Developing method

A developing method and a developing method technology, applied in the developing field, can solve the problem of uneven graphic development and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

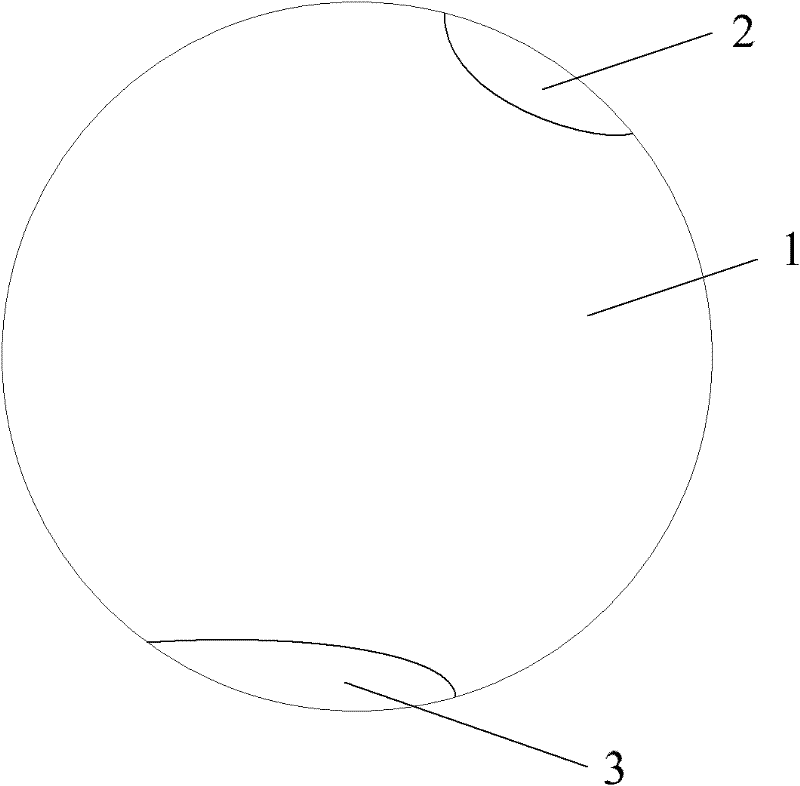

Image

Examples

Embodiment 1

[0027] As mentioned in the background section, due to the high surface tension on the wafer surface, the developer at the edge of the wafer often shrinks due to the tension, which results in poor development of the edge of the wafer. Although the problem of poor development at the edge of the wafer can be solved by increasing the time of spraying the developer or increasing the dosage of the developer, it will also cause uneven development of graphics at different positions on the wafer, which in turn will worsen the uniformity of the critical dimensions of the device. .

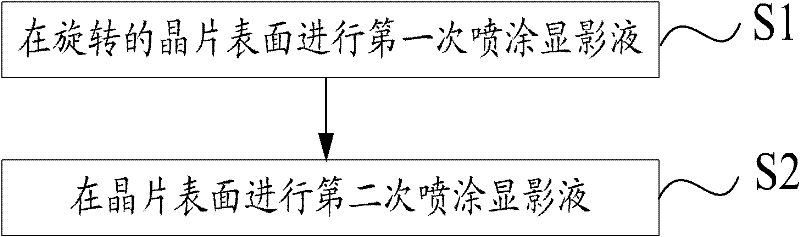

[0028] Based on this, the present invention provides a developing method, with reference to figure 2 , the method includes:

[0029] Step S1: Spraying developer solution on the surface of the rotating wafer for the first time.

[0030] In this step, after the wafer is placed on the vacuum chuck, the rotating motor connected to the vacuum chuck is controlled so that the vacuum chuck rotates together with t...

Embodiment 2

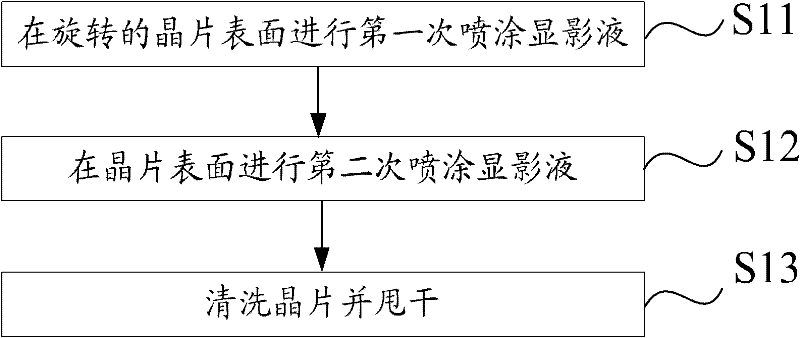

[0036] refer to image 3 , image 3 It is a flow chart of another developing method provided by an embodiment of the present invention, and the method specifically includes the following steps:

[0037] Step S11: Spraying developer on the surface of the rotating wafer for the first time.

[0038] Before this step, there is also a pretreatment step: cleaning the surface of the wafer with deionized water and drying it to ensure that the surface of the wafer is free from any impurities, pollutants or water sources. The wafers are then developed, which can be carried out on the same wafer track system.

[0039] After the wafer is pretreated, it is placed on the vacuum chuck in the automatic wafer track system to ensure that the wafer is placed stably and that the wafer and the vacuum chuck are relatively stationary. The vacuum chuck is connected to the rotating motor through a connecting rod (or pillar). By controlling whether the rotating motor is turned on, the vacuum chuck c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com