Amorphous alloy dry-type transformer coil insulating structure and method of removing local discharge signal noise

A discharge signal, coil insulation technology, applied in the direction of transformer/inductor coil/winding/connection, testing dielectric strength, etc., can solve the problems of high cost, large transformer volume, white noise, etc., and achieve good short-circuit resistance, field The effect of strong uniform distribution and simple process calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

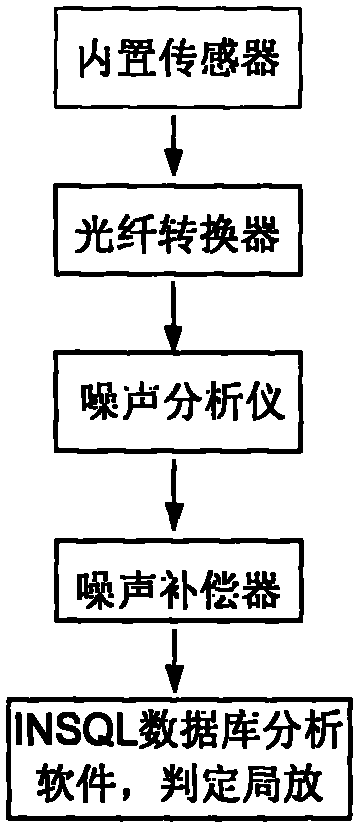

[0018] Below in conjunction with accompanying drawing, the present invention is specifically introduced as follows:

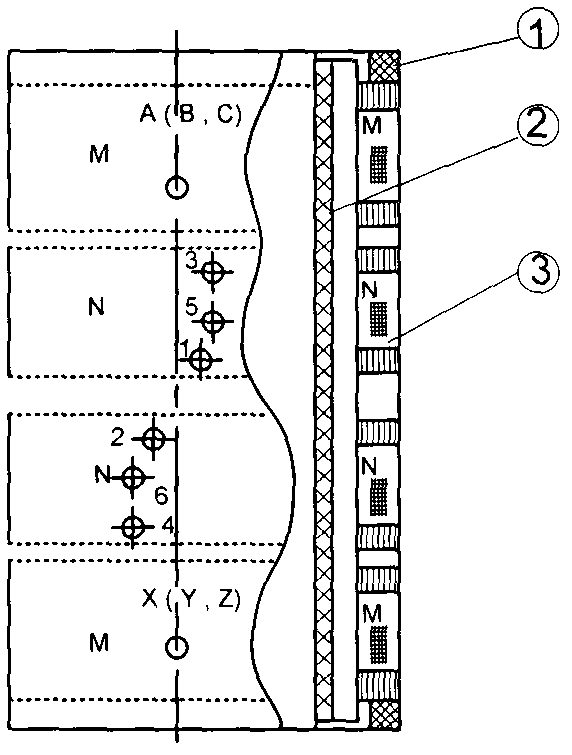

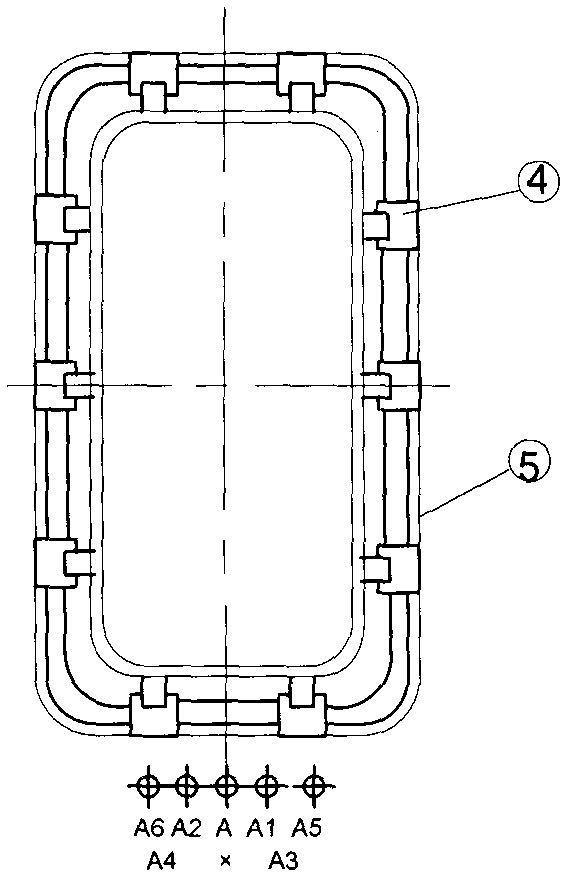

[0019] Such as figure 1 A transformer coil insulation structure is shown, including rectangular end coils, insulating cylinders, coil windings, and external reinforced insulation. The rectangular end coils adopt an end coil structure similar to that of SGB10 products, which has a beautiful appearance and sufficient mechanical strength.

[0020] The coil winding adopts a four-section cylindrical structure, and the number of coil turns between each layer of each section is wound according to the rule of a pyramid, and the number of coil turns from the inner to the outer is from dense to thin;

[0021] Each layer of the coil is separated and insulated by NOMEX paper, and the electromagnetic wire is made of H-grade double-film Dupont paper flat wire;

[0022] The external reinforced insulation is to enclose the four sections as a whole, that is, first wrap a polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com