Bus riveting protection line

A production line and riveting technology, applied in the direction of forming tools, feeding devices, positioning devices, etc., can solve the problems of complex manufacturing process, expensive equipment investment, cumbersome assembly, etc., and achieve the goal of reducing labor intensity, quantity, and labor intensity of workers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

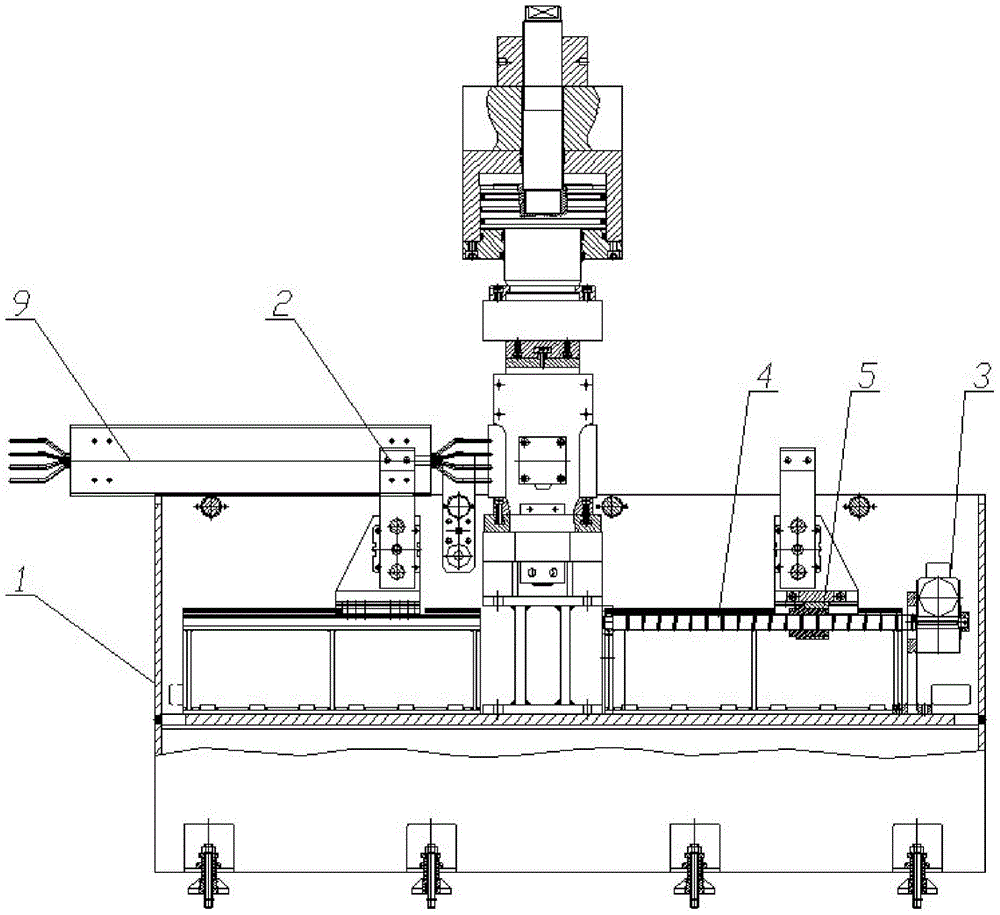

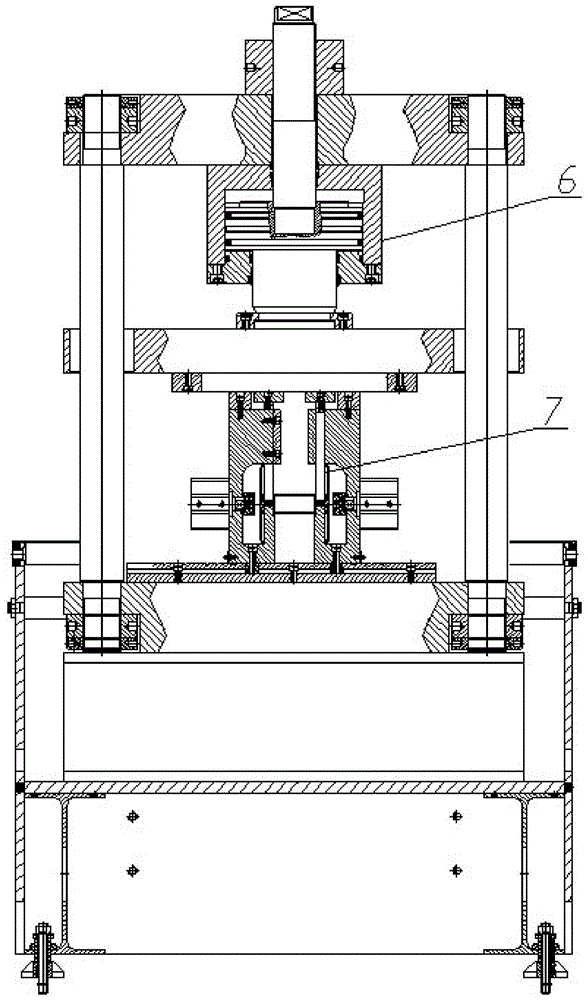

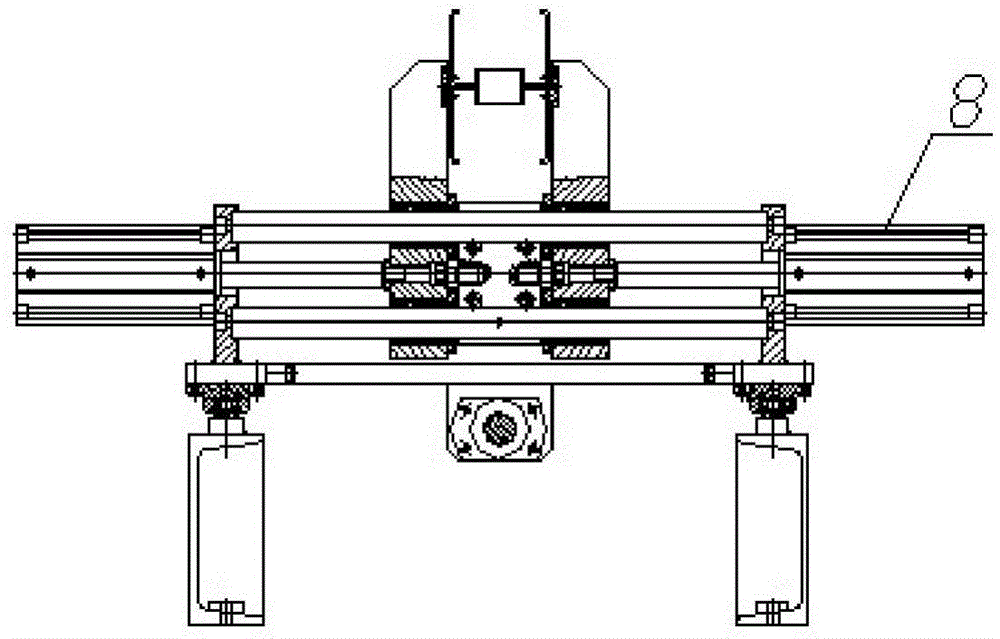

[0013] As shown in the figure, the structure of the busbar riveting production line of the present invention mainly includes a feeding frame 1, a feeding clamp 2, a feeding drive system, a riveting press 6 and a riveting mold 7; the feeding clamp 2 is driven by a clamp cylinder 8 and Provide clamping power. The feeding drive system consists of a servo motor 3, a screw 4, and a screw nut 5. The feeding clamp 2 is fixedly connected to the screw nut 5. The servo motor 3 drives the screw 4 to drive the feeding clamp 2 for linear motion. , the riveting press 6 drives the riveting die 7 to reciprocate up and down, and punches and rives the busbar side cover. The riveting press 6 adopts an upper and lower double piston rod oil cylinder, the lower piston rod is connected with the riveting mold 7, and the upper piston rod is provided with a fine thread and equipped with a round nut for adjusting the riveting depth. Before the riveting of the bus bar, it is necessary to align the conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com