Array type 3D printer for cement-based material

A 3D printer, cement-based material technology, applied in additive processing, ceramic molding machines, manufacturing tools, etc., can solve the problems of low dimensional accuracy and difficulty in making 3D solid models, and achieve the effect of improving printing accuracy and printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

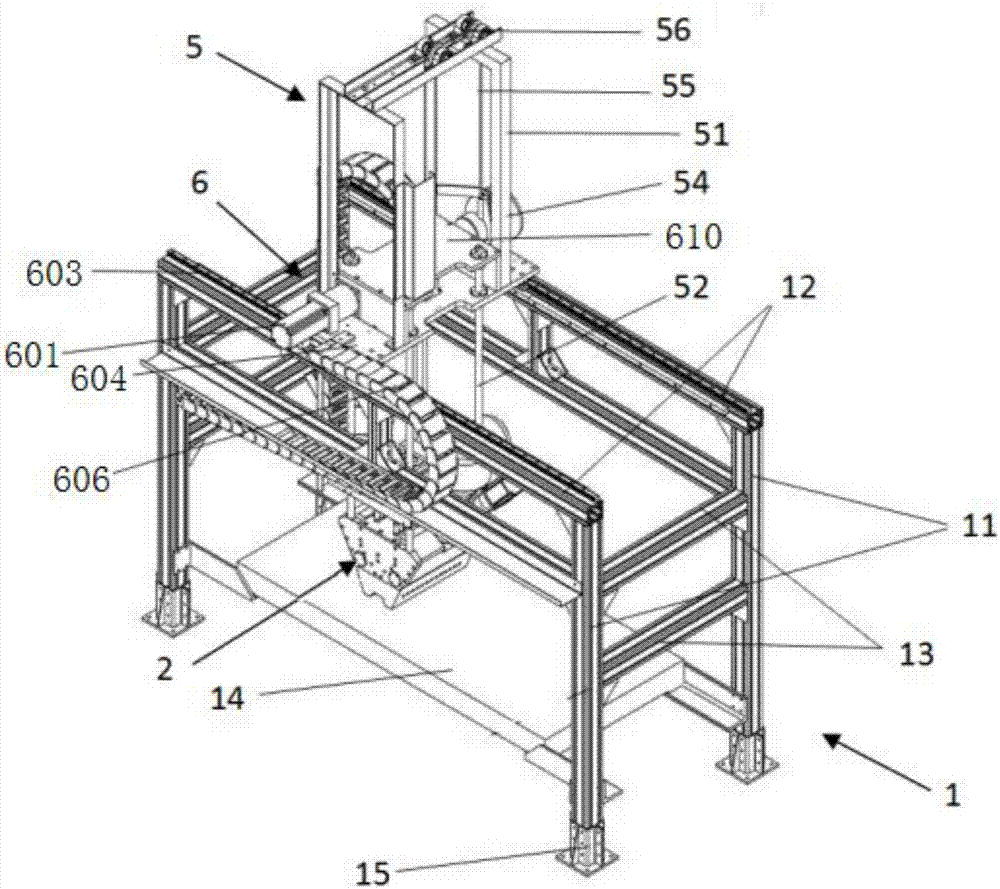

[0049] In an exemplary embodiment of the present invention, a single cement-based material array 3D printer is provided. In this embodiment, the object size of the printed geological body model is: length 3m, width 1.5m, height 1.5m, minimum unit size 12mm.

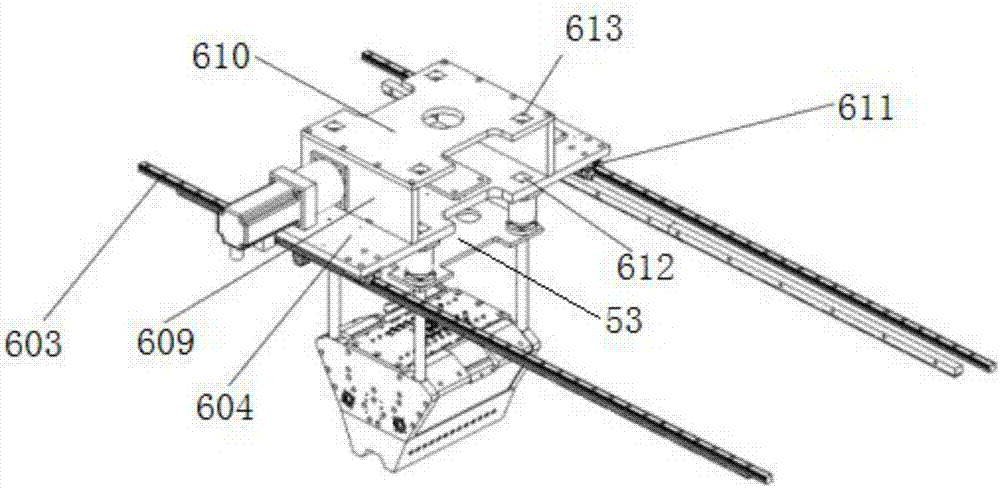

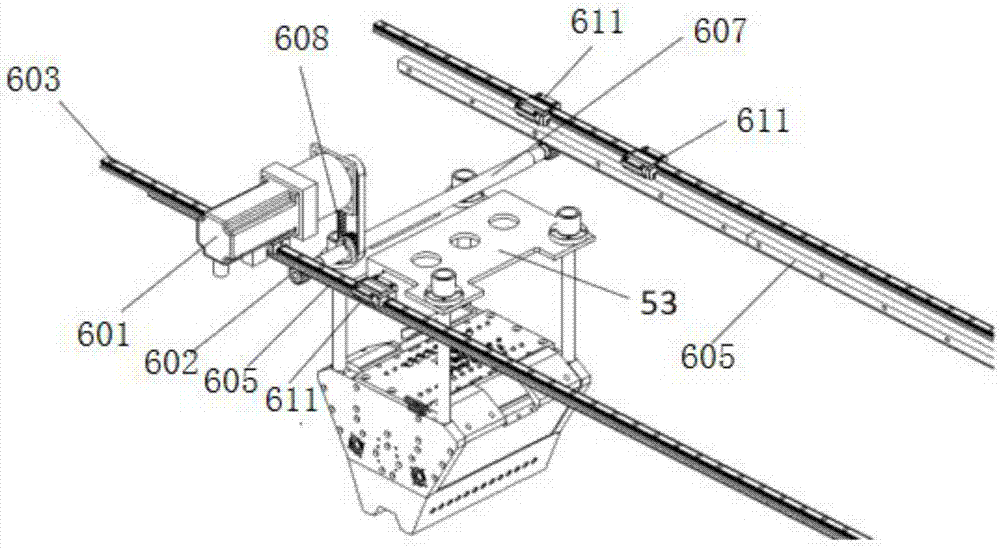

[0050] The cement-based material array 3D printer in this embodiment includes a main frame 1 , an array nozzle 2 , a material storage and delivery mechanism 3 , a control system 4 , a vertical lifting mechanism 5 and a horizontal movement mechanism 6 . The main frame is the main support structure of the 3D printer. The array nozzles are connected to the material storage and conveying mechanism and installed on the vertical lifting mechanism. The vertical lifting mechanism is connected to the horizontal moving mechanism and assembled on the main frame. Driven by the control system, the The interaction realizes the horizontal and vertical movement of the array nozzle.

[0051] Described main frame 1 comprises side pole 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com