a thermal printer

A thermal printer, printing core technology, applied in typewriters, printing and other directions, can solve the problems of different printing shades, high cost, single color, etc., and achieve the effect of avoiding font deformation, avoiding deformation, and low attenuation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

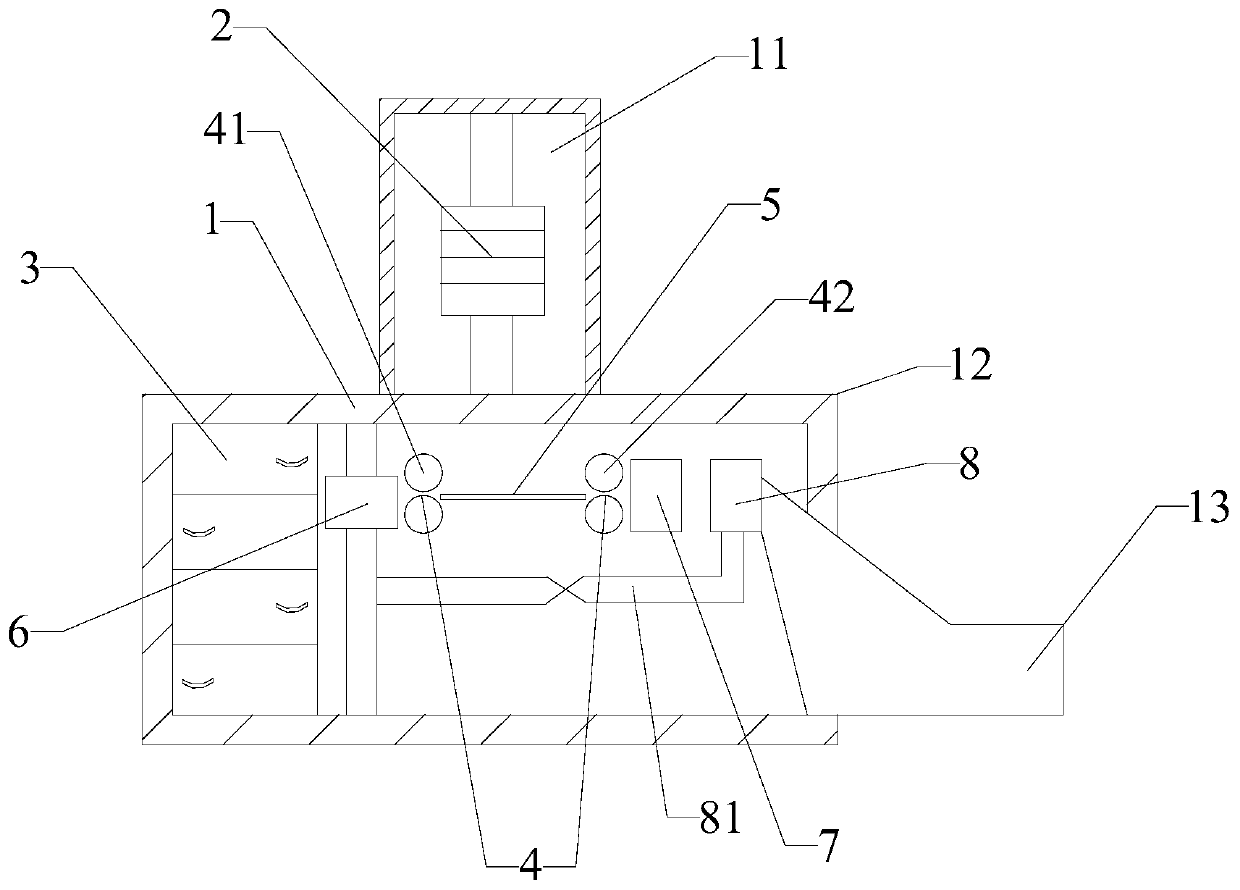

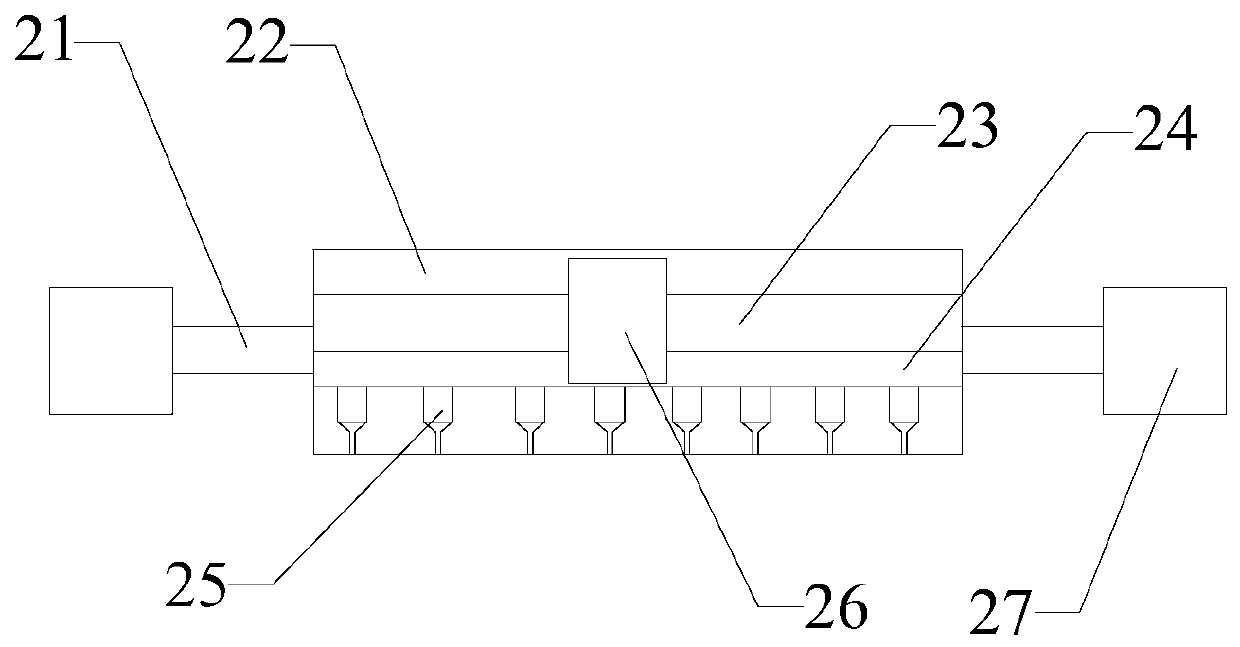

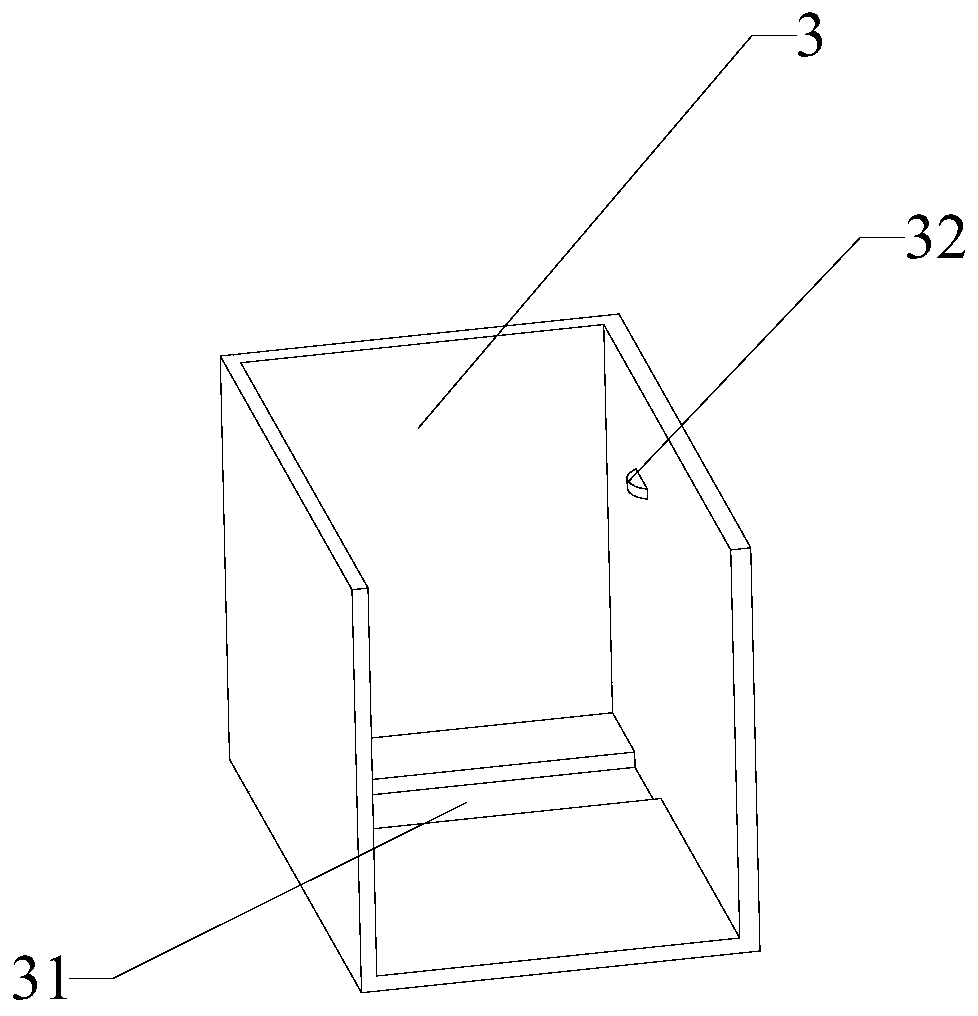

Embodiment 1

[0060] When it is necessary to use ordinary paper for single-sided printing, the first sorter selects the paper storage tank containing ordinary paper, and sends the paper to the conveying device, and the paper feeder of the conveying device sends it to the printing platform. The paper feeder and the output device work together to stretch and lay the paper flat; at this time, the printing core starts to work, and the printing data is converted into bitmap data through the control board, and then the vibration focuser on the printing core is controlled according to the points of the bitmap data Through the current, through the accelerometer sensor, the natural frequency of the molecule