Sub-dam construction method of Bayer process red-mud dry-stacking field

A Bayer method of red mud and sub-dam technology, applied in chemical instruments and methods, filling, construction, etc., can solve the problems that are not suitable for sub-dam construction, and the dam slope ratio of sub-dam construction methods cannot be applied to empirical data. Achieve the effect of large storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

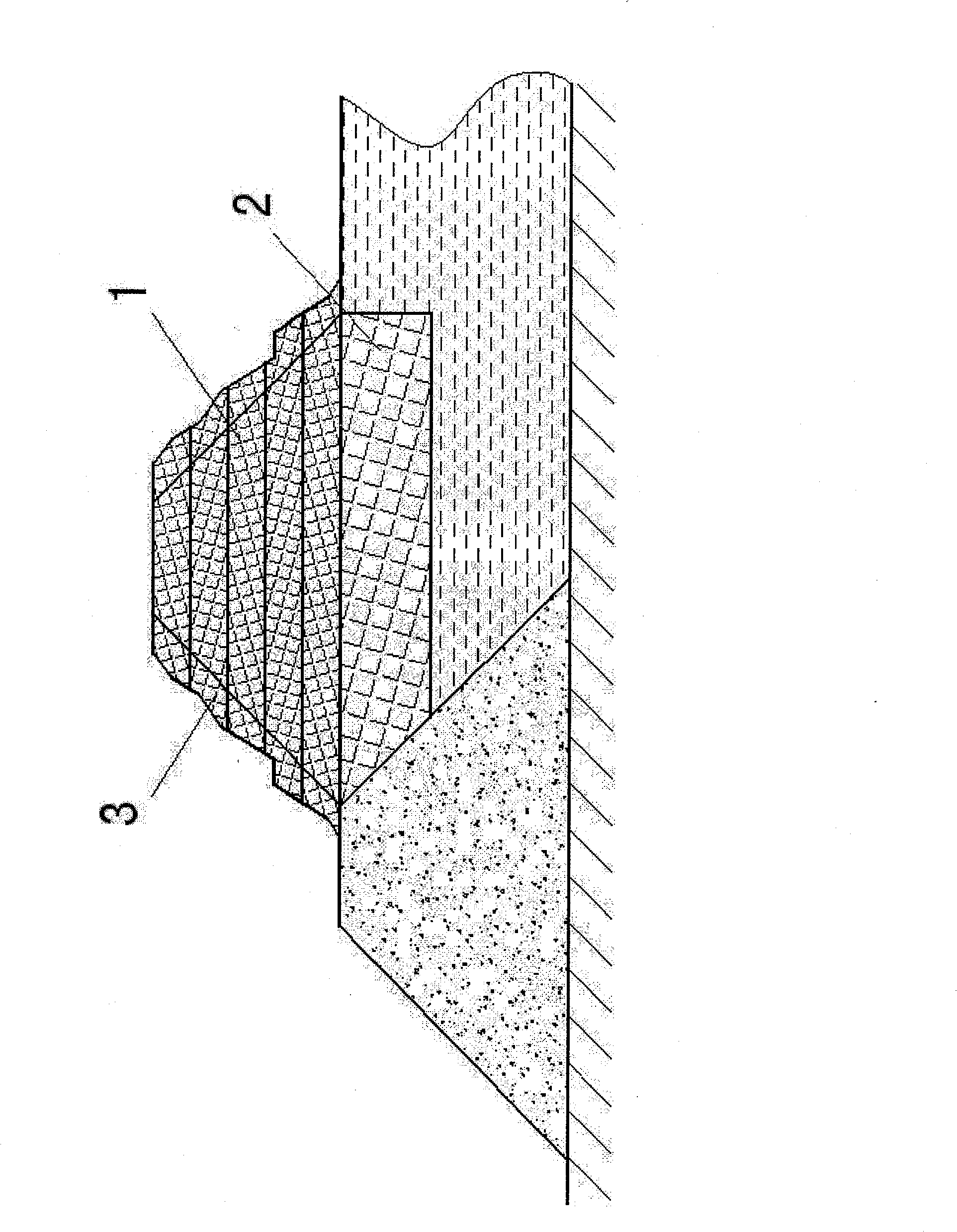

[0014] Embodiments of the present invention: as attached figure 1 As shown, first of all, prepare the dam building materials, select the red mud that has been sun-dried and has a water content of 25% to 35% in the red mud layer of the storage yard, and transport it to the sub-dam to be constructed by bulldozers, excavators and other machinery Stacked nearby and protected by measures (such as discharging a small amount of red mud slurry on the surface) to maintain its water content.

[0015] Secondly, the dam foundation of the sub-dam is reinforced. The sub-dam 1 is located on the red mud layer, and the red mud layer is used as the sub-dam foundation. First, use a bulldozer to break the shell and perform preliminary rolling operations on the red mud layer within the scope of the dam foundation 2, and then use a vibratory road roller to further compact it until the water content of the red mud within 3m depth within the dam foundation range reaches 35% or less. , the reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com