orientation, number and size of the conductive filaments can be controlled, the randomness of the growth of the conductive filaments can be reduced and the current fluctuation of the resistive random access memory can be reduced, thereby reducing the parameter fluctuation of the resistive random access memory and improving the reliability of the resistive random access memory.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com