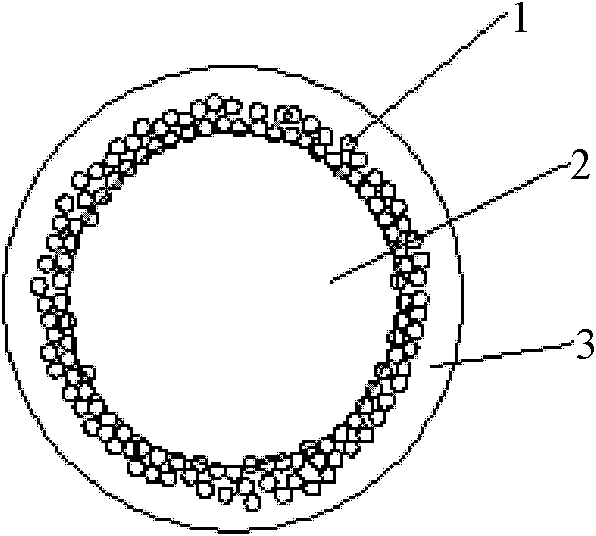

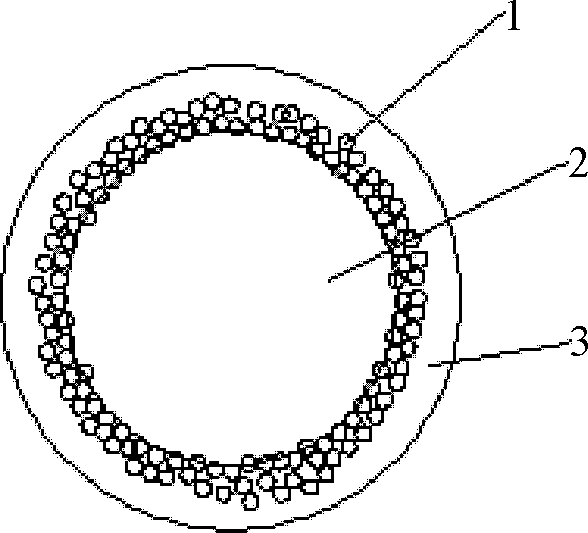

Electronic ink microcapsule and preparation method thereof

An electronic ink and microcapsule technology, applied in the directions of microcapsule preparation, microsphere preparation, ink, etc., can solve the problem that the barrier property of electrophoresis medium needs to be further improved, so as to meet the mechanical strength and flexibility, save energy, and improve the barrier. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] Preparation of electrophoretic suspension

[0021] Mix 20g of titanium dioxide, 20g of azo dyes, 55g of carbon tetrachloride, and 5g of polyisosuccinic anhydride as a charge control agent to prepare 100g of electrophoretic suspension for later use.

Embodiment 1

[0023] Using deionized water to prepare 100 g of silica sol with a silica mass percentage of 7%, which is alkaline. Add 12 g of the electrophoretic suspension to the silica sol under stirring to form a Pickeriing emulsion. Dissolve 3.5 g of gelatin in 31.5 g of deionized water at 60°C to obtain an aqueous gelatin solution. The prepared aqueous gelatin solution was then added to the aforementioned Pickering emulsion. And slowly add acetic acid therein to adjust the pH value to 4.0, and carry out the re-coagulation reaction for 2 hours. The reaction solution was cooled to 5° C., and 3 ml of 37% formaldehyde aqueous solution was added to solidify and crosslink for 5 hours. Slowly add 3% sodium hydroxide solution to the reaction solution to adjust the pH value to 8, then raise the temperature to 55° C., and continue the reaction for 2 hours to obtain electronic ink microcapsules.

Embodiment 2

[0025] Using deionized water to prepare 100 g of silica sol with a silica mass percentage of 16.5%, which is alkaline. Add 23g of the electrophoretic suspension to the silica sol under ultrasonication to form a Pickeriing emulsion. Dissolve 5.5g of gelatin in 49.5g of 60°C deionized water to obtain an aqueous gelatin solution. The prepared aqueous gelatin solution was then added to the aforementioned Pickering emulsion. And slowly add citric acid therein to adjust the pH value to 2.5, and carry out the re-coagulation reaction for 2 hours. The reaction solution was cooled to 5° C., and 3 ml of 37% acetaldehyde aqueous solution was added to solidify and crosslink for 5 hours. Slowly add 3% sodium hydroxide solution to the reaction solution to adjust the pH value to 8, then raise the temperature to 55° C., and continue the reaction for 2 hours to obtain electronic ink microcapsules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com