Metamaterial and preparation method thereof

A technology of metamaterial and slurry, which is applied in the field of supermaterial and supermaterial preparation, to achieve the effect of high mechanical strength, thermal stability and high electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

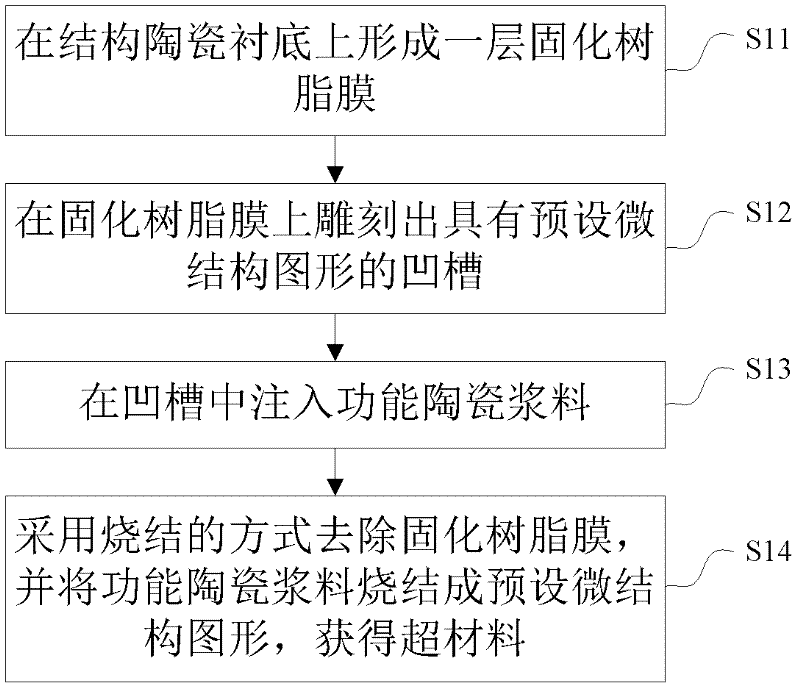

[0021] see figure 1 , is a flowchart of a method for preparing a metamaterial provided in Embodiment 1 of the present invention, and the method includes:

[0022] S11: forming a cured resin film on the structural ceramic substrate.

[0023] Wherein, the material of the structural ceramic substrate is alumina, silicon dioxide, or magnesium oxide.

[0024] S12: Engraving grooves with preset microstructure patterns on the cured resin film.

[0025] Among them, the preset microstructure graphics are axisymmetric graphics, such as "I" font, "big" font, "ten" font, snowflake shape, etc.; they can also be non-axisymmetric graphics, such as "Swastika" font, parallelogram etc.

[0026] S13: inject functional ceramic slurry into the groove.

[0027] Among them, the functional ceramic slurry can be a ferroelectric material, such as barium titanate, barium strontium titanate, potassium dihydrogen phosphate, etc.; it can also be a ferrite material, usually made of ferric oxide and one ...

