Solution bath near-field cell 3D printing forming device and forming method thereof

A 3D printing and molding device technology, applied in the field of cell 3D printing, can solve the problems of low precision and low cell viability, and achieve the effects of improving accuracy, high cell density and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

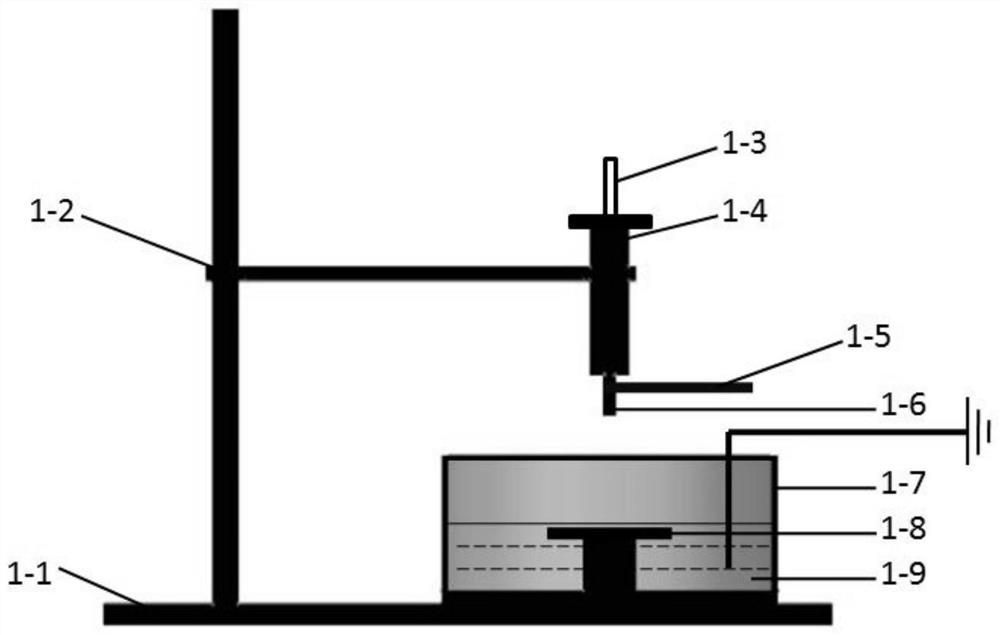

[0054] like figure 1 The solution bath near-field cell 3D printing forming mechanism shown includes a 3D printing support platform 1-1, a 3D printing motion mechanism 1-2, an extrusion-control module 1-3, a cell ink holding chamber 1-4, and a low-pressure near-field cell 3D printing mechanism. Field modules 1-5, print nozzles 1-6 and solution bath collection modules. The solution bath collection module includes an insulating container 1-7, a conductive electrolyte solution 1-9 placed in the insulating container 1-7, and a lifting deposition platform 1-8 immersed in the conductive electrolyte solution 1-9.

