Variable valve timing and direct-injection gasoline engine cam shaft

A valve timing and camshaft technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as insufficient space for camshaft layout, complex manufacturing process of camshaft, and difficulty in ensuring structural strength, and achieve structural strength Difficult to guarantee, simple structure and process, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate structure of the present invention below in conjunction with accompanying drawing:

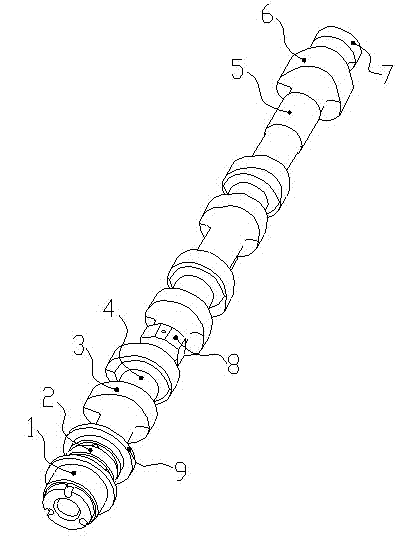

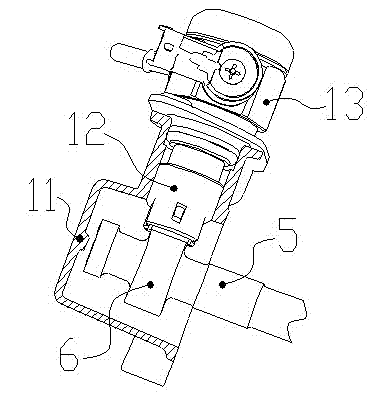

[0020] Such as figure 1 The camshaft shown includes: first, second, third, fourth and fifth camshaft journals 1, 2, 4, 5, 7, ventilation cam 3, oil pump drive cam 6, outer hexagonal structure 8 And annular boss 9.

[0021] Among them, the first section of camshaft journal 1 is at the front end of the camshaft, and is closely matched with the phaser during assembly to seal the local oil passage at the front end of the camshaft.

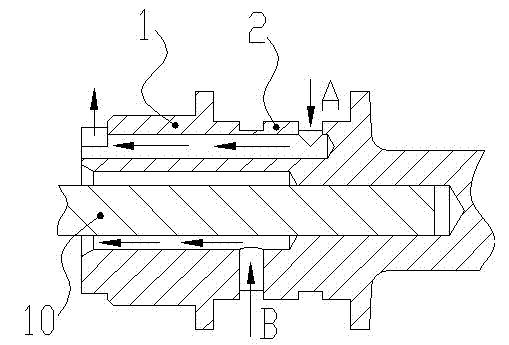

[0022] The second section of camshaft journal 2 is arranged behind the first section of camshaft journal 1, and is processed with annular oil grooves and radial oil holes required for variable valve timing. Both sides of the neck are respectively provided with annular bosses 9, which are used to limit the axial movement of the camshaft.

[0023] There are 3 pairs of ventilation cams 3, separated by a certain distance, and evenly arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com