Embodiment 2

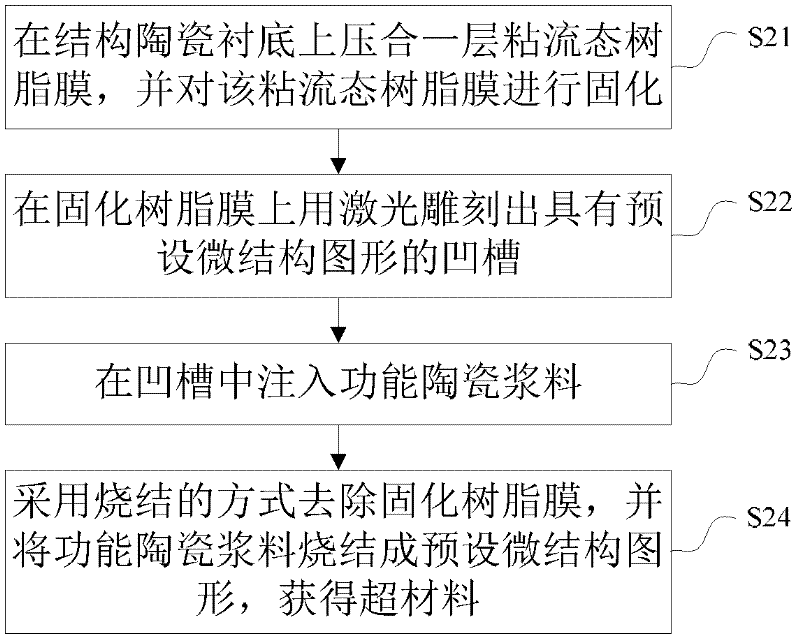

[0032] see figure 2 , is a flowchart of a method for preparing a metamaterial provided in Embodiment 2 of the present invention, and the method includes:

[0033] S21: laminating a layer of viscous fluid resin film on the structural ceramic substrate, and curing the viscous fluid resin film.

[0034] S22: Laser engraving grooves with preset microstructure patterns on the cured resin film.

[0035] Among them, laser engraving is a technology well known to those skilled in the art, and will not be repeated here.

[0036] Among them, the preset microstructure graphics are axisymmetric graphics, such as "I" font, "big" font, "ten" font, snowflake shape, etc.; they can also be non-axisymmetric graphics, such as "Swastika" font, parallelogram etc.

[0037] S23: inject functional ceramic slurry into the groove.

[0038] Among them, the functional ceramic slurry can be a ferroelectric material, such as barium titanate, barium strontium titanate, potassium dihydrogen phosphate, et...

Embodiment 3

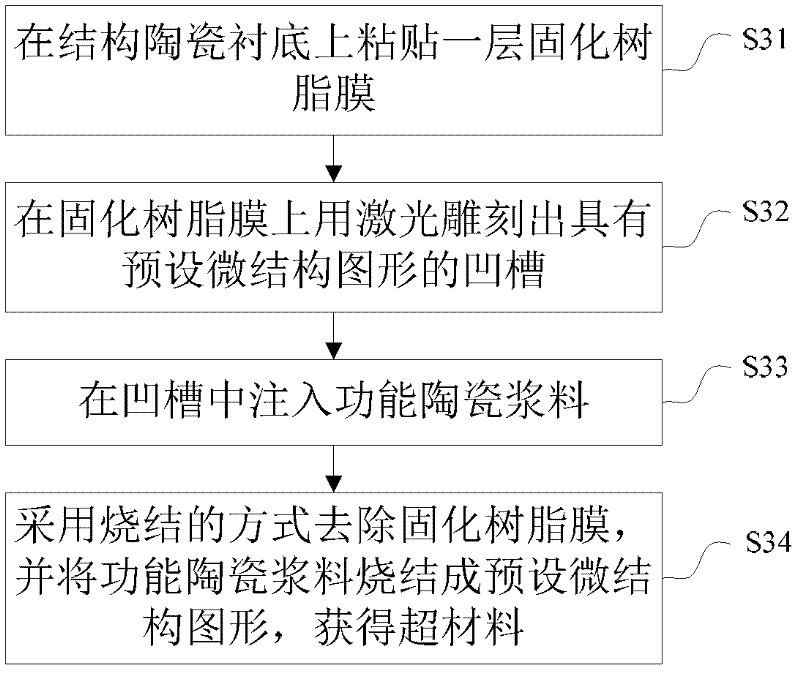

[0042] see image 3 , is a flowchart of a method for preparing a metamaterial provided in Embodiment 3 of the present invention, and the method includes:

[0043] S31: paste a layer of cured resin film on the structural ceramic substrate.

[0044] Specifically, a layer of adhesive is coated on the structural ceramic substrate, and then a layer of cured resin film is pasted on the structural ceramic substrate coated with the adhesive.

[0045] S32: Laser engraving grooves with preset microstructure patterns on the cured resin film.

[0046] Among them, the preset microstructure graphics are axisymmetric graphics, such as "I" font, "big" font, "ten" font, snowflake shape, etc.; they can also be non-axisymmetric graphics, such as "Swastika" font, parallelogram etc.

[0047] S33: inject functional ceramic slurry into the groove.

[0048] Among them, the functional ceramic slurry can be a ferroelectric material, such as barium titanate, strontium barium titanate, potassium dihy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com