can be detected for different papers passing through the sorter, and the detected structure is fed back to the control board of the printer head, and the same frequency as the molecular natural frequency of ordinary paper is selected to work , the distance sensor cooperates with the horizontal adj...

Embodiment 2

[0062] When it is necessary to use double-sided printing, through the first sorter, select the paper storage tank containing ordinary paper or select suitable paper, and send the paper to the conveying device, and the paper feeder of the conveying device is sent to the printing table. When the paper feeder and paper output device work together, the paper is stretched and paved; at this time, the printing core starts to work, and the printing data is converted into bitmap data through the control board, and then the vibration on the printing core is controlled according to the points of the bitmap data The focuser can detect the molecular natural frequency of different papers passing through the sorter through the current and the accelerometer sensor. The detected structure is fed back to the control board of the printer head, and the appropriate frequency is selected for work. The distance sensor cooperates with the level The adjuster and the vertical adjustment motor adjust th...

Embodiment 3

[0064] When it is necessary to use color thermal paper for printing, the first sorter selects the color thermal paper in the paper storage tank and sends it to the conveying device, and the paper feeder of the conveying device is sent to the printing table. Work with the paper output device to stretch and lay the paper; at this time, the printing core starts to work, converts the printing data into bitmap data through the control board, and then controls the vibration focuser on the printing core to pass current according to the points of the bitmap data , through the accelerometer sensor, it is possible to detect the molecular natural frequency of different papers passing through the sorter, and the detected structure is fed back to the control board of the printer head to select the content of the thermal sensitive material on the surface of the color thermal paper. The three molecular natural frequencies of the RGB pigment microcapsules are switched at the same frequency; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com