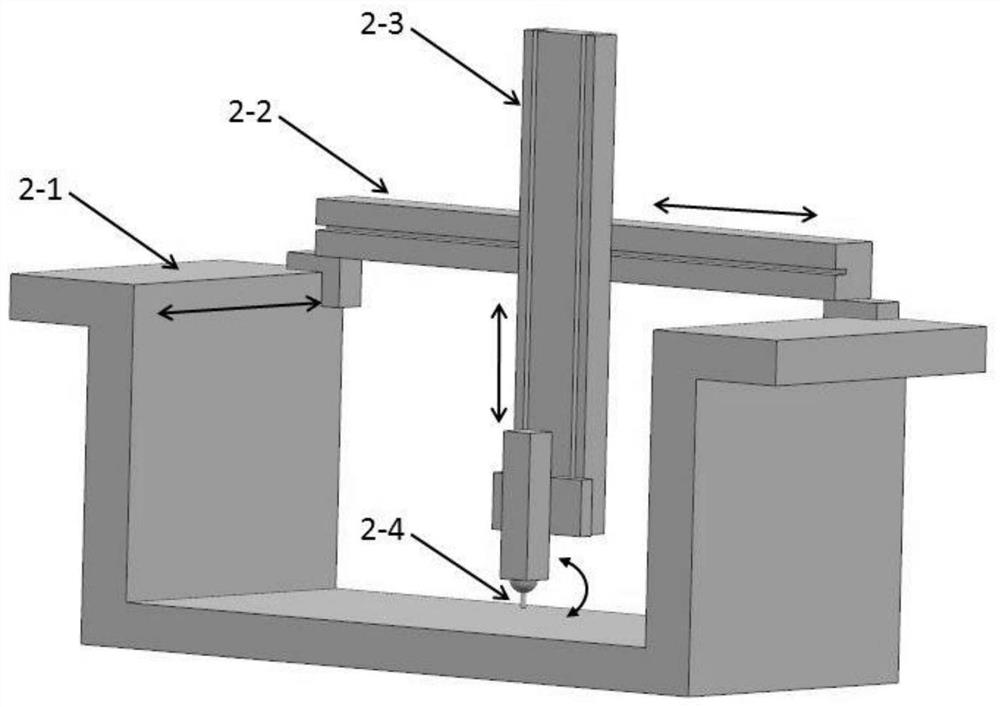

[0055] The 3D printing movement mechanism 1-2 adopts the gantry type 3D printing mechanism, such as figure 2 As shown, it includes a linear motion module, a rotary motion module, and a control mechanism respectively connected to the linear motion module and the rotary motion module. The linear motion module and the rotary motion module are respectively connected to extrus...

Embodiment 2

[0063] The difference from Example 1 is that there are multiple print nozzles, and a nozzle temperature adjustment module is installed on the multiple print nozzles to realize the adjustment from -10°C to 260°C to meet the printing requirements of different cells.

Embodiment 3

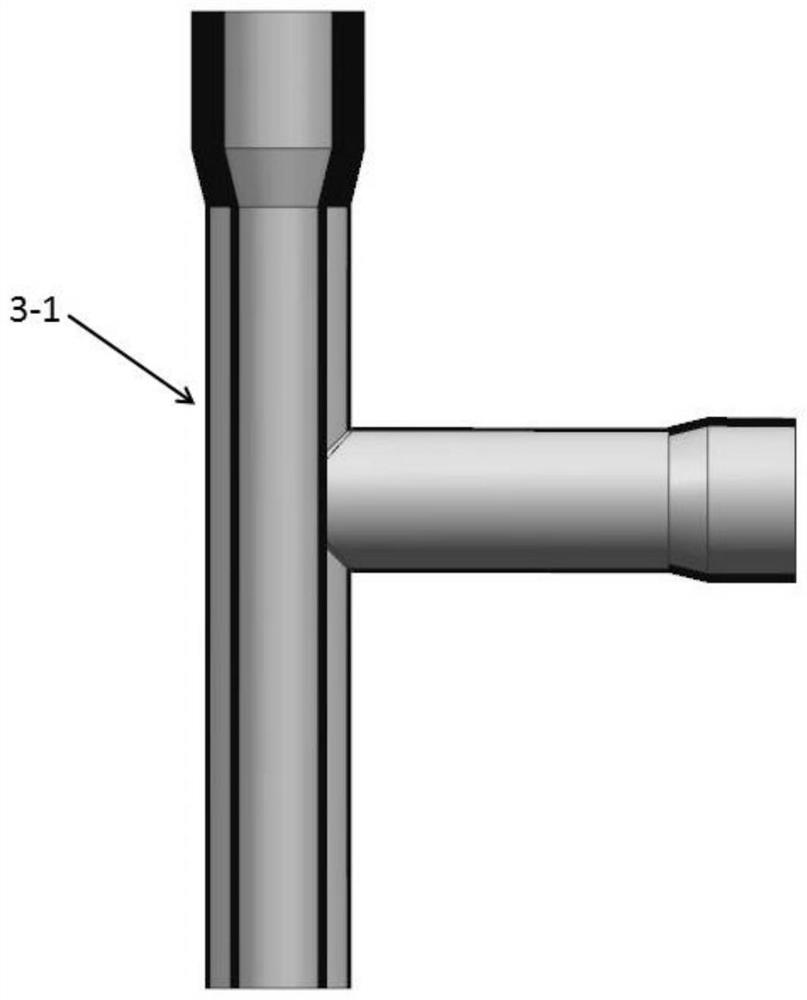

[0065] The difference from Example 1 is that the print nozzle is a multi-nozzle structure, and the nozzle is divided into two types: one nozzle is used to print cells and their cell culture substrates, and can print multiple different cells; the other nozzle is used to print Print brackets. The same as in Embodiment 1, the structure of the print head is the same as the coaxial print head, and the inner channel and the outer channel can print different cell inks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com