High-porosity separator film with coating and shut down function

A technology of porosity and coating, applied in the field of film preparation, can solve the problems of unsatisfactory mechanical strength, poor penetration resistance and high tearing tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

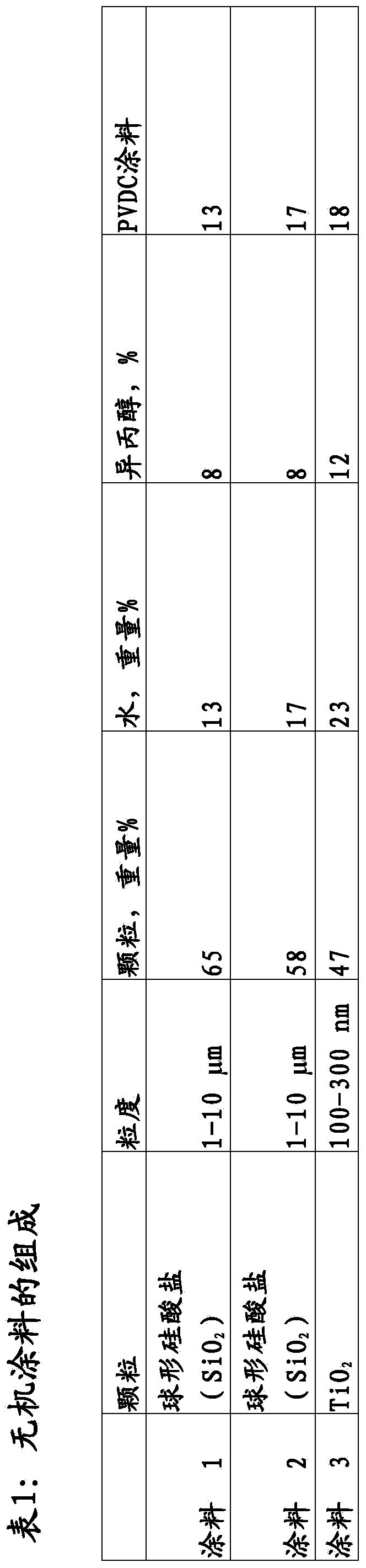

[0172] A silicate coating having the composition of Coating 1 (Table 1) was manually applied onto a microporous BOPP membrane with a cut-off function (Film Example 1) using a wire knife coater (wire diameter: 0.4 mm). Wetting of the membrane with the ceramic suspension was uniform. The coated film was then dried in a drying oven at 90° C. for one hour. After drying, the coating showed good adhesion to the film. Next, the coating weight, the layer thickness of the coating and the air permeability are determined by means of the Gurley value. Only a small increase in the Gurley value was observed, from 360s to 380s.

Embodiment 2

[0174] A silicate coating with the composition of Coating 2 (Table 1 ) was manually applied onto a microporous BOPP film with cut-off function (film example 1 ) using a wire knife coater (wire diameter: 0.4 mm). After coating, the wetting of the membrane with the ceramic suspension was uniform. After drying, the coating, as in Example 2, showed better adhesion than in Example 5. The Gurley value also increased significantly. Observe that the Gurley value increases from 360s to 570s.

Embodiment 3

[0176] A titanium oxide coating having the composition of Coating 3 (Table 1 ) was manually applied onto a microporous BOPP film with cut-off function (film example 1 ) using a wire knife coater (wire diameter: 0.4 mm). After coating, the wetting of the membrane with the ceramic suspension was uniform. After drying, the coating showed good adhesion to the film. An increase in the Gurley value is observed, from 360s to 460s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gurley value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com