Method for synthesizing polypren phosphate

A technology of polypentenyl phosphate and synthesis method, applied in the direction of phosphorus organic compounds, etc., to achieve the effect of simple source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A kind of polypentenyl phosphate synthetic method, comprises the following steps:

[0061] In the first step, an oily substance with a plant polyprenol content higher than 85%, for example, a plant polyprenol content of 90%, is added to a non-polar organic solvent to form a mixed solution, and phosphorus is catalyzed by a nitrogen-containing organic base. Add the acylating agent dropwise to the above mixed solution, and stir at a speed of 50-800rpm while adding dropwise. The stirring speed can be selected as 100rpm, 350rpm, or 740rpm. °C, 25 °C, 36 °C, 48 °C, 55 °C, 62 °C, 74 °C, 79 °C, and make the reactant in a vacuum of 50-200 mmHg, for example, the vacuum can be selected as 100 mmHg, 160 mmHg After the dropwise addition, continue to react for 1 to 4 hours. For example, the reaction time can be selected as 1.2 hours, 2.5 hours, and 3.4 hours to obtain a mixed solution containing the reaction product.

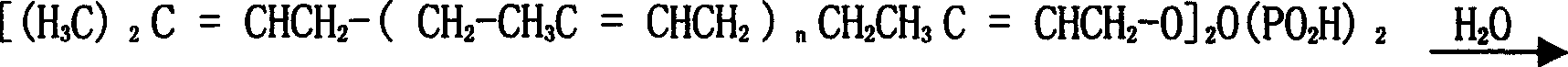

[0062] Wherein, the structure of plant polyprenol is (H 3 c) 2...

Embodiment 2

[0067] Synthesis of Polypentenyl Phosphate Monoester Using Pyrophosphoric Acid as Phosphorylating Agent

[0068] Take 5 g of refined polyprenol samples, dissolve them in 70 ml of carbon tetrachloride solution, and transfer them to a 250 ml three-neck flask. Take 3.5g of pyrophosphoric acid solution, add it to 70ml of carbon tetrachloride solution, and then slowly drop it into the reactor for reaction, the dropping rate is 1-5ml / min., the reaction temperature is 50°C-60°C, and the stirring speed is 100-800r / min. Min, the vacuum degree is 50-200mmHg, after 2 hours of reaction, add 3 grams of triethylamine, continue the reaction for 1-2 hours, then add 80ml of acetone, 20ml of water and 0.5ml of triethylamine to carry out catalytic and hydrolysis reactions. The reaction temperature is 65°C-75°C, the stirring speed is 100-800r / min, the vacuum degree is 50-200mmHg, and the reaction time is 1-2 hours. Stop the reaction, add 100ml of water and 0.5ml of triethylamine after cooling, e...

Embodiment 3

[0070] Synthesis of Polypentenyl Dichlorophosphate Using Phosphorus Oxychloride as Phosphorylation Agent

[0071] Take 5 g of refined polyprenol samples and dissolve them in 100 ml of n-hexane solution. Take POCl 3 Dissolve 2.8ml of solvent in 100ml of n-hexane solution, transfer it to a 500ml three-neck flask, stir under ice bath at a stirring speed of 100-800r / min, dissolve 4.2ml of triethylamine in 30ml of n-hexane solution, slowly add triethylamine dropwise Put the amine n-hexane solution into the reactor at a rate of 1-5ml / min. During the dropping process, when a large amount of white mist is generated, stir in vacuum at a stirring speed of 100-800r / min, with a vacuum degree greater than 600mmHg, and react for 30min.

[0072] Then slowly drop 100ml of polypentenol n-hexane solution into the reactor, the dropping speed is 1-5ml / min., the stirring speed is 50-800r / min, react in ice bath for 1 hour, and the reaction product is polypentenyl chlorophosphoric acid Esters mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com