Gas dehumidification film, preparation method and application thereof

A gas and wet membrane technology, applied in the field of gas dehumidification membrane and its preparation, can solve the problem of low water selectivity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, a gas dehumidification membrane is provided. The raw materials for the preparation of the gas dehumidification membrane include polyether-b-polyamide (Pebax1074) and sodium hyaluronate, and the mass ratio of Pebax1074 and sodium hyaluronate is 3 :7. Among them, Pebax1074 is a block copolymer.

[0030] The preparation method comprises the following steps:

[0031] Dissolve the vacuum-dried Pebax1074 in ethanol and water with a mass ratio of 7:3, the dissolution temperature is 100°C, and stir until uniform and transparent to prepare a Pebax1074 solution with a mass concentration of 0.1%, and add sodium hyaluronate to the Pebax1074 solution , Stir again until uniform and transparent, let it stand for defoaming, pour the defoamed solution on the tetrafluoro board and spread evenly, keep the temperature of the tetrafluoro board at 40°C, and volatilize the solvent to obtain the primary film, and then remove the primary film from Carefully remove the PTFE...

Embodiment 2

[0033] In this embodiment, a gas dehumidification membrane is provided. The raw materials for the preparation of the gas dehumidification membrane include polyether-b-polyamide (Pebax1074) and sodium hyaluronate, and the mass ratio of Pebax1074 and sodium hyaluronate is 1. :1. Among them, Pebax1074 is a block copolymer.

[0034] The preparation method comprises the following steps:

[0035] Dissolve the vacuum-dried Pebax1074 in ethanol and water with a mass ratio of 7:3, the dissolution temperature is 90°C, and stir until uniform and transparent to prepare a Pebax1074 solution with a mass concentration of 20%, and add sodium hyaluronate to the Pebax1074 solution , stirred again until uniform and transparent, degassed under negative pressure, poured the defoamed solution on the flat filter membrane and spread it evenly, kept the temperature of the flat filter membrane at 50°C, and volatilized the solvent to obtain a nascent membrane, and then the nascent membrane was removed ...

Embodiment 3

[0037] In this embodiment, a gas dehumidification membrane is provided, and the preparation raw materials of the gas dehumidification membrane include polyether-b-polyamide (Pebax4011) and lithium chloride, and the mass ratio of Pebax4011 and lithium chloride is 9:1 . Among them, Pebax4011 is a block copolymer.

[0038] The preparation method comprises the following steps:

[0039]Dissolve the vacuum-dried Pebax4011 in ethanol and water with a mass ratio of 7:3, the dissolving temperature is 70°C, and stir until uniform and transparent to prepare a Pebax4011 solution with a mass concentration of 0.5%. Add lithium chloride to the Pebax4011 solution, Stir again until uniform and transparent, let it stand for defoaming, pour the defoamed solution on a glass plate and spread evenly, keep the temperature of the glass plate at 60°C, and volatilize the solvent to obtain a primary film, and then remove the primary film from the glass plate Take it off carefully, put it in a vacuum o...

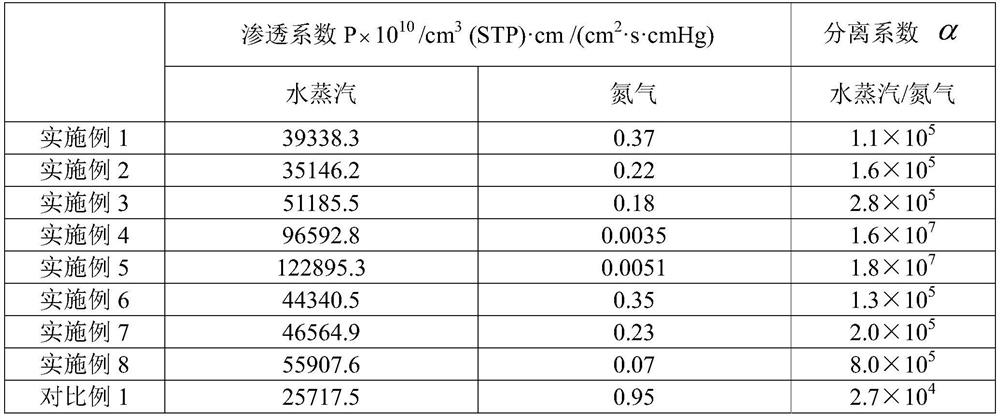

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com